What is Teflon PCB? Let’s explore its material composition, dielectric constant, properties and applications, cost and comparison with Rogers PCB through this blog.

Are you troubled with these questions?

- How to boost device performance when high-frequency signal loss is high?

- How to ensure circuit stability when temperature swings cause deformation?

- How to avoid risks from fluorinated materials under stricter environmental regulations?

As a Teflon PCB manufacturer, EBest Circuit (Best Technology) can provide you service and solutions:

- Customized Formulation Service: Tailor Teflon composite material ratios based on high-frequency/temperature-resistant/corrosion-resistant needs, reducing loss, enhancing mechanical strength, and resolving deformation challenges.

- Process Adaptation Support Package: Provide Teflon processing parameter whitepapers with temperature/pressure/time control curves, optimizing processes to minimize defects like sintering bubbles and delamination, while improving production efficiency.

- Eco-Compliance Certification System: Supply PFOA-free/low-fluorine Teflon PCB substrates with third-party test reports and recycling guidelines, enabling clients to pass RoHS/REACH audits swiftly and mitigate production risks.

Welcome to contact us if you have any request for Teflon PCB: sales@bestpcbs.com.

What is Teflon PCB?

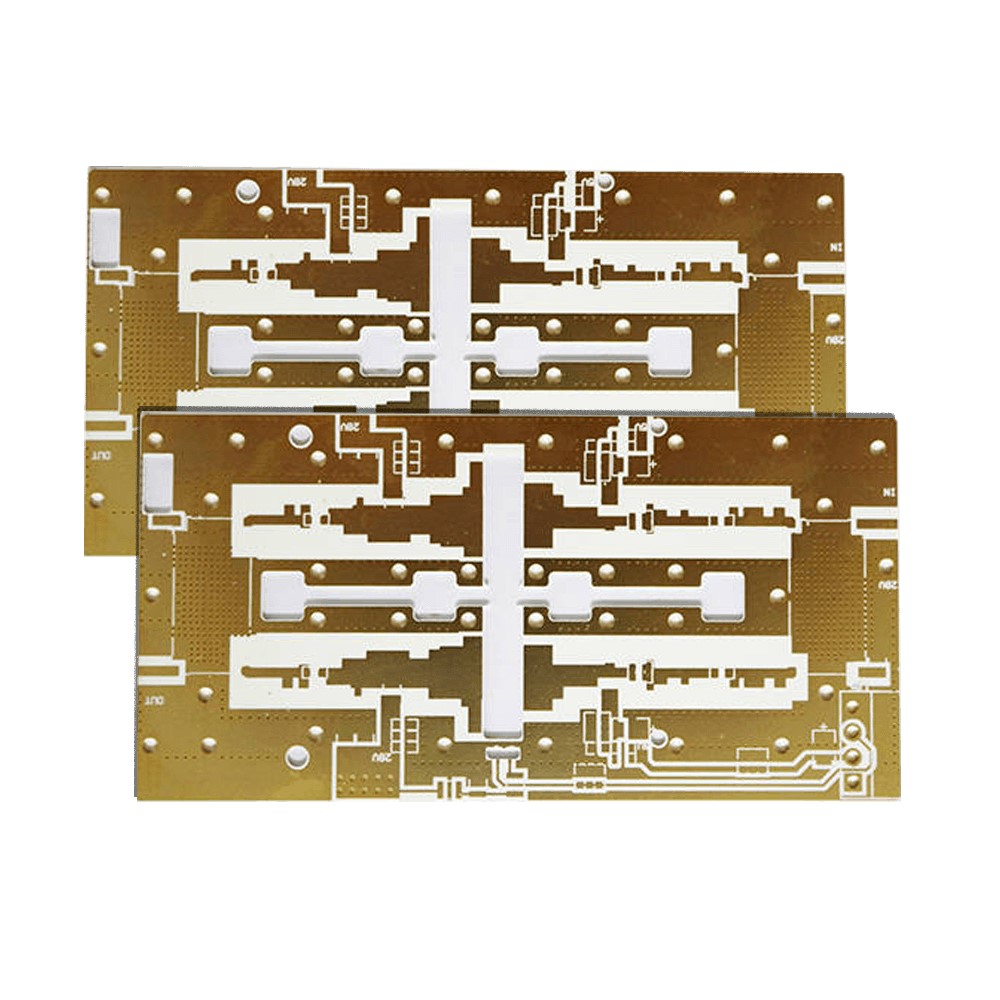

Teflon PCB (also called as PTFE PCB), which utilizes polytetrafluoroethylene (PTFE) as its substrate material, is a high-frequency circuit board renowned for its exceptional dielectric properties, high-temperature resistance, and chemical stability.

