MCPCB LED refers to a Metal Core Printed Circuit Board designed specifically for LED applications. It uses a metal base, usually aluminum, instead of traditional fiberglass to manage heat from LED chips. Thanks to its excellent thermal conductivity, MCPCB LED is widely used in high-power lighting like automotive lamps, streetlights, and industrial fixtures.

What is the full form of MCPCB LED?

MCPCB stands for Metal Core Printed Circuit Board, and when paired with LEDs, it becomes MCPCB LED. Unlike standard PCBs, which use FR4 (a fiberglass-based material), MCPCBs are designed specifically for high-heat-generating components like LEDs.

Hereās what sets it apart:

- āMetal Coreā typically refers to aluminum, known for its excellent heat dissipation and durability.

- It keeps your LED cool, boosting lifespan and brightness.

- It forms the backbone of LED lighting systems like floodlights, strip lights, spotlights, and even vehicle lights.

In short, MCPCB LED is not just a circuit board. It can make your LED lights brighter, longer lasting and better performing.

What is the difference between FR4 and MCPCB?

FR4 is a standard PCB made from fiberglass. Itās fine for low-heat applications like remote controls or digital clocks.

However, when it comes to LED lights, FR4 struggles. LEDs generate heat. FR4 canāt handle it well, which leads to overheating, performance drops, and reduced product life.

Now compare that to MCPCB:

- Aluminum core for better thermal conductivity.

- Keeps LED junction temperature under control.

- Allows for higher power output and longer operation.

- Reduces the need for extra cooling systems.

This makes MCPCB LED boards ideal for applications like automotive headlights, industrial luminaires, or any setting where heat is the enemy.

Do LED lights have PCBs?

Absolutely. Every modern LED light you see today has a PCB behind it. In high-power or long-lasting LEDs, manufacturers choose metal-based PCBs, especially aluminum LED MCPCB, because they offer:

- Efficient heat dissipation.

- Stable mechanical support.

- Compact design for space-saving fixtures.

Even LED strip lights, which look thin and flexible, and often, itās a MCPCB LED strip when used for heavy-duty applications.

Is SMD LED better than COB LED?

both SMD (Surface-Mounted Device) and COB (Chip-on-Board) are great, but they serve different needs.

