Looking for annular ring PCB solutions? Let’s dive into its benefits, application, design tips, and why choose EBest Circuit (Best Technology) as an annular ring PCB partner.

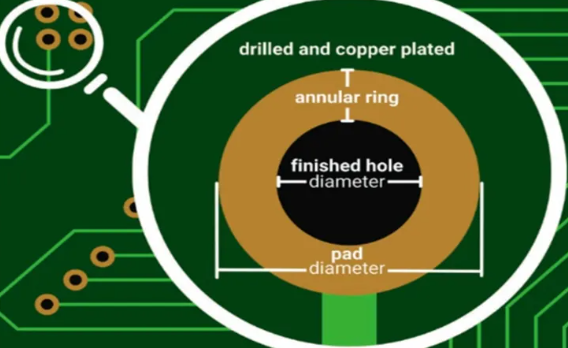

What Is Annular Ring In PCB?

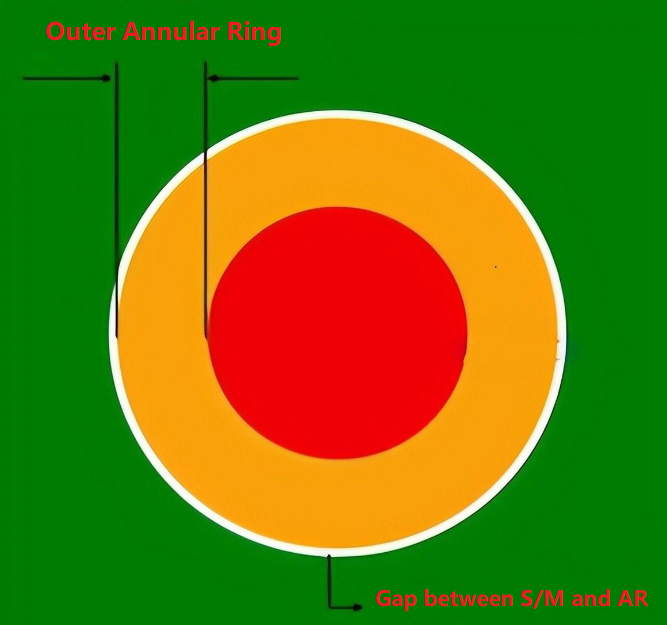

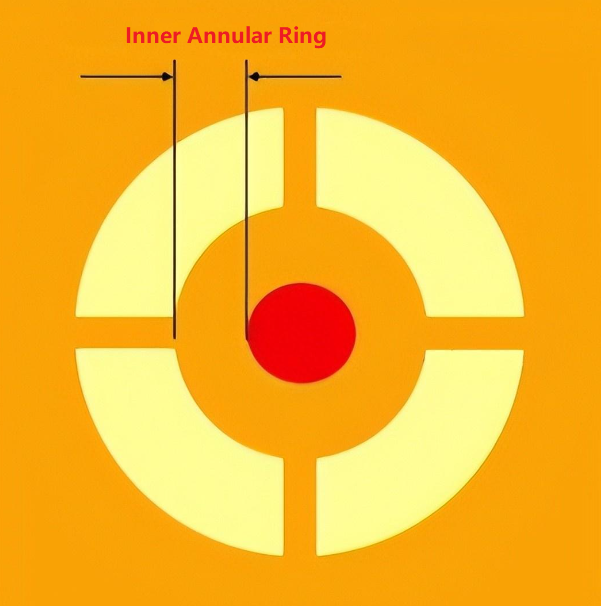

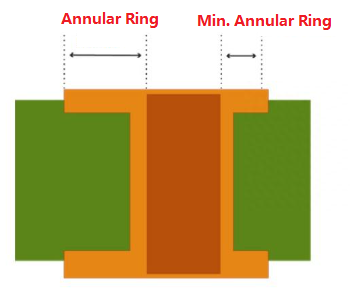

Annular ring in PCB refers to the copper pad area that surrounds a drilled hole, typically used for vias or component mounting. It is the conductive material that connects the hole to the surrounding traces or planes. The annular ring is a critical aspect of PCB design, as it ensures proper electrical connectivity and mechanical stability for components and vias.

Why Is the Annular Ring PCB Important?

The annular ring plays a vital role in PCB functionality and reliability. Here’s why it matters:

- Electrical Connectivity: Ensures reliable connections between holes (e.g., via, component pins) and surrounding circuitry by maintaining sufficient copper contact around drilled holes.

