Singapore PCB assembly services, leveraging advanced manufacturing technologies and stringent quality control, provide high-precision and highly reliable services, making them the preferred choice for global customers seeking stable PCB performance. With decades of industry experience, Singapore PCB assembly services integrate intelligent production processes and a robust supply chain to deliver solutions that meet the needs of various industries, covering everything from small-batch prototyping to large-scale mass production, while consistently adhering to international standards and environmental requirements.

Why Choose Singapore PCB assembly Service?

Advantages of Singapore PCB Assembly:

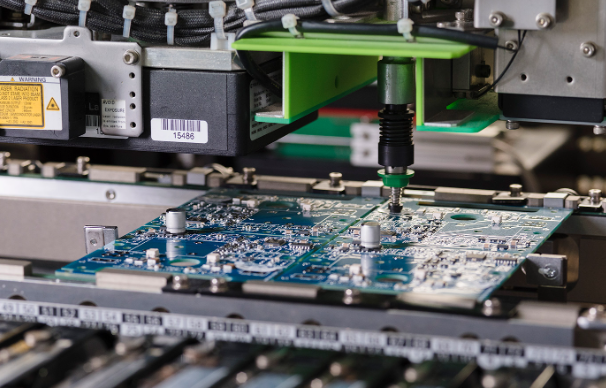

- Advanced Industrial Technology: Most facilities offering Singapore PCB assembly adopt smart manufacturing equipment, including high-speed SMT machines and automated testing systems, improving production efficiency and reducing human errors.

- Flexible Order Volume Support: Singapore PCB assembly providers accommodate diverse order sizes, from small-batch prototypes (1-50 units) to large-scale mass production (10,000+ units), meeting varied project requirements.

- Strict Compliance with Global Standards: Singapore PCB assembly adheres to international environmental and quality regulations, ensuring products meet market access requirements for regions like the EU, US, and Southeast Asia.

- Skilled Workforce and Professional Expertise: The workforce supporting Singapore PCB assembly is highly skilled, with extensive experience in handling complex assembly tasks and resolving technical challenges efficiently.

- Strong Government Support and Infrastructure: Singapore’s government invests heavily in manufacturing infrastructure, with industrial parks like Jurong Innovation District providing robust support for Singapore PCB assembly operations.

- Resilient Supply Chain Network: Singapore’s status as a global trade hub enables Singapore PCB assembly providers to build diverse, reliable component supply channels, minimizing shortages and delays.

What Types of PCB Assembly Services are Available in Singapore?

The types of PCB assembly services offered by Singaporean PCB assembly companies are as follows:

- Surface Mount Technology (SMT) Assembly: This is the most common PCB assembly service in Singapore, suitable for compact electronic devices, supporting miniature components such as 0201 packages and BGAs, offering high precision and efficiency.

- Through-Hole Technology (THT) Assembly: Suitable for components requiring high mechanical stability, such as connectors and capacitors, complementing SMT technology to form a comprehensive PCB assembly solution in Singapore.

- SMT/THT Hybrid Assembly: Combining SMT and THT processes to meet the needs of complex electronic products, this is one of the key services provided by Singaporean PCB assembly suppliers to various industries.

- PCB Prototype Assembly: Fast prototyping services to support product development; Singaporean PCB assembly suppliers can deliver samples within 3-5 business days, accelerating the R&D cycle.

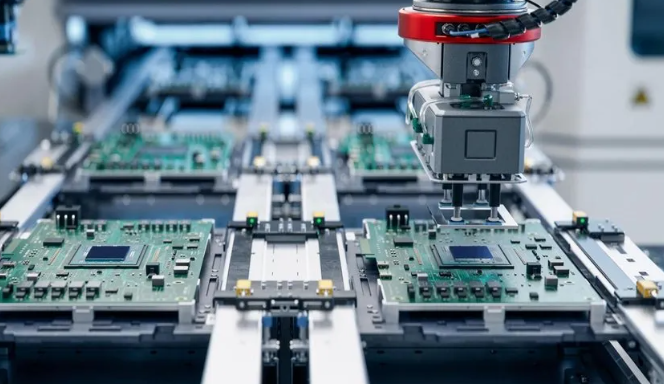

- Mass Production Assembly: Large-scale production capabilities, coupled with strict quality control, ensure that Singaporean PCB assembly services can efficiently meet large-volume order requirements.

