Burn-in test plays a critical role in electronics manufacturing where long-term reliability matters as much as performance. Engineers often rely on burn-in procedures to expose early-life failures before products reach the field. Whether used for high-reliability PCBA, industrial controllers, or medical electronics, this method helps stabilize product quality while reducing unexpected returns.

Below is a practical, engineering-focused guide explaining how burn-in testing works, why it matters, and how it applies specifically to PCB assemblies.

What Is a Burn-In Test in Electronics?

A burn-in test is a reliability testing process used in electronics manufacturing to identify early-life failures in electronic components, PCBs, and assembled electronic products.

During a burn-in test, electronic devices are operated under elevated stress conditionsâsuch as higher temperature, voltage, or loadâover a defined period of time. Components that are defective or marginal are more likely to fail during this phase rather than later in real-world use.

In simple terms:

Burn-in testing accelerates failure so weak components fail earlyâbefore products reach customers.

Burn-in tests are widely used in:

- PCB manufacturing and PCB assembly (PCBA)

- Power electronics

- Automotive electronics

- Aerospace and defense systems

- Medical devices

- Industrial control equipment

- Telecommunications hardware

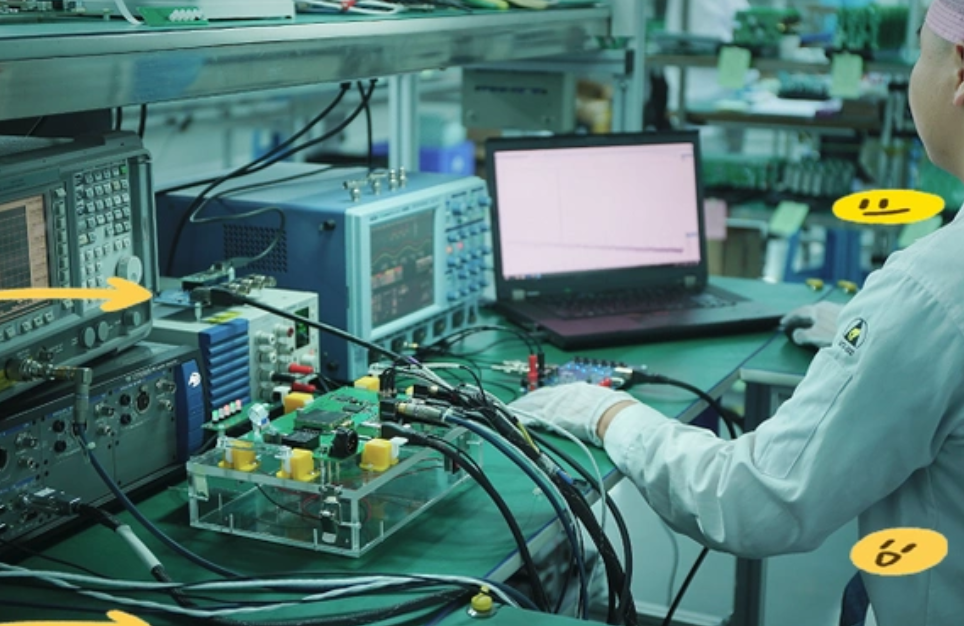

Burn-in Testing

What Is the Purpose of a Burn-In Test?

The primary purpose of a burn-in test is to improve product reliability and reduce field failures.

More specifically, burn-in testing is designed to:

- Detect early-life failures (infant mortality)

- Screen out defective components

- Verify design robustness

- Stabilize electrical performance

- Reduce warranty returns and RMA costs

Electronics failures often follow the bathtub curve, where failure rates are high at the beginning, low during normal life, and rise again at end-of-life. Burn-in testing targets the first phase of this curve.

Why Is a Burn-In Test Important?

Burn-in testing plays a critical role in quality assurance (QA) and reliability engineering.

Key Benefits of Burn-In Testing

1. Reduces Early Field Failures

Burn-in tests catch problems such as:

- Poor solder joints

- Marginal ICs

- Weak capacitors

- Manufacturing defects

- Thermal design issues

2. Improves Brand Reputation

Products that fail shortly after installation damage customer trust. Burn-in testing helps ensure only stable and reliable products ship.

3. Saves Cost in the Long Term

While burn-in testing adds upfront cost, it significantly reduces:

- Warranty claims

- Product recalls

- Field repair costs

- Customer downtime

4. Required by High-Reliability Industries

Industries such as medical, aerospace, automotive, and military electronics often require burn-in testing as part of regulatory or contractual standards.

How to Do a Burn-In Test?

