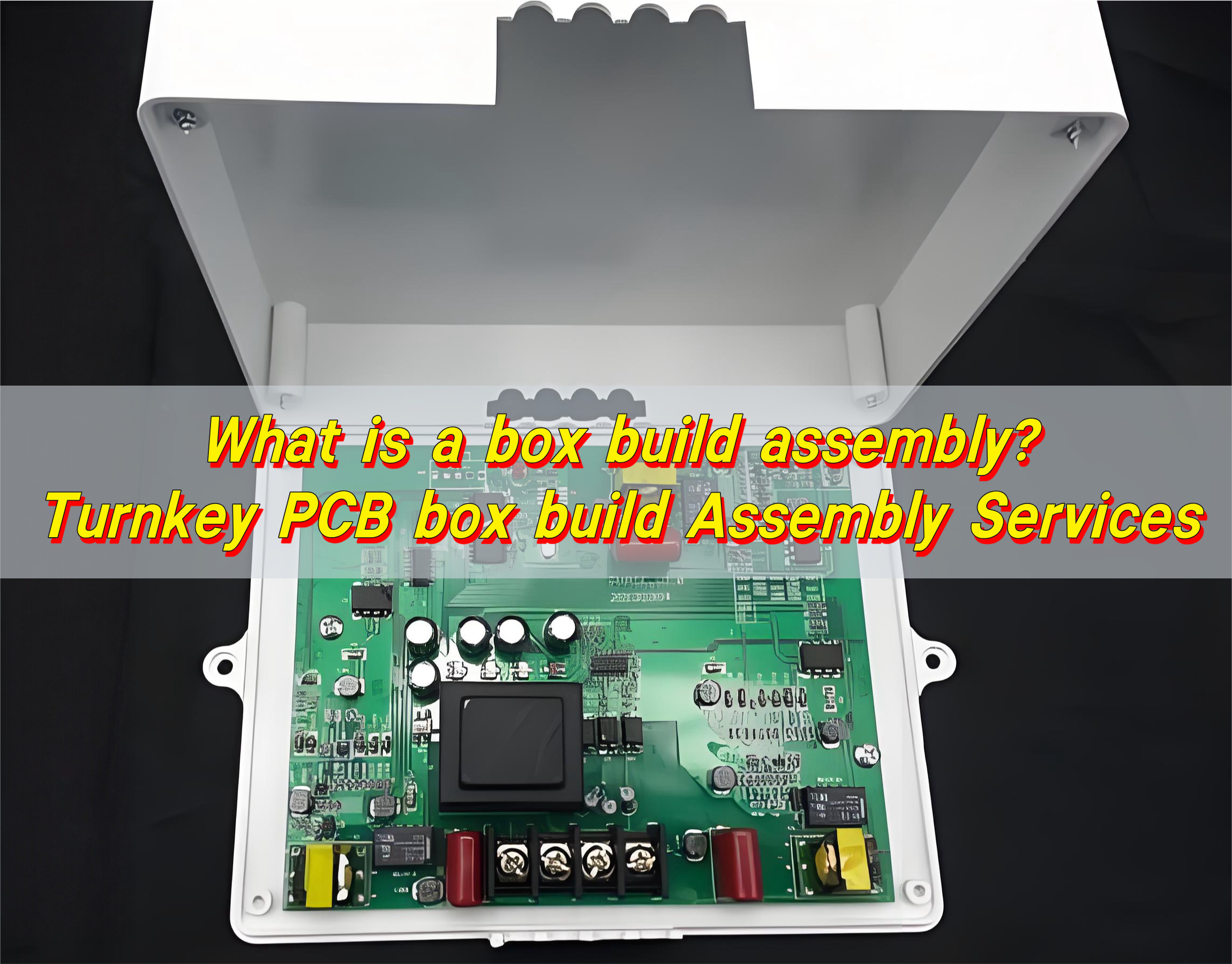

PCB box build assembly services mark the shift from standalone board production to fully integrated system manufacturing. By combining PCB assembly, enclosure integration, cable routing, thermal management, firmware loading, and final validation into one coordinated workflow, they enable U.S. OEMs to achieve stronger reliability, regulatory alignment, and scalable production. This article explains how PCB box build assembly services in the USA operate, how to assess engineering capability, and which design decisions most influence long-term system performance.

