How to design a heart shaped PCB? Let’s discover benefits, applications, design spec and guideline, production process, testing methods for heart PCB.

Are you worried about these problems?

- Low Processing Yield: Heart-shaped arcs prone to burrs/fractures, conventional scrap rate >15%, poor mass production stability.

- Impedance Control Challenge: Signal reflection at heart tip affects LED performance, full-path signal integrity needs guarantee.

- High Customization Cost: MOQ 500pcs/2-week sampling, high cost pressure for small-batch needs.

As a heart PCB manufacturer, EBest Circuit (Best Technology) can provide you service and solution:

- Smart Manufacturing Optimization: AI stress point prediction + 0.1mm milling cutter process, yield 99.2%, surface smoothness Ra≤0.8μm.

- Circuit Design Innovation: Dynamic impedance compensation + gradient RGB lighting, signal fluctuation ≤5%, stable effects.

- Flexible Service Model: 50pcs MOQ, 72-hour rapid sampling with report, free 3D simulation to reduce revision risks.

Welcome to contact us if you have any inquiry for heart PCB: sales@bestpcbs.com.

What Is Heart Shaped PCB?

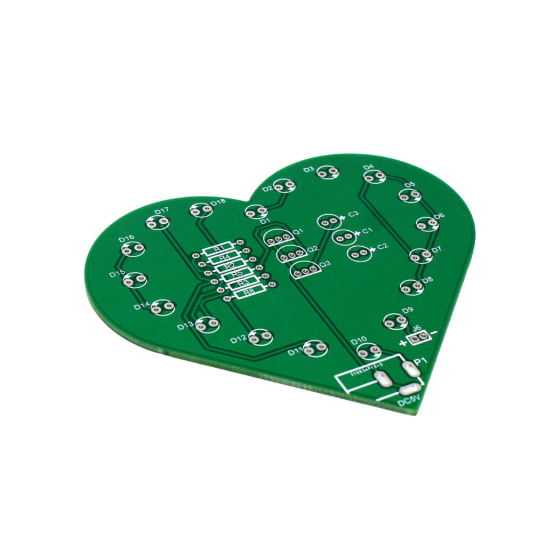

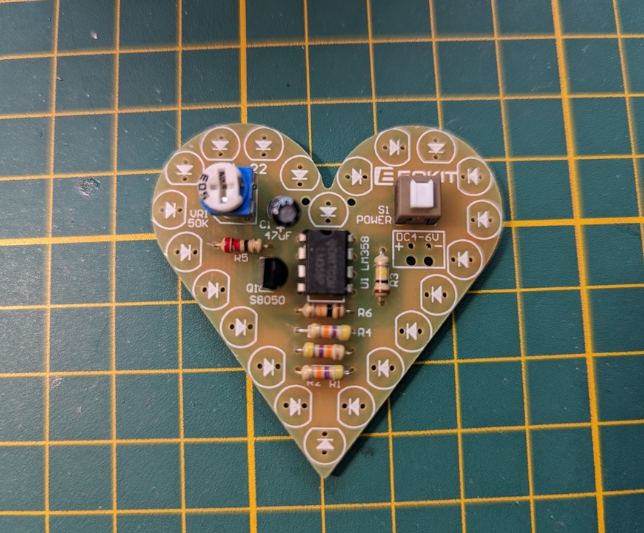

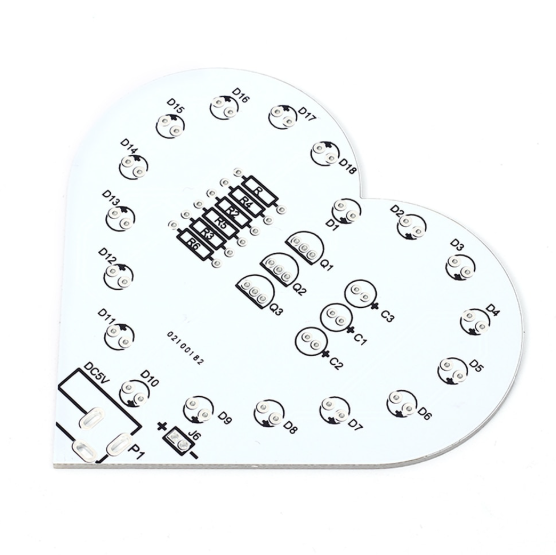

Heart shaped PCB refers to a printed circuit board (PCB) with a heart-shaped contour as its physical boundary, achieved through customized contour cutting (such as CNC milling or laser cutting) to create non-standard geometric structures.

