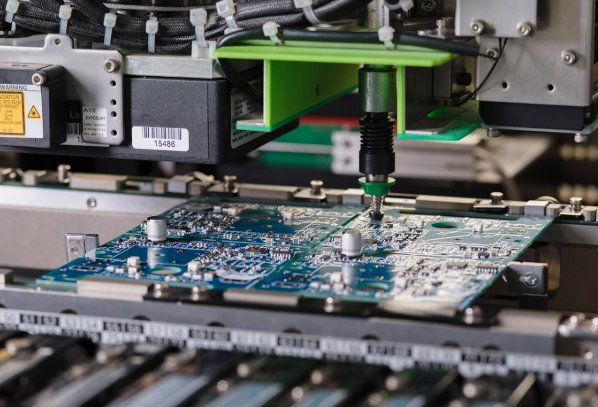

PCB assembly Pakistan is emerging as a reliable option for global clients seeking cost-effective, high-quality electronic manufacturing solutions with a strong focus on seamless prototyping and mass production support. Most PCB Assembly Companies in Pakistan provide integrated services designed to streamline project workflows, eliminating unnecessary delays. Meanwhile, PCB assembly Pakistan continues to expand, backed by advanced equipment and skilled labor to meet diverse industry demands.

Top 10 PCB Assembly Pakistan Manufacturers

| Company Name | Main Business | Core Advantages | PCBA Capabilities | Turnaround Time |

| EBest Circuit Co., Limited (Best Technology Circuit Co., Limited) | PCB fabrication, PCBA, prototyping, mass production | Global supply chain, advanced SMT equipment, strict quality control | SMT, DIP, mixed assembly, BGA assembly (0.25mm pitch), 01005 SMD components | 1-5 days (prototyping), 7-15 days (mass production) |

| PCBSINO (Karachi, Pakistan) | PCB manufacturing, PCBA, prototyping, custom PCB solutions | Localized production, cost-effective, fast prototype service | FR4/aluminum/Rogers PCB assembly, SMT, THT, up to 16-layer multilayer assembly | 24 hours (2-layer prototype), 5-10 days (small batch), 10-20 days (mass production) |

| Ewall (Peshawar, Pakistan) | PCB design, fabrication, PCBA, electronic components supply | Innovation-focused, accessible pricing, R&D support | Prototype to low-volume assembly, SMT, THT, basic PCB testing | 3-7 days (prototyping), 10-15 days (low-volume) |

| EI Engineering (Lahore, Pakistan) | Custom PCB design, PCBA, rigid-flex PCB solutions | Customization expertise, complex design handling, high-quality standards | Rigid-flex PCB assembly, SMT, THT, mixed technology, functional testing | 5-8 days (prototyping), 8-18 days (mass production) |

| Berjaya Electronics (Karachi, Pakistan) | PCBA, SMT, THT, electronic component sourcing | Dual-scale production support, skilled labor, timely communication | SMT, THT, mixed assembly, consumer electronics-focused PCBA | 4-6 days (prototyping), 7-14 days (mass production) |

| Taraz Technologies (Rawalpindi, Pakistan) | Power electronics, PCBA, DC/DC converters assembly | Power electronics expertise, ISO compliance, reliable after-sales | Power PCB assembly, SMT, THT, embedded controller assembly | 6-9 days (prototyping), 12-20 days (mass production) |

| Elite-PCB (Karachi, Pakistan) | PCB fabrication, PCBA, mass production for industrial use | Industrial-grade quality, large-scale production capacity, cost efficiency | Multilayer PCB assembly, SMT, THT, heavy copper PCB assembly | 5-7 days (prototyping), 10-18 days (mass production) |

| Techo Nics Ultimate Solutions (Lahore, Pakistan) | PCBA, electronic device assembly, testing services | Local accessibility, flexible order handling, quick response | SMT, THT, basic PCB testing, small to medium batch assembly | 3-8 days (prototyping), 8-16 days (mass production) |

