Looking for reliable PCB Egypt manufacturing? This guide covers top factory lists, certifications, capabilities evaluation, and lead times for informed sourcing decisions.

PCB Egypt manufacturing has witnessed significant expansion in recent years, fueled by regional industrial growth and strategic policy initiatives. As a vital part of electronic manufacturing in North Africa, PCB Egypt Manufacturing delivers a compelling combination of cost efficiency, technological progress, and strategic market reach that caters to diverse project requirements. This expansion has solidified the region’s status as a reliable destination for high-quality printed circuit board production, supported by a steadily growing ecosystem of factories and supporting industries.

Why Choose PCB Egypt Manufacturing?

Benefits of PCB Egypt Manufacturing:

- Strategic Geographical Advantage: PCB Egypt Manufacturing benefits from Egypt’s prime location connecting Europe, the Middle East, and Africa, enabling efficient logistics and reduced lead times for regional market access.‚Äč

- Government Policy Support: The Egyptian government‚Äôs initiatives under Vision 2030 and the PCP Egypt program provide incentives for manufacturing development, including infrastructure upgrades and investment facilitation for PCB Egypt Manufacturing.‚Äč

- Developed Core Material Base: Egypt‚Äôs growing copper-clad laminate production, with a 10% year-on-year growth in 2022, ensures a stable supply chain for PCB Egypt Manufacturing, reducing reliance on imported raw materials.‚Äč

- Cost-Competitive Production: Compared to European and North American counterparts, PCB Egypt Manufacturing offers competitive labor and operational costs without compromising on quality standards.‚Äč

- Advancing Technological Capabilities: Local factories are increasingly adopting advanced technologies such as SMT, HDI, and rigid-flex manufacturing, enhancing the technical scope of PCB Egypt Manufacturing.‚Äč

- Regional Supply Chain Integration: PCB Egypt Manufacturing is part of a growing electronic manufacturing ecosystem in Egypt, facilitating seamless collaboration with component suppliers and assembly services.

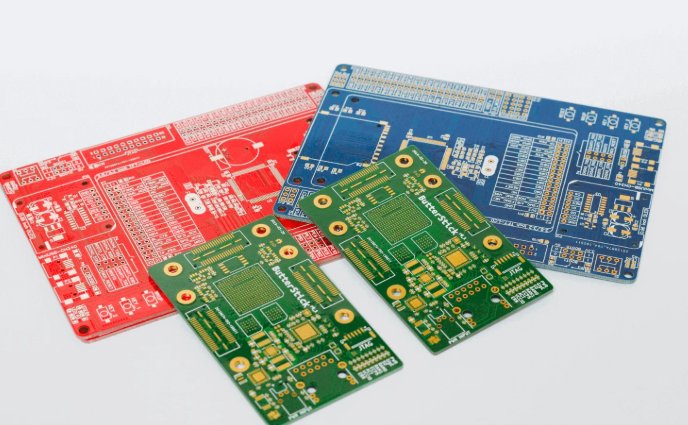

Types of PCB Egypt Manufacturing

- Single-Layer PCBs: Basic configuration ideal for simple electronic applications, widely available in PCB Egypt Manufacturing.‚Äč

- Double-Layer PCBs: Featuring conductive layers on both sides, suitable for medium-complexity devices, a staple offering in PCB Egypt Manufacturing.‚Äč

- Multi-Layer PCBs: Ranging from 4 to 20 layers, supporting high-density interconnects (HDI) for advanced electronics, a growing segment in PCB Egypt manufacturing.‚Äč

- Flexible PCBs: Utilizing materials like polyimide (PI) and LCP for bendable applications, available in PCB Egypt Manufacturing for wearable and compact devices.‚Äč

- Rigid-Flex PCBs: Combining rigid and flexible substrates for versatile design requirements, offered by specialized providers in PCB Egypt Manufacturing.‚Äč

- High-Frequency PCBs: Engineered for signal integrity in communication devices, using low-loss materials, part of the advanced portfolio in PCB Egypt manufacturing.‚Äč

- SMT/THT Assembly PCBs: Integrated manufacturing with surface mount or through-hole technology, a comprehensive service in PCB Egypt Manufacturing.

Quality Certifications for PCB Egypt Manufacturing

- ISO 9001:2015: Quality management system certification, widely adopted across PCB Egypt Manufacturing to ensure consistent production processes.‚Äč

- ISO 14001: Environmental management system certification, increasingly required for sustainable operations in PCB Egypt Manufacturing.‚Äč

- IPC Standards Compliance: Adherence to IPC-A-600 (PCB acceptability) and IPC-A-610 (assembly acceptability), critical quality benchmarks for PCB Egypt Manufacturing.‚Äč

- UL Certification: Safety certification for PCB materials and products, essential for market access in global applications from PCB Egypt Manufacturing.‚Äč

- ISO 13485:2016: Specialized certification for medical device-related PCB production, offered by select providers in PCB Egypt Manufacturing.‚Äč

- IECEx Certification: For PCBs used in explosive atmospheres, a niche certification available in PCB Egypt Manufacturing for industrial applications.

