Exciting news for all PCB designers, engineers and related industries!

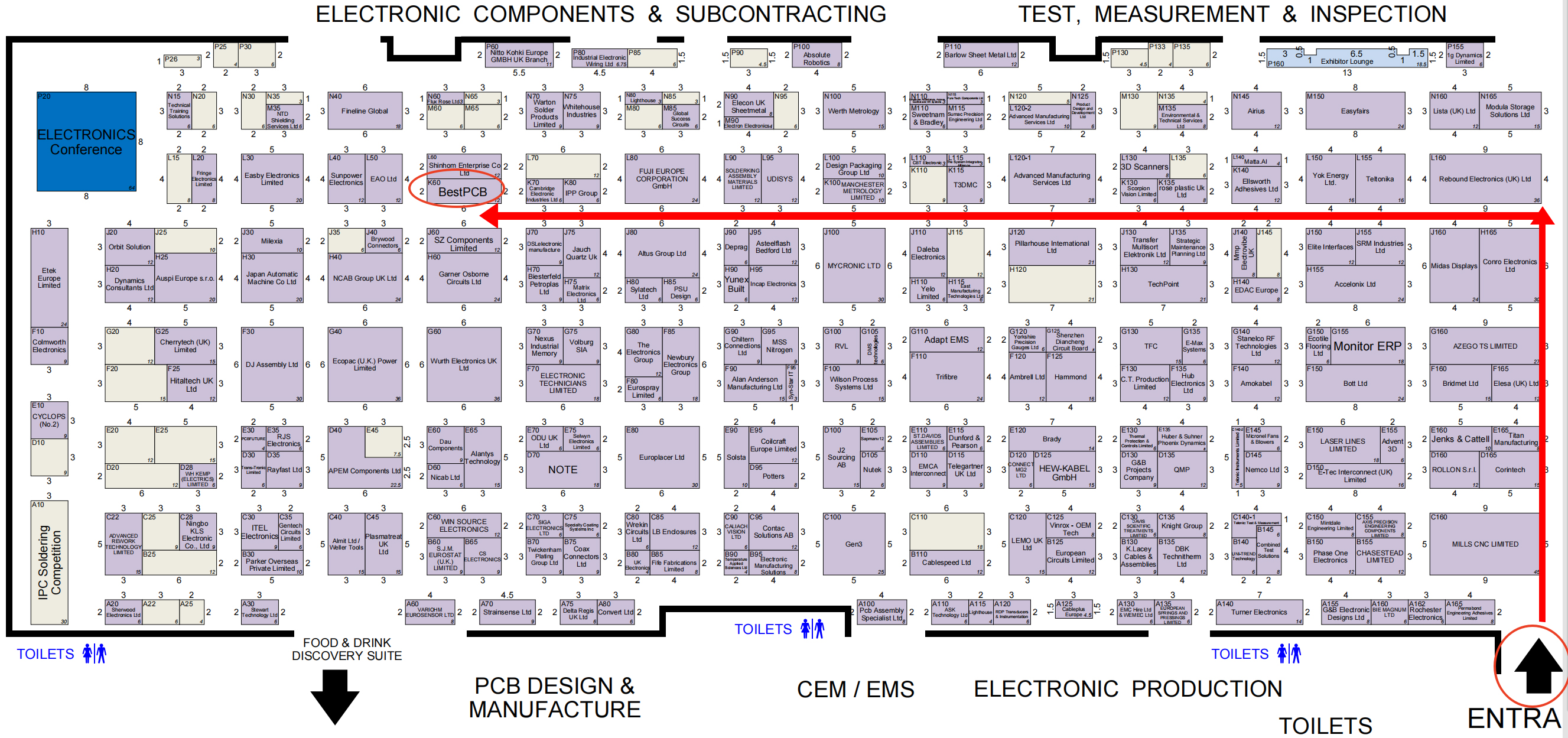

EBest Circuit (Best Technology), one of Chinaâs most trusted PCB manufacturing and assembly partners, is thrilled to announce our participation at Southern Manufacturing & Electronics 2026, taking place in the UK from February 2ndâ5th (Western Time). Youâll find us at Booth No. K60 â ready to connect, collaborate, and inspire.

If you missed meeting us at New Tech or PCB West, this is your perfect opportunity to catch up with our team in person!

What Youâll See at Booth K60

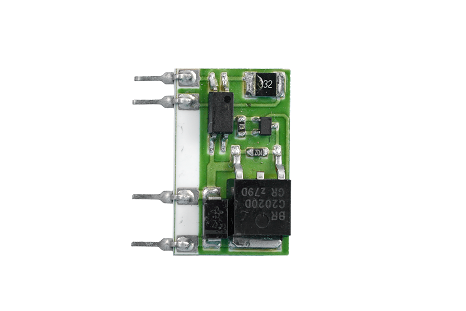

At the show, youâll get hands-on insights into our advanced PCB manufacturing and assembly technologies. Our engineers will be available to discuss every step of the process â from PCB rapid prototyping to low and high-volume production â and demonstrate how we achieve precision, reliability, and speed in every board we produce.