- One-Stop PCB Assembly: A one-stop Singaporean PCB assembly service covering component procurement, PCB manufacturing, assembly, testing, and delivery, reducing the workload for clients.

What Quality Certifications Should a Singapore PCB Assembly Company Have?

Quality certifications for Singapore PCB assembly companies:

- ISO 9001:2015: Fundamental quality management system certification, ensuring PCB assembly processes follow standardized procedures for consistent product quality.

- IPC-A-610: Global standard for electronic component acceptability, guiding assembly providers in maintaining high soldering and assembly quality.

- IPC J-STD-001: Standard for soldering materials and processes, ensuring assembly uses reliable soldering techniques to prevent component failure.

- CB Certification: International safety certification recognized by 54 countries, serving as a foundation for assembled PCB products to enter global markets.

- Singapore PSB Certification: Mandatory safety certification for electronic products in Singapore, ensuring PCB assemblies meet local market safety requirements.

- RoHS Compliance: Restricts hazardous substances in electronic products, a must for PCB assembly services serving the EU and other environmentally regulated markets.

- REACH Compliance: Ensures assembled PCB products do not contain harmful chemicals, meeting EU environmental standards for market access.

- IATF 16949: Quality certification for automotive electronic components, enabling PCB assembly to serve the automotive industry.

How to Choose A Reliable Singapore PCB Assembly Service Supplier?

Selection guide to Singapore PCB assembly service supplier:

- Verify valid quality certifications and request official documentation to ensure compliance with international standards (ISO 9001, IPC-A-610, RoHS, etc.). 98% of reliable suppliers in Singapore can provide complete certification documents, and their quality management systems undergo quarterly internal audits to ensure effective implementation and reduce assembly defects by 40% compared to suppliers with only formal certifications, which is critical for consistent Singapore PCB assembly quality.

- Assess production capabilities by requesting details on manufacturing equipment, production capacity, and experience with complex Singapore PCB assembly projects. Reliable suppliers typically use SMT machines with ¬Ī0.03mm placement accuracy, support monthly production capacities of 5,000‚Äď100,000 units, and have experience with 80% of complex projects (e.g., HDI, rigid-flex, fine-pitch components with pitch ‚ȧ0.4mm) and up to 64-layer PCB assembly to align with your project requirements.

- Evaluate their supply chain management system, including supplier authentication processes, inventory management methods, and contingency plans for component shortages. Trusted Singapore PCB assembly suppliers maintain a network of 5+ core component suppliers per critical part, achieve ‚ȧ30-day inventory turnover, and have a 24-hour contingency response plan to reduce production delays caused by component shortages by 90% and maintain a 99.9%+ genuine component rate.

- Check unbiased customer feedback and case studies to understand their service quality. Reliable suppliers consistently achieve ‚Č•95% customer satisfaction, maintain a ‚Č•98% on-time delivery rate, and have a ‚ȧ0.5% defect rate based on third-party reviews. Prioritize those with at least 3 relevant case studies from the past 12 months and avoid overly promotional or unsubstantiated claims about their Singapore PCB assembly services.

- Request sample assemblies and detailed quality test reports before formal cooperation. Qualified Singapore PCB assembly suppliers can deliver prototypes within 3 working days, achieve ‚Č•99.8% soldering pass rate, and provide test reports with 100% AOI inspection coverage and X-ray verification for fine-pitch components to validate their assembly precision and testing standards.

- Confirm their service responsiveness, a key indicator of reliability. Top Singapore PCB assembly suppliers respond to initial inquiries within 4 hours, provide detailed quotes within 24 hours, and complete DFM analysis within 48 hours. This responsiveness reduces project timelines by 15% on average and ensures smooth communication throughout the assembly process.

