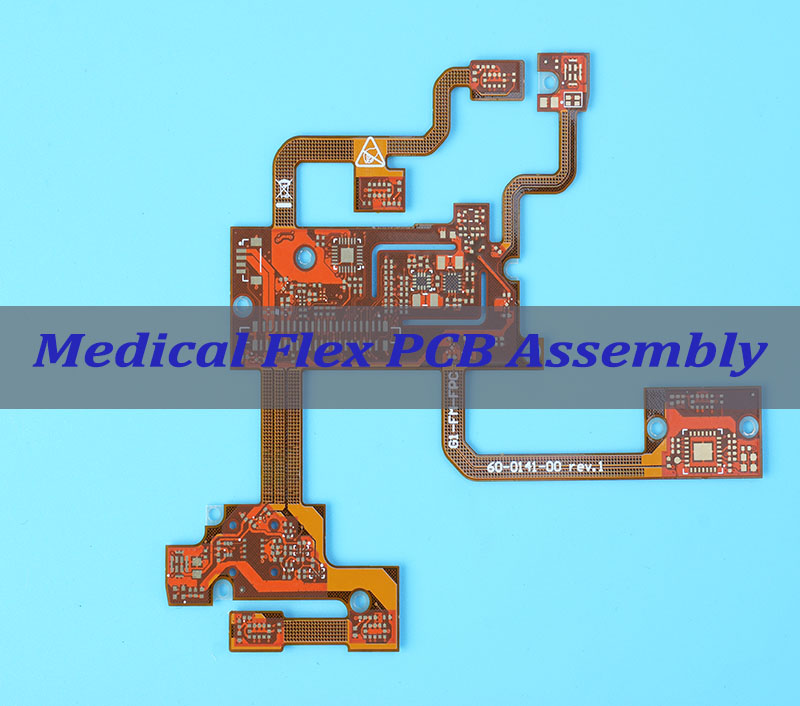

Flex PCB assembly represents a revolutionary approach to electronic circuitry that enables bending and folding to fit compact medical devices. This technology transforms how we design everything from implantable pacemakers to advanced imaging systems by replacing rigid boards and bulky wiring with flexible, reliable alternatives. This guide explores the complete landscape of medical flex PCB assembly, from fundamental concepts to specialized manufacturing considerations for life-critical applications.

Why do medical device manufacturers struggle with implementing reliable flex PCB solutions?

Key Pain Points:

- Ensuring reliability in life-critical medical applications where failure is not an option

- Achieving miniaturization for implantable and wearable devices without sacrificing performance

- Navigating complex medical regulatory requirements and certification processes

- Managing higher initial costs while maintaining uncompromised quality

- Preventing failures in dynamic flexing applications through proper design

Targeted Solutions:

- Implement rigorous testing protocols aligned with medical standards (IPC-6013, ISO 13485)

- Utilize advanced materials like polyimide and adhesiveless laminates for compact, reliable designs

- Partner with manufacturers experienced in medical certifications and documentation

- Optimize designs for manufacturability to control costs without compromising quality

- Apply design guidelines specifically for dynamic vs. static flexing applications

At BEST Technology, we specialize in addressing these challenges through nearly 2 decades of experience in medical flex PCB manufacturing. Our expertise ensures that your medical devices meet the highest reliability standards while navigating the complex landscape of medical electronics. We hold ISO 13485 certification, which governs our quality management system for medical device production. This means our processes‚ÄĒfrom design, FPC prototyping, and sourcing to manufacturing, assembly, and testing‚ÄĒare meticulously controlled to ensure the safety and reliability of medical PCBs.

And it is worth mentioning that we have implemented an MES to digitally transform our shop floor, enabling full traceability and data-driven decision-making. Pls feel free to contact our team at sales@bestpcbs.com to discuss your specific medical flex PCB or medical PCB assembly requirements.

What Is Flex PCB Assembly?

Flex PCB assembly enables modern medical electronics to achieve levels of compactness, reliability, and functionality that rigid boards alone cannot support. Flexible circuits use polyimide substrates that bend, twist, or fold without breaking electrical continuity‚ÄĒmaking them ideal for devices implanted in the human body or worn close to the skin.

Flex PCB assembly requires specialized materials, equipment, and soldering control:

- Components are mounted onto thin polyimide substrates rather than rigid FR4.

- Circuits can fold into 3D structures to maximize internal space.

- Carriers and stiffeners are used during assembly to prevent stretching and distortion.

- Reflow soldering profiles are tuned for thin, heat-sensitive materials.

- The design supports repeated flexing without cracking copper traces or weakening solder joints.

