Why choose LED wall washer aluminum PCB? Let’s explore its benefits, technical parameter, thermal solution, design guide, selection guide through this blog.

Are you troubled with these problems?

- Poor heat dissipation leads to rapid light decay and short product lifespan?â

- Outdoor environments cause PCB corrosion and oxidation?â

- Heavy wall washer fixtures warp during installation?â

EBest Circuit (Best Technology) can provide services and solutions:

- Custom Thermal Designâ â Optimize aluminum PCB thickness and copper layer layout for precise temperature control.

- Environmental Testingâ â Provide third-party certification for waterproofing, shock resistance, and outdoor durability.

- Fast Prototypingâ â 24-hour turnaround for aluminum PCB samples, accelerating R&D cycles.

Welcome to contact us if you have any inquiry for LED wall washer aluminum PCB: sales@bestpcbs.com.

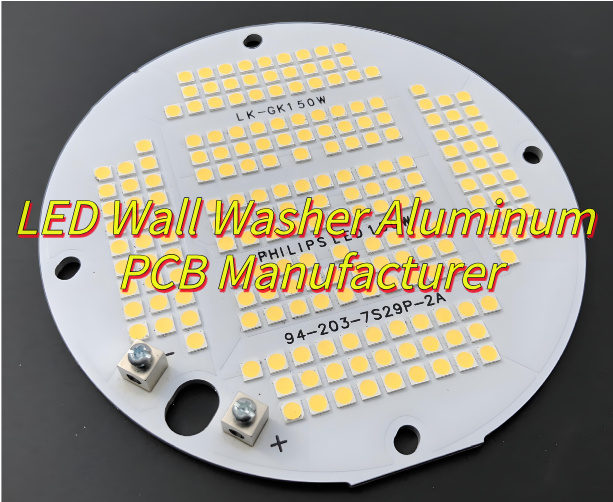

Why Choose LED Wall Washer Aluminum PCB?

Reasons why choose LED wall washer aluminum PCB:

- Efficient heat dissipation and stable operation: The aluminum base plate quickly dissipates heat, preventing LED damage from high temperatures, ensuring long-term stable operation at high power levels and significantly delaying lumen degradation.

- Lower cost and high cost-effectiveness: Aluminum’s low cost and inherent heat dissipation eliminate the need for external heat sinks, significantly reducing material and assembly costs.

- Lightweight and compact, saving space: High heat dissipation efficiency allows for a thinner and lighter luminaire, eliminating the need for additional heat sink components and enabling flexible installation in confined locations.

- Increased lifespan and reduced maintenance: Temperature control extends LED lifespan to over 30,000 hours, reducing maintenance requirements for outdoor applications at high altitudes.

- Weather-resistant and resistant to harsh environments: The aluminum base plate is impact- and vibration-resistant, and the die-cast housing achieves IP67 waterproofing, making it suitable for outdoor use in the sun and rain.

- Environmentally friendly and recyclable, in line with current trends: Aluminum is non-toxic and 100% recyclable, with low energy consumption in production, meeting green manufacturing requirements.

- Supporting high power density: Carrying high current density, it drives densely packed, high-brightness LEDs for uniform, powerful wall-washing lighting.

LED Wall Washer Aluminum PCB Technical Parameter

| Parameter Categoryâ | âTechnical Specifications | Descriptionâ |

| Base Materialâ | Aluminum alloy (5052/6061) | Thickness: 1.0-3.2mm, with anodized surface treatment |

| Thermal Conductivity | Conductivity: 1.0-8.0 W/(m·K) | Standard type (1.0-2.0) for medium-low power, high-conductivity (3.0-8.0) for high-power applications |

| Insulation Layerâ | Thickness: 50-200ÎŒm | Epoxy resin with ceramic filler, slightly higher loss than FR-4 |

| Dielectric Constant: 4.5-5.0 (1GHz) | ||

| Dielectric Strength: â„3 kV/mm | ||

| âThermal Resistance | Total thermal resistance: 0.8-3.0°C/W | Depends on copper foil area and insulation layer thickness |

| Interface resistance: <0.5K/W (eutectic soldering) | ||

| âElectrical Parameters | Operating voltage: AC220V/DC24V | Suitable for outdoor environments |

| IP65 protection Operating temp: -40°C to +60°C | ||

| âMechanical Properties | Dimensional tolerance: ±0.1mm (custom modules) | Minimal impact from anodizing |

| Surface roughness: Ra 0.2-0.8ÎŒm | ||

| âProcess Standards | Copper foil thickness: 35-70ÎŒm | Compatible with SMT and reflow soldering |

| Peel strength: 1.0-1.5 kgf/cm UL94 V0 flame retardancy |

How Aluminum PCB Enhances LED Wall Washer Light Efficiency?

