What is a HDI multilayer PCB? Let’s discover its stackup, applications, technical parameter, design guide and manufacturing process through this blog.

Are you troubled with these problems?

- Struggling with sub-0.1mm microvia fabrication in traditional PCB processes?

- Facing high costs from signal loss in high-speed products?

- Delayed by slow 8+ layer HDI prototyping impacting launches?

As a HDI multilayer PCB manufacturer, EBest Circuit (Best Technology) can provide you service and solutions:

- Microvia Precision: 0.05mm laser-drilled vias with plasma treatment for compact designs.

- Signal Stability: End-to-end SI/PI support for 10Gbps+ stable transmission.

- Rapid Prototyping: 7-day standard lead time for 8-layer HDI, 5 days for urgent orders.

Welcome to contact us if you have any request for HDI multilayer PCB: sales@bestpcbs.com.

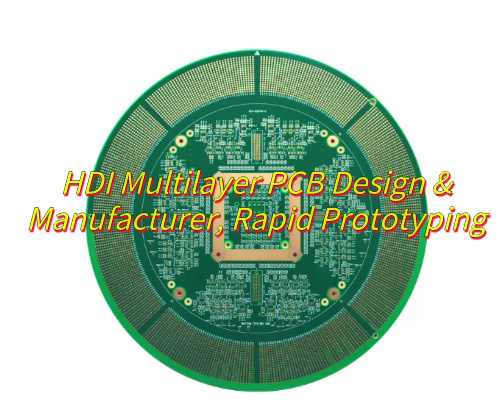

What Is a HDI Multilayer PCB?

HDI Multilayer PCB (High-Density Interconnect Multilayer Printed Circuit Board) is an advanced circuit board that employs precision microvias (aperture ≤0.15mm), blind/buried via technology, and ultra-fine lines (line width/spacing ≤3mil). Through laser drilling and layer-by-layer stacking processes, it achieves high-density routing across 8 or more layers within compact spaces. This design enhances signal transmission speed, reduces interference, and is specifically engineered for miniaturized, high-performance applications such as 5G devices and wearable electronics.

8 Layers HDI PCB Stackup

| Layer | Layer Type | Main Function | Connection Method |

| L1 | Signal Layer | High-frequency signal transmission / Critical component routing | Surface Blind Via (Connecting to L2) |

| L2 | Power/Ground Plane | Power distribution / Ground network | Buried Via (Connecting to L3-L6), Blind Via (Connecting to L1/L3) |

| L3 | Signal Layer | Inner-layer high-speed signal routing | Buried Via (Connecting to L2/L4) |

| L4 | Signal Layer | Inner-layer control signal routing | Buried Via (Connecting to L3/L5) |

| L5 | Signal Layer | Inner-layer low-speed signal routing | Buried Via (Connecting to L4/L6) |

| L6 | Power/Ground Plane | Power distribution / Ground network | Buried Via (Connecting to L5/L7), Blind Via (Connecting to L7) |

| L7 | Signal Layer | Inner-layer auxiliary signal routing | Blind Via (Connecting to L6/L8) |

| L8 | Signal Layer | High-frequency signal transmission / Critical component routing | Surface Blind Via (Connecting to L7) |

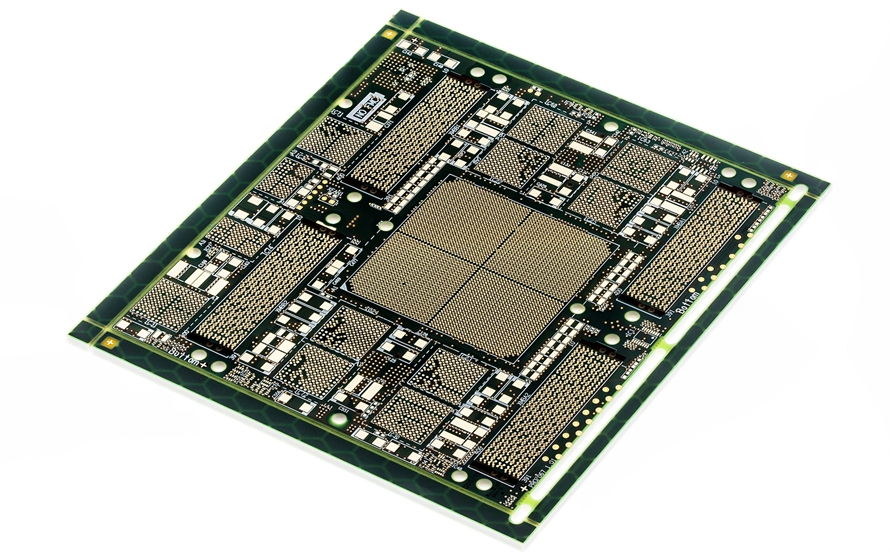

What Are Applications of HDI Multilayer PCB?

