Conformal coating printed circuit boards are PCBs that receive a thin, transparent protective film designed to shield the circuitry from harsh environmental conditions. This film wraps closely around components, solder joints, and copper traces, creating a barrier that helps prevent moisture, dust, chemical vapors, and other contaminants from damaging the board.

What Is Conformal Coating on PCBs?

Conformal coating is a thin, transparent, and protective polymer film that covers the surface of a printed circuit board. It clings to the boardās contours, components, solder joints, and copper traces, forming a reliable defense layer. This layer helps guard against moisture, corrosion, dust, salt spray, chemicals, and other environmental hazards that could damage electronics.

The term āconformalā comes from the coatingās ability to fit the boardās topography. It does not form a rigid shell. Instead, it bends and flexes with the PCB, making it suitable for devices that experience vibration, shock, or temperature cycling.

Conformal coating prevents moisture from forming conductive pathways and slows down the oxidation process, thus ensuring the long-term operational stability of the device. More importantly, this coating protects printed circuit boards from environmental stresses without adding significant weight or thickness.

Typical use cases include:

- Automotive engine systems

- Medical devices exposed to sterilization

- Outdoor communication equipment

- Industrial controllers

- Aerospace and defense electronics

- Wearables and consumer devices

- Marine electronics

What Is the Solvent for Conformal Coating?

Conformal coating materials can be solvent-based, water-based, or solvent-free. Common solvents used in solvent-based conformal coatings include:

- Xylene

- Toluene

- Acetone

- Methyl ethyl ketone (MEK)

- Isopropyl alcohol (IPA)

- Proprietary solvent blends

These solvents help regulate viscosity, drying speed, and coating uniformity. After the coating is applied, the solvent evaporates, leaving behind the protective polymer film.

Water-based coatings use water instead of traditional chemical solvents. They are eco-friendlier and can reduce operator exposure to fumes. UV-curable coatings often require little or no solvent, as they harden when exposed to ultraviolet light.

Conformal Coating Types

There are several widely used conformal coating types. Each offers unique protective and mechanical properties.

Below are the major types you will encounter:

- 1. Acrylic Resin (AR)

Acrylic coatings are popular due to their ease of use and quick drying times. They offer solid resistance to moisture and provide a good balance of protection and affordability. They are simple to remove for rework and are commonly applied in consumer and commercial electronics.

- 2. Silicone Resin (SR)

Silicone coatings excel in extreme temperature environments. They maintain flexibility at low temperatures and stability at high temperatures. They work well in automotive, aerospace, and outdoor devices where temperature cycling is common.

- 3. Urethane Resin (UR)

Urethane coatings deliver superior resistance to chemicals and abrasion. They work particularly well in industrial environments exposed to oils, fuels, and solvents. However, urethane resins can be more difficult to remove during rework.

- 4. Epoxy Resin (ER)

Epoxy coatings form a tough protective barrier. They resist humidity and mechanical wear. They are often used in high-stress applications, but they can be more challenging to repair or modify.

- 5. Parylene (XY)

Parylene is applied using a specialized vacuum deposition process. It creates an exceptionally uniform, pinhole-free coating. This makes it ideal for medical implants, sensors, aerospace parts, and high-precision electronics. It delivers excellent moisture and chemical resistance but requires specialized equipment and a higher cost.

Selecting the right material depends on environmental hazards, board design, rework requirements, and industry standards.

What Is the Best Conformal Coating?

The ābestā conformal coating varies depending on the performance expectations of your product. Each coating type brings different strengths.

- For outstanding moisture protection: Parylene or high-grade urethane

- For extreme temperature environments: Silicone resin

- For consumer electronics that require fast, cost-effective processing: Acrylic resin

- For medical devices that need ultra-thin precision coating: Parylene

- For industrial environments with aggressive chemicals: Urethane or epoxy

- For easy rework and debugging during development: Acrylic or silicone

There is no one ābestā option for all situations. Instead, the optimal solution is the one that aligns with the productās environmental exposure, performance expectations, and long-term reliability needs.

If you need help choosing the right coating for your specific PCB design, EBest Circuit (Best Technology) can provide expert guidance based on decades of manufacturing experience.

Does Conformal Coating Make PCB Waterproof?

Conformal coating does not make a PCB fully waterproof in the same way that a sealed enclosure would. However, it does make the PCB significantly more resistant to moisture and humidity.

The coating creates a thin hydrophobic layer. This layer helps repel water droplets and prevent moisture from reaching sensitive components.

Still, immersion in water or high-pressure spray requires additional protection, such as:

- Encapsulation or potting

- Waterproof housing

- Gasket sealing around connectors

- Conformal coating + selective potting

In other words, conformal coating increases water resistance but does not replace full waterproofing systems.

How to Conformal Coat a Circuit Board?

Conformal coating is applied through several methods. The choice depends on product volume, coating type, and board complexity.