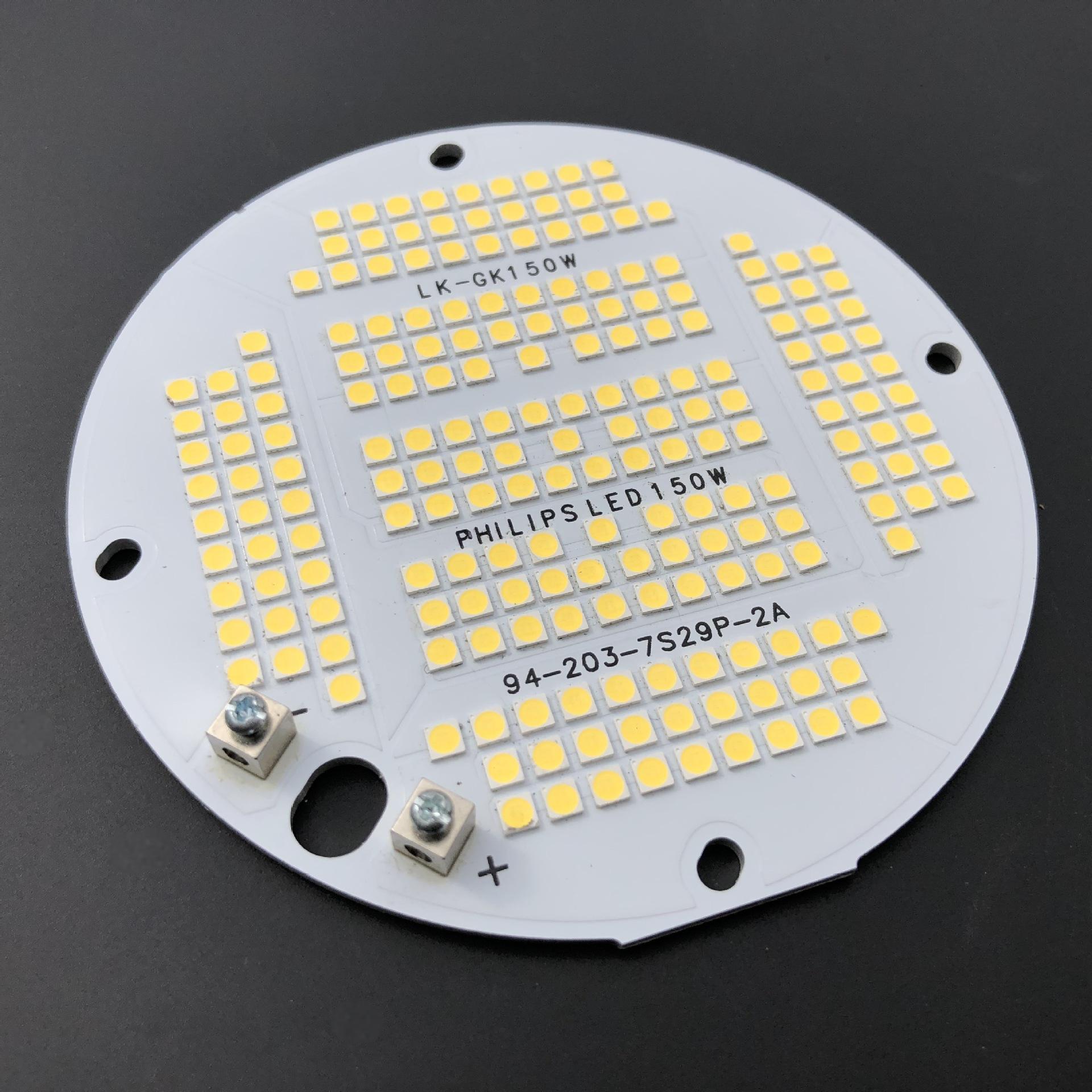

SMD LED is the most common type, where individual LEDs are mounted on the surface of a PCB. Theyāre versatile, bright, and offer color control. When paired with a LED MCPCB board, they deliver exceptional thermal stability and performance.

COB LED, on the other hand, combines multiple chips into a single module. Itās great for high-lumen output with fewer shadows and more uniform light.

SMD LED with MCPCB is typically better when:

- You need multiple color options.

- You want better thermal control.

- You plan for high-speed, automated production.

So if youāre thinking about MCPCB LED applications, especially where heat matters, SMD wins most of the time.

How to make LED MCPCB?