EBest Circuit (Best Technology) delivers integrated PCB and box build manufacturing through a vertically coordinated production model that combines PCB fabrication, SMT assembly, cable harness processing, mechanical integration, and system-level testing under one management structure. Serving industrial control, medical electronics, power systems, and high-reliability applications, we support both prototype and volume production without imposing rigid MOQ limitations, ensuring flexibility for U.S. OEMs seeking scalable and engineering-focused manufacturing partnerships. If you have any questions or specific requirements, contact our team at sales@bestpcbs.com.

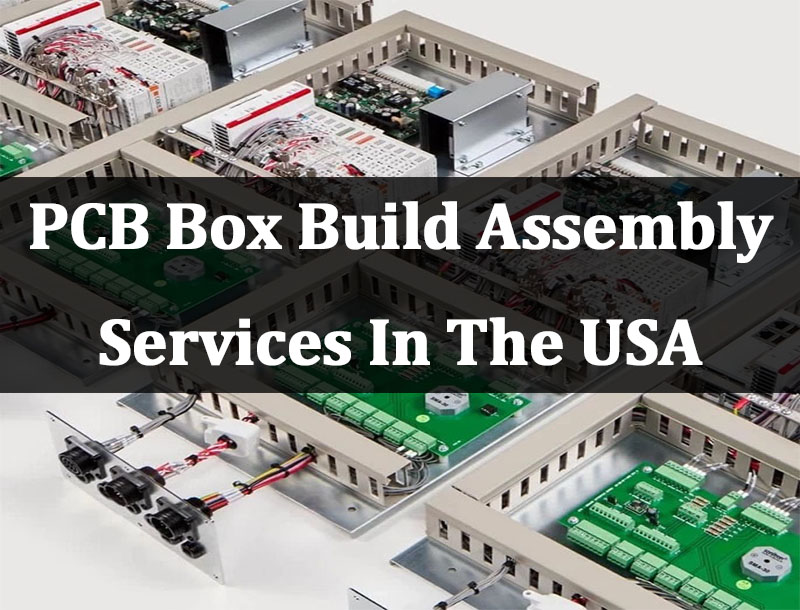

What Are PCB Box Build Assembly Services And How Do They Extend Beyond PCB Assembly Services?

PCB box build assembly services go far beyond traditional pcb assembly services. While printed circuit board assembly services focus on component placement, soldering, inspection, and functional testing of bare boards, box build encompasses:

- Mechanical enclosure integration

- Cable harness and wire routing

- Power distribution and grounding systems

- Thermal management implementation

- Firmware loading and system-level calibration

- Final assembly, labeling, and packaging

In short, box build transforms individual PCB assemblies into finished, deployable electronic systems.

A typical flow includes:

- PCB fabrication and assembly

- Subassembly integration

- Mechanical enclosure mounting

- Cable harness installation

- System-level testing and burn-in

- Packaging and shipment

This holistic approach reduces handoffs between vendors and minimizes interface-related failures.

How Do Box Build And PCB Assembly Services Support Regulated U.S. Industries?

In the United States, box build solutions are heavily driven by industry compliance and application complexity. Examples include:

Industrial Control Systems

- Power distribution modules

- PLC control enclosures

- HMI interface units

- High-current bus bar integrations

These systems require strict thermal validation and vibration resistance.

Medical Equipment

- Patient monitoring devices

- Diagnostic imaging subsystems

- Portable therapy equipment

Medical box build requires traceability, documented assembly records, and validation protocols aligned with ISO 13485 environments.

Aerospace And Defense

- Avionics control units

- Power conversion modules

- Ruggedized communication systems

Here, IPC Class 3 workmanship and environmental stress screening (ESS) are typically mandatory.

Box build and PCB assembly services must align mechanical tolerances, grounding schemes, and EMI shielding to maintain certification readiness.

Who Offers Box Build PCB Assembly Services In Illinois With Engineering Depth?

Illinois has a strong manufacturing base, particularly in industrial electronics and medical devices. When evaluating who offers box build PCB assembly services in Illinois, engineers typically assess:

- In-house PCB fabrication vs subcontracted boards

- Engineering engagement during DFM review

- Cable harness design capability

- UL and IPC certification compliance

- Lead time stability

A provider with real engineering depth will not only assemble hardware but also:

- Suggest wire routing optimization

- Improve airflow within enclosure

- Recommend connector repositioning

- Optimize grounding topology

This consultative approach distinguishes strategic partners from simple contract assemblers.