In medical applications, Flex PCB assembly enables ultra-lightweight designs for tools such as insulin pumps, pacemakers, imaging modules, hearing aids, surgical instruments, and continuous monitoring devices.

Flex PCB technology has become the backbone of miniaturized medical electronics, where every millimeter matters and long-term reliability is non-negotiable.

Table: Comparison of Flex PCB vs. Rigid PCB Characteristics

| Characteristic‚Äč | Flex PCB‚Äč | Rigid PCB‚Äč |

|---|---|---|

| Thickness‚Äč | 0.1-0.3 mm | 1.6 mm+ |

| Weight‚Äč | Lightweight | Moderate to heavy |

| Bend Capability‚Äč | 100,000+ cycles | None |

| Space Efficiency‚Äč | High | Moderate |

| Vibration Resistance‚Äč | Excellent | Poor to moderate |

| Assembly Complexity‚Äč | Integrated approach | Multi-step |

How Does the Flex PCB Manufacturing Process Influence Final Assembly Quality?

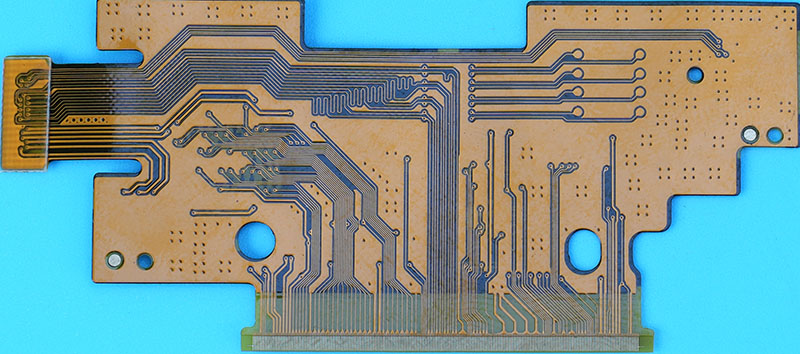

The upstream fabrication process directly determines whether the final Flex assembly will survive medical use. Quality is affected by substrate chemistry, copper type, etching precision, and final surface finishing.

Key factors during manufacturing:

- Material purity

Medical-grade polyimide must withstand heat, chemical exposure, and repeated sterilization cycles without degrading. - Copper selection

Rolled annealed (RA) copper is preferred because its grain structure resists cracking during dynamic bending better than electro-deposited (ED) copper. - Dimensional accuracy

Tight etching control produces consistent trace width and thickness‚ÄĒcritical for devices with high-frequency or low-noise requirements (ultrasound, ECG modules, imaging sensors). - Laser via formation

Precision drilling ensures microvias maintain conductivity and structural strength throughout thousands of bending cycles. - Surface finish quality

ENIG (Electroless Nickel Immersion Gold) or soft gold finishes provide stable solderability and better corrosion resistance under medical conditions.

Assembly quality is only as good as the fabrication process that precedes it. Any manufacturing defect is magnified when the device is used in a hospital, operating room, or implanted inside the human body.

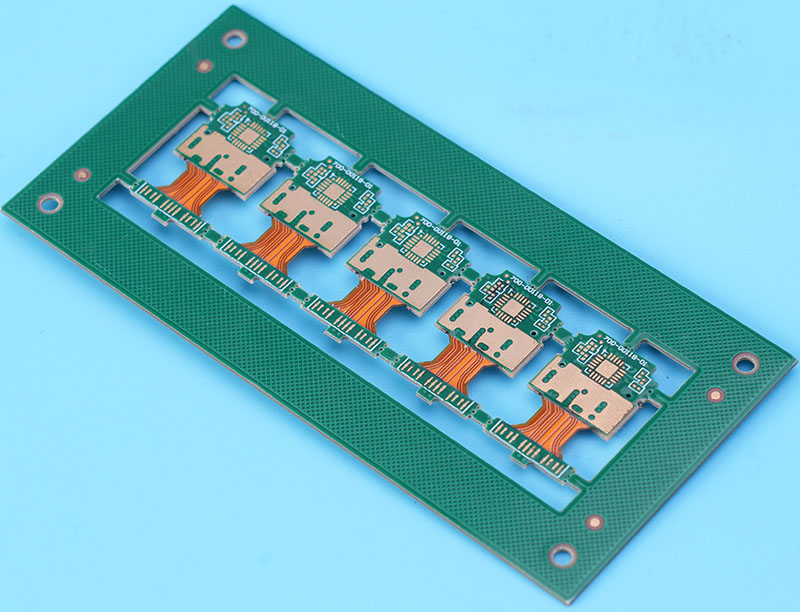

Why Do Engineers Choose Rigid Flex PCB Assembly for Medical Applications?

