How to assemble HDI PCB? Let’s discover benefits, applications, manufacturing process, manufacturer recommendations for HDI PCB assembly.

Are you worried about these problems?

- Struggling with high-density routing complexity and time-consuming design revisions?

- Facing yield instability and cost control issues under miniaturization demands?

- Tight deadlines and urgent orders causing production scheduling headaches?

As a HDI PCB assembly manufacturer, EBest Circuit (Best Technology) can provide you solutions:

- Dedicated HDI design team with DFM-driven early engagement to slash trial cycles by 30%+;

- Smart layer stacking optimization + laser microvia tech ensuring micro-spacing reliability, stabilizing yield at 98%+ while cutting costs by 15%;

- Agile capacity pool + real-time scheduling system for 7-day rush order response and 24/7 lead time tracking.

Welcome to contact us if you have any issues with HDI PCB assembly: sales@bestpcbs.com.

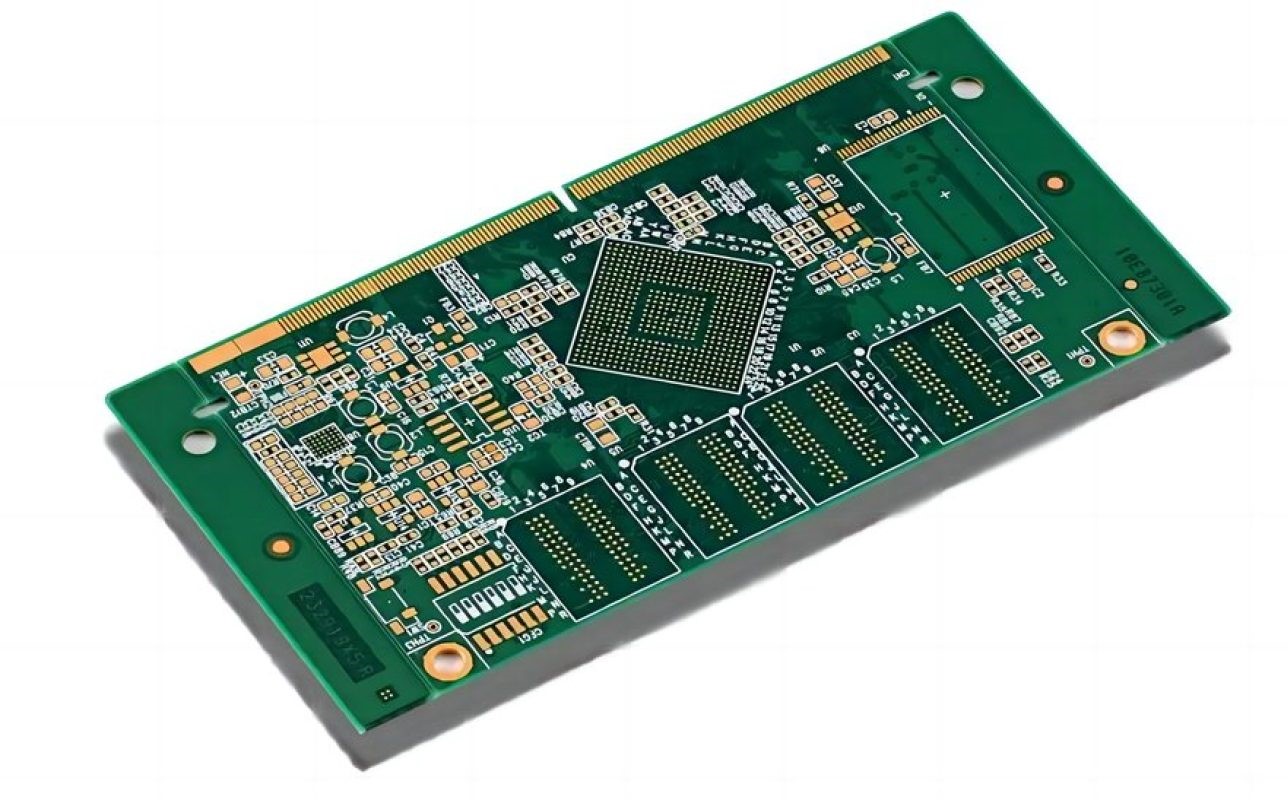

What Is HDI PCB Assembly?

