This blog helps you choose the best prototype PCB manufacturer wisely and introduces how Best Technology stands out in the competitive PCB prototype market. We should choose the right partner who not only has the advantage of making a board but also solves challenges during the early product stages.

Best Technology is one of the best prototype PCB manufacturers in China, not only providing reliable Prototype PCB but also providing comprehensive solutions about the PCB series. Our engineers master sophisticated technology, which gives us access to solve problems like poor thermal management and soldering issues. Best Technology invites state-of-the-art equipment like 3D AOI/X-Ray to micro short circuits and cold soldering. Maintaining the consistency of quality is our corporate responsibility. Kindly contact us at sales@bestpcbs.com for our best prototype PCB support.

What is the best prototype PCB manufacturer?

Finding the best prototype PCB manufacturer depends on several key factors. These include turnaround time, quality control, technical support, and flexibility in small-batch runs. Top prototype PCB board manufacturers also offer online quoting, real-time tracking, and quick modifications based on client feedback. Customers often struggle with slow updates during design changes. The best companies tackle this with agile communication and in-house engineering teams who respond fast.

Moreover, a reliable prototype manufacturer supports you with design tips that reduce failure and speed up revisions. They ensure traceability, offer material flexibility, and run advanced testing like 3D AOI or X-ray, which prevents hidden defects early on.

Who is the largest PCB manufacturer in the world?

The largest PCB manufacturer globally is often considered to be Zhen Ding Tech Group from Taiwan. They serve large-volume OEMs in smartphones and computing. However, being the biggest doesnāt mean being the best for prototypes. Big players focus on mass production. They may lack the agility and quick-turn services startups and R&D teams need.

In contrast, specialized prototype manufacturers like Best Technology focus on one-off or small-batch needs. We prioritize speed, communication, and design support. Thatās what most design engineers and procurement managers need when testing a new idea.

Who is the best prototype PCB manufacturer in the USA?

Several companies in the USA are known for rapid prototyping, including Advanced Circuits, Sierra Circuits, and Sunstone Circuits. These companies offer good services, but many U.S. customers still seek more responsive support, faster turnaround, and a cost-effective balance.

Best Technology, while based in Asia, serves many U.S. clients with local sales reps and round-the-clock support. We offer U.S.-level quality with better pricing and faster delivery. For example, if there is an urgent need, BEST can deliver a 6-layer prototype within 24 hours, including impedance control and surface finishing.

How to make PCB prototyping?

PCB prototyping includes a few steps:

- Design & DFM Check ā You upload your Gerber files and BOM. A good manufacturer provides feedback to avoid design traps like acid traps, poor copper clearance, or edge spacing errors.

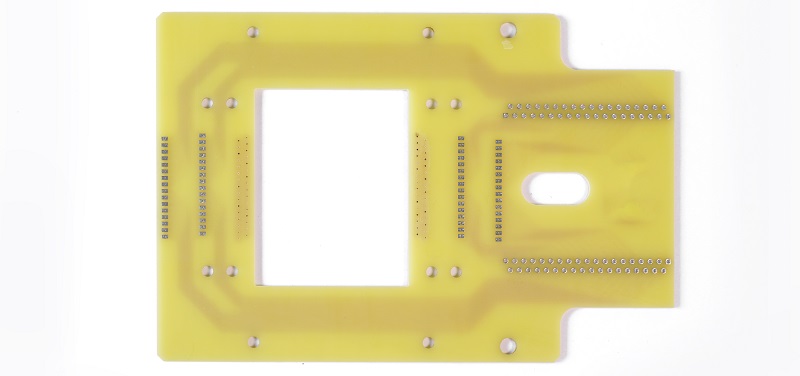

- Material Preparation ā The factory prepares copper-clad laminates based on your specs.

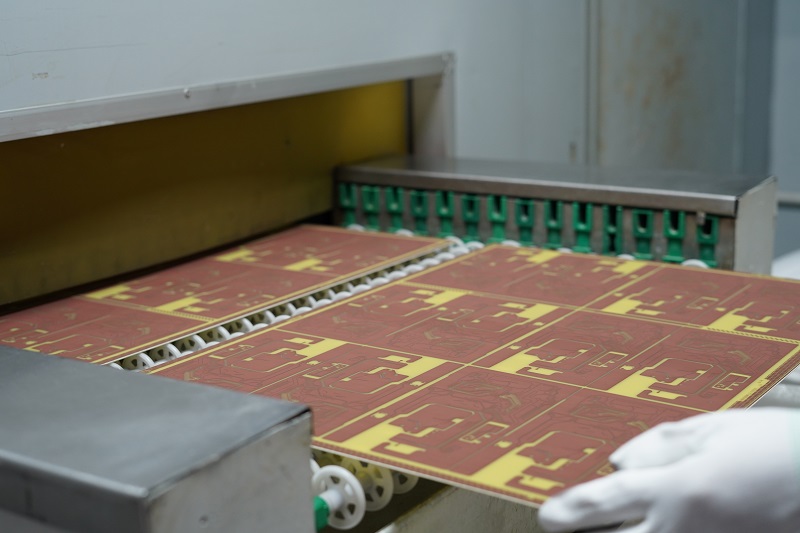

- Imaging & Etching ā The circuit pattern is printed and etched on the board.