- Mechanical Stability: Reinforces the structural integrity of holes, reducing risks of pad lift-off or breakage during assembly, thermal cycling, or mechanical stress.

- Manufacturing Tolerance Compensation: Acts as a buffer for drilling misalignment, ensuring the hole remains within the conductive pad area even with slight positional deviations.

- Signal Integrity: Minimizes impedance discontinuities and reflections by maintaining consistent copper coverage around high-speed/high-frequency signals.

- Current-Carrying Capacity: A wider annular ring supports higher current loads by increasing the copper cross-sectional area, preventing overheating or track failure.

- Weldability & Solder Joint Quality: Provides a sufficient solder anchor point for through-hole components, ensuring robust mechanical and electrical bonds during wave soldering or hand assembly.

- Design Rule Compliance: Facilitates adherence to industry standards (e.g., IPC-6012) for minimum annular ring widths, ensuring manufacturability and long-term reliability.

- Layer-to-Layer Connection Integrity: In multilayer boards, intact annular rings prevent via defects (e.g., ‚Äúnecking‚ÄĚ or barrel cracks) that could compromise interlayer conductivity.

- Thermal Management: Enhances heat dissipation for high-power components by providing a low-resistance thermal path from the hole to the copper plane.

- Design for Excellence (DFX): Enables design flexibility for features like tear-drop pads, which strengthen weak points where traces meet pads, reducing fracture risks.

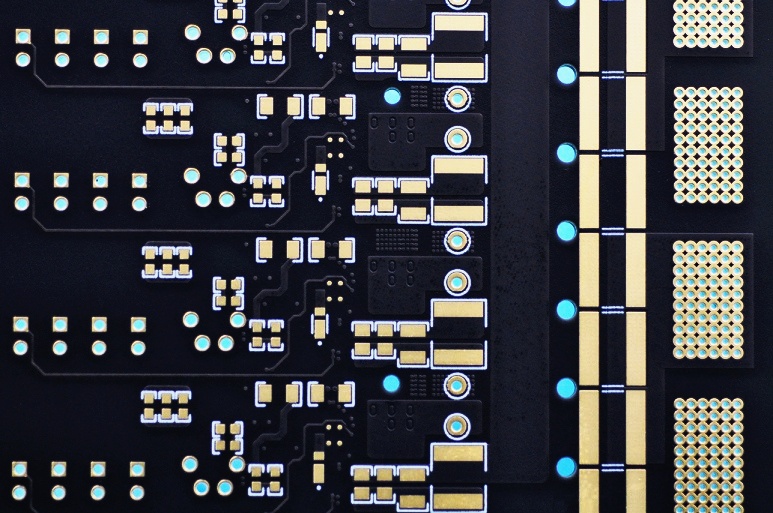

Applications of Annular Ring PCB

- Applications of Annular Rings in PCB Design

- Component Mounting: Secure through-hole parts (e.g., connectors, switches).

- Vias: Connect layers in multi-layer boards (e.g., smartphones, IoT devices).

- High-Speed Circuits: Maintain signal integrity in 5G/RF designs.

- Power Delivery: Support high-current paths for motor drivers.

- Flexible PCBs: Prevent pad cracking in bending zones.

- Automotive/Aerospace: Withstand vibration and thermal stress.

- Medical Devices: Ensure reliability in critical applications.

- Thermal Management: Link to heat sinks via thermal vias.

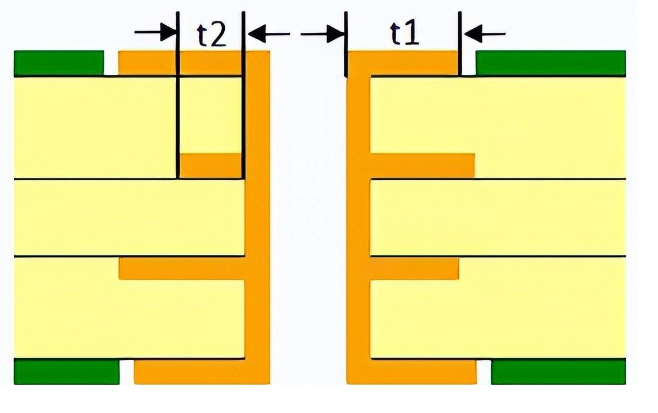

Design Considerations for Annular Ring

When designing PCBs, it’s essential to consider the following factors related to annular rings:

- Width: Maintain ‚Č•0.15mm (6 mils) for reliability; increase for high-stress areas.

