Need high-quality solder lead free? We offer RoHS certified lead free solder, engineered for all PCB through-hole and surface mount soldering processes with strong joint strength.

What is lead-free solder?

Lead-free solder is a solder alloy made without added lead. It was developed to reduce health and environmental risks linked to traditional leaded solder. In electronics manufacturing, it is now the default option for SMT and PCBA work across many markets.

Most lead-free solder material is based on tin. Tin forms the backbone of the alloy. Other metals are added to improve strength, wetting, and durability. These metals often include silver, copper, bismuth, or small amounts of nickel.

In practical use, solder lead free behaves a little differently from older leaded alloys. It melts at a higher temperature. It also forms joints with a different surface look. The joints may appear slightly dull or grainy.

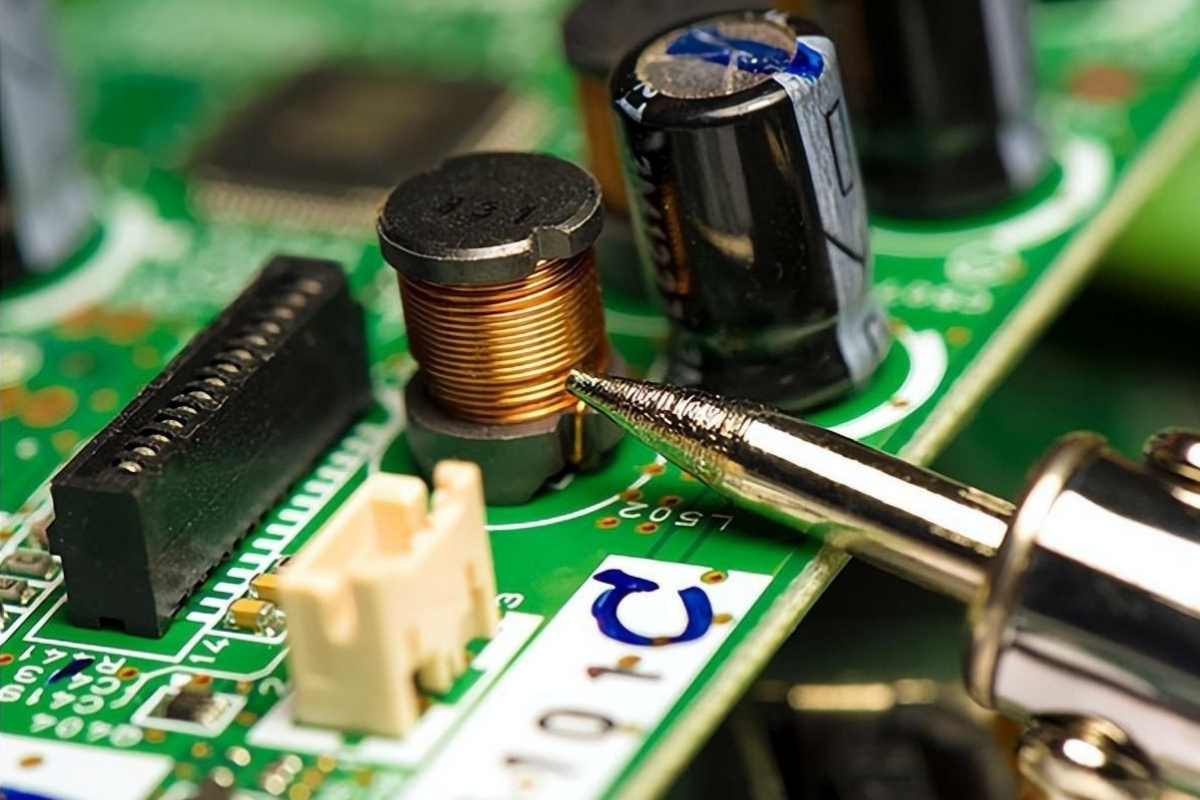

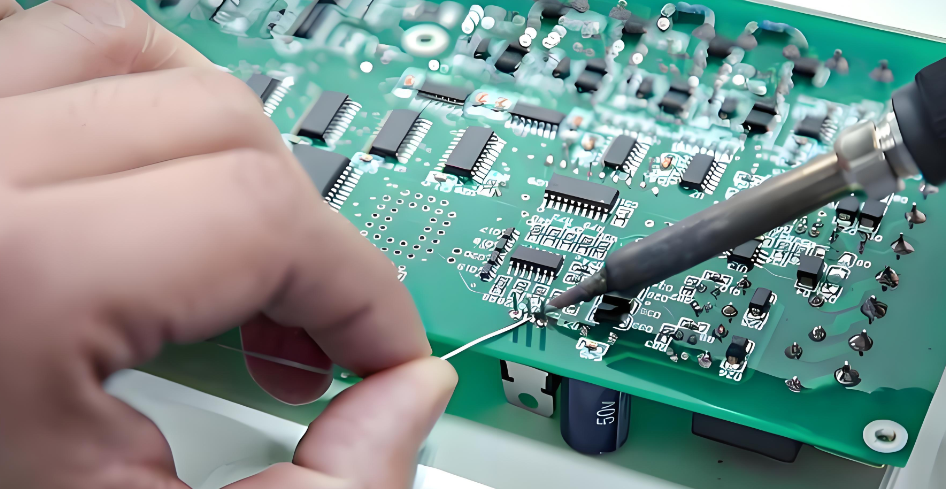

For SMT lines, lead-free solder paste is used to print onto pads before component placement. During reflow, the paste melts and forms joints. For manual work or selective soldering, lead free solder wire is often used. The same alloy rules apply, but the form factor changes.

How to choose solder lead free?

Choosing the right solder lead free option starts with understanding your process. Not all assemblies are the same. Board design, component type, and thermal limits matter.

The first step is to look at the alloy family. The most common choice is SAC alloy. SAC stands for tin, silver, and copper. SAC305 is widely used in SMT and PCBA lines. It balances strength, cost, and reliability well.

Next, consider the melting point solder lead free alloys provide. Lead-free solder melting point is usually higher than leaded solder. This affects reflow profiles and hand soldering settings. Boards with heat-sensitive parts may need a lower-melt alloy with bismuth added.

You should also think about the solder form.

- Lead free solder paste for SMT printing and reflow

- Lead free solder wire for hand soldering and repair

