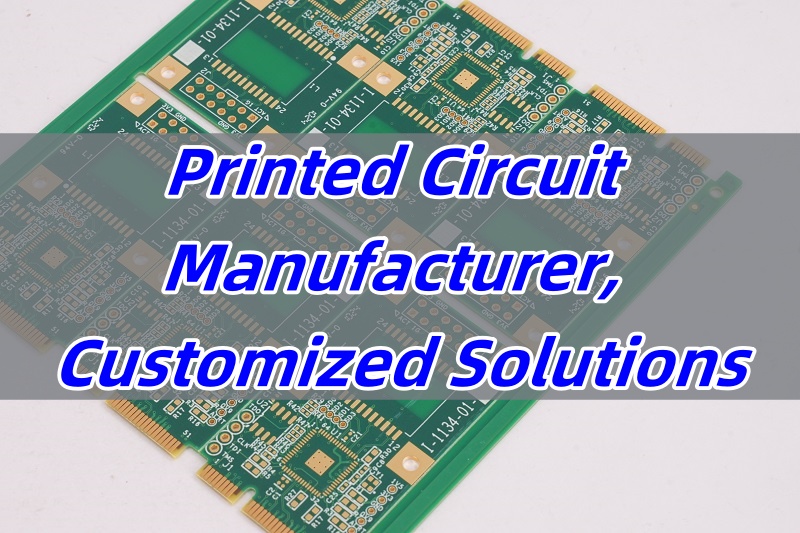

A printed circuit manufacturer is the backbone of the electronics world. They are the ones who transform the theoretical designs of printed circuit boards (PCBs) into tangible, functional components that power our devices. From the smartphones in our pockets to the complex machinery in factories, PCBs are everywhere, and the manufacturers behind them are the unsung heroes.

As a well-established printed circuit manufacturer, âEBest Circuit (Best Technology) has about 10 engineers in the R&D department and about 20 engineers in the quality department. Most of our engineers have worked at EBest Circuit (Best Technology) for over 10 years, who know the ropes and have solved the assorted PCB cases for over 1700 customers across 40 countries. We are committed to providing the turnkey electronic circuit solution to global customers. Your trust is our invaluable treasure. If you have any printed circuit projects, warm welcome to contact us at sales@bestpcbs.com. Looking forward to getting your inquiries soon.

Who is Printed Circuit Manufacturer in China?

China has emerged as a global powerhouse in the field of printed circuit manufacturing. There are several well-known manufacturers in the country that have earned a reputation for quality and efficiency.

EBest Circuit (Best Technology)

- EBest Circuit (Best Technology) is highly regarded for our advanced production technology. We have a factory and a professional R & D team. We can handle a wide range of PCB orders, from small-batch prototypes to large-scale mass production. EBest Circuit (Best Technology) has a comprehensive production system, covering everything from raw material procurement to the final product. Moreover, you not only get the final products, but you also get the solution for assorted PCBs. Our PCBs are known for the high reliability and stability, making us a popular choice for many international clients.

TTM Technologies

- TTM has a significant presence in China. They focus on providing high-end PCB solutions. With a strong emphasis on innovation, they are constantly developing new technologies to meet the evolving needs of the electronics industry.

Top Printed Circuit Manufacturers in USA

The United States also has a number of top-notch printed circuit manufacturers. These companies are known for their high-quality products and strict adherence to industry standards.

Sanmina Corporation

- Sanmina is a global electronics manufacturing services company with a strong focus on printed circuit manufacturing. They offer a wide range of services, including PCB design, assembly, and testing. Their products are used in various industries, such as medical, industrial, and telecommunications. They have a reputation for delivering high-quality products on time.

Celestica Inc.

- Celestica is another well-known printed circuit manufacturer in the US. They provide end to end solutions for PCB manufacturing, from concept to production. They have a global network of manufacturing facilities, which allows them to serve customers around the world. Their products are used in a variety of industries, including automotive, consumer electronics, and energy.

Printed Circuit Manufacturers in India

India’s printed circuit manufacturing industry has been growing steadily in recent years. There are several manufacturers that are making a mark in the global market.

Kaynes Technology India Limited

- Kaynes is a leading PCB manufacturer in India. They have a modern manufacturing facility and a team of skilled technicians. They offer a wide range of PCB products, including single-sided, double-sided, and multi-layer PCBs. Their products are used in industries such as automotive, healthcare, and telecommunications.