Widely deployed in 5G communications, aerospace, and other high-frequency, high-speed application domains, its low dielectric constant (Dk) and low dissipation factor (Df) characteristics significantly minimize signal transmission losses, making it ideal for scenarios demanding superior signal integrity.

However, compared to conventional FR4 materials, its manufacturing complexity and elevated costs stem from the inherent processing challenges of PTFE substrates, necessitating specialized techniques to ensure reliable production.

What Material is Teflon PCB Made of?

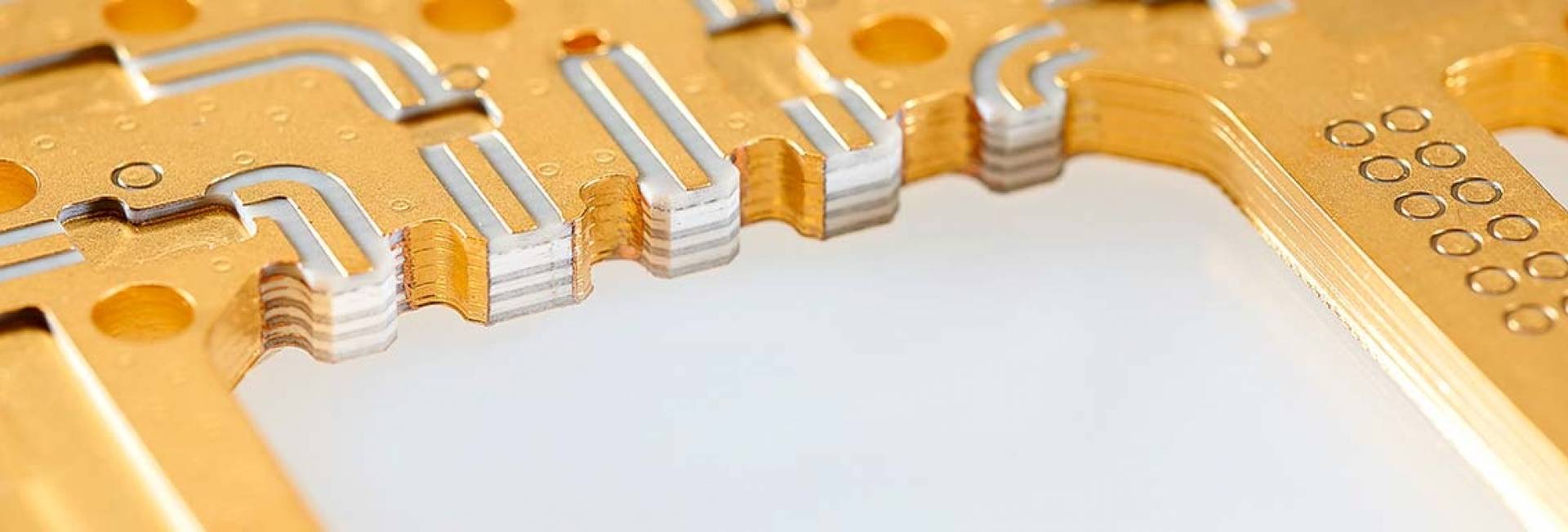

- Core Substrate: Polytetrafluoroethylene (PTFE, Teflon) dominates the structure, with molecular chain -(CF₂-CF₂)n- delivering ultra-low dielectric constant (2.1-2.6), extremely low dielectric loss (Df<0.001), and chemical inertness. Composite with glass fibers/ceramic fillers reinforces mechanical strength and thermal stability.

- Conductive Layer: Copper foil serves as primary conductor, thickness graded by ounces (oz). Ultra-thin copper foil (<9μm) requires carrier support; surface undergoes roughening/antioxidant treatment. Solder pads are plated with gold/nickel/tin for enhanced solderability and corrosion resistance.

- Solder Mask & Coatings: PTFE-based coatings or high-temperature resin systems feature hydrophobic/oleophobic properties, temperature resistance >260°C, and chemical corrosion resistance. Plasma activation/palladium catalysis addresses PTFE surface adhesion deficiencies.

- Auxiliary Reinforcement: Thermosetting resin adhesives fill gaps to strengthen interlayer bonding; glass fibers/ceramic particles reduce thermal expansion coefficient (200-300 ppm/°C) and minimize warpage; metal cores (aluminum/copper) amplify thermal dissipation.

- Specialized Functional Layers: PTFE coatings grant extreme temperature resistance (short-term up to 390°C), anti-adhesion, and corrosion resistance. Nanocomposite coatings integrate fluoropolymers with nanomaterials (e.g., SiO₂) to optimize hydrophobicity and antimicrobial properties.

