Why choose BGA assembly? Let’s discover definition, pros and cons, application, assembly process, quality control methods, package types for BGA assembly.

Are you troubled with these problems?

- Solder joint voiding/shorting causing yield stuck below 95%?

- Struggling with 01005 components & 0.25mm BGA pitch—high density, long cycle times?

- Prototype validation taking 7 days? Slowing time-to-market?

As a BGA assembly manufacturer, EBest Circuit (Best Technology) can provide you service and solutions:

- Solder joint precision ≤0.02mm, yield >99.8%: eliminate voiding/shorting, cut rework costs by 30%.

- Full support for 01005/2mil trace/space/0.25mm BGA pitch: over 5,000 solder joints per board, 40% smaller size with 50% higher functionality.

- 7-day rapid prototyping: 4 SMT lines + 2 BGA lines sync operation, 40% faster than industry average, doubles product lifespan.

Welcome to contact us if you have any inquiry for BGA assembly service: sales@bestpcbs.com.

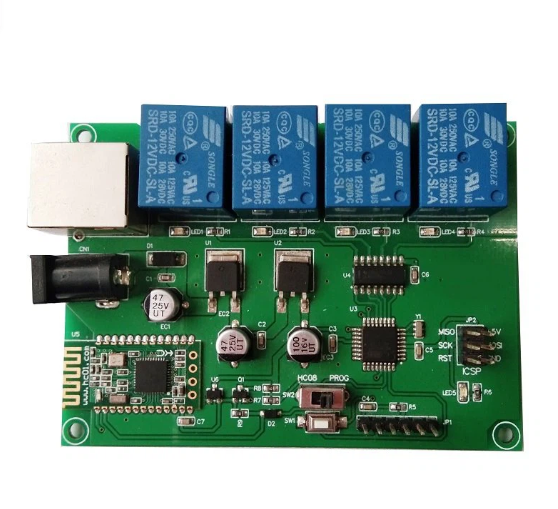

What Is BGA Assembly?

BGA Assembly is an advanced packaging process that achieves electrical connection between integrated circuits (ICs) and printed circuit boards (PCBs) through an array of solder balls arranged at the bottom. Its core feature lies in replacing traditional pins with tin balls, forming high-density, low-resistance interconnection structures via reflow soldering technology. This approach is particularly suited for high-pin-count, high-performance chips such as processors and GPUs.

What Are Pros and Cons of BGA Assembly Service?

Advantages of BGA Assembly Service

- High density and miniaturization: Ball grid array layout increases pin count per unit area by 30%-50%. For equivalent capacity, its volume is only one-third of TSOP packages, suitable for miniaturization needs of high-pin-count chips like CPUs and GPUs.

- Superior electrical performance: Short-path design reduces parasitic inductance/capacitance, cutting signal transmission delay by 40%-60%. Supports high-frequency applications above 100MHz and high-speed communication with 2-3 times improved crosstalk resistance.

- Outstanding thermal efficiency: Solder balls increase contact area by 3-5 times. Combined with metal substrates or thermal materials, chip operating temperature decreases by 15-20°C, ideal for high-power scenarios like servers and automotive electronics.

- High mechanical reliability: Solder ball structure buffers thermal expansion stress, improving shock resistance by 50%. Suitable for vibration-prone environments like mobile devices and industrial controls, reducing failure rates by 30%.

- Optimized production efficiency: Reflow soldering self-alignment reduces placement errors, improving yield by 10%-15%. Automated equipment supports mass production, cutting costs by 20%-30%

Disadvantages of BGA Assembly Service

- Complex inspection and repair: Requires X-ray/industrial CT for internal defect detection (e.g., voids, cracks) with high equipment costs. Rework needs specialized hot air guns or laser reflow devices. BGA becomes non-reusable post-removal, increasing repair costs by 50%-100%.