1. Superior Thermal Management for Optimal LED Operation

- Heat Dissipation Efficiency: Aluminum PCBs (thermal conductivity 1-10 W/m·K) outperform FR4 (0.3 W/m·K) by 10x+, rapidly conducting 70% of LED-generated heat away from chips.

- Temperature Control: Low thermal resistance (0.05â0.2 K/W) enables safe operation at >10W/chip, reducing junction temperature by 10â15°C and minimizing light decay.

2. Electrical Performance Optimization

- Conductivity Advantage: Aluminumâs low impedance cuts power loss, improving system efficiency.

- Light Output Boost: White-coated PCBs enhance reflection efficiency by 30%+, indirectly reducing energy consumption per lumen.

3. High-Density Design Support

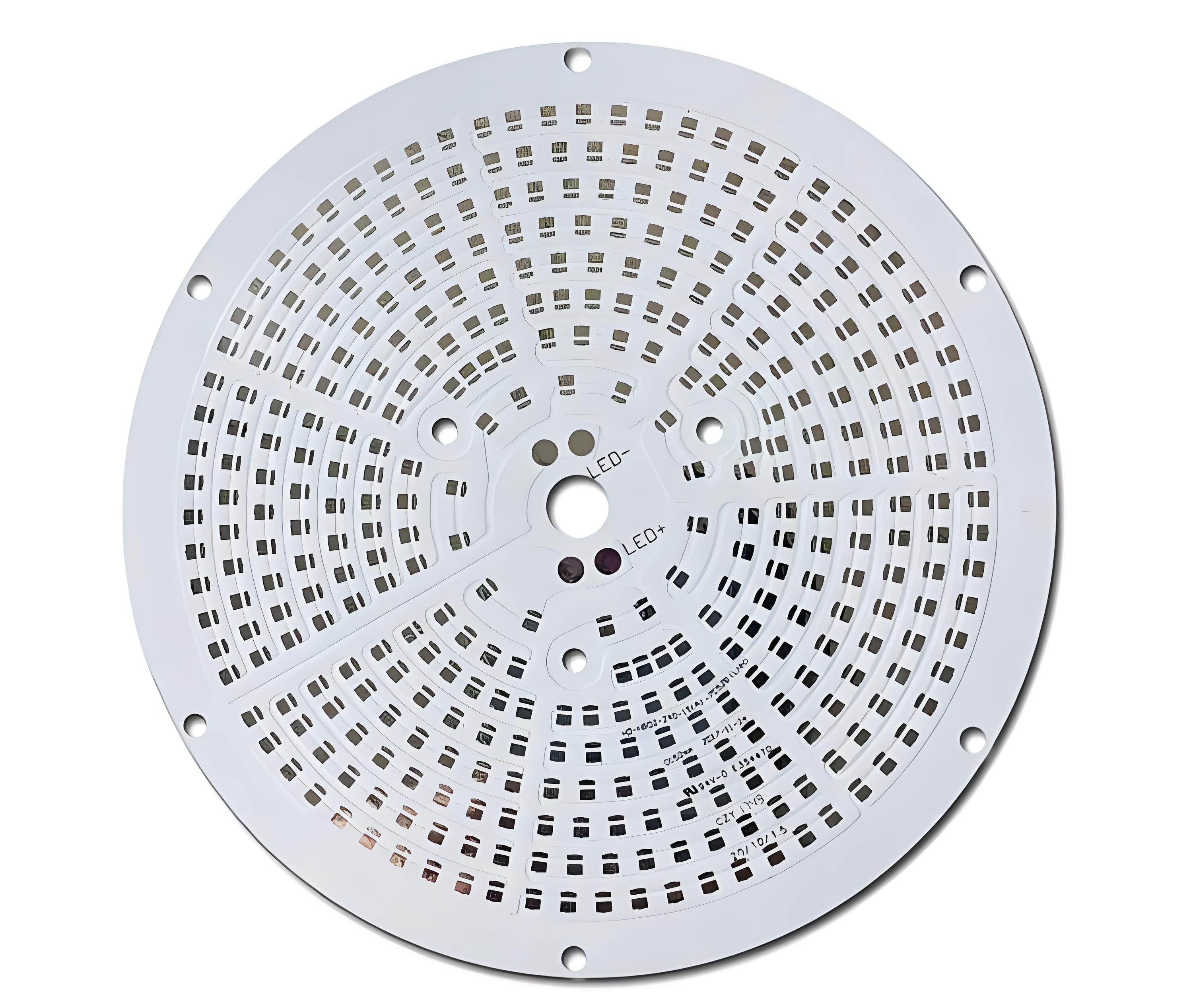

- Compact Integration: Aluminum substrates allow higher LED density (e.g., 500+ LEDs/mÂČ) with uniform light distribution, ideal for large-scale illumination.

- Mechanical Reliability: High bending strength prevents solder joint failures under vibration or thermal stress.

4. Cost & Lifespan Benefits

- Extended Lifetime: Thermal efficiency extends LED lifespan to 50,000+ hours (2â3x longer than standard solutions).

- Simplified Design: Eliminates 40% of external heat sinks, reducing material costs and assembly complexity. Aluminum recycling aligns with sustainability goals.

5. Real-World Application Advantages

- High-Power Models: 48W wall washers leverage aluminum PCBs for compact IP66-rated designs, avoiding thermal failure.

- Optical Optimization: Multi-layer structures (LED â phosphor â resin â reflective layer) maximize light extraction while efficiently managing internal heat.

Wall Wash Light Aluminum PCB Thermal Solution

Copper Layer Thermal Design Optimization

- Prioritize solid plane copper layers for maximum thermal conductivity (highest cost).

- For cost-sensitive designs, grid patterns offer 80-90% thermal efficiency with ~10% cost reduction.

- Avoid star/custom patterns unless required for EMC compliance (70-80% efficiency, unstable cost-benefit).

Thermal Via Design Refinement

