China IMS PCB offers a new level of thermal performance compared to standard PCB, and that is why it has become the top choice for power electronics and LED applications. But is it always better than traditional PCB? Let’s explore the answer in detail.

EBest Circuit (Best Technology) is a reliable IMS PCB manufacturer and turnkey PCB Manufacturing service provider in China. We cater IMS PCB prototype, mass production, IMS PCB SMT assembly, and box build services in a truly free market. If you are looking for a decent quality China IMS PCB factory that is equipped with the cutting-edge manufacturing equipment and inspection apparatus, complete QC system, and strict test means, then EBest Circuit (Best Technology) is the way to go. For specific IMS in PCB questions and inquiries, please email us from our Contact Us page on the website.

What Does China IMS PCB Mean?

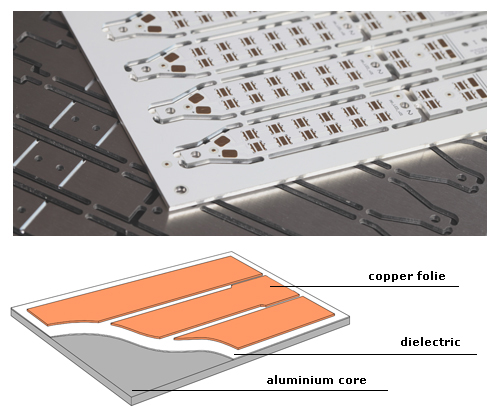

China IMS PCB stands for Insulated Metal Substrate PCB, manufactured by Chinese IMS PCB manufacturers. IMS PCB, also known as thermally conductive PCB, thermal PCB board, thermal Management PCB, and IMPCB.

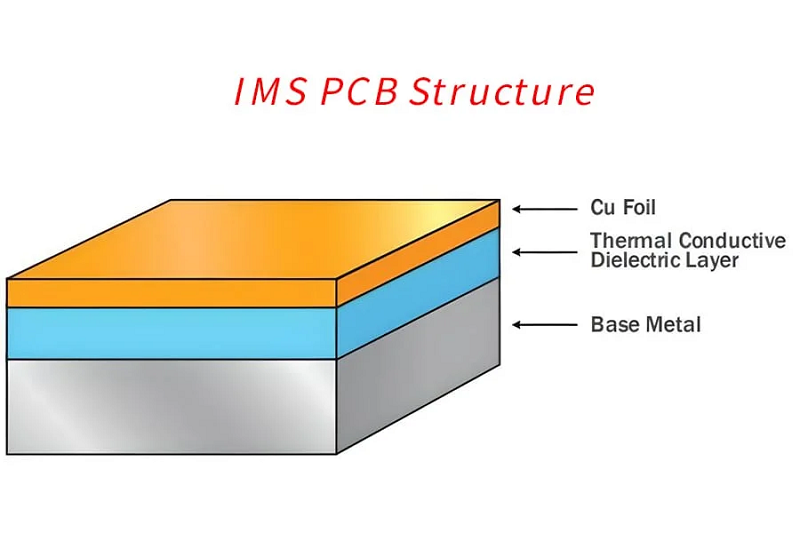

In China IMS PCB, the circuit is built on a metal base, usually aluminum or copper. The core of IMS technology lies in its thermally conductive yet electrically insulating layer, which sits between the metal base and the copper circuit layer. This dielectric is usually filled with ceramic particles, allowing it to conduct heat efficiently while keeping the electrical signals isolated. The thermal conductivity of this insulating layer typically ranges from 1 to 3 W/m·K, but some advanced materials used in high-end applications can exceed 5 W/m·K. Besides ceramic-filled materials, some IMS boards use advanced polymer-based insulating layers, which offer flexibility in thickness and can be tailored for specific thermal or electrical needs.

This design improves heat dissipation and structural strength. Unlike regular PCB made of FR4 material, IMS boards handle higher power loads with ease. Many China-based factories now focus on IMS production due to the growing demand in automotive, LED, and industrial sectors.

Who Are the Best China IMS PCB Manufacturers?

Choosing the right manufacturer can affect quality and cost. EBest Circuit (Best Technology) is a trusted name for China IMS PCB. We follow IPC standards, apply MES systems for traceability, and offer real-time quality monitoring. Our strength lies in custom thermal design, fast delivery, and flexible order sizes. Other reputable suppliers include A-Tech Circuits and JLCPCB.

What Is China IMS PCB Price?