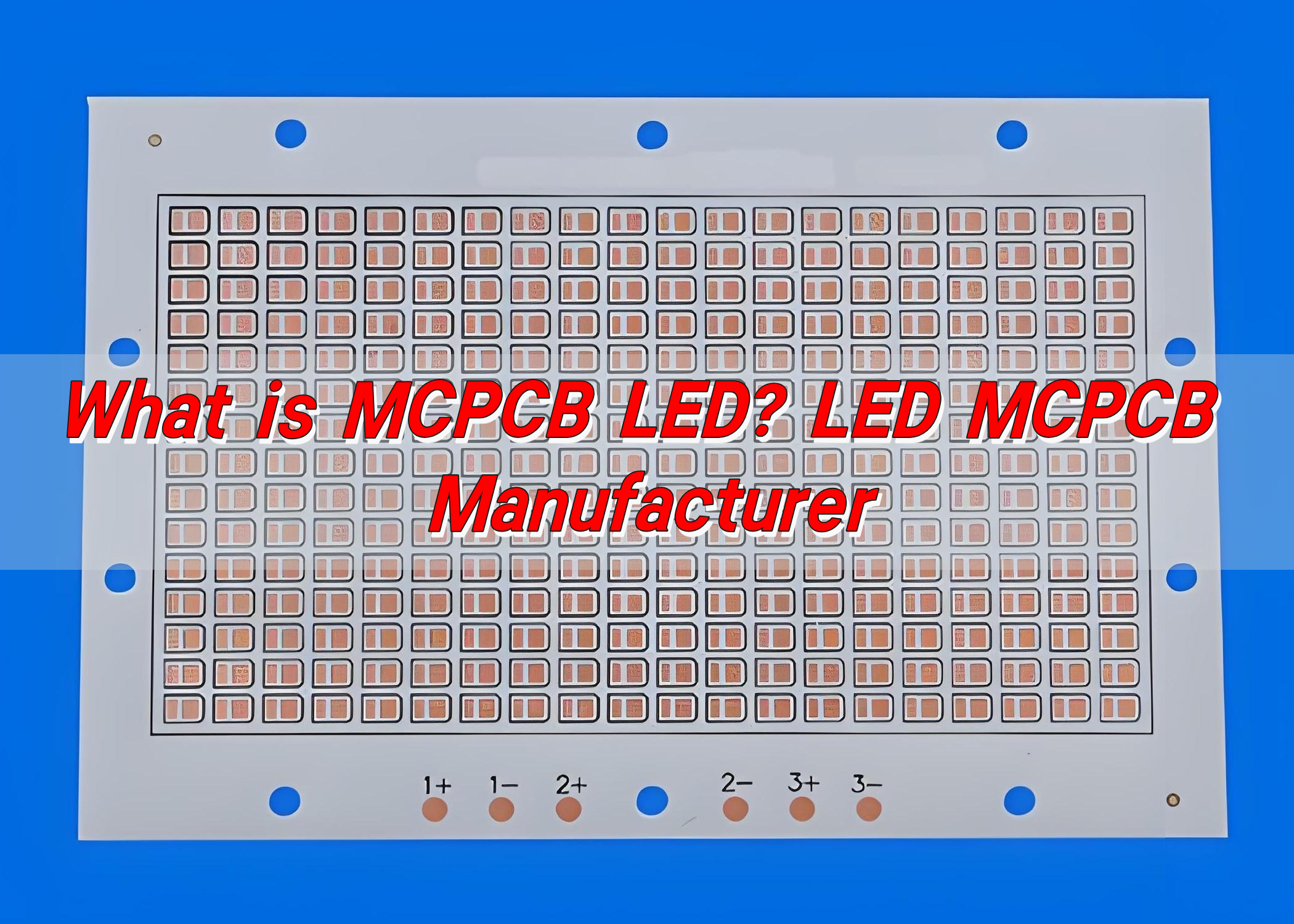

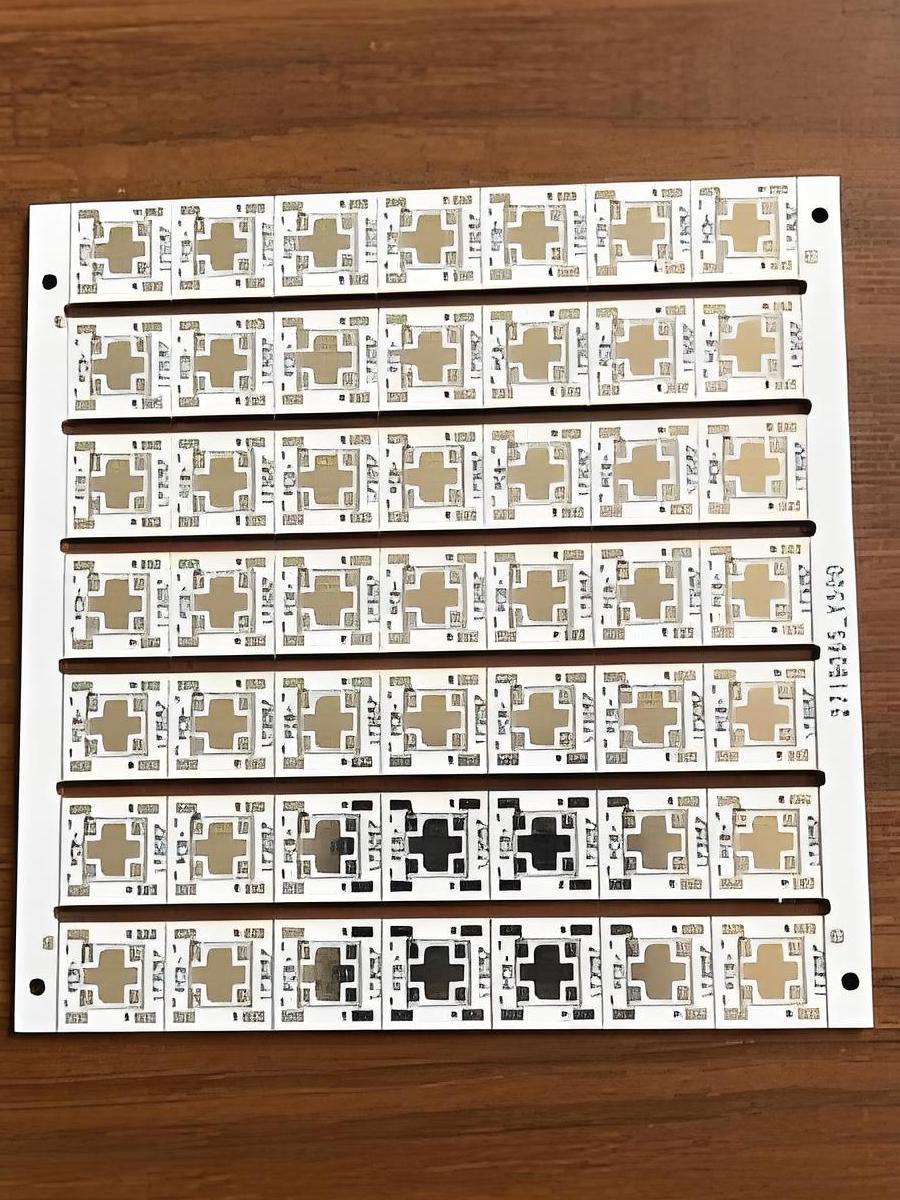

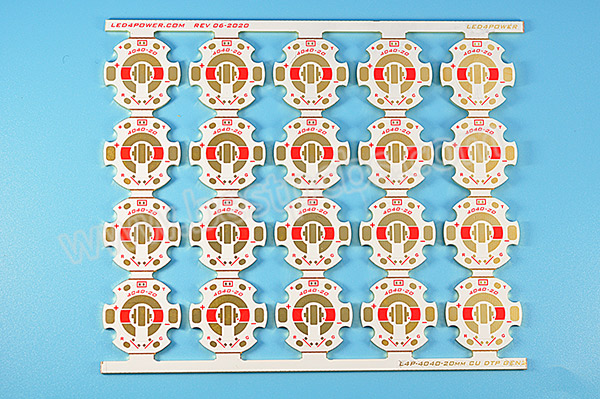

Creating a LED MCPCB involves careful layering and expert engineering. Hereās a simplified breakdown of how it’s made:

- Start with the metal base: usually aluminum.

- Apply a dielectric layer: an insulating material that resists heat and isolates the conductive traces from the metal core.

- Add the copper layer: this is where the circuit paths are etched.

- Finish with a solder mask: often white for LED boards to reflect light.

Mount LED chips via SMD process, or bond them directly using thermal adhesive. Every layer is optimized for thermal conductivity, electrical performance, and physical durability.

What are the characteristics of LED MCPCB?

Here are the top characteristics:

- High thermal conductivity: it can conduct heat away from LED chips faster than FR4.

- Low thermal resistance: ensures the LED runs cooler, which means longer lifespan.

- Mechanical strength: ideal for rough environments and industrial usage.

- Better light output: thanks to lower heat buildup and reflective solder mask.

- Customizability: shape, thickness, hole positioning, and trace layout can all be tailored.

These features make it the go-to option for high-performance lighting in automotive, military, medical, and outdoor systems.

What is the thermal conductivity of MCPCB LED?

Thermal conductivity measures how efficiently a material can transfer heat. Typical LED MCPCB thermal conductivity ranges from 1.0 to 3.0 W/m.K, depending on the material used in the dielectric layer.

Basic MCPCBs have around 1.0 W/m.K, good for standard lighting.

Advanced types like ceramic-filled or nano-filled layers can reach up to 3.0 W/m.K, great for high-power LEDs.

The metal base (aluminum or copper) naturally has higher thermal conductivity. Copper can hit 390 W/mK, while aluminum is around 200 W/mK.

The goal is to minimize thermal resistance between the LED and the aluminum base. Lower resistance = faster heat flow = longer LED life.

How thick is the copper in LED MCPCB?

Copper thickness is crucial. It affects both current carrying capacity and heat management. For LED MCPCB boards, the copper layer usually comes in:

- 1 oz (35Ī¼m): standard for most LED applications.

- 2 oz (70Ī¼m): for high-power or high-current uses.

- 3 oz or more: for heavy-duty applications like floodlights or industrial panels.

The thicker the copper, the better it handles electrical loads and distributes heat. But thicker copper also means higher cost.

What is the use of LED MCPCB?

MCPCB LED boards are used wherever powerful, long-lasting, and compact lighting is needed. Their strength lies in their versatility. Common applications of LED MCPCB include:

- Automotive lighting: headlights, fog lamps, brake lights.

- Street and tunnel lights: where heat and exposure to the elements are concerns.

- Industrial and mining lamps: where performance and reliability are critical.

- Medical equipment: devices requiring precise lighting.

- LED MCPCB strips and panels: used in displays, signage, and architectural lighting.

In all these uses, heat control is vital. MCPCB LED ensures your lights donāt fail in the middle of operation. It protects your components, reduces maintenance, and delivers better light performance for years.

Why choose BEST Technology as Your LED MCPCB Manufacturer?

Weāre not only experienced in manufacturing high-precision LED MCPCB boards, but we also support OEM, ODM, and fully customized orders. Our production lines support aluminum, copper, and even ceramic MCPCBs with fast lead times, consistent quality, and full technical support.

You get:

- Over 19+ years of industry expertise

- High-performance raw materials

- One-on-one engineering consultation

- RoHS and REACH compliant boards

- Fast delivery and sample support

Conclusion:

MCPCB LED boards are not just components, they are the foundation of high-performance lighting systems. From thermal control to mechanical strength, LED MCPCBs empower LED lights to shine brighter, last longer, and perform more reliably in challenging environments.

Whether you need LED MCPCB plates, aluminum LED MCPCB strips, or advanced SMD-based LED boards, choosing the best technology is your best option

For more details or to get a quote, contact us at sales@bestpcbs.com