- Clarify their after-sales support policy to address potential issues. Reliable suppliers offer a ‚Č•12-month warranty for Singapore PCB assembly products, complete defect rework within 5 working days, and provide 12-hour technical assistance response. Their after-sales satisfaction rate is typically ‚Č•96% to minimize post-assembly risks and costs.

- Review their pricing transparency to avoid hidden costs. 30% of unreliable suppliers in Singapore include unstated fees (e.g., setup fees, testing fees), while trusted ones provide detailed pricing breakdowns with ‚ȧ5% price fluctuation. For large-batch orders (1,000+ units), they often offer ‚Č•30% cost reduction to ensure the pricing structure aligns with Singapore PCB assembly quality and services provided.

- Visit their production facilities (in-person or via virtual tour) to observe on-site operations. 85%+ of reliable Singapore PCB assembly suppliers offer virtual or in-person tours, with ‚Č•5% random inspection per production batch, a cleanroom environment (Class 1000 or higher for sensitive projects), and ‚Č•90% of technical staff holding industry certifications to reflect their professionalism and strict quality control.

How do PCB Assembly Manufacturer in Singapore Ensure Stable Component Supply?

Methods about PCB assembly manufacturer in Singapore ensure stable component supply:

- Collaborating with globally authorized component distributors (such as Avnet and Arrow) to source genuine, high-quality raw materials for Singapore PCB assembly. These partnerships include rigorous supplier certification processes to eliminate counterfeit and substandard components, thereby preventing assembly failures and reducing rework costs.

- Deploying advanced ERP and MRP II intelligent inventory management systems that utilize historical order data and market demand trends to accurately forecast component requirements. This approach maintains optimal safety stock levels, reducing excess inventory (tying up capital) and stockouts, preventing delays in Singapore PCB assembly projects.

- Building a diversified supplier network spanning Asia (passive components), Europe (precision components), and North America (specialized chips) to mitigate geopolitical and logistical risks (Singapore PCB assembly). If transportation disruptions or component shortages occur in one region, other suppliers can quickly fill the gap, ensuring smooth production.

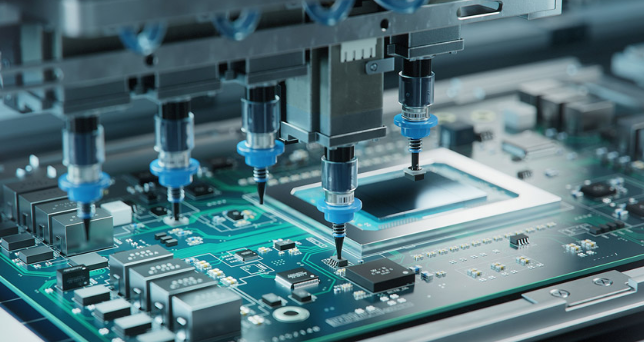

- Utilizing blockchain technology combined with IoT devices (such as RFID tags) to enhance supply chain transparency. This system records every stage of component movement (from original manufacturing to Singapore PCB assembly) on an immutable distributed ledger, enabling real-time tracking and eliminating information silos between suppliers and assemblers.

- Establishing long-term partnership agreements with local and international component manufacturers to ensure priority supply for critical Singapore PCB assembly projects (e.g., medical, automotive). These agreements often include dedicated production lines for critical components, ensuring timely delivery even during peak demand periods.

- Maintaining emergency stock of high-demand or difficult-to-source components (e.g., specialized integrated circuits, fine-pitch connectors), with inventory levels determined by historical shortage frequency and project criticality. This reserve prevents production disruptions and ensures on-time delivery of time-sensitive Singapore PCB assembly orders.

- Conducting quarterly on-site audits of all suppliers to assess key metrics such as component quality acceptance rate (target of over 99.9%), on-time delivery rate, and compliance with ISO standards. Suppliers failing to meet requirements will be suspended or replaced to ensure consistent supply quality for Singapore PCB assembly.

