Why choose aluminum PCB for EV motor controller? Let’s explore design spec and guide, production processes, future trends for EV motor controller aluminum PCB.

Are you worried about these problems?

- Frequent high temperature alarms: How can motor controllers operate calmly?

- (The aluminum substrate has a thermal conductivity of 180W/mĀ·K, three times that of standard FR4, allowing heat to be dissipated instantly from the metal casing.)

- Vehicle vibration can cause cracking in solder joints. How can we prevent them from cracking?

- (The aluminum substrate and metal casing have a perfect CTE match, eliminating thermal stress and passing 2000 hours of mechanical shock testing.)

- Electromagnetic interference distorts signals. How can we restore good signal?

- (The aluminum substrate’s single-point grounding design improves EMC performance by 40%, achieving CISPR 25 certification in one go.)

EBest Circuit (Best Technology) can provide solution and service:

- Thermal design outsourcing serviceāA thermal simulation report is issued within 72 hours, allowing temperature reduction solutions to be directly implemented in PCB layout.

- Vibration compensation technologyāExclusive micro-dimpled copper foil technology extends solder joint fatigue life by five times.

- EMC Express Repair ChannelāProvide impedance adjustment samples within 48 hours, ensuring interference issues are resolved overnight.

Welcome to contact us if you have any request for aluminum PCB: sales@bestpcb.com.

Why Choose Aluminum PCB for EV Motor Controller?

Reasons why choose aluminum PCB for EV motor controller:

- Excellent Heat Dissipation, Ensuring Stability: Thermal conductivity is 5ā10 times that of FR-4, rapidly dissipating heat from the IGBT (>100W/mĀ·K) and preventing thermal runaway.

- High Reliability and Durability: Corrosion-resistant and boasting a wide operating temperature range (-55Ā°C to 125Ā°C), it extends lifespan (MTBF increased by 20%).

- Light weighting and Space Optimization: With a density of only 2.7g/cmĀ³, it is 60% lighter than traditional materials, improving energy efficiency.

- Electrical Safety and Efficiency: The aluminum substrate provides natural EMI shielding, protecting control signals.

- System Cost Advantages: Reduces reliance on heat sinks, lowering hardware costs.

Thermal Dissipation Challenges in EV Motor Controller Aluminum PCB

Heat Accumulation at High Power Density

- Challenge: Localized heat generation in power modules exceeds 100W/cmĀ², easily leading to device overheating.

- Solution: Use a high-thermal-conductivity aluminum substrate (such as an aluminum nitride ceramic substrate with a thermal conductivity ā„170W/mĀ·K) and optimize the layout of thermal vias to improve heat dissipation efficiency.

Performance Bottlenecks in Thermal Conductive Materials

- Challenge: Traditional thermal adhesives have low thermal conductivity, limiting heat dissipation effectiveness.

- Solution: Use nano-ceramic-filled thermal adhesives (with a thermal conductivity ā„5W/mĀ·K) or direct bond copper (DBC) technology to reduce thermal resistance.

Non-Uniform Thermal Stress

- Challenge: Differences in thermal expansion coefficients between the device and substrate lead to solder layer fatigue.

- Solution: Use flexible solder materials (such as silver sintering) to buffer thermal stress and extend service life.

Design Complexity of Liquid Cooling Systems

- Challenge: Improper flow channel layout leads to uneven cooling and reduced heat dissipation efficiency.

- Solution: Optimize flow channel design through CFD simulation to ensure uniform coolant flow (ā„1 m/s) and reduce pressure drop.

Impact of ambient temperature fluctuations

- Challenge: Heat dissipation capacity degrades in high-temperature environments, impacting stability.

- Solution: Integrate an intelligent temperature control system to dynamically adjust cooling strategies (such as increasing air cooling or reducing load).

Insufficient long-term reliability verification

- Challenge: Lack of data on heat dissipation performance degradation after long-term use.

- Solution: Accelerated aging tests (such as high-temperature and high-humidity cycling) are used to develop a lifespan prediction model to ensure long-term reliability.