- High costs and technical barriers: Materials (e.g., lead-free solder balls), equipment (high-precision pick-and-place machines), and inspection costs are 30%-50% higher than traditional QFP packaging. Process control requires ±0.05mm placement accuracy.

- Environmental sensitivity: Requires strict storage conditions (humidity <10% RH, temperature 20-25°C). Prolonged logistics may cause solder ball oxidation, affecting welding quality.

- Coplanarity and warpage risks: Full-array packaging demands coefficient of thermal expansion (CTE) matching between substrate and PCB (difference <5ppm/°C). Otherwise, coplanarity errors or post-soldering warpage may cause voids or shorts.

- Competition from alternative technologies: Faces competition from CSP, flip-chip, and other packaging technologies. Requires continuous innovation (e.g., 3D stacked BGA) to maintain market edge, increasing R&D costs by 20%-30%.

Applications of BGA Assembly

- Smartphones and tablets: Processors, memory chips, and RF modules.

- Laptops: CPUs, GPUs, and mainboard components.

- Server systems: Data center CPUs, GPUs, and storage controllers.

- High-end graphics cards and workstations: High-speed computing modules.

- 5G base stations and network equipment: Switch/router integrated circuits.

- Automotive systems: ADAS domain controllers, navigation units, and control modules.

- Industrial automation: Microprocessors for harsh environment equipment.

- Aerospace systems: Satellite/radar microprocessors and image processors.

- Medical devices: CT machine data processors and patient monitor chips.

- AI and quantum computing: Multi-chip module (MCM) integration platforms.

What Problems Can BGA Assembly Solve?

- Enhanced Routing Density: BGA’s bottom grid array design achieves over 1,000 I/O integrations at 0.4mm pitch, increasing pin density by 3-5x compared to traditional QFP packaging. This resolves routing constraints in compact spaces like smartphones and servers. For instance, 0.3mm pitch BGA with laser soldering technology improves ball placement yield to 99.7%, enabling high-density layouts.

- Signal Stability Optimization: Differential routing and impedance matching (e.g., PCIe 85Ω/100Ω standards) minimize high-speed signal crosstalk and reflections in 5G base stations and high-end GPUs. Blind/buried via technology shortens signal paths, reducing losses and ensuring stability in high-frequency scenarios.

- Thermal Efficiency Improvement: Spherical solder joints expand heat dissipation area, combined with ceramic substrates, thermal via arrays, and heat sinks, to address overheating in high-power chips like GPUs and FPGAs, extending device lifespan.

- Process Reliability Enhancement: X-ray inspection and SPC (Statistical Process Control) mitigate hidden defects like voiding and opens in solder joints. Moisture sensitivity classification (per J-STD-020) and baking processes prevent package warpage, while CTE-matched designs reduce solder fatigue in automotive/industrial environments.

- Cost-Performance Balance: Standardized packaging supports automated SMT assembly, while HDI (High-Density Interconnect) technology optimizes routing density. This balances performance upgrades with PCB layer count and material cost control, ideal for mass production in consumer electronics. For example, PBGA packaging reduces costs by 30% compared to CBGA while maintaining electrical performance.

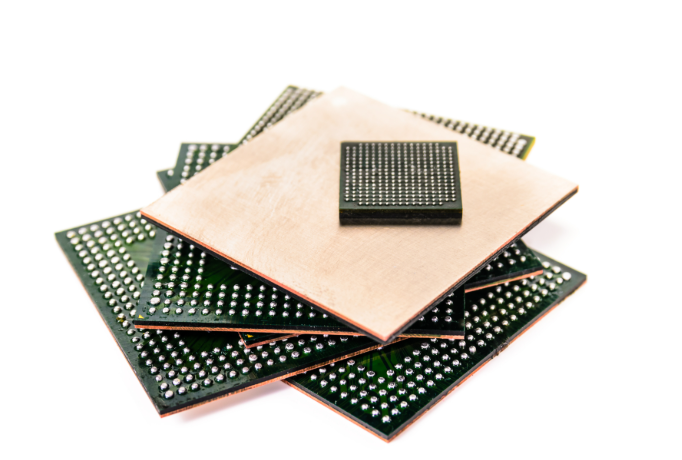

Common BGA Package Types

PBGA (Plastic Ball Grid Array)

- Substrate: BT resin/glass laminate, solder balls made of 63Sn37Pb eutectic or lead-free solder.