Its design core lies in the integration of functional electronic circuits with emotional visual symbols. Such PCBs typically adopt single/double-sided laminate substrates (commonly FR-4 material) and primarily serve holiday gifts, emotional interaction devices, and brand marketing scenarios in the consumer electronics sector (accounting for over 85% of applications).

Compared to standard rectangular PCBs, they carry a cost premium of approximately 40%-60%, primarily due to the material loss from non-standard machining processes.

What Are Advantages of Heart Shaped PCB Board?

Benefits of heart shaped PCB board:

- Emotional Resonance Enhances Brand Identity: The heart symbol is universally recognized, triggering warmth and trust. Heart-shaped PCBs in medical devices, gifts, or wearables quickly build emotional connections with users, boosting customer loyalty and product appeal.

- Differentiated Design Boosts Market Competitiveness: Amid electronics homogenization, the unique heart shape helps products stand out. It targets niche markets like medical health or personal consumer electronics, attracting customers seeking emotional or personalized experiences and creating memorable brand impressions.

- Space Optimization Improves Device Performance: Heart-shaped PCBs fit compact spaces, reducing device size and weight for better portability. Optimized circuit layouts minimize signal interference, ensuring precise data transmission in medical devices (e.g., heart rate monitors) and extending product lifespan.

- Medical Professionalism Strengthens Reliability: The heart shape aligns naturally with cardiac-related devices (e.g., heart monitors, pacemakers), enhancing patient trust in reliability. Flexible heart-shaped PCBs conform to body curves, reducing mechanical stress in implants. High-temperature and vibration-resistant materials further improve durability in complex environments.

- Emotional Value Drives Commercial Success: Heart-shaped PCBs integrate programmable LED lighting and smart interactions, adding emotional attributes to products. Ideal for holiday gifts, keepsakes, or emotional expression items, they increase purchase intent and foster word-of-mouth promotion and repeat business through emotional resonance.

What Are Applications of Heart Shaped Circuit Board?

Applications of heart shaped PCB board:

Medical Devices

- Cardiac Monitoring Equipment: Such as electrocardiogram (ECG) monitors and pacemakers, suitable for minimally invasive surgical endoscopes and wearable ECG monitoring devices.

- Implantable Devices: Such as neurostimulators, using multi-layer heart-shaped PCBs to ensure signal transmission integrity, paired with medical-grade polyimide substrates for biocompatibility.

Wearable Devices

- Smart Bracelets/Watches: Flexible heart-shaped PCBs adapt to body curves, such as blood glucose patches, improving signal transmission stability.

- Emotional Products: Smart bracelets with programmable LED lighting and smart interaction features enhance emotional resonance.

Consumer Electronics

- High-End Smartphones: Foldable phones adopt ultra-thin heart-shaped HDI boards to integrate more sensors and enhance user interaction.

- AI Servers: Heart-shaped multi-layer boards (18+ layers) support high-speed signal transmission for AI computing needs, with single-unit value exceeding $280.

Gift Industry

- Customized Gifts: Memorial smart bracelets and holiday-themed smart lamps combine programmable lighting to boost emotional value.

- Artistic Gifts: Smart bandages and dynamic blood glucose monitoring patches blend practicality with emotional attributes.

