A cold solder joint is one of the most common reliability defects in PCB and PCBA assemblies, and it continues to be a major source of intermittent failures across consumer electronics, industrial controls, medical devices, automotive modules, and aerospace hardware. At Best Technology, we see the long-term consequences of cold joints in incoming failure analyses from global customersâespecially in assemblies where stable conductivity and mechanical strength are critical.

With 19 years of PCBA production experience across China and Vietnam, medical-grade and aerospace-grade certifications, and MES-controlled SMT lines, we understand how cold solder joints emerge, how to eliminate them, and how to engineer assemblies that remain stable throughout the product life cycle.

What Is a Cold Solder Joint?

A cold solder joint forms when solder does not melt or wet the pad and component lead completely. Instead of creating a unified bond, the solder cools prematurely or never flows correctly, resulting in a dull, grainy, or uneven connection.

In the PCBA environment, cold joints are considered a process defect because they weaken the mechanical integrity of a soldered connection and create unstable electrical performance that deteriorates over time.

In high-reliability sectorsâmedical, industrial, aerospaceâthese defects are unacceptable and must be removed at the root cause: temperature control, surface condition, solder alloy behavior, and wetting characteristics.

Do Cold Solder Joints Still Work?

Temporarily, yes. Reliably, no. A cold solder joint may appear functional during a quick test, then fail:

- When the board heats during normal operation

- When vibration or slight mechanical stress occurs

- When humidity or temperature cycles change contact resistance

- When current load increases

This unstable behavior is what makes cold joints one of the most misdiagnosed failure sources. Many customers approach Best Technology believing they have a âcomponent issueâ or âfirmware bug,â when the real cause is inconsistent solder metallurgy.

Cold Solder Joint Symptoms

From a PCBA viewpoint, cold joints create early-life failures that escalate under stress. Common symptoms include:

- Intermittent booting or power instability

- Flickering LEDs, displays, or inconsistent sensor readings

- Weak or noisy signals in communication lines

- Overheating around a soldered component

- Boards that only work when pressed or tapped

- Modules that behave differently under temperature changes

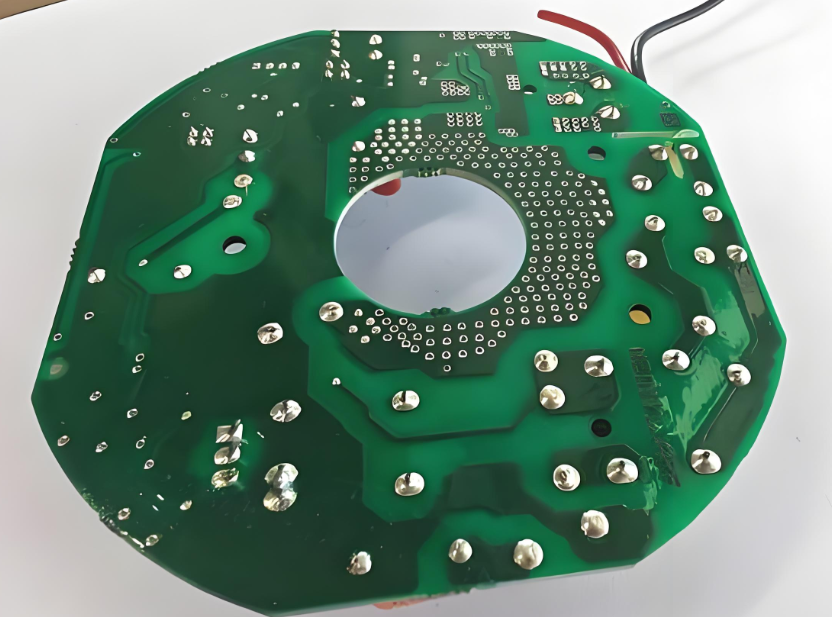

During incoming quality analysis at Best Technology, we often find that unstable BGA balls, hand-soldered connectors, and TH pins are common locations for cold joints.

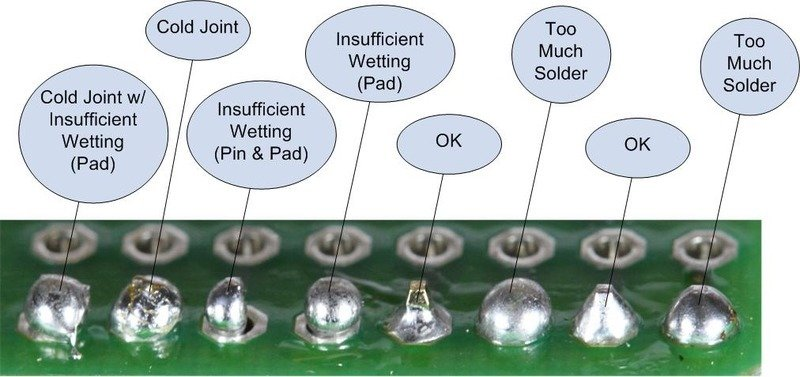

What Is the Difference Between a Cold Solder Joint and a Good Solder Joint?