What Is Dielectric Constant of Teflon PCB?

According to Rogers RO4000™ series specifications, the dielectric constant (Dk) of Teflon PCB ranges from 2.0 to 10.2, with exact values determined by PTFE substrate formulation. Pure PTFE exhibits the lowest Dk (2.04 ± 0.04), while ceramic-filled modified variants (e.g., RO4350B™) can reach 3.48–10.2. Precise adjustment of filler ratios enables optimized impedance matching and signal integrity for 5G/millimeter-wave applications, ensuring minimal signal loss and phase distortion in high-frequency scenarios.

What Are Properties of Teflon PCB Board?

- Ultra-Low Dielectric Constant & Low Loss: Dielectric constant ≈ 2.1-3.5 (significantly lower than FR4’s 4.5), enabling faster signal transmission; loss tangent as low as 0.0002 (vs. FR4’s 0.02), ensuring excellent signal integrity and minimal energy loss.

- Exceptional Thermal Stability & Temperature Resistance: Operable in a wide temperature range of -100°C to +150°C; low coefficient of thermal expansion (CTE) with strong resistance to thermal shock; thermal conductivity ≈ 0.8 W/m·K, superior to conventional materials for efficient heat dissipation.

- Chemical Inertness & Corrosion Resistance: PTFE exhibits extreme chemical stability, resistant to acids, bases, solvents, and oxidizing agents; non-stick surface (low surface energy) prevents dust/oil adhesion, simplifying maintenance.

- Superior Electrical Insulation & Anti-Interference: High insulation resistance (up to 600V+), effectively isolating high-voltage circuits; low dielectric loss reduces signal crosstalk and enhances circuit anti-interference capability.

- Mechanical Properties & Structural Design Considerations: Rigid substrate with limited flexibility; requires attention to cold flow characteristics (plastic deformation under prolonged pressure); supports high-precision RF circuit layout with minimum trace width/spacing of 0.2mm.

- Environmental Adaptability: UV-resistant and moisture-resistant (low moisture absorption), suitable for outdoor equipment, aerospace, and medical high-frequency devices.

What Are Applications of PTFE Teflon PCB?

- 5G/6G Communication Base Stations: High-frequency antenna modules, RF filters, and base station power amplifiers leverage low-loss properties for efficient GHz-band signal transmission.

- Satellite & Spacecraft Systems: High-frequency circuit substrates for satellite payloads, space probe antenna substrates, and rocket engine high-temperature electronic modules.

- Radar Systems: Military/civilian radar antennas and signal processing boards ensure precise microwave signal transmission and anti-interference capabilities.

- Automotive Electronics: On-board millimeter-wave radar, ECU control boards, and engine high-temperature sensor circuits.

- Medical Equipment: High-frequency surgical scalpel circuits, implantable medical electronics, and medical imaging device probe substrates.

- Industrial Control: High-frequency power modules, industrial robot sensor circuits, and corrosion-resistant chemical instrumentation circuits.

- Aerospace Applications: Aircraft engine coatings, satellite fuel system seals, and space environment electronic packaging.

- Semiconductor Manufacturing: Wafer-handling robotic arm circuits, high-precision test equipment high-frequency modules, and anti-static workstations.

- New Energy Sector: Photovoltaic inverter high-frequency circuits, wind power converter power modules, and energy storage battery management systems.

- Defense & Military: Electronic warfare equipment, missile guidance systems, and shipborne communication device high-frequency circuits.

Which is Better? Rogers vs Teflon PCB

1. Core Performance Comparison & Preferred Scenarios

- Rogers PCB Preferred Scenarios: Ideal for high-frequency/precision applications (e.g., 5G base stations, millimeter-wave radar), high-reliability environments (aerospace, automotive electronics), and multi-layer/HDI designs. Benefits include stable dielectric constant (Dk 2.94–10.2), ultra-low loss factor (<0.002), robust mechanical strength, and exceptional signal integrity for long-term stability.

- Teflon PCB Preferred Scenarios: Suited for extreme environments (chemical/aerospace corrosion resistance, high-power LED heat sinks), ultra-low-loss RF applications (microwave modules), leveraging extremely low Dk (2.0–2.2) and wide temperature tolerance (-196°C to +260°C) for reliable performance under harsh conditions.

2. Cost & Production Feasibility

- Rogers PCB: Higher material costs (5–10× FR4) but compatible with standard FR4 production lines (requires temperature control to prevent degradation), ideal for budget-rich projects prioritizing performance and efficiency.