Heart Shaped Circuit Board Design Specification

| Parameter Item | Mandatory Value/Tolerance | Critical Value |

| Apex Curvature Radius | ≥1.0mm | <0.8mm (Fracture Risk ↑300%) |

| Board Thickness (FR-4) | 0.6mm~1.6mm | >2.0mm (Milling Deformation) |

| Form Symmetry Error | ≤0.05mm | >0.1mm (Visual Defect) |

| Board Edge Exclusion Zone | ≥0.75mm | <0.5mm (Cutting Short Circuit Rate 32%) |

| Minimum Trace Width/Spacing | 0.15mm/0.15mm | 0.10mm (Yield ↓45%) |

| Impedance Control Tolerance | ±7% (50Ω System) | ±10% (Signal Reflection ↑18dB) |

| Copper Foil Thickness | 1oz (35μm) Base Value | 0.5oz (Current Carrying Capacity ↓40%) |

| Substrate TG Value | ≥130℃ | <110℃ (Thermal Deformation Temperature) |

| Flexible Zone Bend Radius (PI Substrate) | ≥5.0mm | <3.0mm (Fracture Life <100 Cycles) |

| Component Distance to Board Edge | ≥2.0mm | <1.0mm (Stress Failure ↑60%) |

| Component Size Restriction in Apex Zone | ≤0603 (1608 Metric) | >1206 (Shear Force Risk) |

| BGA Distance to Outline | ≥5.0mm | <3.0mm (Solder Joint Crack Rate ↑70%) |

| V-Cut Depth Tolerance | Board Thickness/3 ±0.05mm | >Board Thickness/2 (Fracture Risk) |

| Minimum Hole Copper Thickness | ≥25μm | <18μm (Via Resistance ↑200%) |

| Laser Cutting Position Accuracy | ±0.03mm | ±0.08mm (Form Distortion) |

| Flying Probe Test Coverage | Critical Nets 100% + Full Board ≥95% | <90% (Potential Open Detection Leakage) |

| Thermal Cycling Range | -40℃~+125℃, 5 Cycles | 0℃~85℃ (Reliability Insufficient) |

| Insulation Resistance | ≥100MΩ (@500VDC) | <10MΩ (Leakage Risk) |

How to Design a Heart Shaped PCB Board?

Below is a guide for heart shaped PCB design:

1. Scenario-Specific Requirement Analysis & Deep Definition

- Scenario Segmentation: Medical applications require device-specific compliance (e.g., cardiac pacemakers/ECG monitors) adhering to ISO 13485 medical device quality management systems, with signal integrity targets (e.g., ECG signal error <1%). Wearable scenarios demand ergonomic curve matching (e.g., wrist curvature adaptation) and motion-state noise suppression for stable signal transmission.

- Quantified Performance Metrics: IPC-2221B-compliant electrical parameters (e.g., ±7% impedance control), mechanical durability (e.g., ≥1000-cycle flex zone bending life), and environmental robustness (e.g., -40℃~125℃ thermal shock testing per IEC 60068-2-14).

2. Advanced Geometric Design & Multi-Dimensional Validation

- CAD Implementation Details: Use Altium Designer’s “Interactive Routing” for heart-shaped contour drafting, with “Design Rule Check” enforcing apex curvature radius ≥1.0mm. ANSYS HFSS electromagnetic simulation validates form symmetry error ≤0.05mm impact on signal integrity, preventing >0.1mm errors causing visual defects.

- Tolerance Risk Quantification: FMEA analysis shows <0.8mm apex curvature increases fracture risk by 300%, requiring CT scan verification of internal structure integrity during prototyping. FR-4 thickness (0.6mm~1.6mm) avoids milling deformation risks associated with >2.0mm plates.

3. Material & Stack-Up Optimization with Verification

- Substrate Selection Rationale: Medical implants prioritize PI-based flexible substrates (e.g., DuPont Kapton) with TG ≥130℃ for thermal stability and ISO 10993 biocompatibility. FR-4 substrates balance cost-performance for general applications.

- Copper Thickness Validation: ANSYS SIwave current density simulation verifies 1oz (35μm) copper foil maintains <20℃ temperature rise at 50A, avoiding 40% current-carrying capacity degradation in 0.5oz alternatives. Flex zone bend radius (≥5.0mm) achieves ≥1000-cycle fracture life per JIS C 6471 cyclic bending tests.

