You may have found such a situation, most of the PCB boards are with green colors, while other colors are relatively rare to see, do you know why?

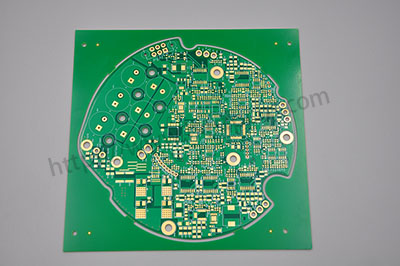

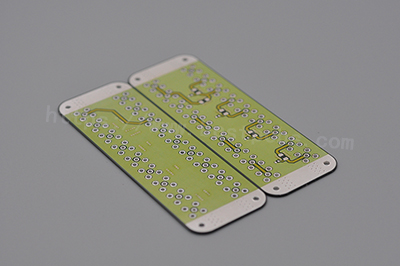

As we know that the Printed Circuits Board consists of Solder Mask Layer, Silk screen layer, solder PAD, Copper traces, surface finishing and other parts, etc.

Among them, the solder mask refers to the part of the PCB that is covered by oil. Since most PCB boards use green oil, the part of the green oil that can be seen on the board surface is the solder mask, which play an important role during the reflow soldering process.

Then why are most of the PCB boards green? The main reasons are as follows:

- Green is less irritating to the eyes. We all know that green is good for the eyes and can resists fatigue. So when the PCB board with green solder mask, relative production and maintenance personnel are not prone to eye fatigue when staring at the PCB board for a long time, and it is less harmful to the eyes.

2. Cost for Green oil is lower. Since green is the mainstream in the production process, the purchase of natural green oil will be larger, and the purchase cost of green solder mask will be lower than other colors. At the same time, using the same color oil in mass production can also reduce the replacement cost.

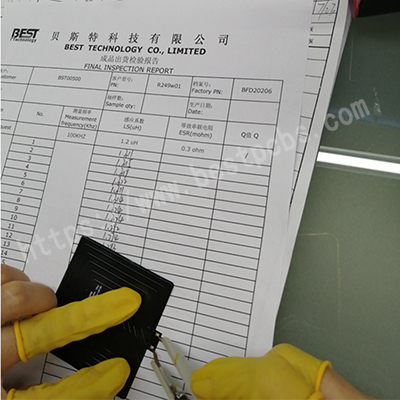

- When the board works on the SMT soldering process, it needs to go through the process from Tinning, post soldering and final AOI inspection. These processes all need to be optically positioned and calibrated. The green background color is better for the recognition of the instrument.

Okay, now, do you understand why most of PCB boards are with green colors?

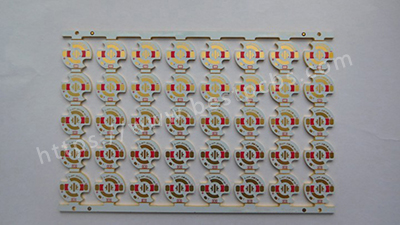

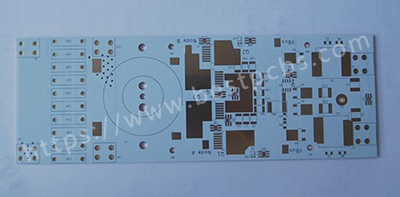

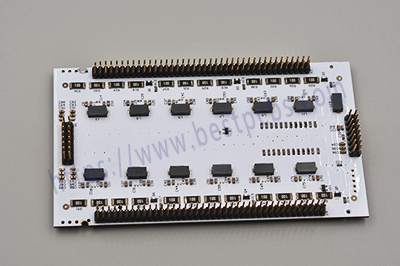

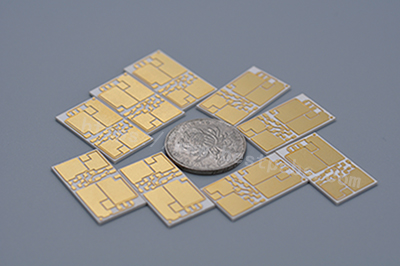

Though we know green is the most common one, but other colors such as red, yellow, blue, purple, black or some other colors are okay for us to make.

If you have PCB board with a special color want to make, please contact us and we will try best effort to meet your request.