Top 10 PCB Factory in Egypt List

| Company Name | Main Business Advantages | Core Advantages | Process Capabilities | Lead Time |

| EBest Circuit (Best Technology) Co.,Ltd | Multi-layer PCB manufacturing and assembly | Advanced HDI technology and strict quality control | Up to 20-layer PCBs, HDI, rigid-flex, SMT assembly | Standard: 7-15 days; Express: 3-5 days |

| Pyramid Electronics | PCB design, manufacturing, and mechanical enclosure integration | One-stop solution and reverse engineering capabilities | Up to 12-layer PCBs, SMT/THT assembly, 3D printing support | Standard: 5-12 days; Express: 2-4 days |

| Egyptian Electronic Technology | Multi-layer PCB assembly and testing | High-throughput robotics and advanced testing facilities | Up to 16-layer PCBs, SMT (0201 to CSP packages), AOI testing | Standard: 8-14 days; Express: 3-6 days |

| Metanoia Ltd | Rapid prototyping and custom PCB fabrication | Fast response and small-batch production expertise | Up to 8-layer PCBs, prototype to small-batch, flying-probe testing | Standard: 3-7 days; Express: 24-72 hours |

| BTC Electronics | PCB manufacturing and electronic component distribution | Strong supply chain and Panasonic partnership | Up to 10-layer PCBs, SMT assembly, large-batch production | Standard: 10-20 days; Express: 5-8 days |

| Ronex Misr | SMT-based PCB assembly | Dual Fuji and Siemens SMT lines for high efficiency | Up to 8-layer PCBs, SMT assembly, automated testing | Standard: 6-13 days; Express: 3-5 days |

| Ultima True Engineering Industries | Electronic control products and PCB manufacturing | Serving MENA and Africa markets, regional logistics expertise | Up to 14-layer PCBs, rigid PCBs, industrial-grade assembly | Standard: 9-16 days; Express: 4-7 days |

| Entech Electronics Egypt | Medical and industrial PCB manufacturing | ISO 13485 certification and cleanroom production | Up to 18-layer PCBs, high-reliability PCBs, IPC-A-610 Class 3 | Standard: 12-20 days; Express: 6-9 days |

| Multi Technology | PCB design, maintenance, and custom manufacturing | Specialized in automatic control systems PCBs | Up to 6-layer PCBs, custom circuit design, repair services | Standard: 7-10 days; Express: 3-4 days |

| Egypt Italy for Modern Industry Co., Ltd | High-quality PCB manufacturing and export | International quality standards and export experience | Up to 12-layer PCBs, rigid PCBs, RoHS-compliant production | Standard: 10-18 days; Express: 5-7 days |

How to Identify a Reliable PCB Factory in Egypt?

Identification Guide to PCB Factory in Egypt:

1. Validate International Quality Certifications: Prioritize factories with globally recognized certifications relevant to PCB Egypt Manufacturing, such as ISO 9001:2015 (quality management system) and IPC standards (including IPC-A-600 for PCB acceptability and IPC-A-610 for assembly quality). For application-specific needs, verify certifications like ISO 13485 (medical devices) or UL (safety for global markets). You can cross-check certification validity via official databases (e.g., IPC‚Äôs certification verification portal) to ensure authenticity.‚Äč

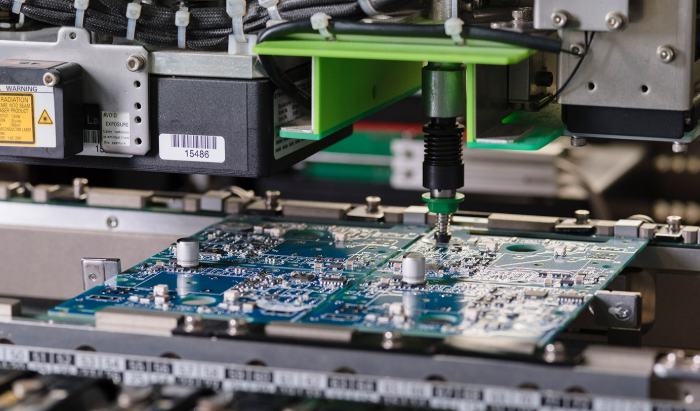

2. Conduct Production Facility Audits: Inspect or request detailed videos of production facilities to confirm access to advanced, well-maintained equipment. Key equipment indicators include SMT lines (e.g., Fuji, Siemens), automated optical inspection (AOI) systems for defect detection, and high-precision drilling machinery. This ensures the factory can meet the technical requirements of your PCB projects in PCB Egypt Manufacturing.‚Äč

3. Review Relevant Project Portfolios & Track Records: Ask for case studies or project samples similar to your PCB type (e.g., multi-layer, rigid-flex) or complexity level. Focus on their track record in delivering projects with comparable specifications, including batch size and lead time commitments. Reliable factories will also provide third-party test reports for past projects to demonstrate quality consistency.‚Äč

4. Evaluate Comprehensive Quality Control (QC) Processes: Assess the factory‚Äôs end-to-end QC system, which should include in-house testing capabilities for electrical performance (e.g., flying-probe testing, impedance testing) and defect detection. Confirm they follow IPC-defined quality classes (Class 1/2/3) and have documented QC procedures, this ensures adherence to international quality benchmarks for PCB Egypt Manufacturing.‚Äč