HDI PCB Assembly refers to the process of soldering and interconnecting electronic components on highly compact and complex High Density Interconnect circuit boards using advanced manufacturing techniques, such boards include the use of microvias (e.g., blind or buried vias formed via laser drilling), finer line widths/spacings, increased routing layers, and tightly stacked interlayer technologies, enabling significantly higher routing density and electrical connection complexity within smaller areas compared to traditional PCBs.

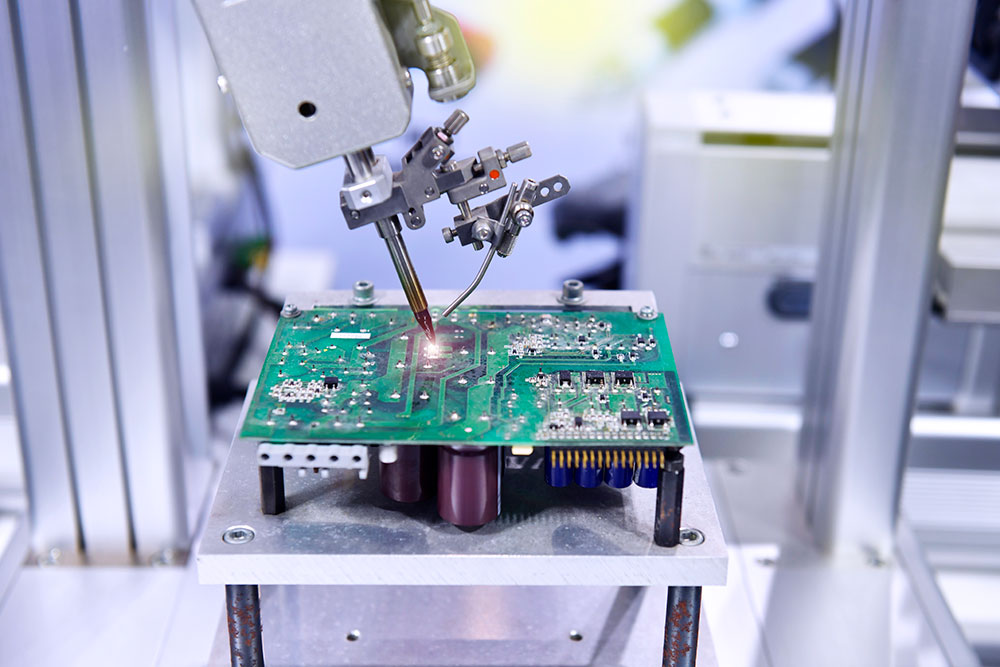

This assembly process demands ultra-high-precision placement equipment (such as for miniature BGA or CSP chips), precise soldering techniques (e.g., laser soldering or specialized reflow processes), and rigorous inspection methods to ensure reliable electrical connections and functionality of all components and microvia interconnections in such miniaturized spaces.

Why Choose HDI PCB Assembly?

Benefits of HDI PCB Assembly:

- Maximizing Space Utilization Efficiency: HDI technology employs microvias, blind vias, and buried vias to drastically reduce wiring area, enabling complex circuit layouts within limited space. This supports compact structural designs for volume-sensitive products like smartphones and wearables.

- Enhancing Electrical Performance and Signal Integrity: Shortened signal transmission paths minimize impedance and signal attenuation while reducing electromagnetic interference (EMI). This ensures stable data transmission quality in high-frequency applications such as 5G communication devices.