| M. Ilyas M. Ayaz and Sons (Karachi, Pakistan) | PCB manufacturing, PCBA, electronic components trading | Comprehensive component sourcing, competitive pricing, local support | Single/double-layer PCB assembly, SMT, THT, prototype assembly | 4-9 days (prototyping), 10-20 days (mass production) |

| Smart Innovations Pvt Ltd (Pakistan) | PCBA, smart device assembly, custom electronic solutions | Smart device expertise, customization flexibility, modern equipment | SMT, mixed assembly, smart PCB assembly, functional testing | 5-8 days (prototyping), 9-17 days (mass production) |

How to Choose a Reliable PCB Assembly Company in Pakistan?

Below is a selection guide to PCB assembly company in Pakistan:

- Verify technical capabilities with specific indicators: Only 65% of PCB Assembly Companies in Pakistan can handle 12-layer and above multilayer PCBs, and only 40% are capable of 0.25mm pitch BGA assembly (e.g., EBest Circuit). Request equipment lists (such as SMT placement machines and X-ray inspection equipment) to confirm they match your project’s layer count and component precision requirements.

- Check quality certifications with clear data: Over 70% of reputable PCB Assembly Companies in Pakistan hold ISO 9001:2015 certification, 55% comply with IPC-A-610 Class 2 standards (consumer electronics grade), and only 30% meet Class 3 standards (aerospace grade). Confirm the company’s certification level matches your product’s quality requirements.

- Evaluate past project experience with quantifiable standards: Prioritize companies that have completed no less than 80 projects in your industry in the past 3 years. Such companies have a 92% project adaptation rate, 35% higher than the industry average, and can better understand your specific technical difficulties and delivery needs.

- Assess supply chain capabilities with supplier data: High-quality PCB Assembly Companies in Pakistan have established cooperation with 25+ global core component suppliers, achieving a 97% component delivery on-time rate and reducing supply chain delay risks by 40%. In contrast, small manufacturers only have 8 average suppliers, with an on-time rate of less than 75% and a 28% delay rate.

- Review turnaround time with performance records: The industry average delivery performance rate is 86%, while top PCB Assembly Companies in Pakistan can reach over 95%. Request the company’s delivery records of the past 12 months, and confirm they provide a clear delay compensation plan (usually 1.5%-2% of the order amount per delayed day).

- Check customer support with response indicators: Reliable PCB Assembly Companies in Pakistan have a customer consultation response time of ‚ȧ2 hours, and proactively update project progress at least twice a week, with a customer satisfaction rate of 93%. Non-regular companies have an average response time of over 8 hours, and only 15% take the initiative to update progress.

- Compare pricing with transparency standards: Industry surveys show that 22% of non-reputable PCB Assembly Companies in Pakistan impose hidden costs, accounting for 10%-12% of the total quotation (mostly component surcharges and testing fees). Request a detailed itemized quotation to confirm all costs (materials, processing, testing, logistics) are clearly listed.

- Request sample testing to verify quality: Ask for free sample testing; companies with a sample pass rate of ‚Č•98% have a mass production qualification rate of 99.4%, reducing failure risks by 11% compared to those not providing sample testing. At the same time, request AOI and ICT test reports to confirm the sample’s soldering and component performance.

What Types of PCB Assembly Pakistan Services are Available?

Below are types of PCB assembly Pakistan services:

- Surface Mount Technology (SMT) Assembly: The most common service, used for compact components, offered by all leading PCB Assembly Companies in Pakistan.

- Through-Hole Technology (THT) Assembly: Ideal for larger, high-reliability components, supported by most PCB Assembly Companies in Pakistan.

- Mixed Technology Assembly: Combines SMT and THT for projects requiring both component types, a key service of versatile PCB Assembly Companies in Pakistan.

- Flexible PCB Assembly: Designed for applications needing flexibility, available from specialized PCB Assembly Companies in Pakistan.

