Printed circuit card edge connectors‚Äč are essential components that enable direct, reliable connections between a printed circuit board (PCB) and a mating socket without additional cables or intermediate connectors. This article provides a comprehensive overview of card edge connectors‚ÄĒcovering their working principles, common types, design best practices, and selection criteria‚ÄĒto help engineers optimize reliability and signal integrity in modern electronic systems.

Many designers face challenges when integrating ‚Äčprinted circuit card edge connectors, especially in high-frequency or high-durability applications. Below are common pain points:

- Poor contact reliability due to inadequate gold plating thickness on gold fingers.

- Impedance mismatch causing signal reflection and data errors.

- Mechanical misalignment or wear after repeated mating cycles.

- Difficulty choosing the right ‚Äčcard edge connector types‚Äč for power or high-speed data.

- Inefficient ‚Äčcard edge connector PCB design, leading to manufacturing rework.

To address these challenges, advanced design and manufacturing approaches are essential:

- Apply selective hard gold plating (‚Č•3¬Ķm) on ‚Äčprinted circuit card edge connectors gold fingers‚Äč for durability.

- Implement controlled impedance routing and minimize stub lengths on the PCB.

- Use guiding features and reinforced housings in the ‚Äčedge connector socket.

- Select specialized ‚Äčcard edge power connector‚Äč or high-speed versions based on current/speed needs.

- Adhere to DFM rules for pad geometry, solder mask clearance, and plating thickness.

At EBest Circuit (Best Technology), we specialize in high-precision PCB manufacturing and assembly, with a focus on supporting reliable ‚Äčcard edge connector PCB design. Our capabilities include impedance-controlled multilayer PCBs, precise gold finger plating, and full traceability via MES‚ÄĒall compliant with ISO 9001, ISO 13485, IATF 16949, and AS9100D standards. For robust PCB solutions tailored to your interconnect requirements, please feel free to contact our team at sales@bestpcbs.com.

What Are Printed Circuit Card Edge Connectors?

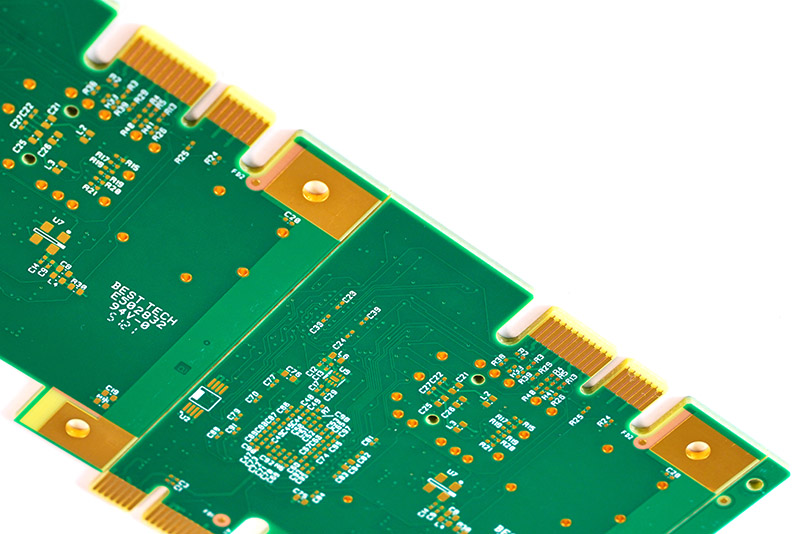

‚ÄčPrinted circuit card edge connectors‚Äč provide a direct interconnect solution where the edge of the PCB itself‚ÄĒfitted with exposed gold-plated contacts (‚Äúgold fingers‚ÄĚ)‚ÄĒis inserted into a matching socket. This eliminates the need for a separate connector component soldered onto the board, saving space and cost while enhancing signal integrity in high-speed applications.

Key structural elements include:

- ‚ÄčGold Fingers: Edge-plated contacts on the PCB, typically hard gold over nickel for low resistance and wear resistance.

- ‚ÄčMating Socket: The receptacle containing spring-loaded contacts that grip the PCB edge.

- ‚ÄčPolarization and Keying Features: Ensure the board is inserted correctly.

These connectors are widely used in memory modules (DDR), expansion cards (PCIe), and industrial control systems due to their simplicity, reliability, and high-density contact capability.

How Do Printed Circuit Board Edge Connectors Work in Electronic Systems?

A ‚Äčprinted circuit board edge connector‚Äč works by establishing electrical contact between the gold-plated traces on the PCB edge and the corresponding terminals in the socket. When the PCB is inserted, the socket‚Äôs spring contacts press firmly against the ‚Äčgold fingers, creating a gas-tight connection that minimizes oxidation and maintains stable conductivity over numerous mating cycles.

Signal transmission relies on:

- Consistent contact pressure from the socket springs.

- Low-contact resistance due to gold’s excellent conductivity.

- Impedance matching between the PCB traces and the connector interface to prevent reflections.

This makes ‚Äčedge connector sockets‚Äč ideal for applications requiring frequent board insertion/removal, such as test fixtures or modular systems.

What Are the Main Card Edge Connector Types Used in Modern Devices?

Various ‚Äčcard edge connector types‚Äč have been standardized to meet specific mechanical, electrical, and environmental needs. Common configurations include:

- ‚ÄčPCI Express (PCIe)‚Äč: Used for graphics and expansion cards, with staggered contact lengths for hot-plug capability.

- ‚ÄčDDR Memory Connectors: Designed for high-speed data transfer with precisely controlled impedance.

- ‚ÄčIndustrial Card Edge Connectors: Feature robust housings and higher mating cycles for harsh environments.