- Drilling & Plating ā Holes are drilled, plated through, and surface finishes applied.

- Testing ā AOI, flying probe, and sometimes X-ray for assembly.

- Assembly (optional) ā Soldering components based on BOM.

The entire cycle is often slowed by unclear feedback or lack of engineering support. Best Technology offers real-time DFM correction and dedicated engineers to follow up your prototype from start to end.

How much does prototype PCB assembly cost?

The cost of prototype PCB assembly varies depending on board complexity, layers, finish type, component count, and urgency. A simple 2-layer PCB might cost under $100 for bare boards and $200ā$400 for turnkey assembly. A complex 6-layer impedance-controlled board with BGA components may exceed $1,000. Rush fees, part sourcing, and inspection methods (like X-ray) also affect the price.

One major pain point for customers is cost control during prototyping. Best Technology addresses this by offering flexible quotes, suggesting alternate components, and combining small batches when possible. This reduces waste and keeps performance balanced with cost.

How to choose a best prototype PCB manufacturer?

When choosing a prototype PCB board manufacturer, focus on:

- Speed: Do they offer real 24-hour service or just advertise it?

- Communication: Can you get fast feedback, especially during design changes?

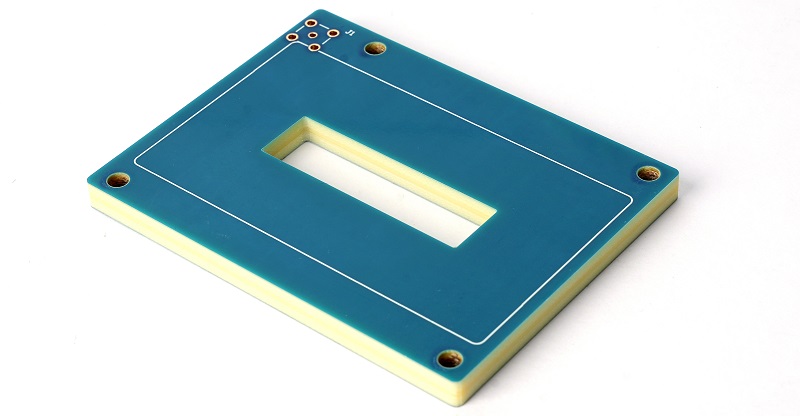

- Technology: Do they support HDI, RF, impedance control, or aluminum PCBs?

- Testing: Do they use 3D AOI, flying probe, and X-ray?

- Support: Is there technical help for stack-up, layout, and component replacement?

Companies like Best Technology meet all the above. We also offer thermal cycling testing, salt spray tests, and humidity simulations to ensure your prototype works in real-world conditions that is an edge many prototype manufacturing companies ignore.

Why should you choose Best Technology as your best prototype PCB manufacturer?

Best Technology isnāt just a prototype PCB manufacturer. We are your solution partner. Here are our competitive advantages:

- Quick Response to Iterations: Design changes can be applied within hours. BEST uses digital workflows to shorten response time.

- Real 24-hour Turnaround: We have a separate line for urgent prototype projects. Six-layer boards can be finished within 24 hours and are fully tested.

- Cost Flexibility: BEST offers tiered pricing and design advice to keep cost and performance aligned. No hidden fees, even on low-volume projects.

- Advanced Testing: Using X-ray, 3D AOI, and impedance scans to detect short circuits or cold joints during early testing. You donāt have to wait until the final build to find out somethingās wrong.

- Real Environmental Testing: Salt spray, humidity, and temperature cycling tests (-40ā to 125ā) can be done on request. This is vital for automotive, outdoor, and industrial IoT devices.

- End-to-End Support: From layout reviews to stack-up consulting, BESTās engineers help you avoid manufacturing traps like acid traps, trace voids, and via-in-pad issues.

- Smooth Transition to Mass Production: Your prototype is reviewed for volume production readiness. We assure you that there will be no surprise rejections later.

When you choose Best Technology, you get more than a board. You get the all-round solution for your PCB needs. Our proactive support ensures you test your design faster and move to market sooner.

As a final point, choosing the best prototype PCB manufacturer is more than just finding a fast PCB prototype service supplier. The best prototype PCB manufacturer provides specific solutions that reassure you as well.

Best Technology has a competitive edge in speed, communication, cost, and quality to support your PCB project directly. From advanced quality inspections and fast PCB prototype service to full technical support and final testing, Best Technology gives your prototype the best support. Plus, with certifications like ISO 9001, ISO 13485, IATF 16949, and AS9100D, we meet the strict industry standards for the medical, automotive, and aerospace sectors. We use the MES system that guarantees full traceability in material incoming inspection and real-time material using control in PCB manufacturing. Don’t hesitate to reach out to us at sales@bestpcbs.com if you have any PCB prototype demands for support.