- Bar solder for wave or selective soldering

Each form must match the equipment used on the line.

Flux type is another key factor. Flux helps cleaning and wetting. No-clean flux is popular in modern factories. Water-soluble flux is used when cleaning is planned.

Why use solder lead free?

The strongest reason to use solder lead free is safety. Lead is toxic. Removing it reduces risk to workers and users.

Environmental protection is another major driver. Electronics waste is a growing issue. Lead-free solder lowers the impact when products reach the end of life. It supports cleaner recycling and disposal.

Compliance is also critical. Many markets require lead-free materials. RoHS rules limit lead content in electronics. Using lead-free solder helps products enter global markets without legal barriers.

Performance has improved over time. Early lead-free alloys had limits. Today, advanced formulations deliver strong joints. With the right profile, reliability is high in SMT and PCBA use.

At EBest Circuit (Best Technology), lead-free soldering is part of standard production. Our SMT lines are tuned for stable lead free solder temp control. This ensures consistent joints and long service life for assemblies.

What are the disadvantages of lead-free solder?

Lead-free solder does bring some challenges. The most known issue is higher process temperature. Lead free solder temperature during reflow is higher than leaded solder. This adds stress to boards and parts.

- Wetting speed can be slower. The solder may take more time to flow across pads. This requires careful profile tuning and good flux selection.

- Another concern is cost. Some alloys include silver. Silver raises material cost. However, the price gap has narrowed over time.

- Lead-free joints may also look different. They are less shiny. This can confuse new operators. Training helps teams understand what good joints look like.

Despite these points, most disadvantages are manageable. Modern equipment handles higher heat well. Proper design reduces risk. Process control solves most issues before they appear.

Is lead-free solder still toxic?