Applications of HDI multilayer PCB:

- Smartphones & Mobile Devices: Mobile phone motherboard, Camera module, Sensor module, Antenna system, Automotive Electronics.

- Engine Control Unit (ECU): In-vehicle navigation system, Airbag control module, Advanced Driver Assistance System (ADAS), In-vehicle entertainment system.

- Medical Equipment: MRI imaging equipment, Cardiac pacemaker, Implantable medical devices, Precision diagnostic instruments, Communication Equipment.

- 5G base station: Router/switch, Fiber optic communication module, Satellite communication equipment.

- Industrial Control: Industrial robot control board, PLC control system, Automated sensor network.

- Servers & Data Centers: High-performance server motherboard, Cloud computing hardware, Data storage devices.

HDI Multilayer Circuit Board Technical Parameter

| Parameters | Specifications |

| Layer Range | 8-24 Layers |

| Minimum Line Width/Spacing | 40/40μm |

| Laser Drill Hole Diameter | 0.1mm |

| Mechanical Drill Hole Diameter | 0.15mm |

| Blind/Buried Via Diameter | 75-150μm |

| Aspect Ratio | <0.8:1 |

| Blind Via Stack Spacing | ≥0.3mm |

| Substrate Type | Rogers/Panasonic MEGTRON/FR-4 |

| Surface Treatment | ENIG/Immersive Silver/OSP |

| Tolerance Range | ±7% |

| Pressing Method | Vacuum Lamination |

| Dielectric Thickness Uniformity | ≤±10% |

| Plating Process – Copper Thickness Uniformity | ≤±5μm |

| Thermal Resistance | -55°C to +125°C |

| Thermal Shock Test Cycles | ≥1000 Cycles |

| Routing Density | >20 pads/cm² |

| Insulation Resistance | ≥10MΩ |

| Reliability Testing | ≥500MΩ |

How to Design a Multilayer HDI PCB?

Below is Multilayer HDI PCB design guide:

1. Modular Schematic Design with Precision

- Divide schematics into functional modules (power, signal processing, interfaces) using hierarchical design.

- Annotate exact component parameters (e.g., 0.4mm pitch BGA CPU) and solder pad dimensions to ensure logical correctness and manufacturability.

2. Advanced Stack-up Structure Planning

- Implement “signal-power-ground” alternating stack-up (e.g., 3-layer signal/3-layer power/3-layer ground).

- Place high-speed signals on outer layers (trace width/space ≤4mil) with microvias (60-150μm laser-drilled) for layer-to-layer connections.

- Use buried vias for interlayer routing (e.g., 1-2 layer blind via + 3-4 layer buried via) and select materials like Rogers 5880 (Dk=2.2) for high-frequency scenarios or FR4-Tg180 for thermal stability.