- Teflon PCB: Moderate material costs but complex processing (requires >300°C high-pressure/high-temperature equipment and PFOA-free protocols), longer lead times, suitable for cost-insensitive industrial scenarios needing extreme durability.

3. Environmental & Safety Compliance

- Rogers PCB: Complies with RoHS/lead-free standards, low environmental risk in production, ideal for clients emphasizing sustainable supply chains.

- Teflon PCB: Requires PFOA-free/low-fluorine substrates with third-party certifications, passes RoHS/REACH audits, but requires ventilation design for fluorine emissions during high-temperature decomposition (>400°C).

4. Supply Chain & After-Sales Support

- Rogers PCB: Mature global supply chain with ample inventory and short lead times. Suppliers offer technical support (e.g., lamination optimization, impedance control guidance) and rapid after-sales response, ideal for fast-to-market and long-term maintenance needs.

- Teflon PCB: Centralized supply chain with longer lead times for custom grades. Suppliers provide tailored services (e.g., material formulation adjustments, process training) but require regional coverage verification for after-sales support, suited to less elastic supply chain scenarios.

5. Selection Decision Tips

- Choose Rogers PCB for high-frequency/precision, long-term reliability, multi-layer/HDI needs, sufficient budget, and fast production/after-sales support (e.g., 5G infrastructure, radar systems, aerospace electronics).

- Choose Teflon PCB for extreme temperature/corrosion resistance, ultra-low signal loss, flexible processing, acceptable longer lead times, and customization needs (e.g., microwave communications, chemical equipment, high-power LEDs).

- Hybrid Solution Combine Rogers for core performance layers and Teflon for surface durability, requiring custom material integration to balance cost and performance.

What is the Price of Teflon PCB?

Based on Q3 2025 high-frequency PCB industry pricing data, Teflon PCB costs range from $50 to $500 per square foot, contingent on material specifications and process complexity. Entry-level ceramic-filled PTFE boards (e.g., RO4350B™) typically cost $50–$150, while premium pure PTFE high-frequency boards (RT/duroid 5880) reach $200–$350. Advanced multi-layer hybrid boards (PTFE + FR4) or 77GHz radar-specific designs, requiring laser drilling and other specialized processes, can exceed $500.

Why Choose EBest Circuit (Best Technology) as Teflon PCB Manufacturer?

Reasons why choose us as Teflon PCB manufacturer:

- Enhanced Price Competitiveness: Through scaled procurement and process optimization, we offer Teflon PCB quotes 15%-20% below market average, paired with cost-sensitive design solutions to maximize budget efficiency and reduce project total costs by over 30%.

- Pioneer in Rapid Prototyping: Urgent orders guaranteed with 24-hour rapid prototyping, 40% faster than industry average ideal for high-urgency sectors like 5G base stations and satellite communications, accelerating full-cycle development.

- Gold-Standard Delivery Reliability: 99.2% on-time delivery rate backed by intelligent production scheduling and global logistics networks, ensuring precision project timelines for medical and aerospace applications, minimizing multi-million-dollar delay risks.

- Precision Quality Control System: Full-process dual-mechanism inspection (visual detection + manual verification) reduces defect rates below 0.03%, exceeding industry standards. Every Teflon PCB undergoes rigorous certification compliance (ISO 9001, IATF 16949) for uncompromised reliability.

- Global Certification Compliance: Medical-grade ISO 13485 for implantable devices, RoHS-compliant lead-free processes for EU standards, and IATF 16949 for automotive electronics, enabling seamless global market access with a single certification suite.

- 19-Year Technical Mastery: Over 5 million Teflon PCBs produced, with expertise honed through national projects like “Tianwen-1” Mars mission and 5G infrastructure. Proprietary process databases and failure analysis models boost first-pass success rates by 40%.

- Intelligent Error Prevention: Real-time defect prediction via production error databases, coupled with closed-loop improvement protocols, slashes rework costs by 50% and saves clients over $1M annually in maintenance expenses.

- Complimentary DFM Optimization: Expert engineering teams provide free Design for Manufacturability analysis to preempt design pitfalls, optimize layouts, and reduce development cycles by 30%, avoiding costly late-stage redesigns.

- End-to-End One-Stop Solution: From prototyping and material selection to volume manufacturing and testing, we deliver integrated solutions that cut client coordination costs by 50% and enhance project efficiency.

- Extreme Environment Specialization: Custom Teflon PCB solutions for space, deep-sea, and high-temperature chemical environments, such as -260°C cryogenic satellite components and corrosion-resistant industrial instrumentation, ensuring unmatched stability in “impossible” conditions to create competitive moats.

Welcome to contact us if you have any request for Teflon PCB board: sales@bestpcbs.com.