Looking for a reliable PCB manufacturer in Spain? This blog is mainly about list, selection guide, quality certification, production capability of PCB manufacturer in Spain.

Top PCB Manufacturer in Spain List

| Company Name | Main Business | Core Advantages | Process Capability | Lead Time |

| EBest Circuit (Best Technology) Co.,Ltd (Global PCB Manufacturer) | Custom PCB manufacturing, rigid PCB, flexible PCB, rigid-flex PCB, HDI PCB, automotive PCB, aerospace PCB | 19+ years of experience, global quality certification, one-stop solution, 24/7 technical support | 1-40 layers, HDI up to 12+2L, minimum line width/spacing 2.5mil/2.5mil | Prototype: 2-5 days; Mass production: 7-15 days |

| Elektroprint PCB Spain S.L. | Rigid PCB, standard PCB, industrial control PCB | Local production base, fast prototype delivery | 1-16 layers, minimum line width/spacing 4mil/4mil | Prototype: 3-7 days; Mass production: 10-20 days |

| PCB Iberica S.A.U. | Consumer electronics PCB, medical equipment PCB | Medical certification advantage, stable quality | 1-20 layers, HDI up to 8+2L | Prototype: 4-6 days; Mass production: 8-18 days |

| Tecnodise√Īo PCB S.L. | Automotive PCB, industrial PCB | Automotive industry cooperation experience, strict testing | 1-24 layers, minimum line width/spacing 3mil/3mil | Prototype: 5-8 days; Mass production: 12-22 days |

How to Choose the Right PCB Manufacturer in Spain?

A detailed selection Guide to PCB Manufacturer in Spain:

1. Certification and Standards Compliance

- When choosing a Spanish PCB manufacturer, prioritize those with ISO 9001 (quality management system), ISO 14001 (environmental management), UL certification (electrical safety), RoHS (environmental compliance), and IPC industry standard certifications. These certifications ensure that production processes comply with international safety, environmental, and process specifications, which is especially crucial for high-reliability fields such as medical and automotive electronics.

2. Technical Capabilities and Equipment Precision

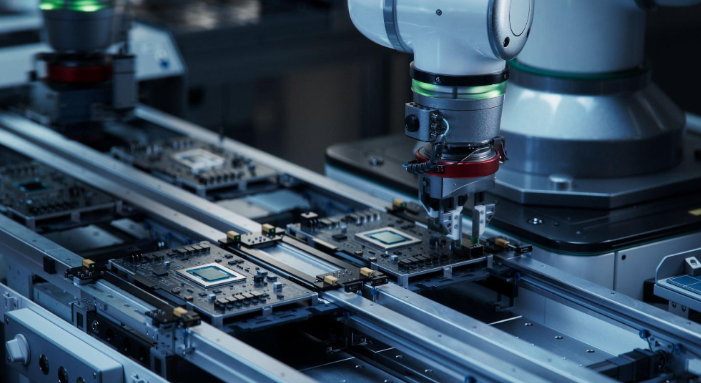

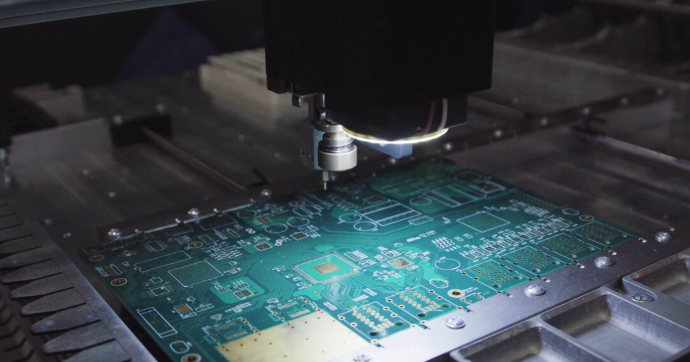

- Focus on manufacturers with high-density/miniaturization design capabilities, such as supporting 0201 component placement, 0.3mm pitch SMT processes, and BGA/QFN package testing (requiring X-Ray or AXI equipment). Equipment should include high-speed pick-and-place machines (such as Siemens HS60, Fuji NXTR series), AOI automatic optical inspection systems, and precision reflow ovens to ensure welding accuracy and yield.

