Why choose China metal clad PCB? This blog is mainly about China metal clad PCB manufacturer list and how to choose a reliable metal core PCB manufacturers in China.

Are you troubled these issues with metal clad PCB?

- Does your heat dissipation solution consistently hinder overall system performance in high-temperature scenarios?

- How to address board deformation and lifespan reduction caused by high-power devices?

- Can traditional substrates simultaneously meet the balance requirements of thermal conductivity and cost control?

As a China metal clad PCB manufacturer, EBest Circuit (Best Technology) can provide you service and solution:

- Precision Thermal Management Service: Achieve stable heat dissipation performance with a thermal conductivity â¥8W/m·K through customized aluminum/copper substrate layer design.

- Structural Reinforcement Process: Utilize metal core lamination technology to increase board bending strength by 40%, adapting to the vibration environments of high-power LEDs/automotive electronics.

- Cost Optimization Solution: Help customers reduce overall material costs by 15% through intelligent matching of conductive layer thickness and standardized production processes.

Welcome to contact us if you have any request for metal clad circuit board: sales@bestpcbs.com.

Why Choose China Metal Clad PCB Manufacturer?

Advantages of China Metal Clad PCB Manufacturer:

- Significant Cost-Effectiveness and Globally Leading Performance: China boasts a complete electronics manufacturing industry chain and large-scale production capabilities, making its raw material procurement, processing costs, and logistics efficiency highly competitive. The production cost of metal-based PCBs (such as aluminum-based and copper-based PCBs) is 20%-40% lower than in Europe and the United States, with no hidden additional costs, helping customers reduce total product costs and enhance market competitiveness.

- Highly Mature Supply Chain and Controllable Delivery Cycle: China’s PCB industry clusters (such as the Pearl River Delta and Yangtze River Delta) bring together a complete industry chain from substrate supply and etching to surface treatment, enabling “one-stop” procurement. The delivery cycle for regular metal-based PCB orders is only 7-15 days, and urgent orders can be shortened to 3-5 days, far faster than the international average, meeting customers’ rapid time-to-market needs.

- Strict Quality Control and Compliance with International Standards: Leading Chinese PCB manufacturers generally hold international quality system certifications such as ISO 9001, IATF 16949 (automotive industry), and UL, and use advanced equipment such as AOI (Automated Optical Inspection) and X-ray inspection to ensure product yield. Key indicators of metal-based PCBs, such as thermal conductivity, withstand voltage, and dimensional accuracy, all comply with EU RoHS and REACH environmental regulations, reducing export compliance risks for customers.

- Rapid Technological Iteration and Outstanding Customization Capabilities: Chinese manufacturers continuously invest in the R&D of metal-based PCBs, mastering core technologies such as high thermal conductivity material formulations, microvia processing, and precision etching. Customized development of specialized substrates for special applications such as high-power LEDs, automotive electronics, and 5G communications is possible, including ultra-thin aluminum substrates (thickness below 0.3mm) and high-heat-dissipation copper substrates (thermal conductivity > 200W/m·K), meeting diverse customer needs.

- Leading Environmental Processes and Sustainable Green Manufacturing: Chinese PCB companies actively adopt environmentally friendly processes such as lead-free soldering, water-based inks, and waste gas recovery, reducing carbon emissions and harmful substance emissions during production. Metal substrates have a recyclability rate of up to 95%, meeting the requirements of European and American customers for a circular economy and ESG (Environmental, Social, and Governance) principles, helping customers enhance their brand image.

Top China Metal Clad PCB Manufacturers List

Shennan Circuits

- Business: High-end printed circuit boards, package substrates, electronic assembly.

- Strengths: Technologically advanced in metal-based PCBs (e.g., power amplifier metal substrates); products certified by multiple industry standards; offers end-to-end services from design to manufacturing. Its “power amplifier metal-based printed circuit boards” are recognized as a manufacturing single-champion product by the Ministry of Industry and Information Technology (MIIT).

Jingwang Electronics

- Business: Full-range PCB products including rigid, flexible, and metal-based circuit boards.

- Strengths: One of China’s few platform-type manufacturers covering rigid, flexible, and metal-based PCBs; leading domestic technology in metal-based PCBs (MPCB); integrates upstream metal-based copper-clad laminate resources; achieves higher product gross margins.

Sihui Fushi

- Business: High-reliability industrial PCBs including metal-based, rigid-flex, and HDI boards.