- Thermal vias are critical for heat transfer from component pads to aluminum substrate. Optimize parameters (diameter, pitch, copper thickness) to minimize thermal resistance.

- Parallel thermal resistance network modeling simplifies design and improves efficiency by 20-30%. Reducing via pitch and increasing quantity is effective but requires cost-balance with drilling.

System Thermal Resistance Reduction

- High-thermal-conductivity substrates: Use aluminum oxide (AlâOâ) substrates (22-24 W/mK), outperforming FR-4/ceramic alternatives.

- Thin dielectric layers: Minimize thickness while meeting electrical insulation requirements (key to low thermal resistance).

- Reduce non-thermal vias: Excessive standard vias increase thermal path length and resistance.

Component Layout & Routing Strategies

- Placement: Avoid hotspots by dispersing high-power components (LEDs, drivers). Position major heat sources near substrate edges or directly over thermal vias. Aim for uniform distribution.

- Routing: Minimize long/thin copper traces to reduce resistive heating. Widen copper traces or increase thermal via contact area in critical paths (15-20% local thermal improvement).

Integrated Thermal Enhancement Measures

- Heat sinks: Most common passive solution, handling ~70% of total heat load. Cost-effective and easy to integrate into housing.

- Forced air cooling: Adds ~85% efficiency in enclosed/high-power units but increases cost, noise, and complexity.

- Thermal interface materials (TIMs): Thermal grease/pads fill micro-gaps, improving interfacial conductivity by ~30% at low cost.

- Liquid cooling: ~95% efficiency but highly complex and costly. Reserved for extreme power densities or specialized applications.

Convection Optimization

- Component orientation: Align temperature-sensitive/heat-generating components with their long axis perpendicular to airflow in natural/forced convection.

- Expose aluminum substrate: Directly expose large PCB aluminum areas to airflow where structurally feasible.

- Airflow management: Arrange tall components parallel to airflow to reduce turbulence and avoid downstream thermal dead zones.

