Selecting the right copper busbar manufacturers is critical for ensuring electrical system reliability and performance. High-quality copper busbar manufacturers adhere to strict material and process standards, while poor suppliers may cause energy loss, equipment failure, or project delays. This guide breaks down key factors to evaluate manufacturers and addresses common pain points in sourcing.

How to Select Reliable Copper Busbar Manufacturers?

Prioritize manufacturers with proven material quality, advanced processes, and industry certifications. Start by verifying copper purity (â„99.9% is ideal), checking customization capabilities, and confirming compliance with global standards like ASTM B187 and UL. Partnering with such manufacturers avoids mismatched specs and delivery risks.

Key Evaluation Criteria

- Raw material sourcing: Ensure use of high-purity copper (C11000 ETP or C10200 OF grade)

- Manufacturing equipment: CNC machining, automated bending, and precision stamping capabilities

- Quality control: In-house testing for conductivity, mechanical strength, and corrosion resistance

- Customer cases: Track record in EV charging, data centers, or renewable energy sectors

What Are the Core Quality Standards for Copper Busbar Manufacturers?

Top copper busbar manufacturers follow strict standards to guarantee product performance. The primary benchmark is ASTM B187/B187M, which defines dimensional, mechanical, and chemical requirements for copper busbars. Additional standards include RoHS for environmental compliance and ISO 9001 for quality management systems.

Must-Meet Standards

| Standard | Key Requirements |

|---|---|

| ASTM B187 | Copper purity, tensile strength, and dimensional accuracy |

| UL | Electrical safety and fire resistance for industrial use |

| RoHS | Restriction of hazardous substances in surface treatments |

Why Material Purity Matters for Copper Busbar Manufacturers?

Copper purity directly impacts conductivity and durability. copper busbar manufacturers using 99.9%+ pure copper minimize energy loss (resistivity â€1.7241 ΌΩ·cm) and reduce overheating risks. Low-purity copper with impurities degrades performance over time, leading to costly system failures.

Common Copper Grades for Busbars

- C11000 (ETP): 99.93% pure, ideal for general industrial applications

- C10200 (OF): 99.95% pure, superior conductivity for high-current scenarios

- C12200 (DHP): For general-purpose applications requiring corrosion resistance

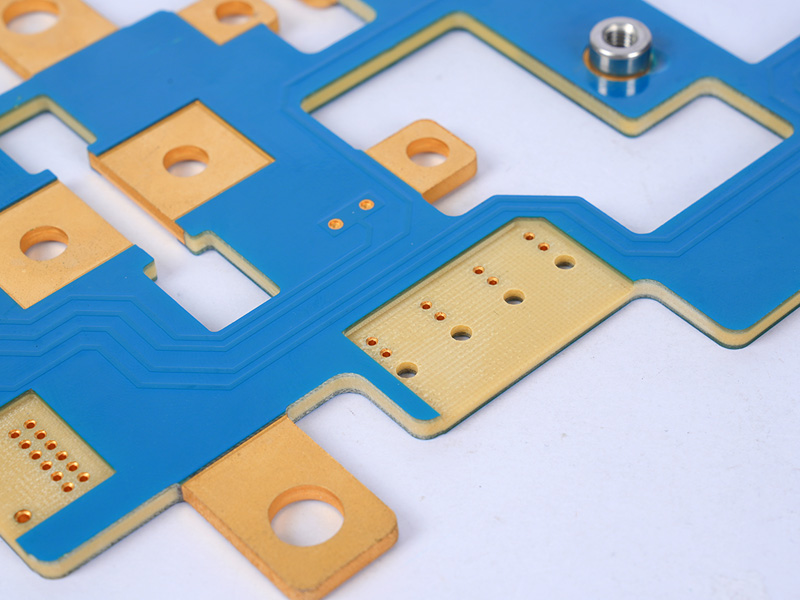

Customization Capabilities: Key Competitiveness of Copper Busbar Manufacturers

Reliable copper busbar manufacturers offer tailored solutions for unique project needs. This includes custom dimensions, shapes, surface treatments, and insulation options. Advanced manufacturers handle complex designs (e.g., laminated busbars) and adapt to tight tolerances (±0.05mm) for seamless system integration.

Customization Options

- Dimensions: Custom width, thickness, and length (up to 6m)