- Drill Size: Balance hole size with pad space; avoid oversizing to prevent weakness.

- Layer Alignment: Ensure precise registration (¬Ī0.075mm tolerance) for multilayer boards.

- Material Thickness: Thicker boards require wider rings (‚Č•0.2mm) for connectivity.

- Thermal/Mechanical Stress: Use tear-drop pads or wider rings (‚Č•0.25mm) for durability.

- Signal Integrity: Keep widths consistent for high-speed circuits; avoid impedance variations.

- Assembly Clearance: Leave ‚Č•0.2mm between rings and adjacent components for soldering.

- Cost vs. Quality: Adjust widths based on application (e.g., 0.1mm for economy designs).

- Testing: Validate rings via cross-section analysis and electrical tests.

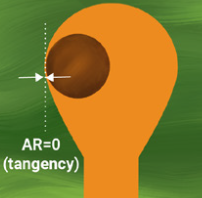

Common Issues with Annular Ring PCB

- Breakout: Misaligned drilling causes holes to exceed pad boundaries, weakening connections.

- Weak Connections: Insufficient width leads to poor solder joints or pad lift-off.

- Signal Integrity Problems: Inconsistent widths create impedance discontinuities.

- Thermal Stress Fractures: Narrow rings crack under repeated heating/cooling cycles.

- Drill Deviation: Worn tools or poor registration enlarge holes, reducing annular ring margins.

- Plating Voids: Uneven copper deposition in holes weakens annular ring conductivity.

- Over-Etching: Excessive chemical etching undercuts pads, narrowing annular rings.

- Mechanical Stress: Vibration or bending tears thin annular rings in rigid-flex designs.

- Material Thickness Mismatch: Thick boards with small rings increase breakout risks.

- Design Rule Violations: Ignoring IPC standards (e.g., minimum width) causes manufacturing failures.

How to Optimize Annular Ring in PCB Design

Below are ways to how to optimize annular ring in PCB design:

- Adhere to Standards: Follow IPC-2221/IPC-6012 for minimum width (e.g., 0.05mm for Class 3 boards).

- Design Software Tools: Use EDA tools (e.g., Altium, KiCad) for DRC checks and 3D visualization.

- Material Selection: Choose for high-TG laminates to reduce thermal expansion affecting annular rings.

- Thermal Management: Increase ring width or add thermal vias for heat-generating components.

- Signal Integrity: Maintain consistent impedance by controlling trace-to-ring spacing.

- Cost-Quality Balance: Widen rings for critical circuits; use narrower rings for non-critical areas.

- DFM Checks: Validate designs for drill registration, copper weight, and aspect ratio.

- Laser Drilling: For microvias, ensure annular rings ‚Č•0.075mm to prevent breakout.

- Tear-Drop Pads: Strengthen trace-to-pad junctions in high-flex or high-vibration applications.

- Test Protocols: Use microsectioning and flying probe tests to verify annular ring quality.

- Documentation: Clearly annotate ring requirements on fabrications drawings for manufacturers.

Why Choose EBest Circuit (Best Technology) As a Annual Ring Manufacturer?

- 18+ Years of Experience: With over 18 years in the PCB industry, we have the expertise to deliver high-quality annular ring PCBs tailored to your needs.

- Competitive Pricing: We offer the best quality products and services at the most competitive prices, ensuring value for your investment.

- No MOQ & Fully Flexible: Whether you need a prototype or medium-volume production, we accommodate orders of any size with no minimum order quantity.

- 99% On-Time Delivery: We prioritize timely delivery, ensuring your projects stay on schedule.

- ISO-Certified Quality: Our manufacturing processes adhere to ISO9001, ISO13485, and IATF16949 standards, guaranteeing reliable and consistent quality.

- Comprehensive Services: From PCB fabrication to assembly, component sourcing, and testing, we provide a one-stop solution for all your PCB needs.

- Industry-Specific Expertise: We understand the unique requirements of industries like medical, automotive, and aerospace, ensuring your PCBs meet the highest standards.¬† 8. Customer-Centric Approach: Our goal is “Total Customer Satisfaction,” and we work closely with you to meet your specific requirements.

Contact Us Today

For high-quality PCBs with precise annular rings, trust EBest Circuit (Best Technology). Contact us today to discuss your project requirements and get a quote: sales@bestpcbs.com.