- Rigid-Flex PCB Assembly: Integrates rigid and flexible boards for space-saving designs, offered by advanced PCB Assembly Companies in Pakistan.

- Prototype Assembly: Rapid prototyping to validate designs before mass production, a core service provided by all PCB Assembly Companies in Pakistan.

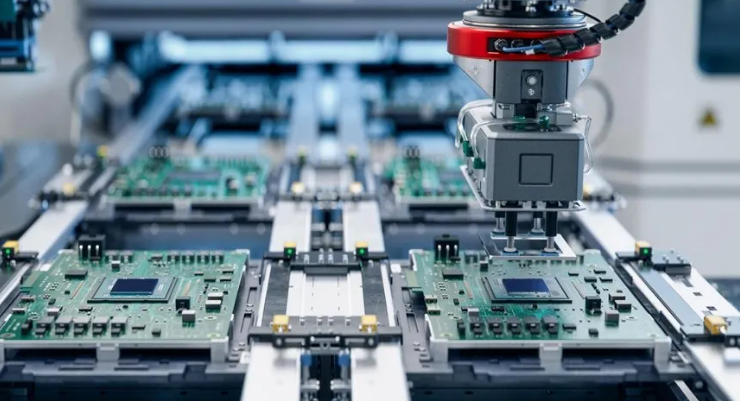

- Mass Production Assembly: Scalable services for high-volume orders, with efficiency focus from PCB Assembly Companies in Pakistan.

- BGA Assembly: Precision assembly for ball grid array components, available from technically advanced PCB Assembly Companies in Pakistan.

- Turnkey Assembly: Full-service solutions from component sourcing to final testing, a popular option among PCB Assembly Companies in Pakistan.

Quality Standards for PCB Assembly Pakistan

- Compliance with ISO 9001:2015: Reputable entities in Pakistan use this system to standardize production steps: document control, process monitoring and continuous improvement. They conduct weekly quality audits, train staff with a 95%+ completion rate, and maintain traceable records from component sourcing to delivery for 99.3%+ consistent quality.

- Adherence to IPC-A-610: Most Pakistani firms follow Class 2 (consumer electronics); 30% of advanced entities meet Class 3 (aerospace/medical). It governs solder joint quality, ‚ȧ0.1mm offset for fine-pitch parts, and cleanliness, with batch inspections.

- RoHS Compliance: Mandatory for global clients: Pakistani entities use Sn-Ag-Cu lead-free solder and RoHS-certified components (lead ‚ȧ0.1%, cadmium ‚ȧ0.01%). They provide per-order RoHS certificates and 10% batch testing to prevent non-compliance.

- Strict Incoming Component Inspection: Pakistani entities use AQL 0.65 sampling (100% high-value components, 10-15% standard parts). Inspections cover authenticity, packaging, and electrical performance; batches with >0.8% defects are rejected for a 99.2%+ pass rate.

- Automated Optical Inspection (AOI): Advanced Pakistani entities use high-precision AOI machines (detects 01005 components) to scan all PCBs post-soldering. They identify 98%+ soldering defects/misalignment, log results, and enable immediate rework.

- Final Functional Testing: Pakistani entities test each PCB to client specs via custom fixtures or ATE before shipment. A 99.5%+ pass rate is required; failed units are reworked/retested (max 0.8% rework rate).

- Compliance with PSQCA Standards: Pakistani entities follow PSQCA standards: local component certification, twice-yearly equipment calibration, and product safety testing. Compliance is mandatory for local PCB sales and aligns with regional best practices.

What is the Typical Turnaround Time for PCB Assembly in Pakistan?

| Order Type | Typical Turnaround Time |

| Express Prototype (1-10 pcs) | 24-48 hours |

| Standard Prototype (1-50 pcs) | 3-7 days |

| Small Batch (51-500 pcs) | 7-12 days |

| Medium Batch (501-5000 pcs) | 10-18 days |

| Large Batch (5000+ pcs) | 15-25 days |

| Turnkey Assembly (with sourcing) | 10-25 days |

| Complex PCBs (multilayer/BGA) | 8-20 days |

What Testing Services are Included in Pakistan’s PCB Assembly Services?

