When searching for the best PCB manufacturers in usa, you need a partner that balances quality, speed, and technical expertiseâsomething EBest Circuit (Best Technology) delivers as a global leader in PCB solutions. Whether youâre working on high-frequency PCBs for aerospace or rigid-flex PCBs for consumer electronics, the best PCB manufacturers in usa should offer more than just fabrication: they need end-to-end support to avoid delays, quality issues, and hidden costs. EBestâs 20+ years of experience, strict certifications, and 24-hour expedite service make us the top choice for businesses looking to align with the standards of the best PCB manufacturers in usa.

What Defines the Best PCB Manufacturers in USA? (Key Criteria to Check)

The best PCB manufacturers in usa arenât just about producing circuit boardsâthey excel in four core areas that eliminate common pain points. First, they hold industry-leading certifications (like ISO 9001:2015, IATF 16949) to guarantee consistent quality. Second, they offer full turnkey services, covering PCB Design, PCB Prototype, Component Sourcing, PCB Assembly, and mass production, so you donât have to manage multiple vendors. Third, they have transparent pricing with no hidden fees, plus design-for-manufacturability (DFM) advice to cut costs. Finally, they provide fast lead timesâcritical for meeting product launch deadlines.

EBest meets all these criteria and more. Our monthly production capacity of 260,000 square feet (28,900 square meters) means we handle both small prototypes and large-scale orders, while our 24-hour expedite service ensures urgent boards ship on time. Weâre certified to ISO 9001:2015, IATF 16949, ISO 13485:2016, and AS9100Dâmatching the quality standards expected from the best PCB manufacturers in usa.

Why Certifications Matter for PCB Manufacturers in USA

Certifications arenât just logosâtheyâre proof a manufacturer follows strict processes to avoid defects. For example:

- IATF 16949: Ensures compliance with automotive industry quality requirements, critical for PCBs used in vehicles.

- ISO 13485:2016: Mandatory for medical device PCBs, where failure can risk patient safety.

- AS9100D: Required for aerospace and defense PCBs, which need to withstand extreme conditions.

EBestâs full suite of certifications means we can support projects across industries, from medical to aerospaceâjust like the top best PCB manufacturers in usa.

How Do the Best PCB Manufacturers in USA Solve Common Pain Points?

Businesses searching for best PCB manufacturers in usa often face four major challenges: inconsistent quality, slow lead times, fragmented services, and communication gaps. The top manufacturers address these head-on with targeted solutions, as shown in the table below.

| Common Pain Point | Solution from the Best PCB Manufacturers in USA | EBestâs Implementation |

|---|---|---|

| Substandard PCBs that fail testing | Rigorous quality control (QC) at every production stage | QC checks for raw materials, fabrication, and assembly; defective rate < 0.09% |

| Lead times over 2 weeks | Streamlined production and expedite services | 24-hour shipping for urgent orders; standard lead times 5â7 days |

| Needing multiple vendors for design, fabrication, and assembly | Full turnkey services (design to box build) | One-stop solution: PCB Design â Prototype â Component Sourcing â Assembly â Mass Production |

| Miscommunication leading to errors | Dedicated English-speaking project managers | 1:1 project support; 2-hour response time for queries |

What Types of PCBs Do the Best Manufacturers in USA Specialize In?

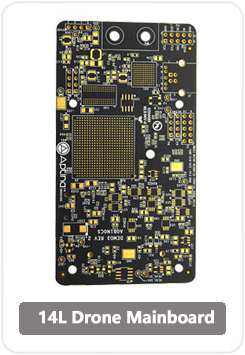

The best PCB manufacturers in usa donât just make standard FR4 boardsâthey handle complex, industry-specific PCBs that require advanced technical skills. EBestâs product range aligns with these demands, covering:

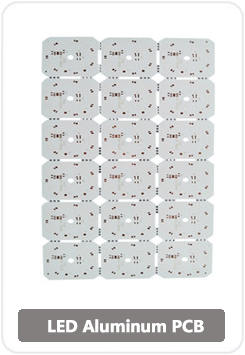

- Metal Core PCBs (MCPCBs): For LED lighting and power electronics, where heat dissipation is critical.

- Ceramic PCBs: Ideal for high-temperature applications (e.g., automotive sensors, industrial controls) due to their thermal conductivity.