3. Design Collaboration and DFM Support

- Excellent manufacturers should provide DFM (Design for Manufacturability) feedback, identifying potential problems in layout, pads, and stencil openings during the PCB design phase, optimizing signal integrity (such as high-speed signal length matching and impedance control) and thermal management design. They should support mainstream EDA tools such as Altium Designer and Cadence Allegro, and provide BOM optimization, alternative material recommendations, and process feasibility analysis.

4. Quality Control and Testing Capabilities

- Manufacturers must adhere to standards such as IPC-A-610 and IPC-J-STD-001, implementing full-process quality control. Testing methods should include flying probe testing, ICT (in-circuit testing), FCT (functional testing), and environmental reliability testing (such as HAST high-temperature and high-humidity testing, TCT temperature cycling, and vibration testing). Failure analysis should utilize SEM (scanning electron microscope) and X-Ray equipment to quickly locate problems such as cold solder joints and short circuits.

5. Supply Chain and Material Management

- Support both Consigned (customer-provided materials) and Turnkey (manufacturer-procured materials) models, with strict material control processes, including anti-static storage, batch traceability systems (such as MES records), and moisture-sensitive device (MSD) management. Prioritize manufacturers that collaborate with authorized distributors to reduce the risk of counterfeit parts and support VMI (Vendor Managed Inventory) to reduce inventory pressure.

6. Delivery Flexibility and Production Capacity Assurance

- Assess the manufacturer’s production capacity stability, level of automation (such as AOI coverage and selective wave soldering), and production scheduling priorities. They should support flexible switching between small-batch prototyping (low MOQ) and large-scale production, and possess rapid line change capabilities. For urgent projects, confirm the response speed of expedited services, such as standard prototyping cycles, bulk delivery times, and logistics coordination efficiency.

7. Engineering Support and After-Sales Service

- The manufacturer should provide a 24-hour response from their engineering team for any issues, supporting DFM analysis, process optimization, and design iterations. After-sales service should include repairs, failure analysis, batch traceability, and long-term technical support. A Non-Disclosure Agreement (NDA) should be signed to protect customer intellectual property, and financial stability should be assessed to avoid supply chain disruption risks.

8. Industry Experience and Case Studies

- Prioritize manufacturers with proven track records in niche areas such as medical, automotive electronics, and industrial control. Their technical capabilities can be verified through industry reputation, customer reviews, and third-party factory audit reports. Consider their R&D investment (such as AI visual inspection and digital factories) and adaptability to emerging technologies (such as 5G and RF PCBs) to ensure long-term partnership potential.

Quality Certification for PCB Manufacturer in Spain

PCB manufacturers in Spain must adhere to strict quality and safety standards to meet the demands of local and European markets. The certifications include:‚Äč

- ISO 9001: Quality Management System certification, ensuring standardized production processes and consistent product quality.‚Äč

- IATF 16949: Mandatory for automotive PCB manufacturers, focusing on quality control in the automotive supply chain.‚Äč

- UL Certification: Ensures PCB compliance with fire safety and electrical performance standards for electronic products.‚Äč

- RoHS Directive (2011/65/EU): Restricts the use of hazardous substances in PCBs, a must for products sold in the EU.‚Äč

- ISO 13485: Required for PCB manufacturers serving the medical equipment industry, ensuring compliance with medical device quality standards.‚Äč

EBest Circuit (Best Technology), as a professional PCB Manufacturer, holds all the above certifications, providing clients with qualified and compliant products.

Production Capability of PCB Manufacturing Company in Spain

| Process Type | Layer Range | Minimum Line Width/Spacing | Maximum Board Size |

| Rigid PCB | 1-40 layers | 2.5mil/2.5mil | 1200mm√ó600mm |

| Flexible PCB | 1-12 layers | 3mil/3mil | 1000mm√ó500mm |

| Rigid-Flex PCB | 2-24 layers | 3mil/3mil | 800mm√ó400mm |

| HDI PCB | 4-14 layers (up to 12+2L) | 2mil/2mil | 600mm√ó400mm |

Challenges Facing the PCB Manufacturing in Spain

- When designing high-frequency PCBs for 5G base stations, local manufacturers often refuse due to “inadequate processes”, how to find a PCB manufacturer in Spain capable of achieving 2mil line width and supporting PTFE materials?

- After adjusting component layouts in accordance with the updated EU RoHS 2.0 requirements, manufacturers fail to provide compliant lead-free soldering certification, how to avoid design invalidation caused by non-compliant materials?