Moser Baer India Limited

- Moser Baer is a diversified company with a significant presence in the printed circuit manufacturing sector. They have a focus on research and development, which allows them to produce innovative PCB solutions.

Pratibha Industries Limited

- Pratibha Industries is involved in the manufacturing of PCBs as well as other electronic components. They have a strong commitment to quality control and use advanced manufacturing processes. Their products are used in various industries, including consumer electronics and industrial automation.

What is Printed Circuit Board Manufacturing?

Printed circuit board manufacturing is the process of creating PCBs, which are essential components in almost all electronic devices. A PCB is a board made of insulating material with conductive pathways etched or printed on it. These pathways connect different electronic components, such as resistors, capacitors, and integrated circuits, allowing them to work together as a single unit.

The manufacturing process involves several steps, from the initial design to the final testing. It requires a combination of technical expertise, advanced machinery, and strict quality control measures. The goal is to produce PCBs that are reliable, durable, and meet the specific requirements of the end-user.

What Materials are Commonly Used to Manufacture Printed Circuit Boards?

1. **Substrate Materials**

- Â Â – **FR-4**: This is the most commonly used substrate material for PCBs. It is a glass fiber reinforced epoxy laminate. FR-4 is known for its good mechanical and electrical properties, as well as its relatively low cost. It can withstand high temperatures and is resistant to moisture, making it suitable for a wide range of applications.

- Â Â – **Polyimide**: Polyimide is a high-performance substrate material. It has excellent thermal stability, chemical resistance, and flexibility. Polyimide-based PCBs are often used in applications where high-temperature resistance and flexibility are required, such as in aerospace and flexible electronics.

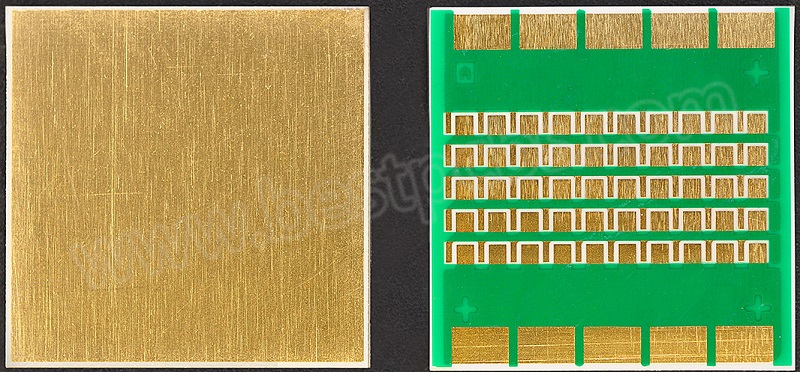

2. **Conductive Materials**

- Â Â – **Copper**: Copper is the primary conductive material used in PCBs. It has high electrical conductivity, which allows for efficient transmission of electrical signals. Copper is usually applied to the substrate in the form of a thin layer, either through electroplating or lamination.

- Â Â – **Gold**: Gold is sometimes used as a plating material on the contacts of PCBs. It has excellent corrosion resistance and low contact resistance, which ensures reliable electrical connections. Gold-plated contacts are commonly used in high-end applications such as military and aerospace.

3. **Solder Mask**

- Â Â – Solder mask is a layer of polymer material that is applied to the PCB to protect the copper traces and prevent solder from flowing to unwanted areas during the soldering process. It is usually green in color, but other colors are also available. Solder mask helps to improve the reliability and appearance of the PCB.

4. **Silkscreen**

- Â Â – Silkscreen is a layer of ink that is printed on the PCB to provide information such as component names, part numbers, and polarity markings. It helps technicians to assemble and troubleshoot the PCB more easily.

How are Printed Circuit Boards Manufactured?

- **Conceptualization**: The first step is to understand the requirements of the end-product. This includes determining the number of layers, the size of the PCB, and the types of components that will be used.

- **Schematic Design**: A schematic diagram is created to show the electrical connections between different components. This is a crucial step as it forms the basis for the physical layout of the PCB.

- **Layout Design**: The layout design involves placing the components on the PCB and routing the conductive traces. This step requires careful consideration of factors such as signal integrity, power distribution, and thermal management.