- Strengths: Focused on industrial and automotive sectors; products meet international reliability standards; well-regarded in Japanese markets; offers rapid response and customization capabilities.

Xingsen Technology

- Business: IC package substrates, PCB prototypes, and small-batch boards.

- Strengths: Deep technical accumulation in semiconductor test boards and package substrates; FC-BGA package substrates in small-batch production; expanding into high-end metal-based PCBs.

Yito Electron

- Business: High-precision multilayer boards, metal-based PCBs, thick copper boards.

- Strengths: Long-term supplier to international clients for automotive electronics and telecom equipment; stable quality systems and scalable delivery capabilities.

EBest Circuit (Best Technology)

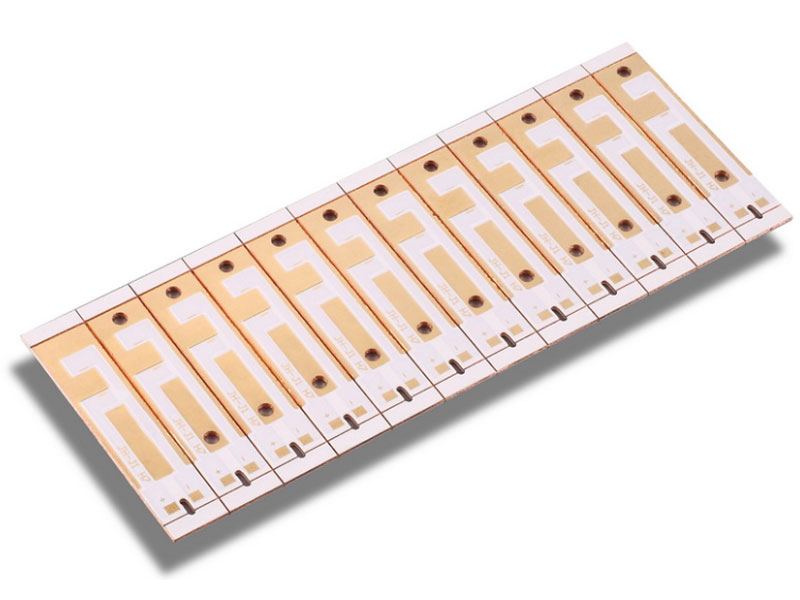

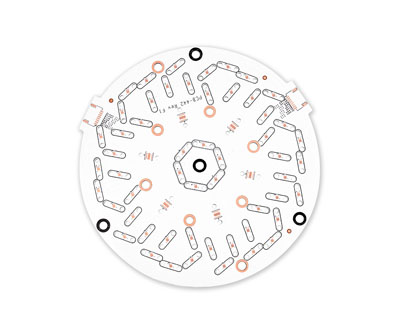

- Business: Specializes in metal-based PCBs (aluminum, copper) for LED lighting and power modules.

- Strengths: Patented technologies in thermal design and high-thermal-conductivity insulation layers; automated production lines with strong cost control.

Zhuoyue Huayu Circuits

- Business: Research, production, and sales of various metal-based PCBs.

- Strengths: Supplies high-end LED lighting brands with metal-based PCBs; holds multiple patents; products certified by UL, CE, and other international standards.

How to Choose China Metal Clad PCB Manufacturer?

1. Professional Qualifications and Industry Experience Verification

- Certification Standard Verification: Prioritize manufacturers with ISO 9001 quality management system certification, UL safety certification, and RoHS environmental certification. These internationally recognized certifications directly reflect the standardization of their production processes and the safety of their products.

- Industry Focus Assessment: Examine whether the manufacturer focuses on the metal substrate PCB field, rather than simply offering it as an ancillary product line for general PCBs. Check their website’s case study library to see if they have successful project experience in high-heat-dissipation-demand scenarios such as LED lighting, automotive electronics, and high-frequency communications.

- Technology Patent Reserves: Focus on whether the manufacturer possesses core technology patents in metal substrate material processing, thermal management design, and special surface treatments. This reflects their technological barriers and innovation capabilities.

2. End-to-End Quality Control System

- Raw Material Traceability Management: Require manufacturers to provide a supplier list and material testing reports for metal substrates (such as aluminum, copper, and stainless steel) to ensure that parameters such as substrate purity, thickness tolerance, and thermal conductivity meet international standards (such as IPC-4101).

- Production Process Monitoring: Focus on whether the company uses automated production lines combined with manual quality inspection, particularly its control over key process points such as drilling accuracy, circuit etching uniformity, and solder mask adhesion.