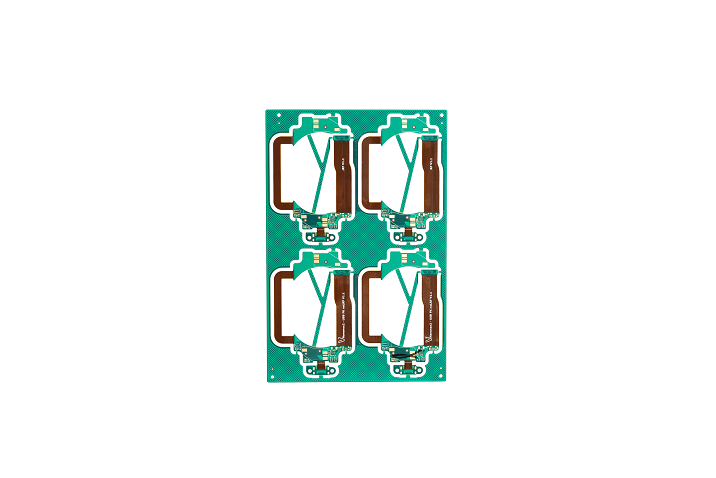

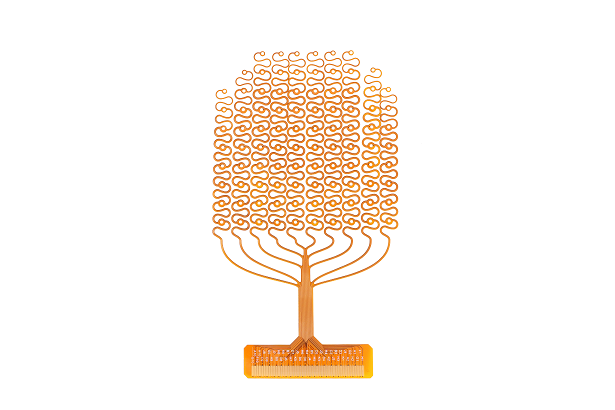

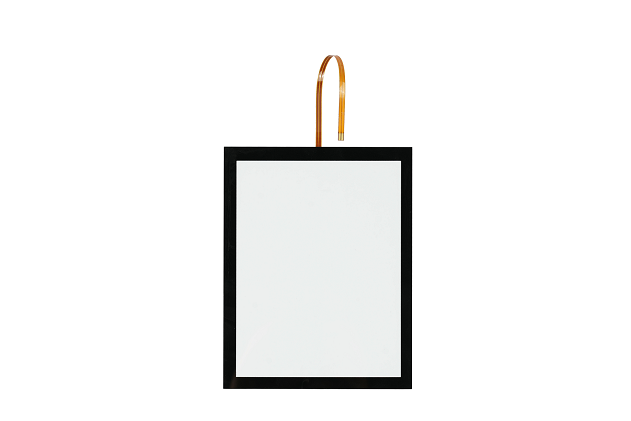

Visitors can explore a full spectrum of PCB solutions, including:

- Flexible and rigid-flex circuits (2â50 layers)

- Copper weights ranging from 1/2 OZ to 30 OZ

- Ultra-thin FR4 PCBs (as thin as 0.15mm)

- Heavy copper boards for power-intensive designs

- Embedded Busbar PCBs for high current & high power devices

- Comprehensive services, from component sourcing and board fabrication (FPC, PCB, MCPCB, Ceramic PCB) to final assembly, programming, and testing

Our full turnkey service covers everything from component sourcing, PCB fabrication, SMT assembly, testing, programming, to final system integrationâall handled under one roof for seamless project execution.

What Youâll Learn

During the exhibition, our engineering team will be available to discuss:

- How we minimize component wastage through process optimization

- Strategies to reduce production costs and shorten lead times

- The latest trends in PCB technology

- Best practices for reliable high-density interconnect (HDI) designs

Whether you are in the early stages of product design or managing mass production, our experts will share actionable insights to help streamline your next project.

Event Details

Show Opening Times:

- Tuesday, February 3: 09:30 â 16:30

- Wednesday, February 4: 09:30 â 16:30

- Thursday, February 5: 09:30 â 15:30

Address: Farnborough International Exhibition Centre, UK â Hall 1

If you want to know more about this showcase, click below:

Southern Manufacturing & Electronics 2026.

Why Work with EBest Circuit (Best Technology)?

- 19+ years experienced in PCB manufacturing

- Wide Product Range: Ceramic PCB, HDI, Heavy Copper, IC Substrate & more

- One-Stop Services: PCB Design, Assembly, Testing, Box Build

- Full Certifications: ISO9001 | ISO13485 | IATF16949 | AS9100D | UL | RoHS

- FREE Stack-Up Suggestions

- Free DFM, DFA and DFT check

- 100% original components from authorized distributer

- 100% Testing – Flying probe, function testing, ICT, etc

- Quality control system – X-ray, AOI, FAI

- IPC class II, IPC class III, IPC 3/A standard

Join Us in the UK

If you missed meeting us at New Tech or PCB West, this is your next chance to connect in person. Stop by our booth to see how weâre advancing PCB performance through innovation, precision, and dedication to quality.

We look forward to meeting you in Farnborough, UK, and discussing how EBest Circuit (Best Technology) can support your next electronics project.