Here are the most common application processes:

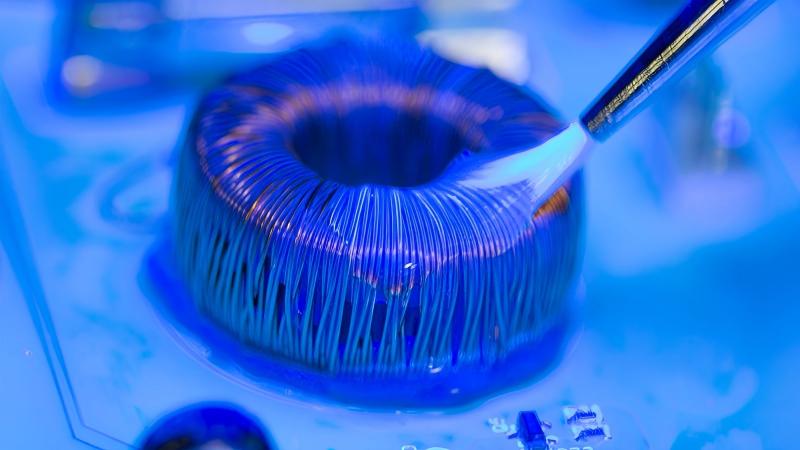

- 1. Brushing

This is a manual method used for small batches, prototypes, or touch-ups. An operator applies the coating with a small brush. It is inexpensive but not ideal for uniform coverage on large volumes.

- 2. Spraying

Spray coating provides better uniformity than brushing. It can be done manually with a spray gun or automatically using a selective coating machine. This method is efficient for mid-volume and high-volume production.

- 3. Dip Coating

The entire PCB is submerged in a coating tank. This ensures consistent coverage on all surfaces. It works well for simple board layouts but may not be suitable for designs with connectors or open mechanical parts.

- 4. Selective Coating Machines

These automated systems apply coating precisely around components, connectors, and keep-out zones. They deliver the most accurate control and are widely used in large-scale production.

- 5. Vapor Deposition (for Parylene)

Parylene coating uses a vacuum chamber. The coating material vaporizes and polymerizes during deposition. This produces a pinhole-free film with unmatched uniformity.

Regardless of the method, the process usually includes:

- PCB cleaning

- Masking of connectors and excluded areas

- Controlled coating application

- Curing or UV-hardening

- Final inspection

A clean, dry PCB is essential for proper adhesion. Even small residues can weaken coverage, so high-quality cleaning processes are mandatory.

How Thick Should Conformal Coating Be?

Recommended thickness varies depending on the coating type:

| Coating Type | Typical Thickness |

|---|---|

| Acrylic (AR) | 25ā75 Āµm |

| Silicone (SR) | 50ā200 Āµm |

| Urethane (UR) | 25ā75 Āµm |

| Epoxy (ER) | 50ā200 Āµm |

| Parylene (XY) | 10ā50 Āµm |

A thickness that is too thin may not provide complete protection. A coating that is too thick may cause pooling around components or interfere with connectors.

Thickness must be controlled precisely using measurement tools such as:

- Micrometers

- Ultrasonic thickness gauges

- Specialized optical systems

What Is the Lifespan of Conformal Coating?

The lifespan of conformal coating largely depends on:

- Coating type

- Environmental exposure

- Temperature cycling

- Vibration levels

- UV exposure

- Chemical exposure

- Application quality

Under typical conditions, conformal coating can last anywhere from 5 to 20 years. Parylene often offers the longest life due to its uniform structure and resistance to moisture and chemicals.

Silicone coatings also perform well in long-term applications because they maintain elasticity even after many years. A properly applied coating can protect the PCB for the entire product lifecycle.

What Are the Disadvantages of Conformal Coating?

Although conformal coating provides many benefits, there are a few limitations to be aware of. These issues can be managed with proper planning.

- 1. Rework Challenges

Removing certain coatings, such as urethane or epoxy, can be difficult. This increases rework time during repair or testing.

- 2. Masking Requirements

Components like connectors, switches, and sockets need to be masked before coating. Masking adds time and labor cost.

- 3. Application Sensitivity

Humidity, dust, and contaminants can affect adhesion.

- 4. Equipment Cost for Automation

Selective coating machines and vapor deposition systems require investment.

However, the above challenges are manageable. In most cases, the protective value of conformal coating far outweighs these drawbacks.

How to Remove Conformal Coating From a Circuit Board?

Removal depends on the coating type. The most common removal methods include:

- 1. Solvent Removal

Acrylic coatings dissolve easily in solvents such as acetone or specialized stripping agents.

- 2. Mechanical Removal

Scraping, brushing, or micro-abrasion can remove coatings like silicone.

- 3. Thermal Removal

Heat softens some coatings, allowing easier removal.

- 4. Chemical Strippers

There are chemical agents designed to break down thicker coatings such as urethane and epoxy.

- 5. Plasma Cleaning

Plasma systems can remove thin coatings through ionized gas. This is widely used in high-precision electronics repair.

Conclusion:

Conformal coating printed circuit boards play a pivotal role in modern electronics. They defend sensitive circuitry against moisture, chemicals, dust, and temperature stress. They extend product lifespan and enhance reliability under challenging conditions.

If you need expert advice or high-quality PCB and conformal coating services, our engineering team is ready to support your next build.

For inquiries, please contact: sales@bestpcbs.com