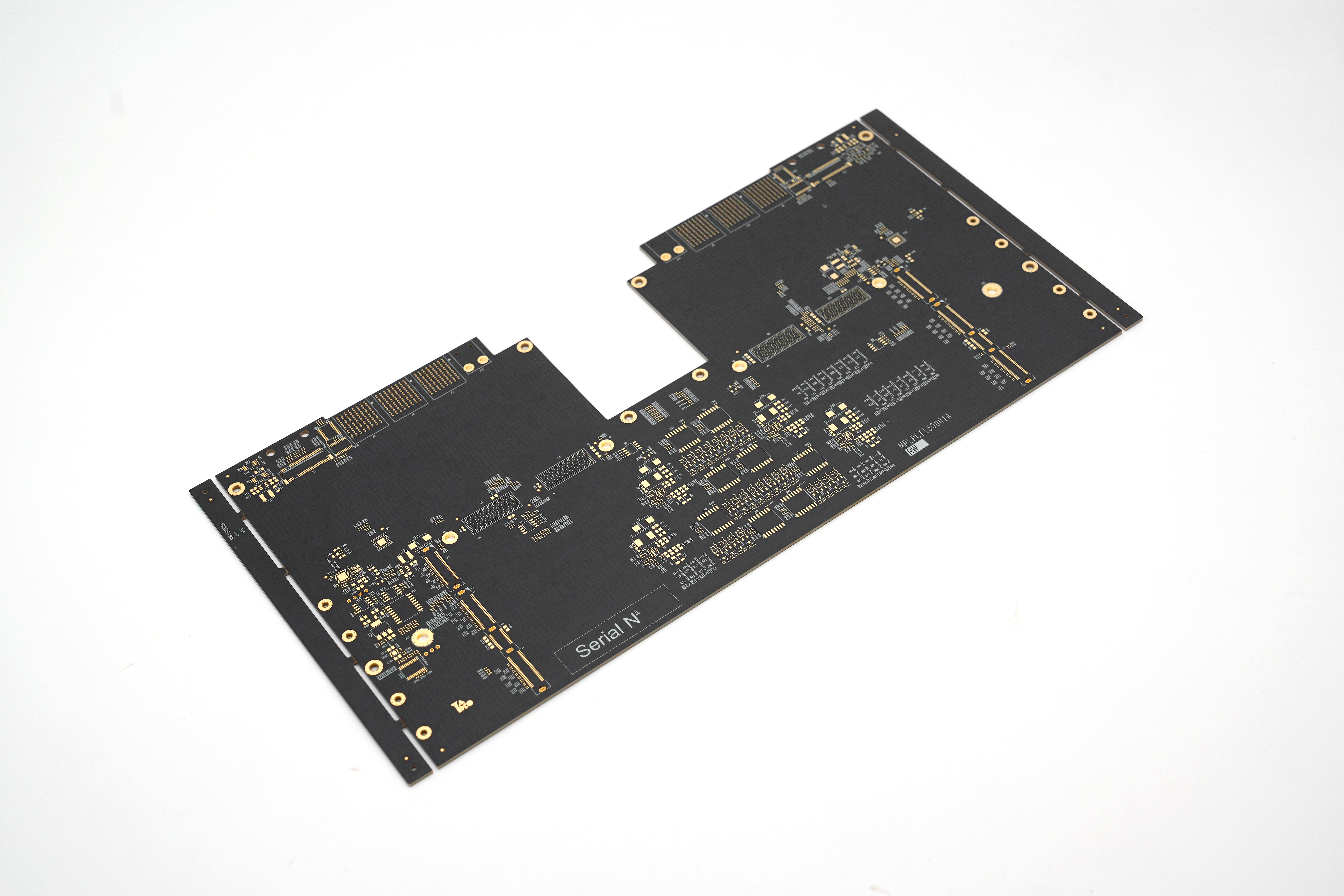

3. Intelligent Component Placement with Thermal Optimization

- Center critical components (e.g., BGA-packaged CPU/FPGA) and position heat-generating devices near thermal via arrays.

- Use “escape routing” from BGA centers to minimize trace length. Implement grid-pattern thermal vias (≥150 vias/inch², 0.3mm diameter, 1.0mm spacing) and thermal interface materials (TIMs) with ≥5W/m·K conductivity for efficient heat dissipation.

4. High-Speed Signal Routing with Strict Rules

- Enforce differential pair length matching (≤2mil difference) using serpentine routing for via delay compensation (bend radius ≥3× trace width).

- Avoid crossing power splits to reduce crosstalk. Use stacked microvia structures (e.g., VIA1-2 + VIA2-3) for higher routing density and impedance continuity at connectors via “cross-connection + ground shield” (3× trace width spacing) with GND via pairs ≤3mm apart.

5. Optimized Power/Ground Plane Design

- Segment multi-layer planes with decoupling capacitor networks (0201 package 10nF+100nF parallel) to achieve PDN impedance ≤1Ω.

- Maintain continuous ground planes for low-impedance return paths (≤0.5mΩ) and use grid-pattern power planes to minimize eddy current losses.

6. Detailed Impedance & Signal Integrity Control

- Calculate trace width/spacing for target impedances (e.g., 6mil/7mil for 50Ω single-ended lines). At connector pads, implement “cross-connection + ground shield” with 3× trace width spacing.

- Add GND via pairs (≤3mm spacing) for transmission delay compensation and ensure via aspect ratios <0.8 to prevent stress fractures.