5. Assess Supply Chain Stability & Material Sourcing: Investigate the factory‚Äôs core material supply chain, especially for copper-clad laminates (a critical PCB component). Reliable suppliers in PCB Egypt Manufacturing will source materials from certified vendors and maintain consistent stock to avoid production delays. Verify if their materials meet RoHS or REACH compliance, which is essential for global market access.‚Äč

6. Check International Customer Feedback & Reputation: Gather feedback from the factory‚Äôs international clients (e.g., via industry forums or reference checks) to evaluate on-time delivery rates and after-sales support. A strong reputation for resolving issues promptly and honoring commitments is a key indicator of reliability for foreign partners engaging in PCB Egypt manufacturing.‚Äč

7. Confirm Environmental & Sustainable Compliance: Ensure the factory adheres to international environmental standards such as ISO 14001 and local Egyptian environmental regulations. Sustainable practices (e.g., proper waste disposal of chemical solvents) not only reduce environmental risks but also align with the sustainability requirements of many global buyers for PCB production.

How to Evaluate the Manufacturing Capability of PCB Factory in Egypt?

Evaluation Guide to Manufacturing Capability of PCB Factory in Egypt:

- Assess maximum layer count and PCB size capabilities to ensure alignment with project requirements in PCB Egypt manufacturing.

- Evaluate advanced process adoption, such as HDI, blind/buried vias, and rigid-flex manufacturing technologies.

- Review equipment sophistication, including the type and condition of SMT machines, drilling equipment, and testing tools.

- Check production capacity and throughput rates to confirm ability to handle order volume, both small-batch and large-scale.

- Evaluate material range options, including support for high-frequency laminates, high-Tg materials, and flexible substrates.

- Assess quality control metrics, such as defect rate, yield percentage, and compliance with IPC standards.

- Review research and development capabilities for custom solutions and technological innovation in PCB Egypt manufacturing.

- Evaluate employee expertise and training programs to ensure skilled personnel for complex manufacturing processes.

- Check ability to integrate additional services, such as PCB assembly, testing, and packaging.

How to Evaluate the Lead Time of PCB Factory in Egypt?

Evaluation Guide to Lead Time of PCB Factory in Egypt:

- Assess maximum layer count and PCB size capabilities to ensure alignment with project requirements in PCB Egypt Manufacturing.

- Evaluate advanced process adoption, such as HDI, blind/buried vias, and rigid-flex manufacturing technologies.

- Review equipment sophistication, including the type and condition of SMT machines, drilling equipment, and testing tools.

- Check production capacity and throughput rates to confirm ability to handle order volume, both small-batch and large-scale.

- Evaluate material range options, including support for high-frequency laminates, high-Tg materials, and flexible substrates.

- Assess quality control metrics, such as defect rate, yield percentage, and compliance with IPC standards.

- Review research and development capabilities for custom solutions and technological innovation in PCB Egypt manufacturing.

- Evaluate employee expertise and training programs to ensure skilled personnel for complex manufacturing processes.

- Check ability to integrate additional services, such as PCB assembly, testing, and packaging.

Frequently Asked Questions of PCB Egypt Manufacturer

Q1: Is it easy to find reliable PCB prototyping services in Egypt for small-batch builds?

A1: Yes, but options are limited compared with larger manufacturing hubs. Many Egyptian engineers on Reddit mention that while local prototype services exist, they often rely on overseas partners for faster turnaround or advanced features. Local shops can handle simple FR4 prototypes and small runs efficiently, but high-density boards or RF designs typically require offshore fabrication.

Q2: Can Egyptian PCB manufacturers handle multilayer designs or HDI structures?

A2: Capability varies by facility. Reddit discussions often point out that standard multilayer PCBs (4‚Äď8 layers) are supported locally, but HDI stack-ups, microvias, or very fine line widths usually exceed local equipment limits. For complex designs, engineers frequently choose China or Europe, while keeping simple layers and revisions with local Egyptian shops.

Q3: Are PCB assembly services in Egypt able to source components locally?

A3: Many Reddit users note that component sourcing within Egypt can be challenging, especially for specialized ICs, high-frequency passives, or automotive-grade parts. As a result, most local assembly houses request that clients supply components or allow them to import parts. This may extend lead times but ensures component authenticity and proper lot control.

Q4: What files do Egyptian PCB shops typically require for a clean manufacturing handoff?

A4: According to Reddit users, the standard requirements include Gerber files, Excellon drill files, BOM, pick-and-place file, and fabrication notes. For SMT builds, Egyptian assembly houses also ask for centroid files, clear polarity markings, and preferred part orientation to minimize placement errors.

Q5: How long does it normally take to get PCB prototypes manufactured in Egypt?

A5: Reddit feedback suggests lead times of 5‚Äď12 business days for simple prototypes, depending on the shop‚Äôs workload. Urgent jobs may be accepted but usually incur a premium. More advanced boards or assembly-ready PCBs often require additional time, especially if components need to be imported or if the design involves controlled impedance or special materials.