Industrial assembly solutions‚Äč form the backbone of modern manufacturing, integrating disparate components into functional, high-performance electronic systems. This article explores the critical role of custom assembly solutions, driven by rapid prototyping, in enhancing efficiency, reliability, and innovation across demanding industries such as aerospace and semiconductor manufacturing.

Many engineering teams struggle with recurring bottlenecks that slow down the transition from prototype to stable mass production.

- Prototype-to-production delays: Long prototype lead times delay validation and increase development cost.

- Integration complexity: Difficulty aligning PCBAs, cable harnesses, and mechanical parts into one reliable system.

- Inconsistent quality: Manual processes or unqualified suppliers introduce defects and variability.

- Fragmented supply chains: Multiple vendors create coordination gaps and unclear accountability.

- Compliance pressure: Managing certifications such as AS9100 or ISO 13485 consumes time and resources.

These challenges are best resolved by working with a single partner delivering integrated industrial assembly solutions.

- Faster development cycles: Rapid system-level prototypes enable quicker testing and iteration.

- Turnkey system integration: Seamless integration of PCBA, industrial cable assembly solutions, firmware, and enclosures.

- Automated and controlled processes: Automated industrial assembly solutions ensure repeatability and high yield.

- Unified supply chain ownership: One partner manages BOMs, procurement, assembly, and testing.

- Built-in compliance support: Proven experience guiding assemblies through regulated industry standards.

EBest Circuit (Best Technology) is a specialist in advanced PCBA manufacturing and complete electronic system integration. We excel in delivering custom industrial assembly solutions with fast prototypes, particularly for high-reliability and regulated markets. Our vertical integration and rigorous process control allow us to manage complex projects from initial prototype through to full-scale production, ensuring quality, consistency, and speed. Pls feel free to contact our engineering team at sales@bestpcbs.com‚Äč to discuss your industrial PCB assembly project.

What Are Industrial Assembly Solutions in Modern Electronic Manufacturing?

Industrial assembly solutions refer to the end-to-end services and methodologies used to populate, interconnect, and house electronic components to create a finished, functional product. In modern electronics, this extends far beyond basic PCBA to encompass the holistic integration of hardware, firmware, and sub-assemblies.

- Core Components:‚Äč This includes Printed Circuit Board Assembly (PCBA), industrial cable assembly solutions‚Äč (wire harnesses, connectors), enclosure integration, software loading, and final system testing.

- The Customization Imperative:‚Äč Off-the-shelf solutions rarely suffice. Customization is driven by unique form factors, thermal management needs, signal integrity requirements, and environmental conditions (e.g., vibration, temperature extremes).

- The Prototype Link:‚Äč Fast prototypes‚Äč are the critical first step in any custom solution, allowing for physical validation of the assembly design, manufacturability, and performance before capital is committed to production tooling.

- Evolution from Manual to Automated:‚Äč While manual assembly persists for complex, low-volume tasks, automated industrial assembly solutions‚Äč dominate for scalability, precision, and consistency, especially in surface-mount technology (SMT) placement.

In essence, modern industrial assembly solutions‚Äč are the orchestrated processes that transform a design file into a dependable, market-ready electronic device, with rapid prototyping serving as the essential risk-mitigation phase.

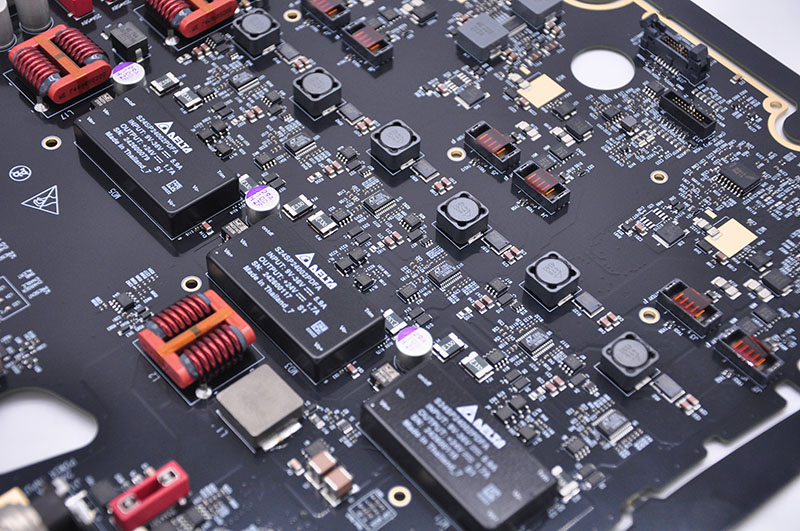

How Do Automated Industrial Assembly Solutions Improve PCBA Efficiency and Consistency?