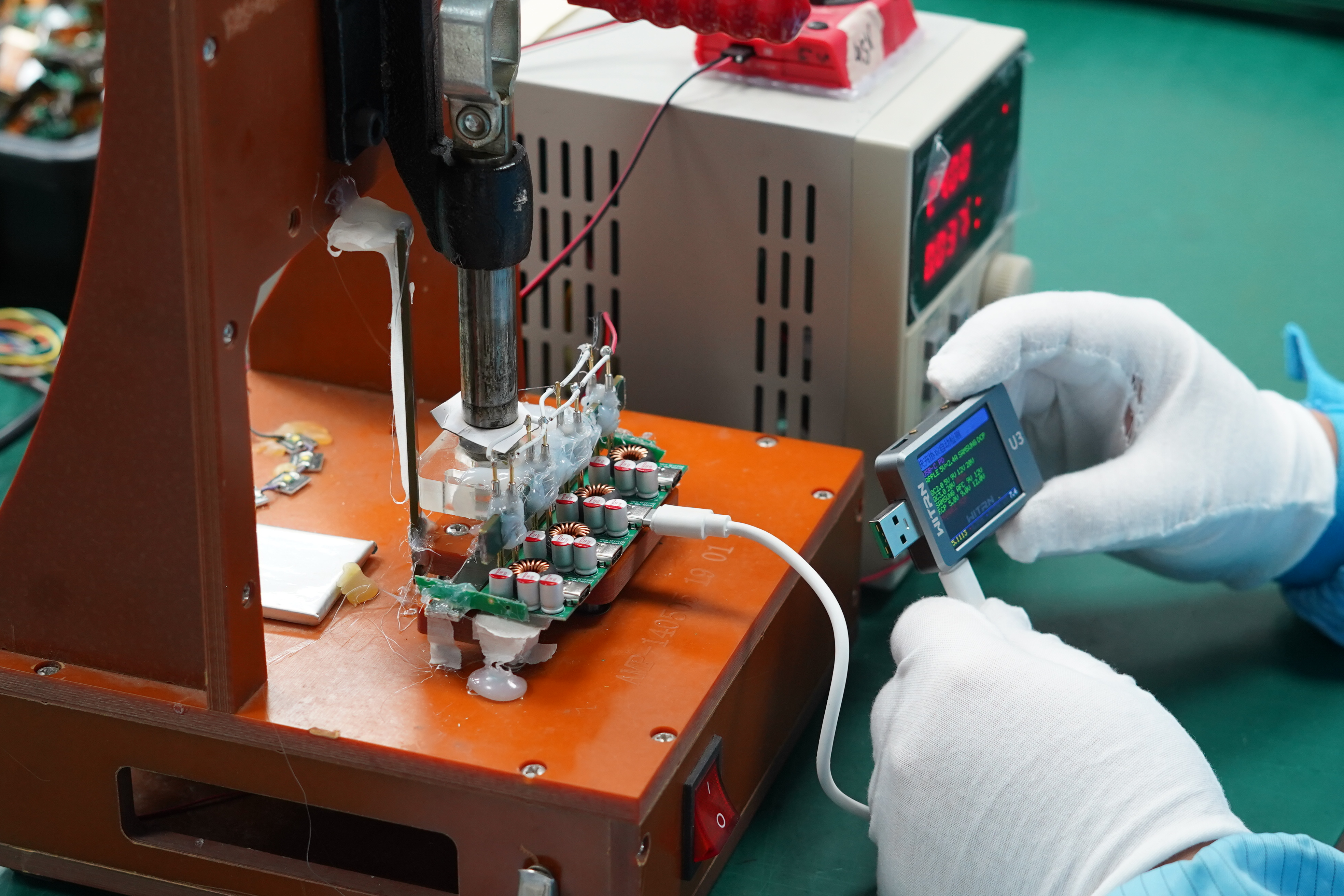

What Defines High-Reliability Box Build PCB Assembly Services In USA?

High reliability is not a marketing phrase. It is measurable.

Key defining characteristics include:

- IPC-A-610 Class 3 workmanship standards

- Documented torque control during mechanical fastening

- Controlled cable bend radius management

- Ground continuity testing

- Thermal profiling under load conditions

- Serialized traceability per unit

In industrial and aerospace programs, providers often conduct:

- Functional test validation

- Hi-pot testing

- Vibration screening

- Environmental stress screening

These layers ensure that system integration does not introduce latent defects.