A good solder joint creates a smooth, bright, and uniform connection that wraps around the lead with full wetting.

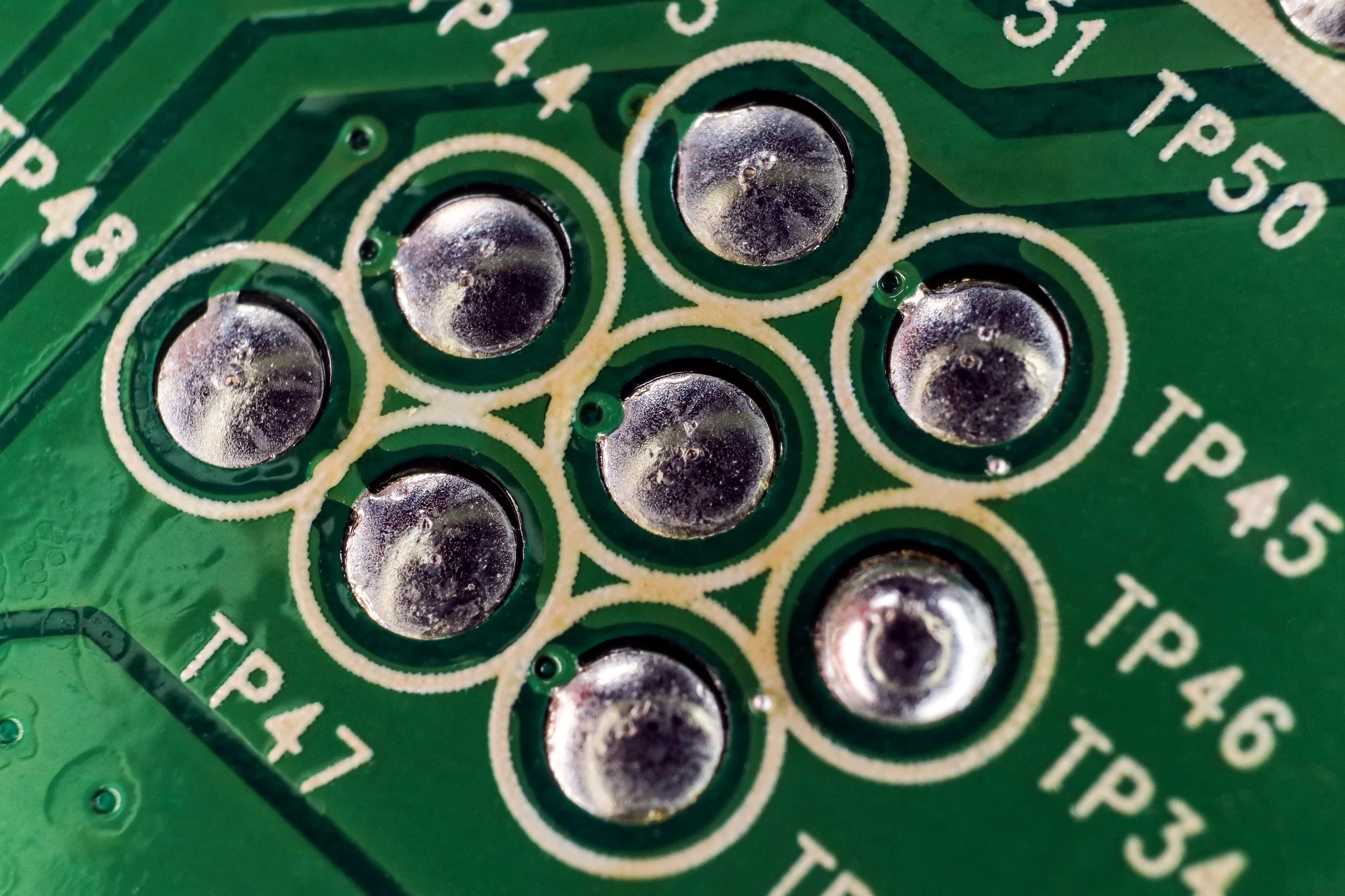

A cold joint typically shows:

- A dull or matte finish

- Crystalline or grainy texture

- A ring fracture around the lead

- A small gap between solder and pad

- Solder balled up instead of flowing

Experienced technicians immediately recognize these visual cues because they suggest weak mechanical support and unstable electrical conductivity.