- Features: Low cost, good thermal matching (CTE ≈14ppm/°C), compatible with PCB (CTE ≈17ppm/°C), supports self-alignment soldering.

- Applications: Consumer electronics chips like CPUs and GPUs, e.g., Intel Pentium II/III/IV processors.

- Limitations: Susceptible to moisture (requires moisture-proof packaging), reliability affected by “popcorn effect,” slightly taller than QFP.

CBGA (Ceramic Ball Grid Array)

- Substrate: Multilayer ceramic, solder balls use 10Sn90Pb high-temperature solder, requires low-temperature solder for auxiliary connection.

- Features: Excellent air tightness (moisture resistance), low thermal conductivity (ceramic substrate CTE ≈7ppm/°C), superior heat dissipation, good electrical insulation.

- Applications: High-reliability scenarios like aerospace and military, early Intel Pentium Pro processors.

- Limitations: High cost, significant thermal expansion coefficient difference with PCB (causing thermal stress), solder joint fatigue failure risk.

TBGA (Tape Ball Grid Array)

- Substrate: PI multilayer wiring substrate, solder balls use high-melting-point solder (e.g., 10Sn90Pb), soldered with low-melting-point solder.

- Features: Ultra-thin profile (thickness ≤1mm), better heat dissipation than PBGA, good thermal matching with flexible tape and PCB.

- Applications: Mobile devices and high-frequency communication chips, e.g., smartphone processors.

- Limitations: Moisture sensitivity, reliability affected by multi-material combinations, larger self-alignment deviation.

FCBGA (Flip-Chip Ball Grid Array)

- Structure: Chip flip-mounted, connected to substrate via gold bumps or high-lead solder (e.g., 90Pb10Sn).

- Features: High density (pin count >1000), short signal paths (low inductance/capacitance), supports 3D stacking.

- Applications: High-performance computing like server CPUs/GPUs, Intel Pentium III mobile processors.

- Limitations: Complex process, requires precise placement accuracy (±0.05mm), underfill needed for mechanical strength.

CCGA (Ceramic Column Grid Array)

- Structure: Solder columns (diameter 0.5mm, height 1.25-2.2mm) replace solder balls, mitigating thermal stress.

- Features: Strong fatigue resistance, suitable for high-vibration environments (e.g., automotive electronics).

- Applications: Industrial controls, automotive ECUs, long-term reliability scenarios.

Micro BGA/High-Density BGA

- Features: Solder ball pitch ≤0.5mm (Micro BGA) or ≤0.3mm (high-density BGA), pin density increased by 300%.

- Applications: Portable devices (e.g., smartwatches), high-performance microprocessors, ultra-thin design (thickness <1mm).

- Challenges: Requires X-ray/CT inspection for internal defects, high repair costs, sensitive to humidity (<10% RH).

EBGA (Enhanced Ball Grid Array with Heatsink)

- Structure: Integrated metal heatsink or thermal spreader for enhanced heat dissipation.

- Applications: High-power chips (e.g., server CPUs), optimized thermal performance via thermal interface materials (TIMs).