- Chip shortages have led to frequent PCB order volume adjustments by automakers like Renault, how to negotiate a flexible cooperation plan with manufacturers that can cope with order fluctuations without affecting delivery schedules?

- Spain continues to tighten environmental regulations (contrary to the demands of Germany and France), how to balance the requirement of ‚Č•95% wastewater recovery rate in production while controlling treatment costs?

- When customizing PCBs for medical monitors, manufacturers hold ISO 13485 certification but cannot provide separate test reports for Class III products, how to ensure safety in clinical use?

- Small-batch prototype orders (‚ȧ50 pieces) are often deprioritized by local large manufacturers, how to obtain high-precision samples delivered within 10 days without paying a 30% premium?

Our Solutions to These Challenges

- For 5G high-frequency PCB demands: We partnered with DuPont to build an exclusive PTFE material supply chain, Our process stably achieves 2mil line width/spacing with a 98.5% yield rate, fully meeting 5G base station PCB standards.

- To ensure RoHS 2.0 compliance: We implement a three-level material quality inspection mechanism. Every batch of lead-free solder paste is tested by SGS, and each order is accompanied by a third-party lead-free compliance report (including specific heavy metal content data), completely eliminating the risk of design invalidation due to material issues.

- To cope with automotive order fluctuations: We reserve 20% of our global production capacity for automotive PCB orders, forming a flexible scheduling system. Through our customized order management platform, we can respond to order volume adjustments within 4 hours, and our on-time delivery rate for fluctuating automotive PCB orders has remained at 99.2% for Spanish clients.

- For environmental regulation balance: Our production base adopts a closed-loop wastewater treatment system with a recovery rate of ‚Č•97%, exceeding Spain‚Äôs 95% requirement. Energy-efficient production equipment reduces treatment costs by 18%, and we hold the RoHs environmental certificate, ensuring compliance with Spanish regulations without increasing additional costs for clients.

- For medical Class III PCB testing: Based on ISO 13485, we developed a Class III-specific testing process. Each order is equipped with an independent test report covering biocompatibility, temperature resistance (-40‚ĄÉ~125‚ĄÉ), and 10,000-hour stability verification.

- To solve small-batch prototype issues: We set up a dedicated prototype production line (for orders ‚ȧ50 pieces) with 15% of daily capacity allocated. And we guarantee 7-day delivery for high-precision prototype.

Why Spain Clients Choose EBest Circuit (Best Technology) for PCB Manufacturer?

9 Reasons why Spain clients choose EBest Circuit (Best Technology) for PCB manufacturer:

- 19-year experience tailored to Spanish markets: We’ve served over 500 Spanish clients, understanding the unique demands of automotive, medical, and telecom industries here to provide more targeted solutions.

- Comprehensive certifications cover all scenarios: Hold ISO 9001, IATF 16949 (automotive), ISO 13485 (medical), and RoHS certifications, ensuring your PCBs meet strict EU and Spanish market access standards.

- Free DFM analysis within 4 hours: Our technical team provides professional DFM reports for your Gerber files, identifying issues like improper pad size to avoid rework losses, all at no extra cost.

- Cost-saving solutions cut procurement expenses by 10-18%: Leveraging global supply chain resources and 19 years of process experience, we optimize material specs and layout designs to reduce waste rate to below 3%, directly lowering overall costs for your projects.

- 24-hour urgent prototyping for time-sensitive needs: We reserve 15% of global production capacity for emergency orders, completing high-precision prototypes in 24 hours‚ÄĒ70% faster than local average lead time, supporting your tight new product launch schedules.

- 99.2% on-time delivery with clear compensation clauses: Our smart scheduling system ensures stable order progress. Every contract includes “3% deduction per delayed day” terms, and we‚Äôve maintained a 99.2% on-time rate for Spanish clients over 5 years.

- 100% full inspection for mass production, 99.8% qualification rate: We implement 6-step quality control (incoming inspection ‚Üí in-process testing ‚Üí AOI ‚Üí X-ray ‚Üí flying probe ‚Üí final sampling), with 100% full inspection for batches‚ÄĒfar exceeding Spain‚Äôs 97.5% industry average.

- One-stop service simplifies your workflow: Integrate design optimization, production, testing, and logistics into a single process, you only need one contact to manage the entire PCB procurement chain.

- Small-batch orders supported with no premium: Dedicated prototype lines handle orders ‚ȧ50 pieces, guaranteeing 7-day delivery without the 30% premium common among local large manufacturers.