7. EMC & Reliability Enhancement with Fine Details

- Deploy 3-stage EMI filtering (source common-mode choke + board-level filter + cable ferrite) and 360° beryllium copper grounding springs at connectors (contact resistance <0.5mΩ).

- Apply ENIG/ENEPIG surface finish (≥3μm thickness) to prevent oxidation and use X-ray inspection for solder joint voids <10%.

8. Comprehensive Design Rule Verification

- Execute DRC checks (line width/space, via dimensions, impedance compliance) per IPC-6012 Class 3 standards.

- Collaborate with PCB manufacturers( like EBest Circuit (Best Technology)) for DFM analysis: confirm minimum trace/space 3mil, laser drilling accuracy ±10μm, and process margins (etching tolerance ±0.5mil).

9. Standardized Manufacturing File Generation

- Output Gerber (RS-274X), drill (Excellon), solder mask, and BOM files with precise version control. Include assembly-specific annotations (e.g., polarity marks, fiducial placement) to streamline manufacturing.

10. Prototype Testing & Iterative Optimization

- Conduct electrical tests (flying probe for impedance continuity), thermal tests (infrared thermography for hotspot mapping), and mechanical tests (vibration/shock for reliability).

- Refine designs based on test results (e.g., topology adjustments, additional decoupling capacitors) and prepare for mass production with cost-optimized processes (resin-plugged vias) and quality control measures (AOI/X-ray inspection).

How Are Multilayer HDI PCBs Made?

Manufacturing processes for multilayer HDI PCBs:

1. Inner Layer Substrate Cutting & Pretreatment: Cut high-speed substrates (e.g., FR4, Rogers RO4350B) to design dimensions. Perform chemical cleaning to remove surface oxidation and contaminants, enhancing adhesion between copper layers and prepreg.

2. Inner Layer Pattern Transfer & Etching: Apply dry film, transfer circuit patterns via UV exposure and development. Etch unprotected copper using alkaline solution, followed by AOI (Automated Optical Inspection) to verify circuit integrity.

3. Brown Oxidation & Stack Alignment: Treat inner copper surfaces with brown oxidation to create nano-scale roughness. Stack inner layers, prepreg sheets, and copper foils in sequence, secured with rivets to prevent layer misalignment.

4. Vacuum Hot Pressing: Execute three-stage pressing (heating → main pressure → cooling). Gradually raise temperature at 2-3℃/min to Tg point under 20-35kg/cm² pressure, ensuring resin fills voids without cavities.

5. Laser Microvia Drilling: Use UV/CO₂ lasers to drill blind/buried vias with diameter ≤0.15mm and depth tolerance ±0.05mm. Clean hole walls via plasma desmear to remove drilling debris.

6. Via Plating & Filling: Deposit copper electrolessly on via walls, then electroplate to 8-12μm thickness. Implement via-filling plating (e.g., copper paste) to eliminate voids in blind/buried vias, ensuring reliable electrical conduction.

7. Outer Layer Patterning & Etching: Repeat inner layer processes, apply dry film, expose, develop, and etch to form high-precision lines (width/spacing ≤3mil). Strip tin to retain circuit traces and via walls.

8. Solder Mask Printing & Curing: Print UV-curable solder mask ink to protect non-soldering areas. Expose and develop to reveal pads and test points, ensuring soldering reliability.

9. Surface Finish Selection: Apply ENIG (electroless nickel immersion gold), OSP (organic solderability preservative), or ENEPIG (electroless nickel electroless palladium immersion gold) based on application requirements, enhancing corrosion resistance and high-frequency signal integrity.

10. Reliability Testing: Conduct thermal shock (-55℃~125℃ cycles), humidity resistance (85℃/85%RH), vibration (≥5G random), and electrical tests (flying probe/4-wire Kelvin testing) to meet IPC-6012 standards and client specifications.