A burn-in test procedure varies depending on the product, industry, and reliability requirements, but the core steps are similar. Typical burn-in test procedure including:

Step 1: Visual & Electrical Pre-Inspection

Before burn-in:

- Visual inspection (AOI or manual)

- Basic electrical tests (continuity, shorts, power-on test)

- Ensure boards are safe to energize

Step 2: Load the PCB or Device into Burn-In Fixtures

PCBs or assemblies are mounted in:

- Burn-in racks

- Test sockets

- Custom fixtures

- Edge connectors or cable harnesses

Fixtures allow:

- Power supply access

- Signal monitoring

- Temperature exposure

Step 3: Apply Electrical Stress

The device is powered on continuously or in cycles using:

- Rated voltage or slightly elevated voltage

- Simulated operating loads

- Functional test patterns

Step 4: Apply Thermal Stress

Temperature is raised using:

- Burn-in ovens

- Environmental chambers

- Heated racks

Typical burn-in temperatures:

- 55°C to 85°C for commercial electronics

- 85°C to 125°C for industrial or automotive electronics

Step 5: Continuous Monitoring

During the test:

- Voltage and current are monitored

- Functional signals are checked

- Failures are logged automatically or manually

Step 6: Post Burn-In Inspection

After burn-in:

- Functional testing

- Electrical performance verification

- Visual inspection for thermal damage

- Failed units are analyzed and scrapped or repaired

What Equipment Is Needed for Burn-In Testing?

Burn-in testing requires specialized equipment to safely operate electronics under stress for long periods.

Common Burn-In Test Equipment

1. Burn-In Chambers / Ovens

- Temperature-controlled environments

- Uniform heat distribution

- Safety protection and airflow control

2. Burn-In Racks & Fixtures

- Hold PCBs or assemblies vertically or horizontally

- Provide power and signal connections

- Custom-designed for product type

3. Power Supplies

- Stable, programmable DC power supplies

- Over-current and over-voltage protection

4. Data Acquisition & Monitoring Systems

- Voltage/current monitoring

- Temperature sensors

- Failure logging software

5. Functional Test Systems

- Automated test equipment (ATE)

- Simulated loads

- Communication interfaces (RS485, CAN, Ethernet, etc.)

How Long Is a Burn-In Test?

The duration of a burn-in test depends on:

- Product complexity

- Reliability requirements

- Industry standards

- Cost considerations

Typical Burn-In Test Duration

| Application | Burn-In Time |

| Consumer electronics | 8â24 hours |

| Industrial electronics | 24â72 hours |

| Automotive electronics | 72â168 hours |

| Aerospace / military | 168â500+ hours |

Shorter burn-in tests are often used for screening, while longer tests are used for qualification and validation.

Burn-In Test for PCB and PCBA

A burn in test for PCB or PCBA focuses on identifying assembly-related and component-level issues.

What Burn-In Testing Detects in PCBs

- Cold solder joints

- Micro-cracks in solder

- Poor component placement

- Thermal expansion issues

- Marginal ICs

- Power instability

PCB Burn-In vs Functional Testing

| Test Type | Purpose |

| Functional Test | Verifies correct operation |

| Burn-In Test | Screens early failures |

| Thermal Cycling | Tests expansion/contraction |

| HALT/HASS | Stress limit testing |

Burn-in testing is not a replacement for functional testingâit is a complementary reliability process.

How to Tell If a Circuit Board Is Burnt?

A burnt PCB usually shows visible, electrical, or functional symptoms.

Visual Signs of a Burnt PCB

- Discoloration (brown or black areas)

- Burn marks or charring

- Melted solder or components

- Cracked IC packages

- Delaminated PCB layers

Electrical Symptoms

- Short circuits

- Abnormal current draw

- Voltage drops

- Failure to power on

Functional Symptoms

- Intermittent operation

- Random resets

- Overheating

- Communication errors

Burn-in testing often reveals latent damage that may not be obvious in quick functional tests.

Can a Burnt PCB Be Repaired?

Whether a burnt PCB can be repaired depends on damage severity.

Repairable Cases

- Burnt passive components (resistors, capacitors)

- Minor trace damage

- Isolated solder joint failures

Non-Repairable Cases

- Carbonized PCB substrate

- Internal layer damage (multilayer PCB)

- Widespread delamination

- Repeated thermal failure

In high-reliability industries, burnt PCBs are usually scrapped, not repaired, due to long-term reliability risks.

Burn-In Test vs Other Reliability Tests

| Test Method | Main Purpose |

| Burn-In Test | Early failure screening |

| Thermal Cycling | Mechanical stress testing |

| HALT | Find design limits |

| HASS | Production screening |

| Aging Test | Long-term performance |

Burn-in testing remains one of the most cost-effective reliability screening methods in electronics manufacturing.

FAQs

1. Is burn-in testing mandatory?

No, but it is highly recommended for high-reliability or mission-critical electronics.

2. Does burn-in testing damage electronics?

When properly controlled, burn-in testing does not damage good productsâit only accelerates failure in weak units.

3. What temperature is used in burn-in testing?

Typically 55°C to 125°C, depending on component ratings and standards.

4. Is burn-in testing expensive?

It adds cost, but often reduces total lifecycle cost by preventing failures in the field.

5. Can burn-in testing replace functional testing?

No. Burn-in testing supplements functional and electrical testing.

6. What standards reference burn-in testing?

Common references include:

- MIL-STD-883

- JEDEC standards

- IPC reliability guidelines