Types of Our PCB Manufacturing

- Rigid PCB( Single Layer FR4 PCB, Double Sided FR4 PCB, Multilayer FR4 PCB)

- Flexible PCB( Single Layer Flex PCB, Double Sided Flex PCB, Multilayer Flex PCB)

- Rigid-Flex PCB

- Ceramic PCB

- Metal Core PCB( Aluminum Core PCB/ Copper Core PCB)

- HDI PCB

- RF PCB

- High Speed PCB

- Busbar PCB

- Heavy Copper PCB

- High TG PCB

- Extra Thin PCB

Our PCB Manufacturing Capabilities

| Item | Capabilities |

| Layer Count | 1 – 32 Layers |

| Max Board Dimension | 24×24 inches (610x610mm) |

| Min Board Thickness | 0.15mm |

| Max Board Thickness | 6.0mm – 8.0mm |

| Copper Thickness | Outer Layer: 1oz~30oz, Inner Layer: 0.5oz~30oz |

| Min Line Width/Spacing | Normal: 4/4mil (0.10mm); HDI: 3/3mil (0.076mm) |

| Min Hole Diameter | Normal: 8mil (0.20mm); HDI: 4mil (0.10mm) |

| Min Punch Hole Diameter | 0.1″ (2.5mm) |

| Min Hole Spacing | 12mil (0.3mm) |

| Min PAD Ring (Single) | 3mil (0.075mm) |

| PTH Wall Thickness | Normal: 0.59mil (15őľm); HDI: 0.48mil (12őľm) |

| Min Solder PAD Diameter | Normal: 14mil (0.35mm); HDI: 10mil (0.25mm) |

| Min Soldermask Bridge | Normal: 8mil (0.2mm); HDI: 6mil (0.15mm) |

| Min BAG PAD Margin | 5mil (0.125mm) |

| PTH/NPTH Diameter Tolerance | PTH: ¬Ī3mil (0.075mm); NPTH: ¬Ī2mil (0.05mm) |

| Hole Position Deviation | ¬Ī2mil (0.05mm) |

| Outline Tolerance | CNC: ¬Ī6mil (0.15mm); Die Punch: ¬Ī4mil (0.1mm); Precision Die: ¬Ī2mil (0.05mm) |

| Impedance Controlled | Value >50ő©: ¬Ī10%; Value ‚ȧ50ő©: ¬Ī5ő© |

| Max Aspect Ratio | 0.334027778 |

| Surface Treatment | ENIG, Flash Gold, Hard Gold Finger, Gold Plating (50őľm), Gold Finger, Selective Gold Plating, ENEPIG, ENIPIG; HAL, HASL(LF), OSP, Silver Imm., Tin Imm. |

| Soldermask Color | Green/White/Black/Yellow/Blue/Red |

How to Get a Quote for Your PCB Project?

All information you need to submit to your PCB manufacturer:

1. Layer & Thickness

- Single/double-sided: Base price; each additional 2 layers increases cost by 15-30%; 0.8-2.0mm thickness standard.

- Multilayer (4+ layers): Impedance control/lamination fees apply; 6-layer costs 2-3x double-sided.

2. Material

- FR-4: Budget option for consumer electronics.

- High-frequency (Rogers/Taconic): 3-5x cost for RF/high-speed signals.

- Aluminum/copper substrate: 20-50% extra for thermal management.

3. Surface Finish

- HASL: Low-cost general use.

- ENIG: 30-50% premium for reliability/fine-pitch; keypads/connectors.

- OSP: Eco-friendly/low-cost; 6-month shelf life.

- Immersion gold: 1-3x cost for gold fingers/high-frequency modules.

4. Process Details

- Line width/spacing <4mil: Laser drilling/plating required; 20-50% extra.

- Hole size <0.2mm: 30% higher mechanical drilling fee.

- Impedance control: $5-10 per trace for test reports.

5. Quantity & Lead Time

- Prototypes (1-5pcs): High unit cost + engineering/setup fees.

- Small batch (50-100pcs): Moderate unit cost + NRE fees.

- Bulk (>500pcs): Lowest unit cost; volume discounts negotiable.

- Rush orders (3-5 days): 30-50% premium; standard 7-10 days.

Welcome to contact us to get a free DFM for your PCB project now: sales@bestpcbs.com.