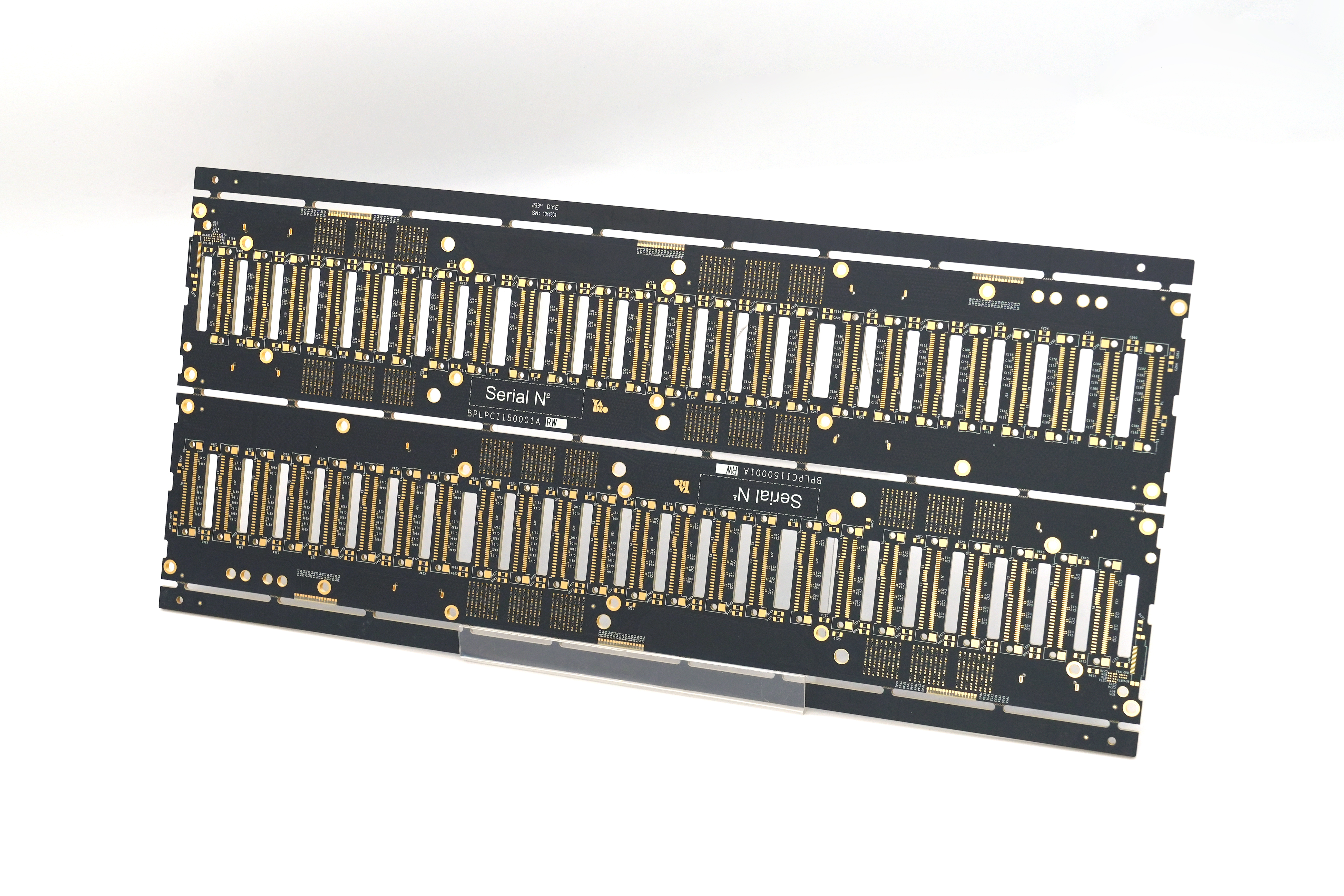

11. CNC Profiling & V-Scoring: Shape boards via CNC routing, implement V-groove scoring for easy separation, ensuring edge dimensional accuracy ≤±0.1mm without burrs or delamination.

12. Final Inspection & Packaging: Perform FQC (Final Quality Control) to check for defects, dimensional tolerances, and electrical performance. Vacuum-pack products to prevent moisture/oxidation during transport and storage.

Why Choose EBest Circuit (Best Technology) as HDI Multilayer PCB Manufacturer?

Reasons why choose us as HDI multilayer PCB manufacturer:

- Cost-Sensitive Design Solutions: Offer tiered pricing systems and material substitution options, optimizing trace width/spacing and substrate selection (e.g., FR-4/high-frequency material ratios) to reduce per-board costs by 10%-15% while ensuring performance, ideal for price-sensitive products like consumer electronics and IoT devices.

- 24-Hour Rapid Prototyping: Establish dedicated green channels for end-to-end tracking from design file receipt to sample delivery, supporting real-time online progress queries. For urgent needs like prototype validation or exhibition samples, achieve “same-day order placement, next-day shipment” to shorten iteration cycles to 1/3 of traditional timelines.