Substrate Material Selection

- Aluminum-based PCBs (MCPCBs): Preferred for wall washers due to excellent thermal performance, mechanical robustness, CTE matching (reduces solder joint fatigue), and recyclability. Thickness range: 0.4-6.0mm.

- Alumina ceramic substrates: Suitable for high-temperature/high-reliability applications (350-1500°C resistance) with good thermal conductivity.

Thermal Simulation Utilization

- Use finite element analysis (FEA) in design phase to predict temperature distribution and identify hotspots.

- Simulation-driven optimization reduces post-development thermal issues by 20-30%, lowering risk and cost, especially for mass production.

LED Wall Washer Aluminum PCB Color Consistency Design Guide

1. LED Selection & Color Parameters

- Color Tolerance (SDCM): Use SDCM â€5 LEDs to ensure batch consistency.

- Color Rendering Index (CRI): Prioritize Ra â„80 LEDs (e.g., Lumileds LUXEON) for accurate color reproduction.

- Dimmable Options: Support 1900K-5700K CCT ranges with SDCM â€5 across all settings.

2. Aluminum PCB & Thermal Design

- Material: High-thermal-conductivity 6063 aluminum (â„200W/m·K) with anodized coating.

- Layout: LED spacing â„20mm (adjust per power) to prevent localized overheating.

- Wiring: 45° traces (width â„0.5mm, spacing â„0.3mm) to minimize current interference.

3. Optical System Optimization

- Mixing Distance: Short-distance lenses (â€15mm) for RGBWY uniform blending.

- Lens: Optical-grade PC/PMMA (transmittance â„92%) with recessed design (depth â„5mm).

4. Environmental Adaptability

- Protection: IP65/IP66 with silicone sealing (e.g., Dow Corning 7091).

- Temperature: Operate from -20°C to +60°C without deformation.

5. Production & Quality Control

- Supplier Collaboration: Verify PCB color process (UV-resistant ink, reflection â„85%).

- Inspection: Tighten tolerances (PCB size ±0.1mm, pad alignment ±0.05mm).

- Soldering: Through-hole preferred; SMT requires epoxy reinforcement.

6. Control System Compatibility

- Dimming: DMX512 0-100% smooth control with Îu’v’ â€0.005.

- Driver: PF >0.9, ripple â€5% (e.g., PFC circuit design).

7. Long-Term Reliability

- Testing: 50,000-hour LM-80 validation, Îu’v’ â€0.003 post-aging.

- Coating: Acrylic varnish (50-80ÎŒm) for UV/chemical resistance.

LED Wall Washer Aluminum PCB Selection Guide

1. Thermal Performance Priority

- Thermal Conductivity: 1.0-2.0 W/(m·K) for low-power (<50W) â„3.0 W/(m·K) for high-power (>50W).

- Substrate Thickness: 1.0mm (lightweight) or 2.0-3.0mm (heavy-duty cooling).

- Construction: 6061 aluminum base + ceramic-filled insulation for low thermal resistance.

2. Electrical Safety Standards

- Protection: IP65 dust/water resistance mandatory for outdoors.

- Insulation: Dielectric strength â„3 kV/mm, copper foil adhesion â„1.0 kgf/cm.

- Voltage: Match input (AC220V/DC24V) with driver compatibility.

3. Optical Compatibility

- Beam Angle: 120° standard lens requires PCB layout alignment.

- Color Quality: High CRI (Ra>90) needs low-decay LEDs.

- Efficacy: â„10 lm/W for white light; RGB requires independent control zones.

4. Mechanical & Environmental Durability

- Coating: Anodized + conformal coating (humidity/mold resistance â€Class 1).

- Impact Resistance: Die-cast aluminum housing (IK10 certified).

- Temperature Range: -40°C to +60°C operational certification.

5. Cost & Supply Chain

- Material Efficiency: Smart panel layout reduces waste by 23%.