- Shapes: Bending, punching, and CNC-machined complex profiles

- Insulation: Epoxy coating, heat-shrink tubing, or powder coating

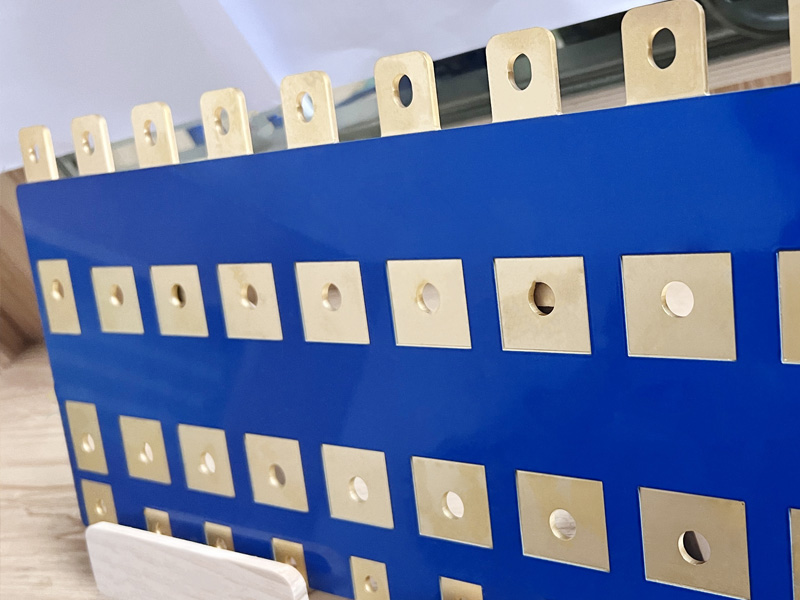

Surface Treatment Options from Top Copper Busbar Manufacturers

Surface treatments protect busbars from corrosion and enhance conductivity. Leading copper busbar manufacturers provide multiple finishing options to suit different environments, from humid industrial settings to clean data centers.

Popular Surface Treatments

- Tin plating: Prevents oxidation, ideal for low-voltage applications

- Nickel plating: Enhances wear resistance and solderability

- Powder coating: Superior corrosion protection for outdoor use

How Do Copper Busbar Manufacturers Ensure Delivery Stability?

Delivery delays disrupt project timelines. Trusted copper busbar manufacturers maintain stable supply chains, keep inventory of standard specs, and offer clear lead-time commitments (7-15 days for standard orders, 2-4 weeks for custom). They also have backup production lines to handle unexpected demand.

Supply Chain Management Tips

- Choose manufacturers with global raw material sourcing channels

- Verify production capacity (minimum 100 tons/month for bulk orders)

- Request clear delivery contracts with penalty clauses for delays

Industry Certifications to Verify Copper Busbar Manufacturers

Certifications are proof of a manufacturerâs expertise. Reputable copper busbar manufacturers hold ISO 9001 (quality management), IATF 16949 (automotive), and UL certifications. These credentials confirm compliance with global standards and reduce sourcing risks.

Differences in Manufacturing Processes Among Copper Busbar Manufacturers

Process gaps separate high-quality and low-grade copper busbar manufacturers. Advanced facilities use automated processes for consistency, while low-cost suppliers rely on manual labor (prone to errors). Precision machining ensures tight tolerances, avoiding fitment issues in assembly.

Process Comparison

- Automated vs. manual: Automated processes reduce error rates to <0.5%

- Heat treatment: Annealing (O60 temper) for flexibility or hardening (H04 temper) for strength

- Testing: In-line conductivity testing vs. post-production sampling

Applications of Products from Copper Busbar Manufacturers

Copper busbar manufacturers supply components for diverse industries, where high conductivity and durability are critical. Key applications include EV charging stations, data center power distribution, renewable energy systems (solar/wind), and industrial machinery.

FAQ: Common Issues About Copper Busbar Manufacturers

Below are answers to frequent questions when sourcing from copper busbar manufacturers.

Q1: How to verify copper purity from manufacturers?

Request material test reports (MTRs) showing chemical composition. Reputable manufacturers provide MTRs compliant with ASTM standards, confirming copper purity â„99.9%.

Q2: What is the typical lead time for custom busbars?

Most manufacturers deliver custom orders in 2-4 weeks. Rush orders (1 week) are available for urgent projects, often with a 10-15% premium.

Q3: Can manufacturers handle small-batch orders?

Yes, top manufacturers accept small batches (â„5 pieces) without compromising quality. Some offer discounted rates for repeat small orders.

Q4: How to resolve surface oxidation issues?

Choose manufacturers offering anti-oxidation treatments (tin/nickel plating). Post-delivery, store busbars in dry environments and avoid direct contact with corrosive substances.

Q5: Do manufacturers provide technical support for selection?

Reliable manufacturers assign engineers to assist with selection, based on current, voltage, and environmental requirements, ensuring optimal busbar design.

Q6: What certifications are mandatory for automotive busbars?

Automotive applications require IATF 16949 certification, along with RoHS compliance and UL 94 flammability ratings for insulation.

How to Evaluate the Cost-Effectiveness of Copper Busbar Manufacturers?

Cost-effectiveness goes beyond unit price. Evaluate total ownership cost, including quality (avoiding rework), delivery (preventing delays), and after-sales support. Cheap copper busbar manufacturers may cut corners on material or testing, leading to higher long-term costs.

Global Sourcing Guide for Copper Busbar Manufacturers

When sourcing globally, prioritize copper busbar manufacturers with local service centers to reduce logistics time and costs. US manufacturers excel in custom designs, while Asian suppliers offer competitive pricing for bulk orders. Always confirm import compliance with local standards.

We provide high-quality products from trusted copper busbar manufacturers, adhering to ASTM B187 and UL standards with customizable solutions for diverse industries. If you need reliable copper busbars, place your order with us via email at sales@bestpcbs.com.