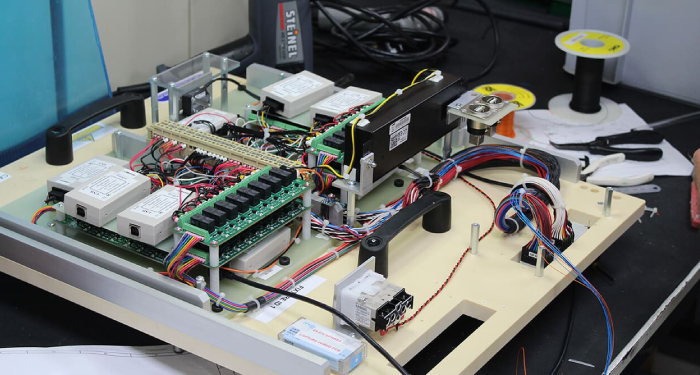

Engineering Design Considerations In PCB Box Build Assembly Services

Many reliability failures originate from early design oversights rather than manufacturing errors. Engineers should consider:

Thermal Management

- Heatsink mounting interface flatness

- TIM (thermal interface material) selection

- Airflow channel modeling

- Fan placement and redundancy

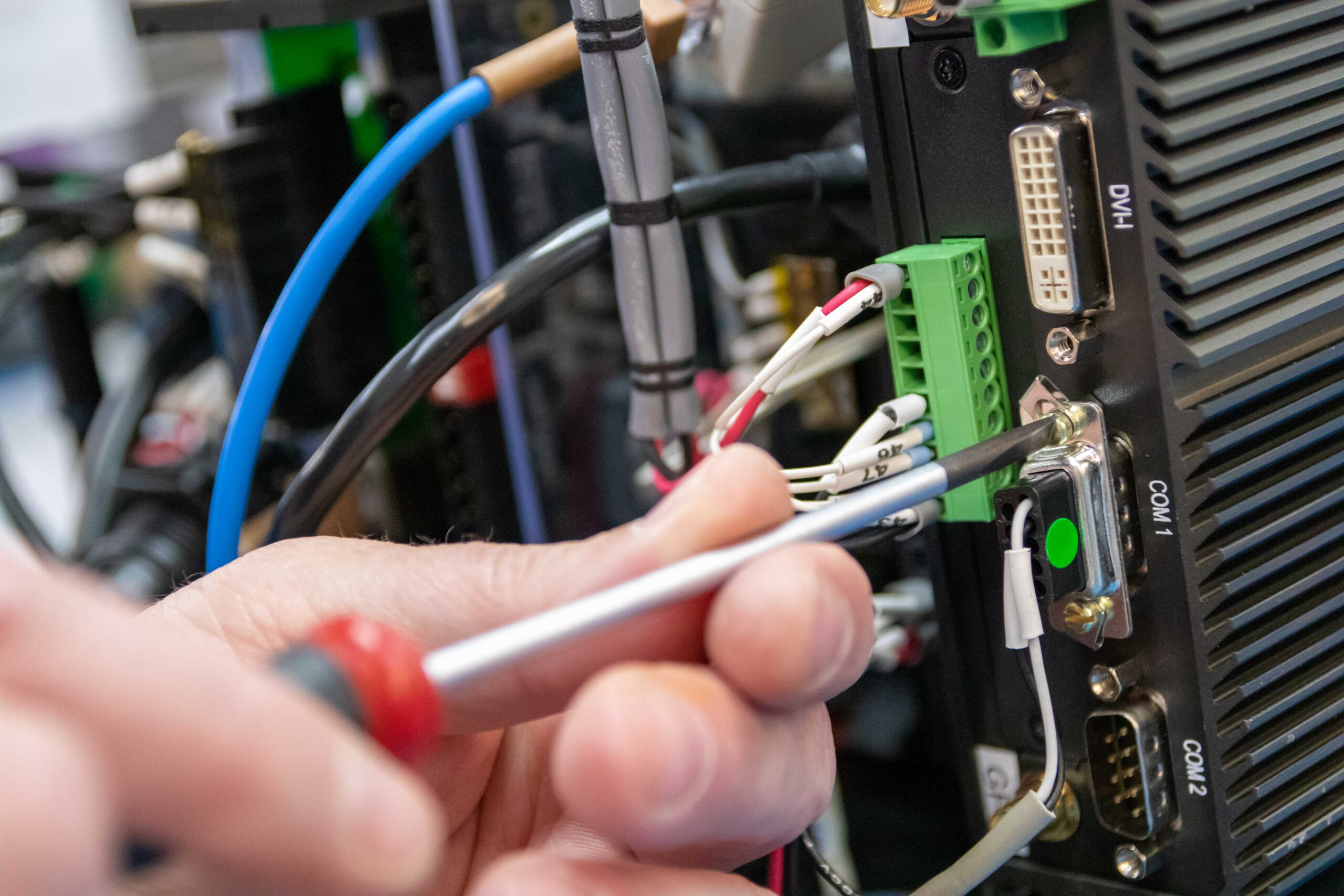

Cable Routing

- Strain relief anchoring

- Separation of signal and power lines

- EMI-sensitive loop reduction

Grounding Strategy

- Star grounding vs chassis grounding

- Shield termination placement

- Earth bond continuity

Mechanical Tolerance Stack-Up

- Mounting hole alignment

- Enclosure tolerance allowances

- Vibration damping materials

Engaging a box build provider during the design stage dramatically reduces redesign cycles later.

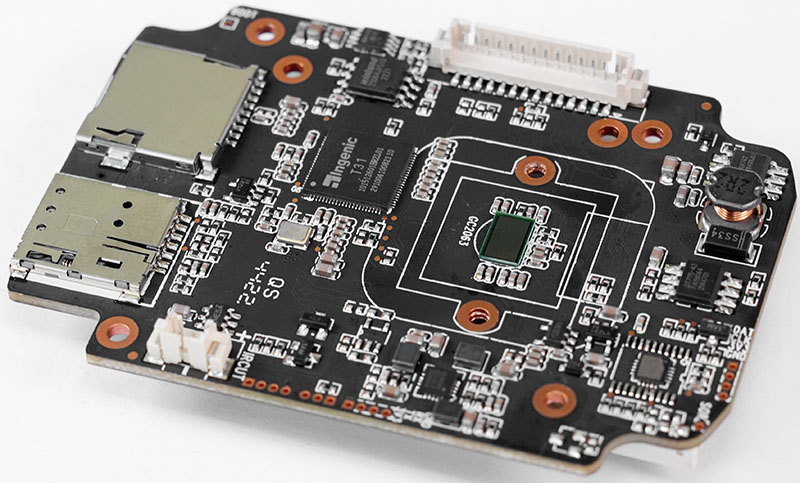

From Prototype PCB Assembly To Full Box Build Integration

The transition from prototype pcb assembly to production-level box build often reveals integration gaps.

Common prototype-to-production challenges include:

- Connector misalignment with enclosure cutouts

- Cable length miscalculation

- Insufficient airflow margin

- Serviceability concerns

Best practice involves:

- Building pilot runs of 5ā20 units

- Conducting full functional and environmental validation

- Documenting assembly instructions with photos

- Locking torque specifications

This structured ramp-up prevents costly mid-production corrections.

Cost Structure Of PCB Box Build Assembly Services In The USA

Cost is influenced by several measurable variables:

- Labor intensity of mechanical assembly

- Custom cable harness complexity

- Testing requirements

- Enclosure fabrication method

- Volume scaling

While cheap PCB box build assembly services may appear attractive initially, hidden costs often emerge in the form of:

- Higher field failure rates

- Warranty returns

- Rework cycles

- Delayed certification

Total cost of ownership should include reliability, lead time predictability, and engineering supportānot just unit price.