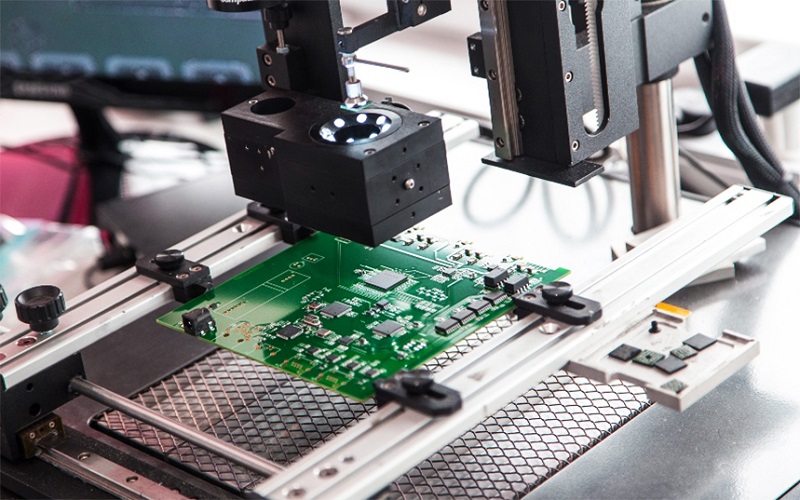

BGA Assembly Process Flow

1. Solder Paste Printing Precision Control

- Utilize 0.12-0.15mm thick stencils with laser-cut apertures to ensure solder paste volume deviation ≤10% for 0.4mm pitch BGA pads. For sub-0.3mm fine-pitch applications, adopt Type 4 solder paste (particle size 15-25μm) with printing speed 30-50mm/s and squeegee pressure 5-10N to prevent solder defects like insufficient solder, bridging, or collapse. Implement AOI systems for real-time monitoring and automatic adjustment for pads with ≥0.1mm misalignment.

2. 3D SPI Detection & Closed-Loop Feedback

- Employ phase-measuring profilometry (PMP) 3D SPI technology for full-field detection of solder paste volume, height, and shape, unaffected by PCB color/reflection. Data feeds back to the printer for dynamic adjustment of squeegee pressure or stencil cleaning. Integrate SPC control to trigger automatic alarms for consecutive critical defects, enabling proactive process optimization.

3. High-Precision Placement & Vision Alignment

- Placement machines achieve positioning accuracy ≤±0.03mm and repeatability ≤±0.015mm, with nozzles matched to BGA size/weight. Control placement pressure within 5-20N to avoid PCB warping or pad damage. Post-placement verification via dual-camera vision systems ensures alignment accuracy <1/4 pad diameter; misalignment >0.1mm triggers automatic rework.

4. Reflow Soldering Profile Optimization

- Customize four-stage temperature profiles based on solder paste melting points (e.g., 217-227°C for lead-free solder): preheat (150-180°C/60-90s), soak (180-210°C/30-60s), reflow (peak 20-30°C above melting point/30-45s), and cooling (≤4°C/s gradient). Nitrogen atmosphere (O₂ <500ppm) reduces oxidation and void rates. Control furnace temperature uniformity within ±2°C and conveyor speed 50-100cm/min.

5. Multi-Stage Cleaning & Residue Control

- Remove flux residues using water-based/semi-aqueous cleaning processes to prevent ionic contamination. For BGA pads, employ specialized cleaners with solder wick to ensure surface flatness. Post-cleaning X-ray inspection verifies solder joint quality, with void rates <25% and no defects like cold joints or bridges.

6. X-ray & AOI Synergistic Inspection

- 3D X-ray CT scans detect internal defects (voids, cracks, missing solder balls), while 2D X-ray focuses on center and perimeter regions. Post-reflow AOI performs three-point correlation analysis to trace defect origins. Data links to equipment via IPC-CFX protocol for smart factory integration.

7. Electrical Testing & Functional Verification

- ICT tests detect solder bridges, opens, and component failures; FT validates circuit continuity and signal integrity. Environmental stress screening (85°C/85%RH/1000h) and ESS accelerate defect detection. Test coverage meets AQL 1.0 standards for reliability assurance.