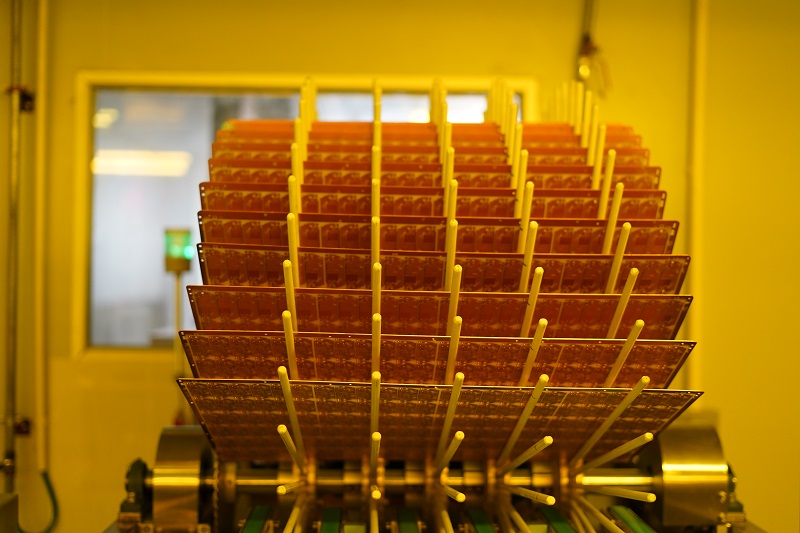

- **Substrate Preparation**: The substrate material is cut to the appropriate size and cleaned to remove any contaminants.

- **Copper Deposition**: A thin layer of copper is deposited on the substrate. This can be done through electroplating or lamination.

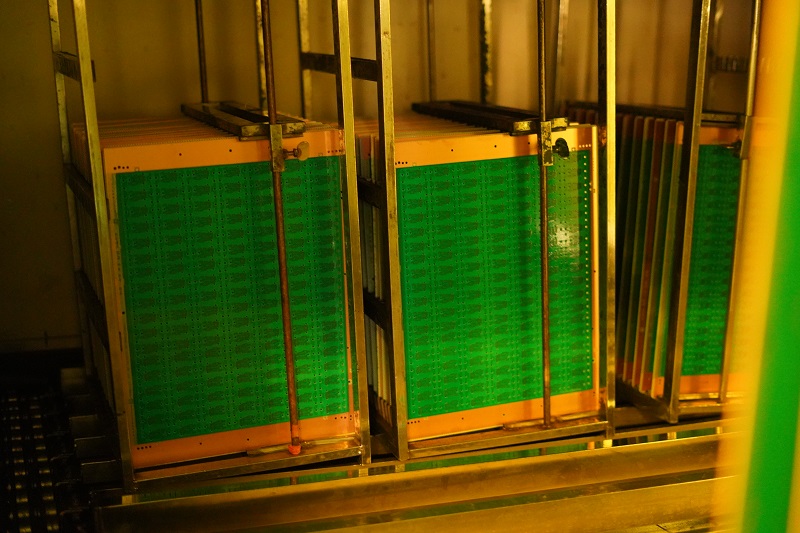

- **Photolithography**: A photoresist is applied to the copper layer, and a pattern is transferred onto it using a photomask. The exposed areas of the photoresist are then removed, leaving behind the desired copper pattern.

- **Etching**: The unwanted copper is etched away, leaving only the conductive traces.

- **Drilling**: Holes are drilled in the PCB to accommodate the component leads.

- **Plating**: The drilled holes are plated with copper to provide electrical connections between different layers.

- **Solder Mask Application**: The solder mask is applied to the PCB to protect the copper traces.

- **Silkscreen Printing**: The silkscreen layer is printed on the PCB to provide component information.

- **Surface Finish**: A surface finish is applied to the copper traces to prevent oxidation and improve solderability. Common surface finishes include HASL (Hot Air Solder Leveling), ENIG (Electroless Nickel Immersion Gold), and OSP (Organic Solderability Preservative).

- **Electrical Testing**: The PCB is tested to ensure that all the electrical connections are working properly. This can be done using automated testing equipment.

- **Functional Testing**: The assembled PCB is tested to ensure that it functions as intended in the end product.

Why Should You Choose EBest Circuit (Best Technology) as Your Trusted Printed Circuit Manufacturer?

Quality Assurance

- EBest Circuit (Best Technology) has a strict quality control system in place. We follow international standards such as ISO 9001 and IPC standards. Our products undergo multiple levels of testing, from in-process inspections to final product testing. This ensures that the PCBs we produce are of the highest quality and meet the specific requirements of the customers.