- Finished Product Testing Standards: Require third-party testing reports, including thermal resistance testing, withstand voltage testing, and salt spray testing, to ensure products meet the mandatory certification requirements of the target market (e.g., EU CE, US FCC).

3. Supply Chain Response and Delivery Capabilities

- Capacity Flexibility Assessment: Inquire about minimum order quantity (MOQ), delivery time (e.g., 7-14 days for standard parts, 15-30 days for customized parts), and peak capacity to ensure they match project timelines.

- Logistics Solutions: Inquire about partnerships with international express companies such as DHL and FedEx, or full container load (FCL) sea freight services, and clarify packaging standards (e.g., moisture-proof and shockproof packaging) and transportation insurance coverage.

- Inventory Management Transparency: For standard products, request a real-time inventory tracking system; for customized products, confirm the complete timeline from design confirmation to mass production.

4. Cost-Effectiveness and Pricing Transparency

- Quotation Structure Breakdown: A detailed quotation is required, including material costs, processing fees, mold fees, testing fees, etc., to avoid hidden charges. Compare quotations from multiple suppliers, but be wary of potentially low-priced quotes that may conceal quality risks.

- Cost Optimization Suggestions: Reputable manufacturers should provide Design for Manufacturability (DFM) feedback, such as optimizing panel structures to reduce material waste or recommending more economical surface treatment processes (e.g., HASL vs. ENIG).

- Long-Term Cooperation Agreements: For large-volume orders, tiered pricing or annual framework agreements can be negotiated to secure more favorable prices and priority in resource allocation.

5. Cross-Cultural Communication and Technical Support

- Multilingual Service Capability: Confirm that the sales team has English or the target customer’s language communication skills to avoid misunderstandings due to communication barriers.

- Technical Liaison Team: A dedicated engineer is required for technical liaison, providing value-added services such as thermal simulation analysis and electrical performance optimization, and supporting collaborative processes such as Gerber document review and BOM verification.

- After-sales service guarantee: Clearly define the warranty period (usually 1-3 years), return and exchange policy, and emergency response time (e.g., 24-hour technical support hotline).

Why Choose EBest Circuit (Best Technology) as China Metal Clad PCB Manufacturer?

Reasons Why Choose Us as China Metal Clad PCB Manufacturer:

- 19+ Years of Expertise in Metal Clad PCB Manufacturing: Deep industry accumulation ensures technical reliability from material selection to final delivery, providing mature solutions for complex designs.

- Free DFM (Design for Manufacturing) Analysis: Professional pre-production optimization identifies potential process risks early, reduces defects, shortens R&D cycles, and improves first-pass yield.

- 24-Hour Rapid Prototyping for Urgent Orders: Accelerates product verification and iteration, enabling faster time-to-market and competitive advantage.

- End-to-End One-Stop Solutions: Integrates design support, manufacturing, and assembly, minimizing cross-process communication costs and enhancing project efficiency.

- Rigorous Multi-Stage Quality Control System: Full-process control from raw materials to finished products, backed by ISO13485:2016, ISO9001:2015, IATF164949, REACH, and RoHS certifications, ensuring consistency and reliability.

- Strict Compliance with International Environmental Standards: Lead-free and halogen-free processes meet REACH and RoHS requirements, facilitating global market access and environmental compliance.

- Competitive Pricing with Guaranteed Quality: Scalable production, lean manufacturing, and optimized supply chains deliver cost efficiency without compromising quality.

- Dual Certifications for Medical & Automotive Applications: ISO13485 (medical) and IATF164949 (automotive) certifications validate expertise in high-reliability sectors, building trust in product performance.

- Customized Technical Collaboration & Support: Expert teams provide tailored design advice and process optimization to resolve challenges like thermal management and CTE matching, enhancing final product performance.