The price of China IMS PCB depends on more than just size. Materials, design complexity, and special processing all affect the cost. Below is a detailed explanations to help you understand the key pricing factors.

1. Material Type

- Aluminum-Based IMS PCB: This is the most common choice due to its balance of cost and thermal performance. A 1.5mm thick aluminum IMS board typically costs around $0.20 per square inch.

- Copper-Based IMS PCB: Provides better thermal conductivity and durability, especially for harsh environments, but usually costs 1.5 to 2 times more than aluminum-based boards.

- Dielectric Layer: Thermal insulation materials filled with ceramic or polymer vary in price. High-conductivity dielectrics (>3 W/m·K) cost more than standard ones.

- Specialty Fillers: Advanced options like boron-filled dielectrics offer improved thermal stability but increase material cost by 10%–25%, depending on the formulation.

2. Thickness and Size

- Thicker Metal Cores (>2mm): These require more raw material and longer machining time, raising both material and processing costs.

- Larger Panel Size: Increases raw material use and slows production speed, slightly raising the per-unit price.

3. Layer Count

- Single-Layer IMS PCB: Most cost-effective; ideal for heat-sensitive, low-complexity designs.

- Double or Multi-Layer IMS PCB: Involve complex bonding and precision drilling, which increases both material cost and labor. These are 10%–30% more expensive than single-layer versions.

4. Surface Finish and Special Processing

- Surface Treatments: Options like ENIG or OSP add to the price. ENIG, for instance, offers better corrosion resistance but is costlier than basic HASL finishes.

- Diamond Cutting: Needed for clean edge finishes on thicker metal cores. This adds a processing premium of around 5%–10%.

- Solder Mask Type: High-temperature solder masks or UV-curable masks may also increase pricing slightly.

5. Comparison to FR4 PCB

- On average, China IMS PCB cost is 20%–50% higher than standard FR4 PCBs of similar dimensions.

- For example, a 1.5mm FR4 board might cost $0.10 per square inch, but lacks the heat handling and strength of IMS.

- The additional cost is often offset by the longer lifespan and reduced maintenance of IMS in demanding applications.

6. Order Volume

- Prototype Orders: Most Chinese suppliers allow no MOQ and quick turnaround for prototypes.

- Small Batch Orders: May include engineering setup fees ($20–$50) for design validation and tooling.

- Mass Production: Larger orders reduce cost per unit. Many suppliers offer tiered pricing, with better rates for orders over 1,000 units.

7. Value in High-Power Applications

- IMS PCBs perform better under thermal stress, so they reduce failure rates in power electronics, LEDs, and automotive systems.

- The higher upfront cost often pays off through longer service life and fewer field failures.

In summary, when assessing China IMS PCB price, it’s important to consider material type, layer count, special processing like boron-filled insulation, and order size. While IMS boards cost more than FR4, they deliver better thermal performance and reliability, especially in power-hungry designs. Over time, this can reduce maintenance costs and improve product lifespan—making IMS a smart investment for many applications.