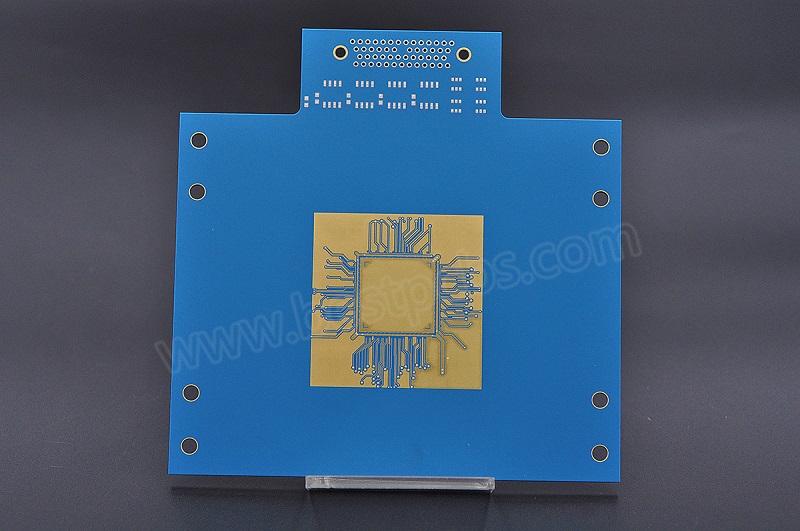

Advanced Technology

- The company invests heavily in research and development. We use the latest manufacturing technologies and equipment, such as high-precision drilling machines and advanced plating systems. This allows us to produce complex PCBs with high precision and efficiency.

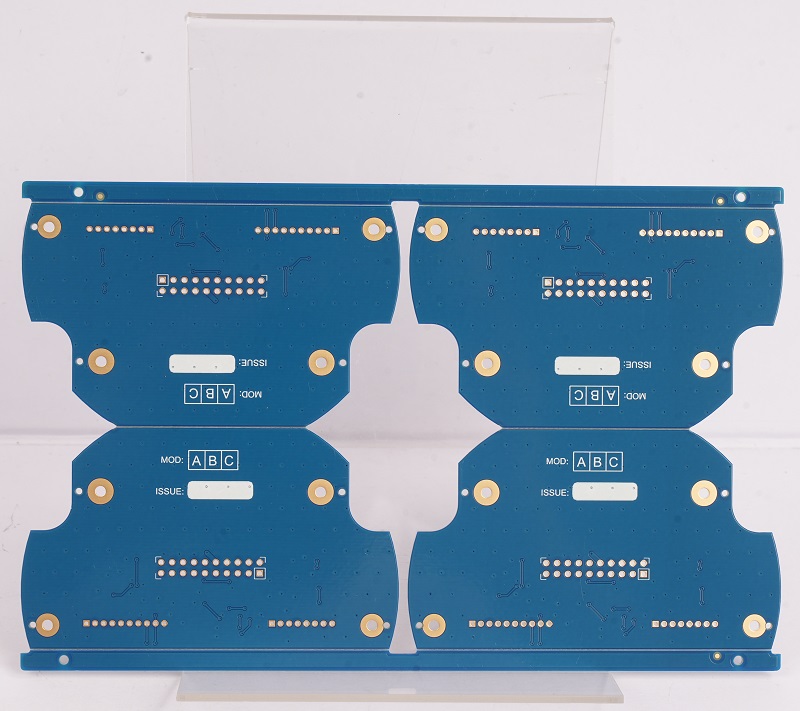

Customization

- EBest Circuit (Best Technology) understands that requirements âvaryâ from customer to customer. We offer customized solutions, from small-batch prototypes to large-scale mass production. Our experienced engineering team can work closely with customers to design and manufacture PCBs that meet their specific needs.

Fast Turnaround Time

- In today’s fast-paced electronics industry, time is of the essence. EBest Circuit (Best Technology) has a streamlined production process that allows us to deliver products quickly. We can provide fast-turn prototypes within a short period, which is crucial for customers who need to test their products quickly.

Excellent Customer Service

- EBest Circuit (Best Technology) has a dedicated customer service team that is available to answer customers’ questions and provide support throughout the manufacturing process. We are committed to building long-term relationships with our customers and ensuring their satisfaction.

To sum up, the world of printed circuit manufacturers is vast and diverse. Whether you are looking for a manufacturer in China, the USA, or India, there are many options available. Understanding the manufacturing process, the materials used, and the key players in the industry can help you make an informed decision.

And if you are looking for a trusted partner, EBest Circuit (Best Technology) offers a combination of quality, technology, customization, and excellent customer service that makes us a top choice. Kindly contact us at sales@bestpcbs.com for any printed circuit demands.