Automated industrial assembly solutions fundamentally improve PCBA performance by replacing operator-dependent steps with programmable, repeatable processes, directly increasing throughput while stabilizing quality.

Manual vs Automated PCBA

| Aspect | Manual Process | Automated Solution | Impact |

|---|---|---|---|

| Placement Speed & Accuracy | Operator-dependent | High-speed SMT placement | Efficiency ‚ÜĎ |

| Solder Paste Control | Variable printing | SPI-controlled printing | Consistency ‚ÜĎ |

| Soldering Quality | Uneven heat input | Profile-controlled reflow | Reliability ‚ÜĎ |

| Traceability & Data | Paper / basic logs | Barcode + MES tracking | Quality Control ‚ÜĎ |

| Scalability | Labor scales with volume | 24/7 machine operation | Cost/Unit ‚Üď |

What Automation Really Changes in PCBA Manufacturing

Automation does more than speed up assembly‚ÄĒit stabilizes the process window:

- Repeatable placement and solder volumes reduce common defects such as tombstoning, bridging, and insufficient solder.

- Controlled thermal profiles eliminate operator-induced variability, improving joint integrity and long-term reliability.

- Digital traceability enables real-time quality monitoring and fast root-cause analysis when issues arise.

- Non-linear scalability allows production to ramp without proportional increases in labor or risk.

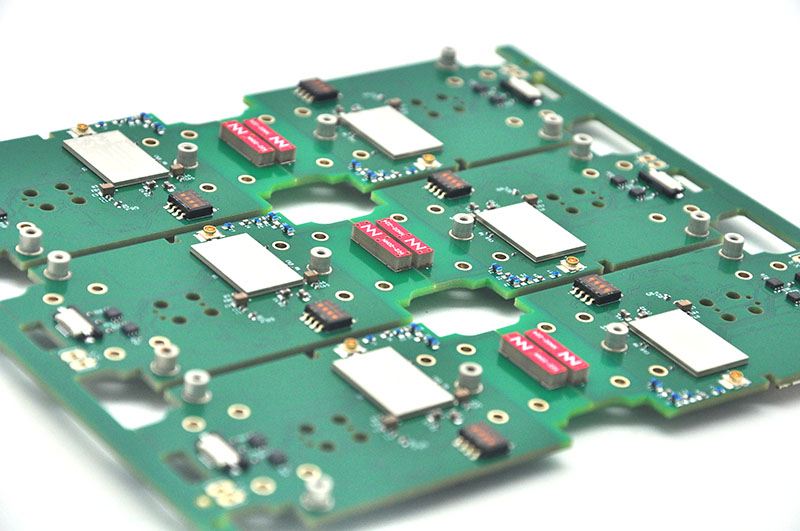

Why Fast Prototypes Still Matter in Automated Assembly

Even in a highly automated environment, fast prototypes remain essential‚ÄĒnot to validate design intent alone, but to validate the automation process itself:

- Stencil aperture design and paste release

- Feeder setup and placement strategy

- Reflow profile tuning and thermal margins

By debugging these parameters early, manufacturers ensure that full-scale automated production runs smoothly, predictably, and with high yield.

Ultimately‚ÄĆ, for modern PCBA, automation is not optional. It is the foundation for consistent quality, scalable output, and competitive manufacturing economics.

What Role Do Industrial Cable Assembly Solutions Play in Complete PCBA Systems?

While the PCBA is the “brain,” industrial cable assembly solutions‚Äč are the “nervous system” and “lifeblood,” transmitting power and signals between PCBs, sensors, actuators, and user interfaces. Their role in system integration is critical.

- Signal Integrity Assurance:‚Äč Properly shielded and impedance-controlled cable assemblies prevent noise, crosstalk, and data corruption, which is crucial for high-speed digital or sensitive analog signals from the PCBA.

- Power Distribution Reliability:‚Äč Robust wiring harnesses with correct gauge and termination ensure stable power delivery to all system components, preventing voltage drops and overheating.

- Mechanical Durability and Serviceability:‚Äč Custom connectors and strain relief allow for modular design, enabling easier field maintenance, upgrades, and repair of both the cable and connected PCBA.

- Environmental Protection:‚Äč Cable assemblies with appropriate jacketing (e.g., for oil resistance, extreme temperatures) protect connectivity in harsh industrial, automotive, or aerospace environments where the PCBA operates.

- System Integration Enabler:‚Äč A well-designed cable harness is the physical roadmap of the system, simplifying the final assembly process and reducing integration errors during the product build.