- Increasing Design Flexibility and Integration: Supports high-density arrangement of components on double-layer or multi-layer boards, allowing seamless integration of complex functional modules (e.g., processors, sensors). Any-Layer Interconnect (ELIC) schemes break traditional PCB wiring constraints.

- Improving Reliability and Durability: Microvia technology reduces mechanical stress concentration points, enhances thermal cycling performance, and extends product lifespan. Stringent lamination and copper plating standards lower connection failure risks, meeting high-reliability demands in automotive electronics and medical devices.

- Accelerating Product Development Cycles: HDI design facilitates rapid prototype verification, streamlines debugging processes, and shortens the transition from design to mass production. Strong compatibility with simulation tools optimizes pre-development schemes and reduces trial-and-error costs.

- Reducing Long-Term Comprehensive Costs: Although initial costs are higher, HDI reduces material layers, optimizes assembly processes, and lowers material and labor inputs. Higher yield rates and product reliability minimize post-sales maintenance expenses, boosting overall economic efficiency.

- Driving Technological Iteration and Innovation: Serves as a carrier for advanced packaging technologies (e.g., wafer-level packaging), supporting R&D in cutting-edge fields like AI chips and IoT devices. Compatible with new materials (e.g., high-frequency substrates) to adapt to future electronic technology evolution.

- Environmental and Sustainability Benefits: Precise material usage minimizes waste and complies with environmental standards like RoHS. Energy-efficient designs reduce power consumption in end products, aligning with green manufacturing trends.

When to Use HDI PCB Board Assembly?

Applications of HDI PCB Board Assembly:

- Smartphone motherboards

- Wearable devices (smartwatches, wireless earphones)

- Automotive ADAS controllers

- In-vehicle entertainment systems and dashboards

- Portable medical devices (ultrasound diagnostic instruments, blood glucose monitors)

- Implantable medical devices (pacemakers, nerve stimulators)

- Satellite communication modules

- Military radar and navigation systems

- Server and data center motherboards

- Edge computing devices

- Industrial PLCs

- Smart home controllers

HDI PCB Assembly Manufacturing Processes

1. Incoming Quality Control (IQC)

- Visual Inspection: Use high-magnification microscopes or automated optical inspection systems to detect defects on HDI PCB bare boards (e.g., scratches, copper peeling, solder mask delamination) and electronic components (e.g., oxidized/bent leads).

- Specification Verification: Utilize XRF spectrometers to validate PCB substrate specifications (copper thickness, layer count, dielectric constant); employ calipers/micrometers to measure component dimensional accuracy.

- Soldability Testing: Conduct wetting balance tests to evaluate solder paste adhesion to pads/component leads; perform thermal shock tests for surface finishes like OSP/ENIG.

- Standards Compliance: Cross-reference IPC-A-610 for pad design/solder mask tolerances; JEDEC standards for chip package dimensions; ASTM D2794 for adhesion testing.

- Batch Traceability: Implement barcode/QR code systems to track material batches, suppliers, and storage dates for full lifecycle traceability.

2. Solder Paste Printing

- Stencil Design: For fine-pitch components (e.g., 01005), use electroformed nickel stencils with ±5μm aperture accuracy; implement stepped stencils for BGA/CSP areas to control solder volume.

- Machine Parameters: Set squeegee pressure (2-5N/cm?), print speed (50-150mm/s), and snap-off speed (0.1-0.3mm/s); employ SPI (Solder Paste Inspection) for real-time 3D measurement of print thickness (0.08-0.15mm) and alignment (±15μm).

- Quality Control: Utilize 3D SPI for defect detection (bridging, insufficient solder, misalignment); perform localized magnified inspection for microvia regions; document parameters in a process database.

3. Surface Mount Technology (SMT) Placement

- Equipment Precision: High-precision pick-and-place machines achieve ±15μm accuracy for 01005 (0.4mm×0.2mm) components; vision systems enable precise BGA/CSP alignment.

- Process Optimization: Conduct DOE (Design of Experiments) to determine optimal placement pressure/nozzle height; implement segmented placement strategies (large components first, then small ones).