Rigid-flex PCBs integrate rigid sections for high-density component mounting with flexible interconnects that navigate compact medical housings. This hybrid architecture delivers exceptional electrical, mechanical, and spatial advantages.

Why engineers select rigid-flex for medical devices:

- Eliminates connectors and cables

Every connector removed equates to one less potential failure point‚ÄĒcritical for life-supporting equipment. - Superior electrical performance

Continuous copper paths ensure clean signals for medical imaging, sensing, and telemetry systems. - True 3D routing

Allows electronics to wrap around curves or fit into cylindrical or irregular implants. - High durability

Rigid-flex structures tolerate movement, vibration, and handling during surgery or patient activity. - Long service life

Especially important when devices remain implanted for years.

Medical devices such as neurostimulators, pacemakers, endoscopes, robotic surgical tools, handheld scanners, and portable ultrasound systems rely heavily on rigid-flex PCBs for their unmatched combination of stability and flexibility.

Table: Medical Applications Benefiting from Rigid-Flex PCB Assembly

| Medical Application | Rigid-Flex Benefits | Key Considerations |

|---|---|---|

| Implantable Devices (pacemakers, neurostimulators) | Ultra-compact, high reliability | Hermetic sealing, long-term stability |

| Surgical Instruments (endoscopes, robotic tools) | Dynamic flexing, tight-space routing | Bend radius control, chemical resistance |

| Diagnostic Imaging (portable ultrasound, MRI) | Clean signals, compact layout | Impedance control, EMI management |

| Wearable Monitors (ECG patches, glucose sensors) | Lightweight, comfortable, stable | Flex endurance, moisture resistance |

| Medical Analyzers (blood analysis, sequencing) | High precision, stable operation | Thermal management, signal integrity |

What Are the Key Steps in a Standard Flex PCB Assembly Process From Start to Finish?

Flex PCB assembly requires a tighter process window compared with rigid PCB assembly due to material thinness, dimensional sensitivity, and bend requirements.

A typical medical Flex PCB assembly sequence includes:

1. Pre-Bake and Moisture Removal

- Polyimide absorbs moisture; if left untreated, it causes delamination during reflow.

- Baking stabilizes the material and prevents blistering.

2. Solder Paste Application

- Custom stencils and backing carriers ensure accurate printing.

- Prevents deformation of the flexible substrate during paste deposition.

3. Component Placement

- Pick-and-place machines are calibrated for extremely thin boards.

- Carriers prevent bending under vacuum nozzles and mechanical pressure.

4. Reflow Soldering

- Uses gentle thermal ramp-up to protect the flexible substrate.

- Nitrogen atmosphere improves solder quality and reduces oxidation.

- Multiple zones allow precise temperature control.

5. Inspection

- AOI checks solder joints and placement accuracy.

- X-ray identifies BGA voids and hidden solder issues.

6. Functional & Reliability Testing

- Electrical continuity testing.

- Flex-cycle endurance tests simulate repeated bending.

- Thermal cycling validates long-term stability.

Medical-grade assemblies often undergo stricter testing than commercial devices, as patient safety depends on flawless performance.

How Can a Flex PCB Design for Assembly Guide Reduce Bending Stress and Improve Yield?

Effective design for assembly (DFA) guidelines reduce stress points, prevent cracking, and increase long-term reliability.

Key DFA principles:

1. Proper Bend Radius

- Dynamic flexing: minimum 10√ó thickness

- One-time bending: minimum 6√ó thickness

Exceeding these minima significantly extends product lifespan.

2. Bend Area Layout Rules

- Use curved traces instead of sharp corners.

- Route traces perpendicular to the bend axis.

- Avoid via holes in bend regions.

- Taper conductors to distribute stress more evenly.

3. Stiffener Placement

- FR4 or polyimide stiffeners reinforce component areas.

- Stiffeners prevent solder joint cracking during flexing.

4. Material Choice

- Adhesiveless laminates improve dynamic flex life.

- Biocompatible coatings support implantable designs.

Applying these rules early reduces rework, improves manufacturing consistency, and protects the assembly during real-world medical use.

Why Is PCB Assembly China a Preferred Choice for Flexible Circuit Production?

China is a leading global hub for Flex PCB and rigid-flex PCB assembly, especially for high-reliability applications like medical devices.

China’s key strengths:

- Advanced factory capabilities

Laser drilling, high-precision AOI, X-ray inspection, and specialized SMT for flexible substrates. - Highly integrated supply chain

Local production of polyimide sheets, adhesives, stiffeners, and high-end electronic components. - Medical-grade quality systems

Many factories operate under ISO 13485 and support FDA documentation requirements. - Rapid prototyping and mass scaling

Efficient transitions from sample to volume production. - Cost advantages without compromising quality

Scale, process maturity, and high yields keep prices competitive.

