FQC stands for Final Quality Control, the last and most critical inspection stage before a product is shipped to customers. At this point, all manufacturing, assembly, and functional processes have been completed, and the item is evaluated as a finished product. The goal of FQC is simple yet essential: ensure that only defect-free, fully compliant products leave the factory.

Are you worried about the following:

- Discovering scratches or poor soldering upon receiving the goods, resulting in time-consuming and costly rework?

- Supplier inspection is sloppy, leading to inconsistent batch quality and making you hesitant to use the products?

- Hidden problems go undetected, only to malfunction after installation, causing increasing headaches with each repair?

Our Services + Solutions:

- Meticulous, end-to-end inspection, from wiring to appearance, leaving no blind spots, preventing problems before shipment.

- Standardized FQC (Factory Quality Control) procedures, with each batch tested according to uniform standards, ensuring consistent quality.

- A professional inspection team and precise testing equipment quickly identify hidden problems, minimizing post-delivery issues.

What Is FQC Inspection?

FQC stands for Final Quality Control. It is the last quality-checking stage before finished PCBs enter packing. FQC teams inspect the completed board after all processes are done ÔÇö soldering, cleaning, testing, marking, assembly, and visual checks.

FQC inspectors confirm that the final product meets the customerÔÇÖs standards and project specifications. They verify appearance, labeling, dimensions, surface quality, hole positions, silk printing, and assembly results. They also check solder joints, component orientation, and basic electrical behavior.

What Is PCB Meaning?

PCB stands for Printed Circuit Board. It is the foundation of modern electronics. It supports components mechanically and connects them electrically through copper traces.

A PCB contains materials like:

- Rogers

- Polyimide

Different applications use different materials. FR-4 stays popular because of its stability and good cost. Ceramic suits high-power and high-temperature environments. Aluminum is common in LED lighting. Polyimide is excellent for flexible circuits.

No matter the material, the basic purpose is the same. A PCB routes signals. It holds parts in place. It keeps the device stable under heat, vibration, and power.

How to Make a Circuit Board?

The full process has a long list of steps, but the flow can be understood in a simple way.

- 1. Engineering review (CAM/DFM)

Before production begins, engineers verify the design. They check layer stack, drill charts, traces, spacing, pads, and impedance. A strong DFM review saves time and prevents issues during production.

- 2. Cutting materials

Large sheets of PCB material are cut into production-size panels.

- 3. Inner layer imaging

For multilayer boards, the inner circuits are printed, exposed, and etched. This forms the initial copper patterns.

- 4. Lamination

Layers are aligned and pressed together to form a solid block.

- 5. Drilling

CNC drills create vias, mounting holes, and component holes.

- 6. Plating

Copper is deposited inside drilled holes, creating conductive vias.

- 7. Outer layer imaging and etching

The outer copper layers follow the design and are etched into final traces.

- 8. Solder mask application

Green, blue, red, yellow, or black solder mask protects copper against oxidation.

- 9. Silkscreen printing

Symbols, markings, polarity, and instructions are printed.

- 10. Surface finish

Common finishes include ENIG, HASL, OSP, ENEPIG, immersion tin, or silver.

- 11. Electrical testing

Flying-probe or fixture tests confirm each trace has correct continuity.

- 12. Cutting and routing

Boards are separated from the production panel.

This gives you a bare PCB. But when you add components, you enter the next level ÔÇö PCB assembly. And that is where inspection steps like FQC come into play.

What Does FQC Mean in PCB Manufacturing?

In PCB manufacturing, FQC refers to the final inspection checkpoint before a product enters packaging. For assembly-level FQC, inspectors evaluate soldered components, cleanliness, polarity, labeling, and functionality.

FQC in PCB production has two directions:

- Bare board FQC: Focused on dimensions, appearance, silk, copper exposure, vias, and surface finish.

- Assembled board FQC: Focused on solder quality, assembly alignment, polarity, mechanical strength, barcode, and overall workmanship.

It validates that the board is ready for delivery. FQC protects that trust.

What Is the Purpose of FQC?

The purpose of FQC is simple but powerful:

- Confirm the product is correct

- Catch any issue before shipment

- Protect the customer experience

- Support traceability

- Build reliability

FQC is the last safeguard. They can spot small deviations that earlier steps missed. It prevents defective boards from reaching the end user.

What Is the FQC Inspection Process?

FQC uses a structured workflow.