4. Electrical Routing & Impedance Control Precision

- Routing Rule Refinement: Board edge clearance (≥0.75mm) undergoes DFM analysis, with <0.5mm clearance showing 32% cutting short-circuit risk. 0.15mm/0.15mm trace/space dimensions require electroplating uniformity testing; 0.10mm widths reduce yield by 45%, mitigated via current density optimization.

- Impedance Control Methodology: Polar SI9000 calculates 50Ω system impedance through dielectric thickness (FR-4 εr=4.2~4.8) and trace width adjustments to achieve ±7% tolerance. ±10% tolerance necessitates back-drilling/impedance matching networks to control 18dB signal reflection rise.

5. Component Placement & Mechanical Constraint Optimization

- Layout Rule Quantification: Component-to-edge distance (≥2.0mm) validated via ANSYS Mechanical stress analysis shows 60% failure risk increase at <1.0mm. Apex zone component size restrictions (≤0603/1608 metric) prevent shear force risks from >1206 packages, confirmed by IPC-TM-650 2.4.4.1 shear tests. BGA-to-outline distance (≥5.0mm) reduces solder joint crack rates by 70% at <3.0mm, validated by JESD22-A104 thermal cycling tests.

6. Process Parameter Optimization & Quality Control

- V-Cut Depth Control: Laser cutting parameters (speed/power) achieve board thickness/3 ±0.05mm tolerance, with cross-section analysis verifying fracture risks at >50% thickness. CCD vision systems monitor ±0.03mm cutting accuracy, with compensation algorithms correcting ±0.08mm deviations causing form distortion.

- Hole Copper Thickness Verification: Electroplating parameter adjustments (current density/plating time) ensure ≥25μm hole copper thickness, with <18μm causing 200% via resistance increase validated by electrical testing.

7. Reliability Testing & Validation

- Test Coverage Enhancement: Flying probe testing achieves 100% critical net coverage + ≥95% full-board coverage via boundary scan techniques, reducing <90% coverage risks of undetected opens. IEC 60068-2-14-compliant thermal cycling (-40℃~125℃, 5 cycles) verifies reliability, with accelerated life testing for 0℃~85℃ ranges.

- Insulation Resistance Validation: Hipot testing confirms ≥100MΩ (@500VDC) insulation resistance, with <10MΩ risks mitigated via solder mask thickness optimization.

8. Iterative Optimization & Documentation

- Closed-Loop Optimization: Adjust routing parameters (e.g., adding shielding layers for crosstalk reduction) or material selections (e.g., high-TG substrates for thermal stability) based on test results. Generate ISO 13485-compliant documentation packages (Gerber/BOM/process specifications) with DFMEA validation of design robustness.

How to Make a Heart Shaped PCB Board?

Heart-Shaped PCB Board Production Process:

1. Material Cutting & Substrate Preparation

- Cut FR-4/PI substrate to specified thickness (0.6mm~1.6mm) per design specifications, ensuring substrate TG value ≥130℃ for thermal stability.

- Pre-treat copper foil layer using 1oz (35μm) copper thickness standard, adjusting plating parameters via electroplating line to ensure uniform copper layer distribution.

2. Heart-Shaped Contour Forming

- Utilize laser cutting machine to cut heart-shaped outer contour according to design files, controlling V-Cut depth at board thickness/3 ±0.05mm to avoid fracture risks associated with >50% thickness.

- Monitor cutting accuracy (±0.03mm) via CCD vision system, activating compensation algorithms to correct ±0.08mm deviations causing form distortion.

3. Electrical Routing & Impedance Control

- Implement minimum trace width/spacing of 0.15mm/0.15mm for routing, optimizing current density through plating uniformity testing to ensure 0.10mm trace width yield compliance (avoiding 45% yield loss).