- Special Handling: Use vacuum nozzles/non-contact grippers for QFN/LGA devices; configure dedicated placement heads for temperature-sensitive components with controlled speed.

4. Reflow Soldering

- Temperature Profile Control: Utilize 10-zone reflow ovens with zones for preheat (150-180°C), soak (180-200°C), peak (217-227°C for lead-free alloys), and cooling (3-5°C/s); monitor via thermocouples.

- Material-Specific Adjustments: Raise peak temperatures to 245-255°C for SAC305 solder; implement nitrogen inerting for high-speed/high-frequency substrates (e.g., Rogers 4350B).

- Defect Prevention: Perform thermal simulation to predict stress distribution; conduct board-level reliability testing (-55°C~125°C thermal cycling) for BGA packages; monitor oven uniformity via infrared thermography.

5. Automated Optical Inspection (AOI)

- Detection Algorithms: Deploy deep learning for 01005 component defects (misalignment, tombstoning); multi-angle lighting for bridging/insufficient solder detection; tilted-view imaging for QFN bottom terminations.

- Defect Classification: Build AI-powered defect libraries for automatic categorization (wrong parts, missing components, polarity reversal); implement false-positive filtering.

- Data Traceability: Generate inspection reports with images/defect locations; integrate with MES for real-time production data synchronization.

6. Through-Hole Technology (THT) Insertion

- Insertion Strategy: Use selective insertion machines for high-density areas; equip manual stations with ESD workbenches/magnifiers.

- Process Control: Monitor insertion depth via force sensors; pre-form THT leads (e.g., 90° bending) to suit HDI density constraints.

- Soldering Protection: Shield SMD areas with fixtures; apply localized cooling for temperature-sensitive components; optimize wave solder parameters (time/temperature) to minimize thermal impact.

7. Wave & Selective Soldering

- Wave Parameters: Set wave temperature (250-260°C), height (8-12mm), and conveyor speed (1.0-1.5m/min); employ nitrogen inerting to reduce oxidation.

- Selective Soldering: Use robotic solder nozzles for point-to-point welding; laser alignment ensures precision; dual-nozzle systems for high-power device leads.

- Defect Detection: Perform X-ray inspection for hidden joints; conduct pull testing for mechanical strength; use dye penetrant tests for micro-cracks.

8. Hand Soldering & Rework

- Tool Configuration: Equip 200-300W soldering stations with microscopes/vacuum desoldering tools; use lead-free solder (Sn96.5Ag3Cu0.5) with temperature control.

- Operational Standards: Standardize rework procedures (heat first, then add solder); employ BGA rework stations for precision temperature control; apply localized cooling for sensitive parts.

- Quality Validation: Microscopic inspection for wetting quality; electrical testing for functional recovery; document rework processes for traceability.

9. Cleaning & Coating

- Cleaning Process: Ultrasonic cleaning with aqueous detergents for flux removal; solvent cleaning (e.g., n-hexane) for high-reliability applications with exhaust treatment.

- Coating Techniques: Automated conformal coating with acrylic/silicone/polyurethane; measure film thickness (25-75μm) via thickness gauges; localized reinforcement for critical areas.

- Potting Process: Encapsulate with two-part epoxy resins; vacuum degassing for bubble removal; thermal curing with insulation resistance testing.

10. Testing & Burn-In

- Electrical Testing: ICT uses bed-of-nails fixtures for component-level testing; flying probe testers contact high-density points without dedicated fixtures; boundary scan (JTAG) for chip-level tests.

- Functional Verification: FCT simulates operational conditions (power fluctuations, signal interference) for system validation; eye diagram tests for high-speed digital circuits; S-parameter measurements for RF circuits.

- Reliability Testing: Conduct 85°C/85%RH tests, -55°C~125°C thermal cycling, and vibration testing (sine/random); perform shear testing for critical solder joints.