Design Specification for EV Motor Controller Aluminum PCB

| Design Dimension | Specification Requirements |

| Minimum Trace Width/Spacing | Power traces: ā„2.0mm |

| Signal traces: ā„0.3mm | |

| Ground trace spacing: ā¤5mm | |

| Insulation Layer Thickness | 50-100Ī¼m (standard), up to 150Ī¼m for high-voltage areas |

| Copper Foil Thickness | Outer layers: 70-140Ī¼m (standard) Inner layers: 105Ī¼m (for multilayer boards) |

| Hole Diameter Tolerance | Ā±0.05mm (mechanical holes), Ā±0.03mm (laser holes) |

| Thermal Design | Heatsink contact surface flatness: ā¤0.05mm/m |

| Thermal grease thickness | 0.1-0.2mm |

| Surface Finish | OSP: 0.2-0.5Ī¼m ENIG: 0.05-0.1Ī¼m gold thickness |

| EMC Design | Metal layer grounding impedance: ā¤0.1Ī© |

| High-frequency signal grounding | trace spacing ā¤3mm |

EV Motor Controller Aluminum PCB Design Guide Ā

1. Material Selection

- Substrate: Use 6061-T6 or 5052-H34 aluminum alloy (thermal conductivity ā„2.0W/mĀ·K). Insulation layer thickness: 50ā150Āµm (thicker for high-voltage areas).

- Copper Foil: 3oz (105Āµm) rolled copper for power circuits; 1oz (35Āµm) copper for signal layers.

- Surface Finish: ENIG (gold thickness 0.05ā0.1Āµm) for high-frequency areas; OSP (0.2ā0.5Āµm) for low-voltage regions.

2. Thermal Management

- Power Plane: Embed 3oz copper (covering ā„70% area) in inner layers, connected via 0.4mm via arrays.

- Metal Embedding: Place 0.6mm copper blocks under high-power components, with 0.3mm buffer slots.

- Liquid Cooling: Integrate 3Ć3mmĀ² cooling channels filled with gallium-indium alloy (thermal resistance 0.3ā/W).

3. Electrical Layout

- High-Voltage Isolation: 8mm clearance for 300V systems; 12mm for 500V systems. Add 2mm safety slots for creepage compensation.

- Signal Integrity: Use 45Ā° arcs for high-frequency traces (>100MHz); impedance tolerance ā¤Ā±5%.

- Power Distribution: Dedicate Layer 6 (for 10-layer boards) as a thermal layer, connected via blind/buried vias.

4. Mechanical Design

- Heat Dissipation Posts: Use inverted T-shaped aluminum posts (diameter 8mm) with insulating sleeves.

- Clearance Control: Maintain ā„1mm gap between posts and PCB to prevent thermal deformation.

- Heatsink Interface: Ensure contact surface flatness ā¤50Āµm; apply nano-thermal paste (thermal resistance 0.1āĀ·cmĀ²/W).

5. Reliability Verification

- Thermal Testing: Infrared inspection under full load (max single-point temperature ā¤85ā; delta ā¤15ā).

- Thermal Cycling: -40ā to 125ā for 1000 cycles; via resistance change <10%.

- EMC Testing: Grounding impedance ā¤0.1Ī©; high-frequency signal shielding spacing ā¤3mm.

EV Motor Controller Aluminum PCB Manufacturing Processes

1. Cuttingā

- Cut large-sized aluminum PCB raw materials into production dimensions. Special attention should be paid to protecting the aluminum and copper surfaces to avoid scratches. Check for delamination or burrs at the edges.

2. Drillingā

- Perform positioning drilling on the board to provide auxiliary support for subsequent processes and customer assembly. Verify the quantity and diameter of holes to avoid scratching and check positional deviation.

3. Dry/Wet Film Imagingā

- Through grinding, lamination, exposure, and development, create the required circuit patterns on the board. Check for open circuits after development, alignment deviations, and prevent dry film residue.

4. Acid/Alkaline Etchingā

- Etch away unwanted copper parts after imaging, leaving only the required circuits. Monitor for incomplete or excessive etching, and verify line width and spacing.

5. Solder Mask & Legend Printingā

- Apply solder mask and legends via screen printing, pre-baking, exposure, and development. Inspect for contaminants, clean stencils, and ensure uniform thickness.

6. V-Cut & Routingā

- Separate individual PCBs from the panel using V-Cut and routing. Check V-groove dimensions, edge defects, and burrs while avoiding surface scratches.

7. Testing & Surface Treatment

- Conduct electrical and voltage resistance tests, then apply OSP (Organic Solderability Preservative) for better solderability. Distinguish between good and defective units without damaging traces.

8. FQC & FQA

- Perform full inspection (FQC) and sampling inspection (FQA), then package and ship. Confirm packaging quantities to prevent mix-ups, errors, or damage.