How to Identify a Cold Solder Joint?

Both technicians and advanced PCBA factories rely on a few inspection methods:

- Bright-light and angled inspection to reveal dull or frosted surfaces

- Magnification to highlight cracks or gaps

- Gentle mechanical pressure to detect movement

- Thermal testing to expose resistance changes under heat

- AOI or X-ray for lead-free and hidden joints

In Best Technologyâs MES-controlled lines, each soldering stepâincluding reflow, wave, and selective solderâis tied to traceable profiles, making it easier to isolate and prevent cold joints during future builds.

Are Cold Joints Acceptable?

No. Cold solder joints are never acceptable in professional electronics.

They violate:

- IPC-A-610 standards

- Reliability requirements

- Safety and quality regulations

Even in low-cost consumer electronics, cold joints significantly reduce product lifespan and reliability.

What Causes a Cold Solder Joint?

Cold solder joints originate from several process-related or operator-related factors:

- Insufficient soldering temperature

- Iron tip or nozzle unable to deliver stable heat

- Oxidized pads, leads, or old components

- Expired or poorly stored solder paste

- Flux burnout or inadequate flux coating

- Component movement during cooling

- Large copper areas absorbing heat too fast

- Incorrect reflow curve in SMT production

With our dual factories in China and Vietnam, Best Technology maintains strict humidity control, paste storage, stencil management, and reflow calibrationâreducing these risks dramatically.

What Are the Risks of Cold Joints?

Cold solder joints introduce cascading reliability issues:

- Intermittent electrical contact

- Overheating of stressed joints

- Noise, distortion, or unstable signals

- Sudden shutdowns during operation

- Premature component failure

- Total system outages in critical environments

In medical, industrial, and aerospace PCBAs, even a single cold joint is considered a critical defect (CD level). Best Technology screens aggressively to ensure these defects never leave the factory.

How to Fix a Cold Solder Joint?

Repair is direct, but must be done properly:

1. Clean the joint with isopropyl alcohol.

2. Apply quality flux to re-activate the surface.

3. Reheat the joint until solder melts fully.

4. Add a small amount of fresh solder if needed.

5. Allow full cooling without movement.

6. Inspect visually to ensure proper fillet and wetting.

For SMD components (QFN, BGA, LGA), reflow or hot-air rework ensures even heating.

How to Avoid Cold Solder Joints?

Prevention stems from controlled process engineering:

- Use calibrated, temperature-controlled soldering equipment

- Maintain component and PCB cleanliness

- Follow correct reflow temperature profiles

- Apply flux or paste with proper wetting characteristics

- Preheat heavy copper boards

- Avoid vibration during cooling

- Use AOI/X-ray to verify solder integrity

- Enforce operator training and certification

At Best Technology, these practices are embedded into MES workflows, ensuring traceability and repeatabilityâfrom prototype to mass production.

FAQ About Cold Solder Joint

1. Can flux prevent cold solder joints?

Flux improves wetting, but without proper temperature, cold joints still occur.

2. Can a cold solder joint cause a short?

Yes. Cracking or partial bonding may create unintended bridges.

3. Why are cold solder joints more common in lead-free solder?

Lead-free alloys require higher melting temperatures and tighter process control.

4. Can a multimeter detect a cold solder joint?

Sometimes, but intermittent faults often remain hidden until the board is heated or flexed.

5. Can reheating permanently fix a cold solder joint?

If the pad and lead are clean and properly wetted, reheating provides a permanent repair.

6. Do professional PCBA manufacturers still encounter cold joints?

Rarely, but only because inspection systems, controlled processes, and trained operators keep solder quality consistent.

When to Consult a Professional or a PCBA Manufacturer?

If your board shows repeated failures, unstable behavior, or numerous questionable joints, professional evaluation is the safest choice. Best Technology supports global customers with:

- In-house FA (failure analysis)

- X-ray and AOI inspection

- Controlled reflow soldering

- Medical-grade and aerospace-grade quality systems

- MES-tracked production across China and Vietnam

Whether you need prototype repair, DFX recommendations, or full PCBA manufacturing, our engineering teams ensure solder reliability at every stage of the product life cycle.