11. Packaging & Logistics

- Packaging Standards: Multi-layer packaging with ESD shielding bags, foam, and desiccants; vacuum packaging for precision components; reinforced crates for large PCBAs.

- Logistics Tracking: Implement barcode/RFID systems for product traceability; monitor temperature/humidity during transit; secure high-value shipments with insurance.

- Documentation: Provide complete process files (BOMs, parameter sheets), test reports, and reliability data; integrate with EDMS (Electronic Document Management System).

Why Choose EBest Circuit (Best Technology) as HDI PCB Assembly Manufacturer?

Reasons why choose us as HDI PCB assembly manufacturer:

- 19 Years of Dedicated HDI Expertise: With 19 years of focused experience in HDI PCB assembly, we cover full-spectrum HDI technologies from 2-stage to 8-stage any-layer solutions. Having completed over 5,000 high-complexity projects, we deliver proven process expertise and problem-solving capabilities as your reliable long-term technical partner.

- ISO-Certified Quality Control System: Adhering to IPC-A-610E/620A standards and our proprietary “dual-inspection, triple-review” process, we implement 360° full-chain traceability from component incoming to final shipment. Defect rates are controlled below 50PPM, with products certified to ISO9001/14001 and RoHS standards, ensuring zero-defect precision for every board.

- Competitive Price: Through scaled production, lean supply chain management, and process optimization, we offer prices 15%-20% below market averages while maintaining cost advantages for premium materials (e.g., high-frequency substrates) and specialized processes (e.g., blind/buried vias, microvia filling), maximizing your cost-performance value.

- One-Stop Solutions: From PCB design optimization and BOM sourcing to SMT assembly, testing, and logistics, we provide end-to-end integrated services that reduce supplier coordination efforts, shorten project timelines by over 30%, and deliver true turnkey convenience.

- Fast Delivery for Market Leadership: Leveraging intelligent production scheduling and flexible capacity allocation, standard HDI projects achieve 7-day prototyping and 15-day volume production. Urgent orders are supported with 48-hour expedited responses, enabling faster market entry and competitive advantage.

- Precision Equipment for Micron-Level Accuracy: Equipped with imported systems like JUKI high-speed placement machines, combined with AOI and X-ray inspection, we achieve ±0.05mm microvia processing accuracy and 01005 component placement capability to meet the most demanding design specifications.

- Custom R&D Support for Technical Challenges: Our 30+ senior engineers provide full-chain technical support, including DFM analysis, signal integrity simulation, and development of specialized processes (e.g., rigid-flex boards, embedded components), helping you overcome technical barriers and drive innovation.

- Sustainable Manufacturing for Global Compliance: We employ lead-free processes, water-based cleaning agents, and recyclable packaging while complying with EU REACH, halogen-free, and other environmental regulations. Carbon footprint tracking optimizes energy use, ensuring seamless compliance with global green standards.

Our Quality Inspection for HDI PCB Assembly

Raw Material Inspection

- Substrate Testing: Utilize TMA thermomechanical analyzer and dielectric constant tester to validate dielectric constant (Dk deviation ≤ ±0.05, frequency range 1MHz-10GHz), CTE (Coefficient of Thermal Expansion ≤12ppm/℃, -50℃ to 250℃), and water absorption rate (≤0.1%).

- Copper Foil Inspection: Employ universal material testing machine to ensure thickness deviation ≤ ±5% (precision 0.1μm), tensile strength ≥250MPa (electrodeposited copper) / ≥300MPa (rolled copper), and peel strength ≥0.7kgf/cm.

- Solder Mask Material Inspection: Apply insulation resistance tester and solderability testing device to confirm insulation resistance ≥10¹²Ω (500V DC), solderability (no blistering/delamination after 10-second dip in 260℃ solder), and chemical resistance (no appearance change after 24-hour immersion in alcohol/acetone).