Our Metal Core PCB Manufacturing Capabilities

| Parameter Category | Specifications/Range |

| Base Material | Aluminum/Copper/Iron Alloy |

| Thermal Conductivity (Dielectric Layer) | 0.8 W/(m·K), 1.0 W/(m·K), 1.5 W/(m·K), 2.0 W/(m·K), 3.0 W/(m·K) |

| Board Thickness | 0.5mm~3.0mm (0.02â³~0.12â³) |

| Copper Thickness | 0.5 OZ, 1.0 OZ, 2.0 OZ, 3.0 OZ, up to 10 OZ |

| Outline Processing | Routing, Punching, V-Cut |

| Soldermask Color | White/Black/Blue/Green/Red Oil |

| Legend/Silkscreen Color | Black/White |

| Surface Finishing | Immersion Gold, HASL (Hot Air Solder Leveling), OSP (Organic Solderability Preservative) |

| Max Panel Size | 600mm à 500mm (23.62â³ Ã 19.68â³) |

| Packing Method | Vacuum Packaging/Plastic Bag Sealing |

| Sample Lead Time (L/T) | 4~6 Days |

| Mass Production Lead Time (MP) | 5~7 Days |

Our Quality Certifications for MCPCB

- ISO9001:2015

- ISO13485:2016

- REACH

- RoHS

- IATF16949

Case Studies of Our Metal Clad PCB Project

Case Name: Metal Clad PCB Solution for High-Power LED Street Light Cooling System

Client Background:

A European urban lighting equipment manufacturer plans to upgrade traditional high-pressure sodium street lights to high-brightness LED street lights to reduce energy consumption and extend service life. The original design used FR-4 substrate, which caused severe LED chip overheating and significant light degradation during prolonged full-power operation, leading to high maintenance frequency and substandard lifespan.

Core Issues:

- LED junction temperature exceeded 105°C, causing approximately 20% reduction in light efficiency;

- FR-4 substrate insufficient cooling in ambient temperature range of -20°C to 50°C, resulting in street light lifespan of only approximately 20,000 hours;

- High urban maintenance costs due to frequent lamp replacements.

Solution:

Material Selection

- Aluminum substrate with thermal conductivity of 2.0 W/(m·K) replaces traditional FR-4 (approximately 0.3 W/(m·K));

- Dielectric layer thickness of 0.1 mm ensures electrical isolation strength >2 kV while maintaining efficient thermal conduction.

Thermal Design Optimization

- Dense thermal vias placed beneath LED solder pads rapidly transfer heat from chips to aluminum substrate;

- Aluminum substrate back directly contacts heat sink housing, forming an integrated cooling path.

Manufacturing Process

- High-reflectivity white solder mask applied to enhance light output efficiency;

- Surface finish with ENIG (Electroless Nickel Immersion Gold) ensures solder joint reliability and environmental durability.

Implementation Results

- Thermal Performance Improvement: LED junction temperature reduced to below 85°C, light degradation decreased from 20% to less than 5%;

- Lifespan Extension: Average street light lifespan increased to 50,000 hours, meeting urban lighting needs for over 10 years;

- Cost Savings: System energy efficiency improved by approximately 15%, maintenance cycle extended from 2 years to over 7 years, saving approximately 30% in total lifecycle costs.

How to Get a Quote for Your Metal Clad PCB Project?

All Documents Required for Metal Clad PCB Quotation:

- Design File Package: Provide complete Gerber files (including outer/inner layer circuits, solder mask layer, silk screen layer), drilling files (Excellon format), BOM list (precise to component model/package/quantity), and schematics to ensure consistency with physical prototypes.

- Technical Parameter Specifications: Clarify layer count (e.g., 2-layer/4-layer), board thickness (1.6mm±0.1mm), copper thickness (1oz/2oz), solder mask color (green/black/blue), surface finish (HASL lead-free/ENIG/OSP), trace width/spacing (â¥5mil/5mil), hole diameter (starting from 0.2mm), impedance control values (e.g., 50Ω differential pair), and substrate material types (FR-4/aluminum/Rogers high-frequency material).

- Process & Quality Requirements: Indicate special process needs (blind/buried vias/back drilling), test point locations, solder mask opening dimensions, pad design rules (avoid overlap with vias), environmental standards (RoHS compliance), reliability test items (thermal shock/vibration tests), and certification marks (UL/CE/ESD symbols).

- Quantity & Logistics: Specify order volume (prototype/batch), lead time (e.g., 10-15 days for rush), packaging methods (antistatic blister box + moisture barrier bag), international shipping methods (air/sea freight), and destination customs documents (invoice/packing list).

- Structural & Ancillary Information: Submit structural element diagrams (including connector/mounting hole positions), no-routing zones, barcode placement (42Ã6mm), board edge clearance (â¥20mil), silk screen specifications (character height â¥50mil/uniform direction), and special area markings (high-voltage warning symbols/isolation strips).

Welcome to contact us if you have any request for metal clad printed circuit board: sales@bestpcbs.com.