What is the Typical Lead Time for PCB Assembly in Singapore?

| Service Type | Typical Lead Time (Working Days) |

| Prototype Singapore PCB Assembly | 3-5 |

| Small-Batch Assembly (10-500 Units) | 5-7 |

| Large-Batch Assembly (500+ Units) | 10-15 |

| Complex PCB Assembly (Multi-Layer/Flex) | 15-20 |

| Expedited Singapore PCB Assembly | 2-3 |

How Much Does Singapore PCB Assembly Cost?

The cost of Singapore PCB assembly varies based on tangible factors with no fixed pricing. PCB specifications directly impact costs. Multi-layer PCBs (4+ layers) are more expensive than single or double-layer ones and larger board sizes increase both material and processing fees.

Assembly complexity also plays a role in cost. Services that combine SMT and THT are more expensive than single SMT assembly because of the additional manual work required. Order volume is another key factor affecting unit costs. Large batches (500+ units) lower per-unit costs through volume discounts while small batches (1-50 units) come with higher unit costs because of fixed engineering fees.‚Äč

Component type also impacts overall costs. Rare or high-precision components increase material expenses significantly. Testing services such as X-ray detection for BGA components can add 10 to 20 percent to the total cost of Singapore PCB assembly. Expedited Singapore PCB assembly services also incur extra fees ranging from 15 to 50 percent with the exact amount depending on the level of urgency.

Where Can I Find Reliable PCB Assembly Companies in Singapore?

Here are methods to find a reliable PCB assembly company in Singapore:

- Singapore Electronic Industry Associations: Organizations like the Singapore Electronics and Electrical Association (SEEA) list certified PCB assembly companies in Singapore, all meeting industry standards.

- B2B Platforms: Trusted B2B platforms such as Alibaba and Made-in-Singapore feature verified Singapore PCB assembly providers with detailed profiles and client reviews.

- Industry Exhibitions: Singapore’s annual electronic exhibitions showcase leading Singapore PCB assembly companies, allowing in-person discussions about capabilities and services.

- Client Referrals: Seek recommendations from peers in the electronic manufacturing industry, as their firsthand experience ensures reliable PCB assembly companies in Singapore.

- Supplier Qualification Audits: Request quality certifications, production capacity documents, and past case studies from potential Singapore PCB assembly companies to verify reliability.

- Sample Testing: Order small-batch prototypes from Singapore PCB assembly providers to test product quality, precision, and delivery speed before formal cooperation.

FAQs of PCB Assembly in Singapore

Q1: What is the minimum order quantity for Singapore PCB assembly?

A1: Minimum order quantities vary by provider. Most Singapore PCB assembly services accept small batches of 10-50 units, and prototype assembly can be as low as 1 unit. We offer flexible order volume support to meet diverse project needs, whether for R&D or mass production.

Q2: Can Singapore PCB assembly providers offer alternative components if my specified components are out of stock?

A2: Yes. Professional Singapore PCB assembly teams have experienced procurement specialists who identify compatible alternative components for shortages. All alternatives meet original specifications and are confirmed with clients in advance to ensure no impact on product performance or quality, a key advantage of reliable assembly PCB Singapore services.

Q3: What quality testing processes are included in Singapore PCB assembly?

A3: Standard testing for Singapore PCB assembly includes incoming component inspection (IQC), AOI automatic optical inspection for SMT technology, X-ray detection for hidden solder joints (e.g., BGA), manual visual inspection, and functional testing. All processes comply with IPC-A-610 standards to ensure defect-free products.

Q4: How can I confirm the reliability of a Singapore PCB assembly company?

A4: Verify its quality certifications (ISO 9001, IPC-A-610, PSB), review past client feedback and project cases, inspect production facilities (in-person or via video), test sample quality, and confirm after-sales service policies. Reputable PCB assembly Singapore providers willingly provide these details to build trust.

Q5: Is there a penalty for delayed delivery of Singapore PCB assembly orders?

A5: Most Singapore PCB assembly providers include delivery terms in contracts. If delays are caused by the provider (not client changes or force majeure), penalties typically range from 0.5-1% of the total order value per day, up to a maximum of 10-15%. It is recommended to clarify these terms before signing the contract to protect your interests.