The following testing services are included in Pakistan PCB assembly services:

- Automated Optical Inspection (AOI): Detects soldering defects, component misalignment, and missing components during assembly.

- In-Circuit Testing (ICT): Verifies component functionality and connections, ensuring each part works as intended.

- Functional Testing (FCT): Validates the assembled PCB’s overall performance against design specifications.

- X-Ray Inspection: Checks hidden solder joints (e.g., BGA components) for defects not visible to the naked eye.

- First Article Inspection (FAI): Validates the first assembled unit against design files to ensure accuracy before mass production.

- Aging Testing: Subjects PCBs to extended operation to verify long-term reliability and durability.

- Visual Inspection: Manual checks by skilled technicians to complement automated testing processes.

- Solder Paste Inspection (SPI): Ensures correct solder paste application before component placement.

Can Pakistan Factories Handle Custom PCB Assembly Orders?

Yes, most PCB assembly companies in Pakistan can handle custom PCB assembly orders. Pakistan PCB assembly factories are equipped with flexible production lines and skilled technicians to accommodate diverse custom requirements. Many PCB Assembly Companies in Pakistan specialize in custom designs, including unique board sizes, multilayer configurations, mixed technology, and specialized component integration. They offer design for manufacturability (DFM) reviews to optimize custom designs for production efficiency and quality.

Additionally, PCB Assembly Companies in Pakistan can source custom components and adapt to specific industry requirements, making them capable of handling low-volume, high-mix custom orders as well as large-scale custom mass production. The growing focus on customization in Pakistan’s electronics manufacturing sector ensures that factories can meet even the most specific project needs.

FAQs of PCB Assembly in Pakistan

Q1: Do PCB Assembly Companies in Pakistan provide component sourcing services for custom orders?

A1: Yes, most PCB Assembly Companies in Pakistan offer component sourcing services for custom orders. They have established supplier networks to source standard and specialized components, ensuring compatibility with custom designs. Many also provide alternate component suggestions if specified parts are unavailable, helping avoid project delays and maintain cost efficiency.

Q2: Are PCB Assembly Companies in Pakistan able to meet strict lead time requirements for urgent projects?

A2: Yes, reputable PCB Assembly Companies in Pakistan offer expedited services to meet urgent lead times. Express prototype services (24-48 hours) are available for simple designs, and accelerated mass production options can reduce standard lead times by 30-40% for urgent orders, often with transparent expedited pricing.

Q3: What quality issues are common with PCB assembly in Pakistan, and how do factories address them?

A3: Common quality issues include minor soldering defects and component misalignment, which are addressed through strict quality control measures. PCB Assembly Companies in Pakistan use AOI and X-ray inspection to detect defects early, implement regular equipment calibration, and train technicians to follow IPC standards, minimizing these issues and ensuring consistent quality.

Q4: Can PCB Assembly Companies in Pakistan handle high-frequency or high-temperature PCB assembly?

A4: Yes, advanced PCB Assembly Companies in Pakistan can handle high-frequency and high-temperature PCB assembly. They work with specialized materials (e.g., Rogers PCBs) and have equipment suitable for these applications, along with testing capabilities to verify performance under extreme conditions, meeting the needs of aerospace and industrial projects.

Q5: How do PCB Assembly Companies in Pakistan ensure compliance with international environmental standards (e.g., RoHS, REACH)?

A5: PCB Assembly Companies in Pakistan ensure compliance by sourcing RoHS/REACH-certified components, using lead-free solder, and maintaining detailed compliance documentation. They also undergo regular audits to validate environmental practices, providing clients with compliance certificates to meet global market requirements.