- Calculate and adjust dielectric thickness (FR-4 εr=4.2~4.8) using Polar SI9000 tool to achieve ±7% impedance tolerance; ±10% tolerance necessitates back-drilling or impedance matching network optimization.

4. Hole Processing & Plating

- After drilling, adjust plating parameters (current density/plating time) to ensure hole copper thickness ≥25μm; <18μm requires re-plating validation due to 200% via resistance increase.

- Perform solder joint thermal cycling testing (JESD22-A104 standard) for BGA regions, ensuring distance to outline ≥5.0mm to mitigate 70% solder joint crack risk at <3.0mm.

5. Surface Treatment & Solder Mask Application

- Apply solder mask with optimized thickness to ensure insulation resistance ≥100MΩ (@500VDC); <10MΩ requires increased solder mask thickness to reduce leakage risk.

- Validate flex zone bending radius (≥5.0mm) through JIS C 6471 cyclic bending tests, ensuring ≥1000-cycle fracture life.

6. Testing & Quality Control

- Execute flying probe testing achieving 100% critical net coverage + ≥95% full-board coverage; <90% coverage requires redundant test point design to improve open detection.

- Conduct thermal cycling tests (-40℃~125℃, 5 cycles) per IEC 60068-2-14 standard, with accelerated life testing for 0℃~85℃ ranges.

7. Final Inspection & Packaging

- Verify apex zone internal structural integrity via CT scanning (curvature radius ≥1.0mm, avoiding 300% fracture risk at <0.8mm).

- Perform visual defect inspection (symmetry error ≤0.05mm, rejecting >0.1mm deviations) per ISO 13845 medical device traceability requirements before packaging and shipment.

Why Choose EBest Circuit (Best Technology) as Heart Shaped PCB Manufacturer?

Reasons why choose us as heart shaped PCB manufacturer:

- Comprehensive Certification Portfolio: Holds quadruple certifications, ISO 9001, IATF 16949, ISO 13485 medical-grade, and RoHS, covering full-scene compliance from consumer electronics to implantable medical devices. Facilitates rapid FDA/CE approval for client products.

- 19-Year Process Expertise: Accumulated over 1 million heart-shaped PCB production units, forming a proprietary “Heart-Shape Process Database” with 5,000+ defect cases and solutions. Mature processes reduce failure rates by 30% compared to industry averages for complex heart-shaped designs.

- Precision Cost Optimization: Utilizes intelligent material selection systems (e.g., dynamic FR-4/PI substrate ratio optimization) and process path algorithms to achieve 15%-20% cost reduction in heart-shaped PCB designs. Case example: A wearable device project increased minimum trace width from 0.1mm to 0.15mm, improving yield by 45% and reducing unit cost by 18% while maintaining ±7% impedance tolerance.

- 24-Hour Rapid Prototyping: Leverages digital smart factory flexible production lines to deliver “same-day order, next-day prototype” emergency services. Proven case: Completed urgent delivery for a cardiac pacemaker manufacturer, accelerating product validation cycle by 30% to seize market opportunities.

- 99.2% On-Time Delivery Rate: Supported by IoT-enabled real-time production monitoring and third-party audit data, maintains >99.2% on-time delivery for three consecutive years. Ensures zero delays in client production planning, outperforming industry supply chain reliability standards.

- Strict Full Inspection System: Implements 100% batch inspection with triple verification—AOI optical inspection, X-ray micro-hole detection, and flying probe testing. Defect rate <0.5%, with form symmetry error strictly controlled at ≤0.05mm, exceeding industry benchmarks.

- Free DFM Analysis: Provides free manufacturability evaluations from apex curvature radius ≥1.0mm verification to ±7% impedance tolerance optimization. Case impact: Saved a client RMB 200,000 in development costs by reducing 3 design iterations and accelerating time-to-market.

- End-to-End One-Stop Service: Integrates full-process resources from design to logistics, eliminating the need for clients to coordinate multiple suppliers. Reduces supply chain management time by 30%, enabling seamless transition from concept to mass production.

Welcome to contact us if you have any request for heart PCB: sales@bestpcbs.com.