- HDI PCBs (High-Density Interconnect): Used in compact devices like smartphones and medical wearables, with 1â2â1 and 2â4â2 stackups.

- Rigid-Flex PCBs: Combine flexibility (for moving parts) and rigidity (for stability) in aerospace and consumer electronics.

- Heavy Copper PCBs: With 4â20 oz copper layers, perfect for high-current applications like EV charging systems.

- High-Frequency PCBs: Made with Rogers or Taconic materials for communication devices (5G, satellites).

Each of these PCBs undergoes specialized testingâe.g., thermal cycling for ceramic PCBs, impedance testing for high-frequency boardsâto meet industry standards.

FAQ: Answers to Common Questions About the Best PCB Manufacturers in USA

1. How do I verify if a manufacturer is among the best PCB manufacturers in USA?

Start by checking their certifications (ISO 9001, IATF 16949, etc.) and production capacityâtop manufacturers will publish these publicly. Next, ask for references or case studies in your industry (e.g., medical, aerospace). Finally, request a sample: a reputable manufacturer like EBest will provide a prototype with no obligation, so you can test quality firsthand.

2. Do the best PCB manufacturers in USA offer custom PCB design services?

Yesâcustom design is a key service. The top manufacturers have in-house engineering teams that create PCB layouts tailored to your projectâs specs (size, layers, materials). EBestâs design team completes 100+ complex projects yearly, with DFM reviews to ensure designs are manufacturable and cost-effective.

3. Whatâs the minimum order quantity (MOQ) for the best PCB manufacturers in USA?

Most top manufacturers donât enforce strict MOQsâthey handle both prototypes (1â10 pieces) and mass production (10,000+ pieces). EBest has no MOQ requirement, so you can order 1 prototype for testing or 100,000 boards for full-scale production.

4. How do the best PCB manufacturers in USA handle component sourcing?

They use a network of verified suppliers to source high-quality components (resistors, capacitors, ICs) at competitive prices. EBest has 12 stable raw material suppliers and stocks common components, reducing lead times by 30%. We also offer consignment sourcing if you prefer to use your own components.

5. Do the best PCB manufacturers in USA provide after-sales support?

Absolutely. Top manufacturers offer warranties (3â5 years) and troubleshooting help if issues arise. EBest provides a 3-year quality assurance on all PCBs and has a dedicated support team to assist with post-delivery testing or modifications.

6. Can the best PCB manufacturers in USA handle international shipping?

Yesâthey have experience shipping to global clients, with compliance for customs and regulations (e.g., RoHS, REACH). EBest ships to 60+ countries, with tracked delivery and assistance with import documentation.

Why Choose EBest Over Other PCB Manufacturers in USA?

When you need a partner that meets the standards of the best PCB manufacturers in usa, EBest stands out for three key reasons:

1. 20+ Years of Technical Expertise

Our team has decades of experience in complex PCB projectsâfrom designing HDI boards for medical devices to manufacturing heavy copper PCBs for EVs. We invest in R&D to stay ahead of trends (e.g., 5G-compatible high-frequency PCBs), ensuring your products are future-proof.

2. Unmatched Speed and Reliability

We understand time-to-market is critical. Our 24-hour expedite service gets urgent boards to you in a day, while our on-time delivery rate is 97.2%âfar above industry averages. We also provide real-time production updates, so you never wonder where your order stands.

3. Transparent, Competitive Pricing

We offer detailed, upfront quotes with no hidden fees. Our DFM team also identifies cost-saving opportunities (e.g., optimizing board size, choosing alternative materials) without compromising quality. This transparency is why 3,000+ clients worldwide trust us as a top alternative to the best PCB manufacturers in usa.

Ready to Partner with a Manufacturer That Meets the Best PCB Manufacturers in USA Standards?

If youâre looking for best PCB manufacturers in usa quality without the limitations of local suppliers, EBest Circuit (Best Technology) is your solution. We offer all the core servicesâPCB Design, Prototype, Component Sourcing, Assembly, and mass productionâbacked by strict certifications and 24/7 support. Whether you need a single prototype or 100,000 production boards, we deliver on time and to your specs.

To get started, send your requirements to sales@bestpcbs.com today. Our team will provide a quote within 12 hours and assign a dedicated project manager to guide you through every step. Choose EBestâwhere the standards of the best PCB manufacturers in usa meet global expertise.