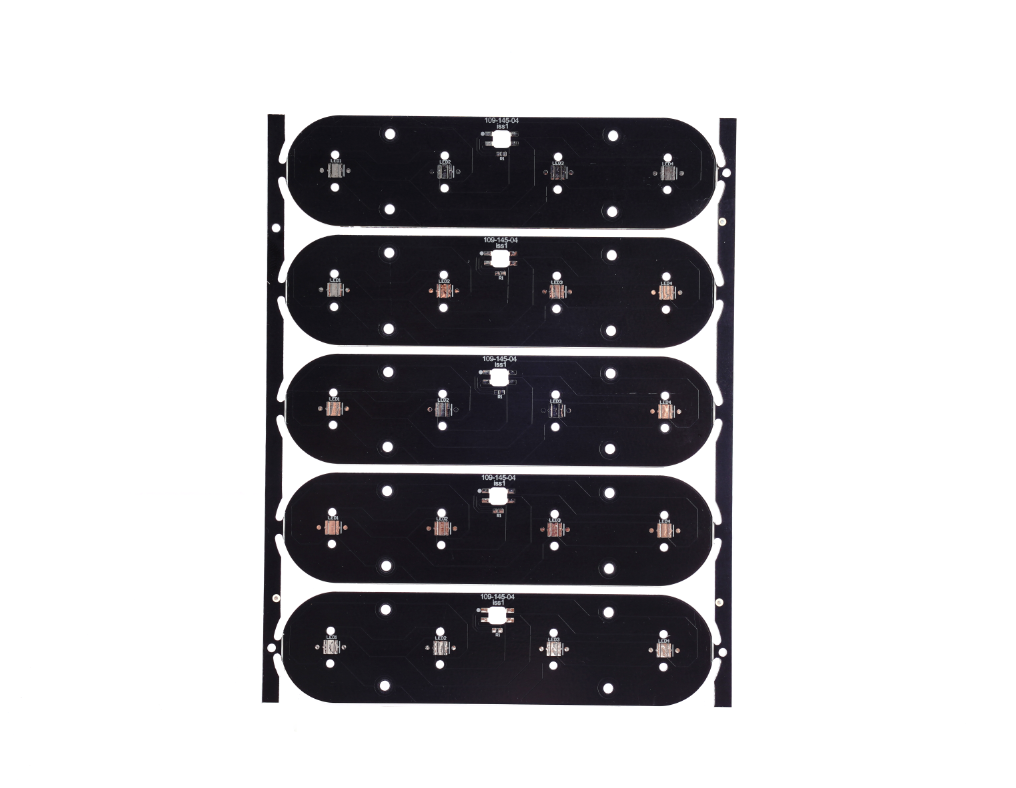

- Packaging: SMT-compatible reel packaging recommended.

- Certifications: UL94 V0 flammability rating + RoHS compliance.

Why Choose EBest Circuit (Best Technology) as Aluminum PCB Manufacturer?

Reasons why choose us as LED wall washer aluminum PCB manufacturer:

1. Premium Quality Assurance

- Material Selection: Use 6063/6061 aluminum with thermal conductivity â„150W/m·K (3x higher than industry average).

- Certifications: UL, RoHS, and IP65 compliance guaranteed for harsh outdoor environments.

2. 19 Years of Industry Expertise

- Specialized Experience: Dedicated focus on LED lighting PCBs since 2005, with 500+ wall washer projects completed.

3. Cost-Effective Solutions

- Price Advantage: 15-20% lower than competitors via optimized production lines and bulk material procurement.

- Design Optimization: Free DFM reduces material waste by up to 25% without compromising performance.

4. Fast Delivery

- Lead Time: 24 hour rapid prototyping, 5-7 days for mass production (50% faster than industry standard).

5. Free DFM Support

- Pre-Production Analysis: Identify thermal bottlenecks, electrical risks, and assembly issues pre-manufacturing.

- Design Adjustments: Optimize LED layouts for 30% higher lumen density while maintaining thermal safety.

6. Stringent Quality Control

- Thermal cycling (-40°C~+125°C, 1000 cycles).

- 48-hour burn-in test for all batches.

- AOI/X-ray inspection for solder joint integrity.

7. Customization Capability

- Flexible Design: Support ultra-thin (0.8mm) to heavy-duty (3.2mm) substrates.

- Special Coatings: White solder mask for 95% reflectivity, anti-sulfur treatment for coastal areas.

Welcome to contact us if you have any request for LED wall washer aluminum PCB: sales@bestpcbs.com.