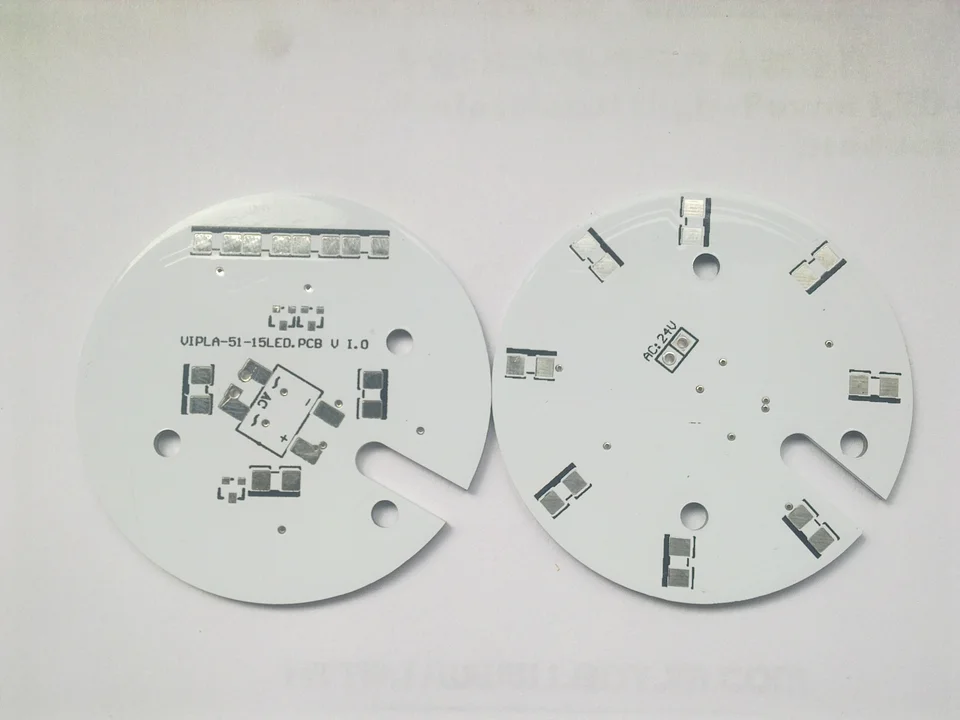

Why Do I Need China IMS PCB?

Thermal control is key in electronics. IMS in PCB helps to reduce heat buildup, which protects components and maintains performance. Applications such as LED lighting, power supplies, and EV chargers often generate excess heat. In these cases, using China IMS PCB can prevent failure. Also, the mechanical strength of metal-core boards improves vibration resistance. If your design needs better heat flow, IMS is worth the extra cost.

What Is the Difference: China IMS PCB vs PCB?

The main difference is in material and thermal performance. Standard PCB uses FR4, a fiberglass material, while IMS uses metal cores. FR4 PCBs have low heat conductivity (0.1 to 0.5 W/m·K), but IMS boards range from 1 to 12 W/m·K. This makes China IMS PCB ideal for high-power systems. However, IMS is less flexible in multilayer designs and costs more. On the other hand, FR4 is cheaper and easier for complex routing. So the choice depends on the application.

What Are the Pros and Cons for China IMS PCB vs PCB?

Here is a clear view of the pros and cons:

Pros of China IMS PCB

- Superior Thermal Control: Prevents overheating and extends component life.

- High Mechanical Strength: Reduces warping and improves durability in harsh environments.

- Ideal for Power Applications: Handles high currents with minimal heat rise.

- Better Heat Flow: No need for thermal vias, direct heat spread through metal core.

Cons of China IMS PCB

- Higher Cost: Material and tooling cost more than FR4 PCB.

- Limited Layer Count: Not suitable for complex, multilayer circuits.

- Thermal Stress Risks: Poor bonding or design can cause delamination in low-quality boards.

Why Choose EBest Circuit (Best Technology) as Your Dependable IMS PCB Manufacturer?

At EBest Circuit (Best Technology), we understand the headaches customers face when sourcing China IMS PCB. Poor thermal design, weak bonding, and long lead times can all lead to delays and failure. We solve these with:

- Thermal Simulation Support: We offer thermal modeling to guide your design and prevent hotspots.

- Advanced Materials: Our boards use hybrid cores and optimized dielectrics to improve heat flow and reduce stress.

- Reliable Production: Our MES system ensures traceability, and all boards pass IPC-compliant testing like thermal cycling. And all the fabrication process is in line with ISO 9001, ISO 13485, IATF 16949, AS9100D, UL, REACH, RoHS.

- Flexible Orders: We support no-MOQ prototypes and offer higher quality mass orders with short lead time.

- Application-Specific solutions: As we have 19 years of accumulation in the rapidly evolving world of electronics, you will get the benefits from our rich experience and technical knowledge to help you choose between FR4/IMS and get an ideal solution.

- Expert Support: From quoting to delivery, our engineers assist you in every step, ensuring clear communication and fast turnaround.

Our clients appreciate not only our quality but also our commitment to problem-solving. With China IMS PCB, success is in the details, and we handle those with care.

To sum up, China IMS PCB brings real advantages in heat management, mechanical strength, and durability. While it comes at a higher cost, the benefits often justify the price in high-power settings. However, design and manufacturing skills make a significant difference.

That’s why working with EBest Circuit (Best Technology) gives you unmatched precision, reliability, and cutting-edge solutions tailored to your needs. Our thermal modeling, strict quality control, and fast delivery remove the usual risks. So if you need reliable IMS PCB solutions, contact us today for a quote. Our engineers are very responsible, caring, professional, experienced, and knowledgeable. They were always available to discuss your case and have returned your phone calls in a timely manner. Please discuss your full requirements with our teams at +86-755-2909-1601 or sales@bestpcbs.com.