These combined advantages make China a strategic manufacturing choice for medical OEMs aiming for excellence and cost balance.

What Should You Look for When Selecting a Professional Flex PCB Assembly Manufacturer?

Your manufacturing partner directly influences device reliability, regulatory success, and long-term product stability. Choosing correctly is essential.

Criteria when evaluating a manufacturer:

- Medical certifications

ISO 13485, ISO 9001, and proven experience with medical documentation. - Technical capabilities

Multilayer Flex, rigid-flex, controlled impedance, microvia processing. - Test infrastructure

AOI, X-ray, flying probe, environmental stress screening, flex-cycle testing. - Engineering collaboration

Early DFM/DFA and stackup consultation to avoid future design risks. - Traceability and documentation

Full material lot tracking, process records, and medical-level reporting.

A qualified manufacturer acts as an engineering partner‚ÄĒnot just a supplier‚ÄĒhelping lift reliability and reduce design risk. Whether you need Rigid-Flex Circuits, Multilayer Flexible Circuits, Double-Sided Flexible Circuits, Dual-Access Flexible Circuits, Single-Sided Flexible Circuits, or complete assembly services, EBest Circuit (Best Technology) can provide full support. We operate our own SMT factories with fully equipped facilities in both China and Vietnam. For more information or if you would like to send us any inquiry, please send us an email through the contact form at the bottom of our Contact Page.

What Factors Shape the Overall Flex PCB Assembly Price and How Are Quotes Calculated?

Medical Flex PCB pricing reflects the complexity and reliability demands of life-critical electronics.

Main Cost Drivers:

1. Material Selection

- Polyimide grade

- RA copper vs. ED copper

- Conformal coatings and sterilization-resistant adhesives

2. Design Complexity

- Layer count

- Trace/space tolerance

- Microvia density

- Rigid-flex transition structure

3. Testing Requirements

- AOI, X-ray, flying probe

- Environmental stress tests

- Biocompatibility documentation

4. Volume & NRE

- Tooling, stencils, fixtures

- Engineering development and validation cost

By understanding these cost drivers, medical companies can design smarter, reduce wasted expense, and maintain required levels of reliability.

Table: Cost Factors in Medical Flex PCB Assembly

| Cost Factor | Impact Level | Optimization Strategy |

|---|---|---|

| Material Selection | High | Use suitable alternatives; avoid over-spec materials |

| Layer Count | High | Reduce layers; consider HDI to simplify stackups |

| Board Size | Medium | Improve panel utilization |

| Tolerances | High | Specify practical tolerances only |

| Surface Finish | Medium | Choose finish based on real reliability needs |

| Testing Requirements | Medium‚ÄďHigh | Test critical areas; combine efficient inspection methods |

| Documentation | Medium | Keep documentation to essential requirements |

Why Choose EBest Circuit (Best Technology) for Best Rigid-Flex PCB Assembly Services for Medical Devices?

BEST Technology provides medical OEMs with fully engineered Flex and rigid-flex PCB assembly solutions built for long-term, life-critical reliability.

What makes BEST Technology a strong partner:

- Decades of expertise in Flex and rigid-flex manufacturing.

- Medical-grade compliance, including ISO 13485-aligned processes.

- Engineering support for stackup, bend radius, materials, and DFM/DFA optimization.

- Advanced inspection using AOI, X-ray, flying probe, and reliability testing.

- Stable production scalability from prototypes to large volumes.

- Full traceability and detailed documentation for medical regulatory needs.

BEST Technology helps medical brands deliver safe, durable, and efficient devices built on precision-engineered Flex PCB and rigid-flex technology.

In a nutshell, flex PCB assembly enables the development of advanced medical devices through its unique combination of reliability, miniaturization, and dynamic functionality. As medical technology continues advancing toward less invasive procedures and more portable equipment, flex circuit technology will play an increasingly critical role in enabling these innovations. Understanding the principles outlined in this guide empowers medical device engineers to make informed decisions that balance performance, reliability, and manufacturability throughout the product development lifecycle .

At BEST Technology, we specialize in translating these principles into reliable, production-ready medical devices through our comprehensive rigid-flex PCB assembly services. Our medical industry expertise, combined with state-of-the-art manufacturing capabilities, ensures your devices meet the rigorous standards demanded by healthcare applications. Pls feel free to contact us at sales@bestpcbs.com to discuss how our flex PCB assembly solutions can enhance your medical device projects.