8. Rework Process & Quality Control

- Use hot-air rework stations for BGA removal (preheat ≤120°C, removal temperature matching peak reflow profile). Clean pads and re-place components with secondary vision alignment. Post-rework executes 100% X-ray inspection and functional testing per IPC-7095C standards, with full process data logged for traceability.

Quality Inspection Methods for BGA Assembly

1. Visual Inspection and Surface Defect Screening

- Application Scenario: First-article and in-process monitoring on production lines.

- Technical Points: Use high-magnification microscopes (≥20X) to inspect solder ball appearance, focusing on bridges, solder balls residue, solder collapse, and oxidation. According to IPC-A-610 standards, the solder wetting angle must be ≤90°, with pad coverage ≥75%.

- Limitations: Only detects surface defects; cannot evaluate internal joint integrity.

2. X-ray Inspection Technology (2D/3D)

- 2D X-ray: Uses planar imaging to detect two-dimensional defects like solder shift, shorts, or insufficient solder volume. Overlapping depth data may cause misjudgment (e.g., stacked layer shadows). Equipment like the YXLON Cougar S series achieves 1μm resolution.

- 3D X-ray (CT Scanning): Employs tomography for 3D modeling, quantifying void ratios, crack lengths, and interface bonding states. Per IPC 7095, Class 3 products require void diameters ≤30% (or area ≤9%); medical/military sectors demand ≤25%. Space-grade BGA mandates total void area ≤5%.

3. Ultrasonic Scanning Acoustic Microscopy (C-SAM)

- Principle: Utilizes 50MHz ultrasonic waves to detect delamination, voids, and interface defects via reflection differences. Excels at identifying microvoids ≤50μm.

- Case Study: Automotive MCUs undergo C-SAM validation post -40°C~125°C thermal cycling, requiring delamination area ≤10% of joint cross-section. “Popcorn effect” (moisture-induced cracking) is detectable via abnormal attenuation coefficients.

4. Thermal Imaging Testing

- Thermal Analysis: Infrared thermal cameras monitor temperature distribution during BGA operation; faulty joints show ≥5°C abnormal rises. Dynamic load testing locates thermal failure points.

5. Electrical Performance Testing

- Electrical Test Systems: ICT/Flying Probe: Tests open/short circuits via PCB contact points; 0.4mm-pitch BGA requires spring-loaded probe arrays (±0.02mm accuracy).

- Boundary Scan (JTAG): IEEE 1149.1-compliant chip self-testing verifies logic functions and pin connectivity with ≤0.1% false error rates.

- High-Frequency Signal Testing: 1GHz+ signals demand insertion loss ≤0.5dB, phase shift ≤5°, using shielded chambers (≥80dB@1GHz) to avoid EMI.

6. Destructive Physical Analysis

- Red Dye Penetration Test: Dye penetration visualizes voids/cracks in joint cross-sections. Requires 100°C/4h baking for dye curing, with ≥25mm cutting margins to prevent artificial damage.

- Shear Strength Testing: JEDEC standards mandate 6gf minimum shear force for 0.8mm-pitch balls; automotive-grade components require ≤15% strength degradation post-125°C/2000h aging.

- Metallographic Cross-Section Analysis: Samples embedded in cold resin undergo grinding/polishing for SEM crack analysis (≤50μm acceptable), paired with EDS for elemental anomaly detection.

7. Environmental Stress and Reliability Verification

- Thermal Cycling: -40°C~125°C for 1000 cycles (500 cycles for industrial), 1h per cycle; crack growth ≤50μm. Automotive-grade components require AEC-Q200 certification for 10-year equivalent lifespans.

- Humidity Testing: 85°C/85%RH for 1000h; insulation resistance ≥10MΩ, solder corrosion ≤5%.

- Mechanical Shock: 1500g/0.5ms pulse simulates drop impacts; no package detachment or joint cracking.

Why Choose EBest Circuit (Best Technology) as BGA Assembly Manufacturer?