Process Inspection

- Laser Drilling Inspection: Use X-ray fluorescence thickness gauge and optical microscope to verify hole diameter tolerance ≤ ±3% (hole size ≤0.15mm), copper wall thickness deviation ≤1μm, and ensure hole position tangent to target pad without pad damage.

- Plating Layer Inspection: Validate copper/nickel/gold layer thickness compliance with design specifications (precision 0.01μm) and fixed plating current density at 1.5A/dm² (verified via DOE) using film thickness tester.

- Laminate Quality Inspection: Employ metallographic microscope and thermal stress tester to confirm layered dielectric thickness ≥40μm after lamination (minimum thickness ≥30μm) and absence of bubbles/delamination.

Inline Detection

- AOI Optical Inspection: Deploy high-precision AOI equipment to detect line width deviation ≤ ±10% (pixel accuracy 0.001mm), identify defects like shorts/opens/metal residues, maintain false call rate ≤0.1%, and achieve detection speed ≥1m/min.

- X-ray Inspection: Utilize X-ray detection system to check blind/buried via alignment accuracy ≤0.005mm, detect copper voids/layer misalignment, and enable full-board non-destructive testing.

- Electrical Testing: Use flying probe tester and hipot tester to verify circuit continuity, insulation resistance ≥10MΩ (40V), and withstand voltage ≥1000VDC without breakdown.

Final Product Reliability Inspection

- Environmental Adaptability Testing: Conduct temperature cycling (-40℃ to 125℃, 1000 cycles, resistance change ≤10%), damp heat aging (85℃/85% RH, 1000 hours, insulation resistance ≥10¹⁰Ω), and vibration testing (10-2000Hz, 20g acceleration, no structural damage) via environmental chambers and shakers.

- Solder Joint Reliability Testing: Perform thermal shock (-55℃ to 125℃, 1000 cycles, solder joint failure probability ≤1%) and dynamic bending (flexible PCB, bending radius 5mm, 10000 cycles no fracture) using thermal shock chambers and bending testers.

- Signal Integrity Testing: Measure signal loss, delay, and noise using high-speed oscilloscopes and network analyzers to ensure transmission stability meets design requirements.

Our HDI PCB Assembly Capabilities

| Item | Capabilities |

| Placer Speed | 13,200,000 chips/day |

| Bare Board Size | 0.2 x 0.2 inches – 20 x 20 inches/ 22*47.5 inches |

| Minimum SMD Component | 01005 |

| Minimum BGA Pitch | 0.25mm |

| Maximum Components | 50*150mm |

| Assembly Type | SMT, THT, Mixed assembly |

| Component Package | Reels, Cut Tape, Tube, Tray, Loose Parts |

| Lead Time | 1 – 5 days |

How to Get a Quote For HDI PCB Assembly Service?

All Documents for HDI PCB Assembly Service Quotation:

- Gerber Design Files: Complete circuit layer designs (including copper layers, solder mask, silkscreen, etc.) to ensure precise circuit replication.

- Bill of Materials (BOM): Detailed list of components with model numbers, specifications, quantities, and supplier information for material procurement and cost calculation.

- Drill Files: Clear specifications of hole positions, diameters, and types (e.g., blind/buried vias) to meet HDI high-density routing requirements.

- Assembly Drawing/Coordinate Files: Precise coordinates of components on the PCB to guide SMT placement and soldering, avoiding misalignment.

- Process Parameters: Surface finish (e.g., ENIG, HASL), solder mask color, substrate material (FR4/high-frequency), board thickness, layer count, and special processes (e.g., blind/buried vias, microvia filling).

- Test Verification Files: Test point diagrams and functional test plans to validate circuit performance.

- Quantity & Lead Time Requirements: Production batch size (prototype/small batch/mass production), delivery time, and urgency level affecting production scheduling and costs.

- Contact & Contract Information: Company name, contact person, contact details, and agreement clauses for communication and legal compliance.

Welcome to contact us if you have any request for HDI PCB assembly: sales@bestpcbs.com.