- 99.2% On-Time Delivery Rate: Leverage intelligent production scheduling systems and localized supply chain layouts, combined with dynamic inventory alerts, to ensure 10-15 day delivery for regular orders and 5-7 day delivery for urgent orders. Historical data confirms over 99.2% of orders meet agreed timelines, supporting clients’ production plans and market windows.

- Full-Batch Quality Inspection: Employ dual AOI+X-ray inspection systems to verify 20+ critical parameters including trace width/spacing, hole precision, and impedance matching, alongside electrical testing and thermal shock trials. All batches meet IPC-6012 standards with defect rates below 0.08%.

- International Authoritative Certification System: Hold ISO 9001, IATF 16949 (automotive), ISO 13485 (medical), and RoHS certifications, enabling global market compliance and reducing re-certification costs for clients targeting EU, North America, and Japan.

- 19 Years of HDI Technical Expertise: Accumulate over 5,000 HDI process case databases across 19 years, covering mobile, server, and medical sectors. The production error database proactively mitigates 90%+ potential issues, minimizing client trial costs.

- Free DFM Design Optimization: Provide end-to-end manufacturability analysis from schematics to Gerber files, including package compatibility checks, routing topology refinement, and impedance matching suggestions, to identify design flaws early, shorten manufacturing cycles, and lower redesign expenses.

- Multi-Tier Material Supply Chain: Strategic partnerships with suppliers like Rogers, Panasonic, and Shengyi ensure stable supply of high-frequency/high-speed materials and eco-friendly substrates, while centralized procurement reduces material costs for clients.

Our HDI PCB Capabilities

| Parameter | Capabilites |

| PCB Layers: | 1-32L |

| Copper Thickness: | Outer Layer:1oz~30oz; Inner Layer:0.5oz~30oz |

| Min Line Width/Line Space: | Normal: 4/4mil; HDI: 3/3mil |

| Min Hole Diameter: | Normal: 8mil; HDI: 4mil |

| PTH/NPTH Dia Tolerance: | PTH: ± 3mil; NPTH: ±2 mil |

| Surface Treatment: | ENIG(Au 4u’’),ENEPIG (Au 5u’’) Gold finger/Hard Gold Plating(Au 50u’’), HASL /LF HASL, OSP, Immersion Tin, Immersion Silver |

How to Get a Quote for HDI Multilayer PCB Project?

All files needs to be submitted to get a quote for HDI multilayer PCB:

- Gerber Files: Include circuit design data for all layers (e.g., signal layers, power layers, silkscreen layers), with annotations for stack-up sequence, impedance-controlled traces, blind/buried via positions, and special process requirements (e.g., via-in-pad, resin plugging).

- BOM (Bill of Materials): Detail component models, package dimensions (e.g., 0201/0402/QFN), supplier information, tolerance grades (e.g., ±1% resistors), and material codes, ensuring alignment with component positions in Gerber files.

- Technical Specifications: Specify layer count range (e.g., 8-24 layers), trace width/spacing (e.g., 40/40μm), hole diameter precision (e.g., 0.1mm laser drilling), surface finish (e.g., ENIG/immersion silver), impedance control (e.g., 50±7Ω differential pairs), and substrate selection (e.g., FR-4/Rogers RO4350B).

- Special Process Requirements: Indicate needs for via-in-pad, back-drilling, stacked blind/buried vias, high-frequency material applications, thermal management solutions (e.g., thermal via arrays), or EMC protection measures (e.g., three-stage filtering).

- Quantity & Lead Time Requirements: Provide batch order quantities (e.g., 500 pieces/batch), urgent order needs (e.g., 24-hour prototyping), standard lead time expectations (e.g., 10-15 days), and packaging specifications (e.g., vacuum packaging + anti-static bags).

- Quality Certification & Testing Needs: List applicable international standards (e.g., IPC-6012, ISO 9001), specific test items (e.g., flying probe impedance testing, ≥1000 thermal shock cycles), and acceptable defect rate thresholds (e.g., ≤0.08%).

- Design File Version & Revision History: Include the latest design file version number, revision history, and design change notes to ensure manufacturing accuracy and timeline.

Welcome to contact us if you have any request for HDI multilayer PCB board: sales@bestpcbs.com.