Reasons why choose us as BGA assembly manufacturer in China:

- Ultra-Precision BGA Ball Placement Process with Yield Exceeding 99.8%: Achieves solder ball position accuracy ≤0.02mm through precision mechanical calibration and multi-stage verification, eliminating void soldering/short-circuit risks while reducing client rework costs by over 30%.

- Ultra-Fine Pitch PCBA Integration Capability: Supports 01005 component packaging, 2mil line width/spacing, and 40μm laser microvias. Enables integration of over 5,000 BGA solder joints per board, reducing product volume by 40% while increasing functional density by 50%.

- 7-Day Rapid NPI Verification Service: Four fully automated SMT lines + two dedicated BGA packaging lines enable prototype delivery within 7 days, 40% faster than industry average, accelerating time-to-market for clients.

- DFM-Driven Cost Optimization Solution: Optimizes BGA packaging layers through Design for Manufacturability (DFM) analysis, combined with cost-effective material substitution and bulk procurement advantages, reducing total PCBA costs by 15% for enhanced market competitiveness.

- End-to-End Transparent Quality Control: MES system enables full barcode traceability from material intake to final shipment, with real-time cloud synchronization of critical process parameters. Clients gain instant access to production progress and quality reports for zero-distance quality monitoring.

- Green Manufacturing Compliance System: Uses lead-free solder paste and halogen-free substrates with 100% compliant wastewater/gas emissions. ISO 14001 certified, ensuring seamless compliance with EU RoHS/REACH regulations to avoid trade barriers.

- Multi-Scenario Failure Analysis Support: Equipped with X-ray inspection, ultrasonic scanning microscopy, and cross-section analysis tools. Offers 24/7 failure analysis services with root cause reports delivered within 48 hours to minimize production line downtime.

- Agile Supply Chain Assurance System: Strategic inventory partnerships with top-tier component manufacturers reduce critical material lead time to 3 days. Multi-site factory coordination ensures stable delivery of large-volume orders while mitigating supply chain risks.

Our BGA Assembly Capabilities

| Item | Capabilities |

| Placer Speed | 13,200,000 chips/day |

| Bare Board Size | 0.2″ × 0.2″ – 20″ × 20″ / 22″ × 47.5″ |

| Minimum SMD Component | 01005 (0.4mm × 0.2mm) |

| Minimum BGA Pitch | 0.25mm (10mil) |

| Maximum Components | 50mm × 150mm (Board Area) |

| Assembly Type | SMT / THT / Mixed Assembly |

| Component Package | Reels / Cut Tape / Tube / Tray / Loose Parts |

| Lead Time | 1 – 5 days (Standard) |

How to Get a Quote for BGA Assembly Services?

All documents required to obtain a quote for BAG assembly services:

- Submit Design Files: Provide Gerber files, a bill of materials (BOM) (including BGA model/parameters), PCB design drawings, and 3D models (if available). Ensure the file version is the final production version.

- Specify BGA technical details: Indicate the BGA pad size, ball diameter, ball pitch (e.g., 0.25mm), package type (e.g., PGA/LGA), and solder requirements (e.g., lead-free/lead-containing).

- Confirm production capacity and delivery time: Indicate annual demand, batch order quantity, and target lead time (e.g., 7 days/15 days/30 days). Indicate whether expedited service is required.

- Specify testing standards: Indicate whether X-ray inspection, AOI optical inspection, flying probe testing, or functional testing is required, and whether third-party certification (e.g., AEC-Q100) is required.

- Indicate material sources: Specify the sourcing method (customer-furnished/contract manufacturing) for BGA chips and other key components, as well as brand preference (e.g., Intel/AMD/Murata).

- Fill out the Quote Request Form: Submit the Quote Request Form containing the above information via our official website or designated email address, along with contact information and decision-maker information for follow-up.

Welcome to contact us if you have any request for BGA assembly services: sales@bestpcbs.com.