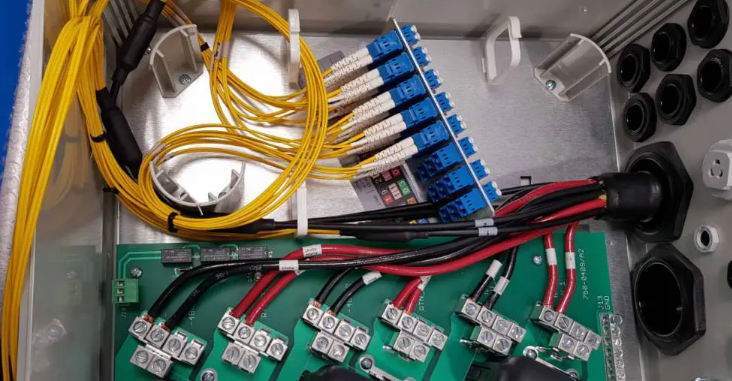

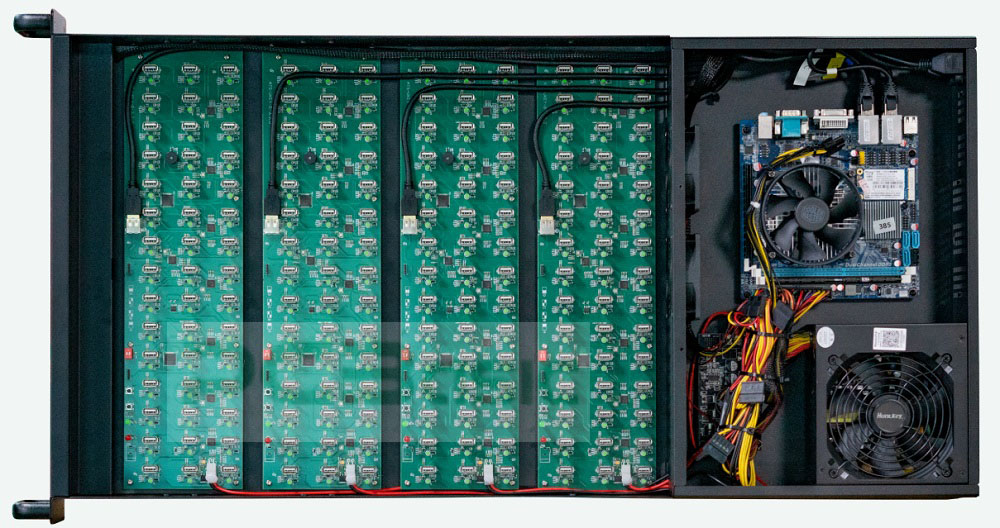

Case Example: Industrial Power Control Enclosure

A U.S.-based OEM developing a 48V industrial power distribution module required:

- 6-layer heavy copper PCB

- Integrated bus bar

- Forced air cooling

- Rugged aluminum enclosure

Initial prototype testing showed excessive thermal rise near MOSFET banks.

During box build redesign:

- Airflow direction was reversed

- Cable harness was repositioned to reduce airflow obstruction

- Thermal pad thickness was adjusted

- Additional chassis grounding was implemented

Result:

- 18% reduction in peak temperature

- Improved EMI performance

- Faster UL validation

This example highlights why box build engineering input is critical early in the product lifecycle.

How To Select A U.S. PCB Box Build Assembly Partner

Engineers should verify:

- IPC and ISO certifications

- In-house engineering review capability

- Supply chain transparency

- Document control systems

- Lead time consistency

Questions worth asking include:

- Is DFM feedback included before mass production?

- Are torque values documented per unit?

- Is cable harness manufacturing internal or outsourced?

- Can they support both PCBA and enclosure integration?

A qualified provider treats system integration as an engineering disciplineānot just mechanical assembly.

All in all, as product architectures become more integrated, the distinction between board-level manufacturing and system-level assembly continues to blur. PCB box build assembly services in the USA provide a structured pathway from individual PCB assemblies to fully validated electronic systems ready for deployment in industrial, medical, and aerospace environments.

If you would like assistance evaluating your next projectāfrom printed circuit board assembly services to full system box build integrationāour engineering team is ready to review your design files and provide structured feedback. Just feel free to let us know your specific requirements via sales@bestpcbs.com.

FAQs About PCB Box Build Assembly Services

1. What Is The Difference Between PCB Assembly And Box Build?

PCB assembly focuses on populating boards, while box build integrates boards into complete electromechanical systems.

2. Are Box Build Services Only For High Volume Projects?

No. Many providers support low-to-mid volume industrial production.

3. How Long Does A Typical Box Build Project Take?

Lead time varies by complexity, typically ranging from 3 to 6 weeks including validation.

4. Can Box Build Providers Assist With Design Improvement?

Yes, engineering-driven providers contribute to thermal, mechanical, and cable routing optimization.

5. What Certifications Are Important For U.S. Projects?

IPC-A-610, ISO 9001, ISO 13485, and UL compliance are commonly required.