Future Trends of EV Motor Controller Aluminum PCB

Continuously Upgraded Thermal Management Performance

- Aluminum substrates will utilize composite materials with higher thermal conductivity (such as ceramic-filled aluminum substrates), significantly improving the heat dissipation efficiency of motor controllers under high-current conditions, preventing overheating and failure of power devices, and extending vehicle life. This reduces system cooling costs, enhances controller reliability, and reduces after-sales maintenance requirements.

Automated Production Drives Cost Optimization

- Through AI-driven automated production lines (such as intelligent optical inspection and precision etching), aluminum substrate manufacturing yields will increase by over 15%. 48-hour rapid prototyping services are also supported, accelerating customer product iteration.

Modular Design Enhances Compatibility

- Aluminum substrates will support standardized interfaces and customized functional area divisions (such as power and signal area wiring), enabling customers to flexibly adapt to motor controller platforms of varying power levels and achieve “one board, multiple models” development.

High-Density Integration and Light weighting Breakthroughs

- Utilizing 3D stacking and microvia technology (HDI process), aluminum substrate wiring density is increased by 40%, while ultra-thin aluminum layers (ā¤0.8mm) achieve a 30% weight reduction, meeting the requirements of compact motor compartment layouts.

Enhanced adaptability to extreme environments

- Through surface nano-coating and alloy substrate optimization, the aluminum substrate can withstand temperature shocks of -40Ā°C to 150Ā°C and 1000 hours of salt spray corrosion, adapting to all climate conditions of electric vehicles.