Neglecting cable assembly design is a common failure point. The best industrial cable assembly companies for manufacturing solutions‚Äč view them not as commodities but as engineered components, designing them in parallel with the PCBA to ensure seamless integration and system-wide reliability.

How to Evaluate the Best Industrial Cable Assembly Companies for Manufacturing Solutions?

From a PCBA and system integration perspective, choosing a cable assembly partner is about finding a seamless extension of your own manufacturing team. Evaluation must go beyond simple quoting.

- Design-for-Manufacturability (DFM) Collaboration:‚Äč Do they proactively provide DFM feedback on your connector choices, harness routing, and termination methods to improve reliability and lower assembly cost?

- Vertical Integration & Component Control:‚Äč Do they manage or have certified sources for connectors, wires, and backshells? Control over this supply chain prevents counterfeit parts and ensures material traceability.

- Testing and Validation Capability:‚Äč Can they perform electrical continuity testing, hipot (dielectric withstand) testing, and signal integrity validation? Their testing should complement your PCBA and final system test protocols.

- Experience in Your Application Environment:‚Äč Do they have a proven track record in environments similar to yours (e.g., high-vibration, sterile, high-temperature)? Ask for case studies.

- Compatibility with Your PCBA Processes:‚Äč Can they provide assemblies that are easy to integrate with your PCBA‚ÄĒusing compatible solders, providing clear pin-out documentation, and supporting your fast prototype‚Äč build schedule?

A top-tier partner functions as a subsystem provider, not just a wire cutter. Their quality and flexibility directly impact the success of your overall custom industrial assembly solutions.

Who Provides Turnkey Assembly Line Solutions for the Aerospace Industry?

The aerospace industry demands absolute reliability, complete traceability, and adherence to strict standards like AS9100. Turnkey assembly line solutions for the aerospace industry‚Äč are provided by highly specialized electronics manufacturing services (EMS) partners with deep domain expertise.

- Providers are Specialized EMS/Contract Manufacturers:‚Äč These are not generic assemblers. They possess:

- AS9100 Certification:‚Äč Non-negotiable quality management system for aerospace.

- Nadcap Accreditation:‚Äč Often for specialized processes like welding or non-destructive testing.

- Component Management Expertise:‚Äč Ability to source, store, and handle aerospace-grade components with full lot traceability.

- Rigorous Testing Facilities:‚Äč Capabilities for environmental stress screening (ESS), vibration, shock, and thermal cycling testing.

- Systems Integration Expertise:‚Äč Experience in building ruggedized consoles, avionics boxes, and satellite communication modules where PCBA, cable, and chassis become one certified unit.

These providers manage the entire line‚ÄĒfrom kitting components with aerospace paperwork to final assembly, conformal coating, testing, and certification support. They are integral partners in navigating the complex aerospace supply chain.

Why Industrial Assembly Solutions Matter for High-Reliability and Regulated Electronics?

In fields like medical devices, aerospace, and automotive, failure is not an option. Here, industrial assembly solutions‚Äč are the critical control point for ensuring safety, performance, and regulatory compliance.

- Process Documentation & Control:‚Äč Every step‚ÄĒsolder paste application, component placement, welding, crimping‚ÄĒmust follow a documented, validated, and controlled procedure. Auditors inspect this, not just the final product.

- Material Traceability:‚Äč The ability to trace every component on a PCBA or within a cable harness back to its manufacturer’s lot is essential for recalls, failure analysis, and regulatory filings.

- Enhanced Testing Regimes:‚Äč Solutions include advanced testing beyond standard PCBA: in-circuit test (ICT), flying probe, functional test (FT), and burn-in/ESS to precipitate early-life failures.

- Cleanliness & Contamination Control:‚Äč For medical or high-voltage applications, assembly processes must control ionic contamination and particulate matter to prevent corrosion or arcing.

- Validation of the Entire System:‚Äč Regulators approve the finished, assembled device. A turnkey provider ensures that the integration of all sub-assemblies is performed under the same quality umbrella, simplifying the validation and submission process.

For high-reliability electronics, the assembly solution is the guarantee of integrity. It transforms a collection of certified parts into a certified, life-critical system.

To summarize, industrial assembly solutions‚Äč are the critical discipline that bridges electronic design and durable, market-ready products. This article has detailed how custom solutions, accelerated by fast prototypes, address core manufacturing challenges from automation to aerospace compliance.

Success hinges on partnering with an expert who can orchestrate this complexity. EBest Circuit (Best Technology) provides these exact custom industrial assembly solutions with fast prototypes, combining deep technical expertise in PCBA and system integration with a steadfast commitment to quality for high-reliability sectors. Pls feel free to contact us anytime at sales@bestpcbs.com to start a conversation about your SMT assembly project.