Lead-free solder is safer than leaded solder. It removes a major toxic element. However, it is not completely harmless.

The metals used, such as tin, silver, and copper, are far less dangerous than lead. In solid form, they pose very low risk. During soldering, fumes come mainly from flux, not metal.

Good ventilation is still needed. Fume extraction protects workers from flux vapors. This applies to both lead-free and leaded solder.

How can I tell if my solder is lead free?

Identifying lead-free solder is usually simple. Most products are clearly labeled. Packaging often states lead-free solder or lead-free solder wire on the label.

There are a few common signs:

- Alloy codes like SAC305 or Sn96.5Ag3Cu0.5

- RoHS or lead-free symbols on packaging

- Higher melting behavior during use

If labeling is missing, material testing can confirm composition. XRF testing is widely used in factories. It quickly checks metal content without damage.

At EBest Circuit (Best Technology), incoming solder materials are verified. This ensures full compliance and stable production from the first print to final inspection.

What is RoHS for solder lead free?

RoHS stands for Restriction of Hazardous Substances. It is a regulation that limits certain materials in electronics. Lead is one of the restricted substances.

For solder lead free compliance, RoHS sets a maximum lead content. The limit is very low. Most lead-free solders are well below this level.

RoHS applies to many product categories. Consumer electronics, industrial controls, and medical devices often fall under its scope.

RoHS is not just a label. It requires traceability and proof. Suppliers must provide declarations and test reports.

EBest Circuit (Best Technology) works with RoHS-compliant solder suppliers. We maintain records for each batch.

Which solder lead free fits PCBA?

PCBA work covers many applications. The best solder lead free choice depends on use case. General SMT assembly often uses SAC305. It offers strong joints and wide acceptance.

For boards with fine-pitch parts, solder paste with good slump resistance is key. This supports clean printing and reduces bridging.

High-reliability products may use modified alloys. Small additions of nickel or bismuth can improve joint life. Automotive and industrial boards often benefit from these options.

Thermal limits matter. If components cannot handle high heat, a lower melting lead-free alloy may be chosen. This protects parts while staying compliant.

EBest Circuit (Best Technology) evaluates each project. We match solder type to board design and product needs. This approach improves yield and long-term stability.

How to use solder lead free for SMT?

Using solder lead free for SMT requires control and consistency. The process is well known but must be followed closely.

- First, solder paste storage is critical. Paste must be kept cold and sealed. Before use, it should reach room temperature naturally.

- Stencil printing comes next. Proper stencil thickness and aperture design ensure even paste volume. Lead-free solder paste is sensitive to print quality.

- Component placement should be accurate. Lead-free solder does not self-align as easily as leaded solder. Placement precision matters more.

Reflow profiling is the heart of the process. Lead free solder temp profiles usually include:

- A controlled preheat stage

- A soak zone for flux activation

- A peak temperature above melting point

- A smooth cooling stage

The peak temperature must be high enough to fully melt the alloy. At the same time, it should stay within component limits.

Inspection follows reflow. Visual checks and AOI confirm joint shape and coverage. Acceptable joints may look matte. This is normal for lead-free solder.

What affects solder lead free performance?

Many factors influence solder lead free results. Material choice is only one part. Process control plays a major role.

Board finish affects wetting. ENIG, OSP, and immersion silver each interact differently with lead-free solder. Selecting the right finish helps joint quality.

Component plating also matters. Tin-based finishes work well. Mixed finishes can cause uneven wetting.

Thermal profile accuracy is critical. Small changes in lead free solder temperature can change joint quality. Regular profile checks keep results stable.

Flux chemistry impacts residue and wetting speed. Choosing the right flux reduces defects and cleaning needs.

Environmental control helps too. Humidity and cleanliness affect paste behavior. Stable factory conditions support consistent output.

Conclusion:

Lead-free solder has become the standard for SMT and PCBA manufacturing. It improves safety, supports global compliance, and delivers strong performance when used correctly.

For professional PCBA and SMT services using proven lead-free soldering processes, contact EBest Circuit (Best Technology) at sales@bestpcbs.com