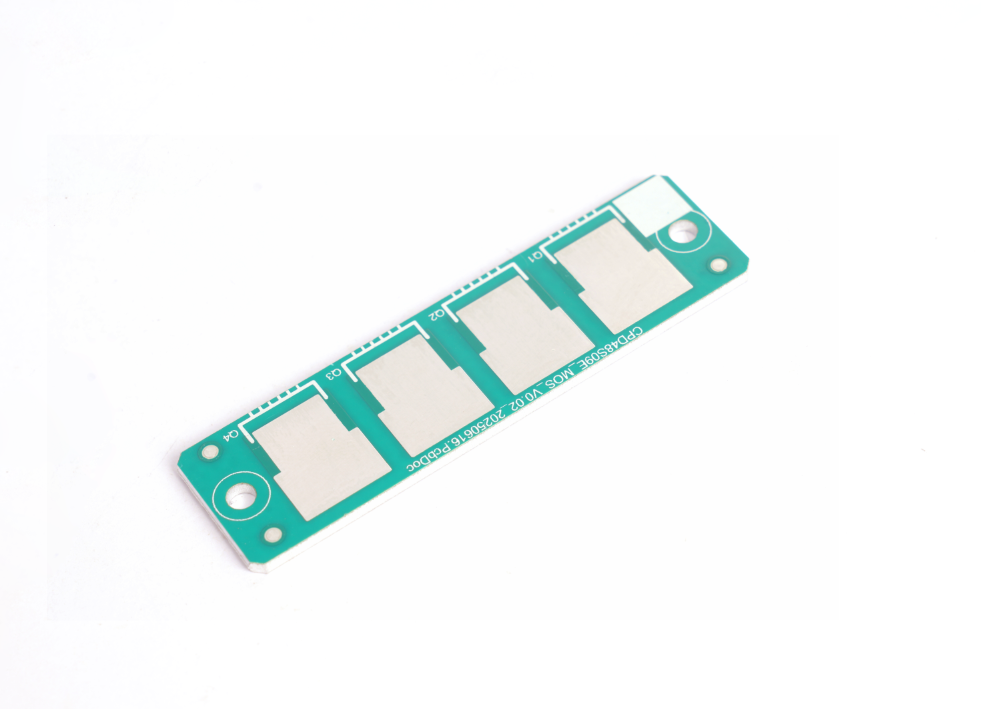

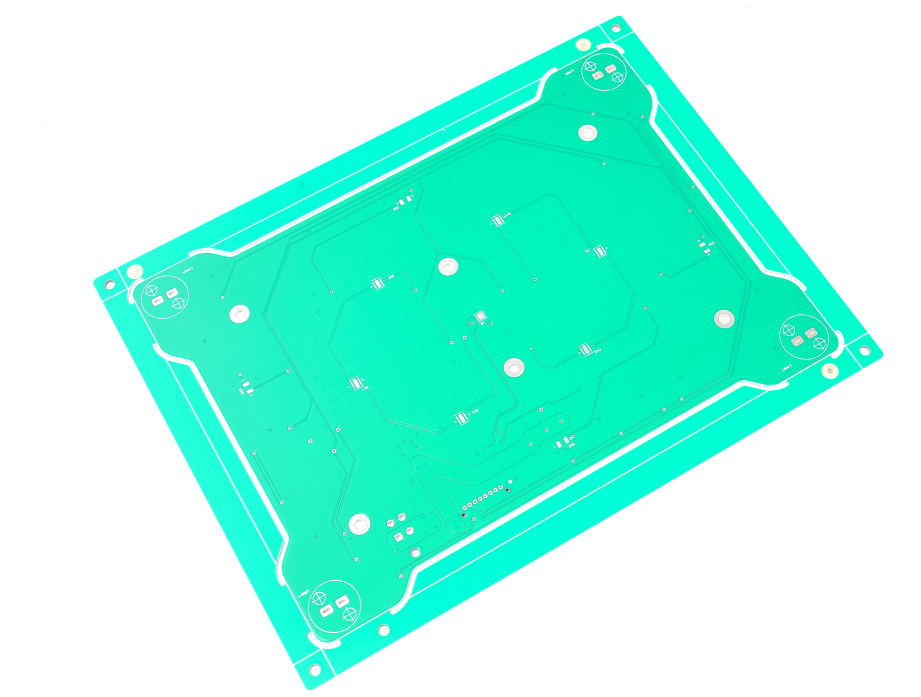

Our EV Motor Controller Aluminum PCB Case Studies

At EBest Circuit (Best Technology), we are deeply engaged in the field of aluminum substrates for electric vehicle motor controllers, successfully delivering hundreds of high-reliability projects, covering the full range of scenarios from 48V mild hybrid to 800V high-voltage platforms. Leveraging sophisticated thermal management design, stringent process control (such as nano-coating insulation and integrated micro-channel liquid cooling), and ISO/TS 16949-certified intelligent manufacturing capabilities, we provide customized solutions with high power density and long lifecycles to customers worldwide. Here is a photo of EV motor controller aluminum PCB we made before:

| Itemā ā | Specificationā |

| āProduct Name | High-Thermal-Conductivity Aluminum PCB for EV Motor Controllers |

| āāBase Materialā | Aluminum Substrate: 6061-T6 High-Thermal Aluminum (Thermal Conductivity ā„180W/mĀ·K) |

| Insulation Layer | Nano-Ceramic-Filled Epoxy Resin (Withstand Voltage ā„4kV) |

| Thicknessā | Total Thickness: 1.5mm/2.0mm/3.0mm (Copper Layer Thickness: 35Ī¼m/70Ī¼m) |

| āSolder Maskā | Green Solder Mask, Thickness 25Ā±5Ī¼m, Heat Resistance ā„260ā |

| Legend Markingā | White/Yellow Characters, Alcohol-Resistant, Line Width ā„0.2mm |

| āSurface Finish | OSP (Organic Solderability Preservative), Thickness 0.2-0.5Ī¼m, Meets IPC-6012 |

| āKey Processesā | Etched Line Width Tolerance Ā±10% |

| Applicationā | EV Motor Controllers |

Why Choose EBest Circuit (Best Technology) as Aluminum PCB Manufacturer?

- Dual Quality Certification: IATF 16949 (automotive) + optional ISO 13485 (medical) compliance.

- Premium Material Innovation: 8W/mĀ·K aluminum nitride substrates, 4kV ceramic-filled insulation for high-power safety.

- Cost-Optimized Supply Chain: 15-20% cost reduction via direct sourcing; tiered discounts (5% for 500+ units).

- 24-Hour Rapid Prototyping: Laser-cut prototypes with free DFM checks, reducing rework by 40%.

- Turnkey Solution: Provide EV motor controller PCB one stop service, including prototyping, design, bulk production, assembly.

- Full-Stack Engineering Support: ANSYS thermal simulation + EMC pre-scan (CISPR 25/DO-160 standards).

- Extreme Environment Resilience: -40Ā°C to +125Ā°C operation; 20G vibration resistance; 1,000-hour damp heat testing.

- Precision Manufacturing: Ā±3Ī¼m laser microvias; 2oz (70Ī¼m) copper for 200A+ current paths.

- 24/7 Technical Escort: 4-hour response for thermal runaway; 72-hour root-cause analysis.

Welcome to contact us if you have any inquiry for aluminum PCB: sales@bestpcbs.com.