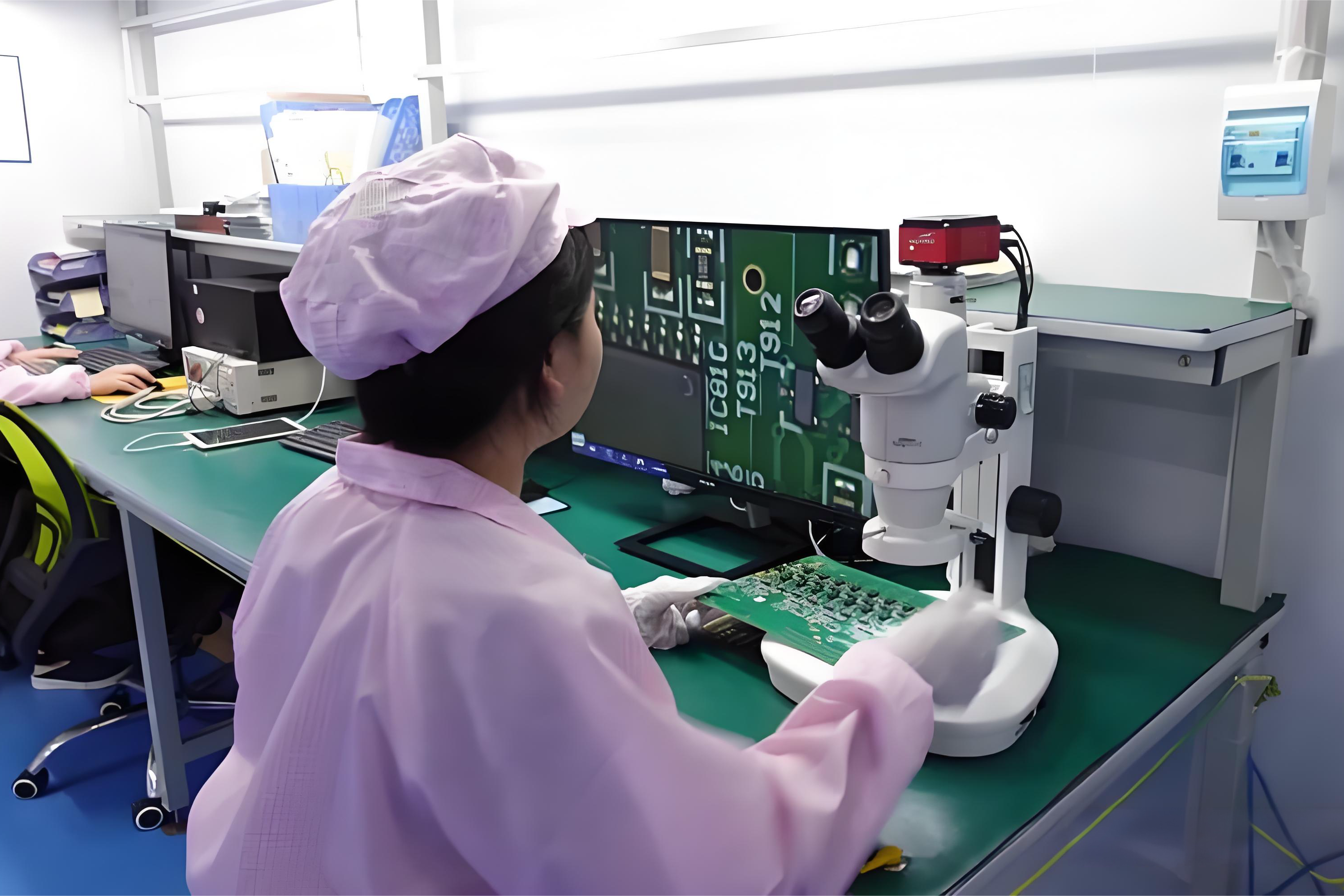

- 1. Visual check

Inspectors check the final appearance: Soldering, cleaning, silk, scratches, color, oxidation, pads, labels.

- 2. Dimensional check

They measure hole size, outline size, thickness, and slot length.

- 3. Component confirmation

They verify the component reference, position, polarity, and value.

- 4. Solder joint evaluation

FQC checks wetting, shape, alignment, bridging, and tombstoning.

- 5. Functional testing

Some boards include a simple power-on test or LED test.

- 6. Documentation

Inspectors record results to maintain traceability.

- 7. Final confirmation

Only approved boards proceed to OQC and packing.

In many cases, FQC also works with engineers to solve recurring issues.

What Is IQC and FQC?

IQC and FQC work at two ends of production.

IQC = Incoming Quality Control

Inspects raw materials such as PCB material, copper foil, solder paste, components, adhesives, and mechanical parts.

FQC = Final Quality Control

Inspects finished boards after production.

IQC keeps poor material out of the factory. FQC keeps poor products out of the customerÔÇÖs hands. Together, they create a strong quality loop.

What Is the Difference Between FQC and OQC?

Many people confuse the two because both take place at the end of production. But the roles are slightly different.

FQC (Final Quality Control)

- Checks the board right after the last process

- Focuses on workmanship, appearance, and functionality

- Aims to identify process-related issues

OQC (Outgoing Quality Control)

- Checks the board before final shipment

- Ensures correct quantity, packaging, labeling, and delivery condition

- Confirms the product is exactly what the customer ordered

FQC = product inspection

OQC = shipment inspection

They operate close together but cover different subjects.

What Is AOI in PCB Assembly?

AOI stands for Automated Optical Inspection. AOI uses high-resolution cameras and pattern-matching algorithms to inspect PCB assembly. It checks for:

- Missing components

- Wrong components

- Polarity issues

- Solder bridging

- Tombstoning

- Misalignment

- Insufficient solder

AOI works quickly and reliably. It detects small issues that the human eye may miss. When AOI catches 90% of the basic defects earlier, FQC can focus on final appearance and functional checks.

Conclusion:

FQC means Final Quality Control. It checks the PCB after all production steps. It confirms appearance, dimensions, soldering, cleanliness, polarity, labels, and basic function. It also reduces cost, prevents failures, and builds trust.

When combined with AOI, IQC, OQC, and other inspection tools, FQC creates a complete and reliable quality system. It is one of the most important steps in the entire PCB manufacturing flow. If you need professional support, feel free to contact us at sales@bestpcbs.com