- ‚ÄčWire-to-Board Card Edge Connector: Allows cables to be terminated directly to the PCB edge, simplifying assembly.

Selecting the right type depends on factors such as data rate, current capacity, space constraints, and required durability.

What Role Do Gold Fingers Play in Printed Circuit Card Edge Connectors?

‚ÄčGold fingers‚Äč on ‚Äčprinted circuit card edge connectors‚Äč are critical for maintaining reliable electrical contact and resisting wear. Gold plating‚ÄĒtypically 3‚Äď15 ¬Ķin (0.075‚Äď0.38 ¬Ķm) of hard gold over nickel‚ÄĒprovides:

- Low and stable contact resistance, even after thousands of mating cycles.

- Excellent corrosion resistance, crucial for maintaining signal integrity in humid or corrosive environments.

- Superior solderability and bond strength for the underlying nickel barrier.

For high-frequency or high-cycle applications, specifying adequate gold thickness and nickel underplating is essential to prevent wear-through and fretting corrosion.

How to Optimize Card Edge Connector PCB Design for Signal Integrity?

Proper card edge connector PCB design is crucial for high-speed digital and RF applications to minimize signal reflection, crosstalk, and degradation. Key considerations cover both electrical and mechanical aspects.

1. Impedance Control

Match trace impedance to system requirements (e.g., 50ő© single-ended, 100ő© differential) by adjusting dielectric thickness, trace width, and copper weight. Use manufacturer-provided simulation tools to verify impedance before fabrication.

2. Pad and Trace Geometry

Ensure gold finger pad pitch and length match connector specs. Taper the transition between pads and internal traces to avoid abrupt impedance changes that cause reflections.

3. Plating Thickness and Surface Finish

Specify adequate plating for durability and reliable contact: typically 3‚Äď5 ¬Ķm nickel under 0.5‚Äď1.27 ¬Ķm hard gold. This ensures wear resistance and corrosion protection.

4. Solder Mask Clearance

Keep solder mask clear of gold fingers to prevent poor contact, uneven plating, or insertion interference.

5. Board Edge Beveling (Chamfering)

Beveling enables smooth PCB insertion and protects both the board and connector:

- Angle: Standard is 30¬į, though 20¬į, 45¬į, or 60¬į may be required.

- Edge Thickness: Minimum post-bevel thickness should be ‚Č•0.25mm.

- Depth Calculation:

where D = PCB thickness, T = final edge thickness, a = bevel angle.

- Example: D=1.6mm, T=0.3mm, a=30¬į ‚Üí L‚Čą1.12mm.

- Additional Features: Alignment notches or contour cuts help secure the board in the connector.

In conclusion, following these guidelines‚ÄĒimpedance control, precise layout, sufficient plating, solder mask clearance, and proper beveling‚ÄĒensures reliable signal integrity and mechanical performance. Early collaboration with your PCB manufacturer is essential to meet all specifications.

When to Choose Wire-to-Board Card Edge Connector for Power or Data Transmission?

A ‚Äčwire-to-board card edge connector‚Äč is advantageous when direct cable attachment to the PCB edge simplifies the assembly or improves current handling. Use cases include:

- ‚ÄčHigh-Current Applications: Thick cables can be terminated directly to the PCB edge, supporting higher currents than standard headers.

- ‚ÄčCompact Designs: Eliminates the need for a separate connector footprint on the board.

- ‚ÄčVibration-Resistant Assemblies: Crimped or soldered wires provide strain relief.

This type is common in power supplies, automotive control units, and telecom infrastructure where space and reliability are paramount.

What Are the Advantages of Card Edge Power Connector in High-Current Circuits?

‚ÄčCard edge power connectors‚Äč are preferred in high-power systems because they:

- Minimize interconnection resistance by directly coupling the power source to the PCB.

- Support high current ratings (up to tens of amps per contact) with robust plating and adequate trace widths.

- Reduce part count and assembly steps compared to discrete terminal blocks.

They are widely used in server power distribution, industrial motor drives, and renewable energy systems.

How to Select the Best Printed Circuit Card Edge Connectors for Your Project?

Choosing the ‚Äčbest printed circuit card edge connectors‚Äč involves evaluating:

- ‚ÄčCurrent Rating: Ensure the connector meets or exceeds the maximum current, with derating for temperature.

- ‚ÄčPlating Material and Thickness: Hard gold for high-cycle applications; selective plating to reduce cost.

- ‚ÄčMechanical Durability: Check mating cycle specifications and housing material strength.

- ‚ÄčEnvironmental Compliance: Confirm ratings for temperature, humidity, and vibration.

Always validate the chosen connector against industry standards and real-world operating conditions.

Why Choose EBest Circuit (Best Technology) for High-Precision PCB Manufacturing Supporting Card Edge Connectors?

At EBest Circuit (Best Technology), we combine advanced PCB fabrication with stringent process controls to ensure your ‚Äčprinted circuit card edge connectors‚Äč perform reliably in the most demanding applications. Our strengths include:

- Precision multilayer PCB production with tight impedance tolerance (¬Ī10%).

- Accurate gold finger plating with controlled thickness and smooth beveling.

- Full traceability via MES and certifications including IATF 16949, ISO 13485, and AS9100D.

We help customers achieve consistent connector alignment, signal integrity, and long-term reliability. Pls feel free to reach out to our team at sales@bestpcbs.com to discuss your Card Edge power connector PCB project requirements.

‚ÄčTo sum up, printed circuit card edge connectors‚Äč remain a robust, cost-effective solution for board-level interconnections in modern electronics. By understanding their types, design rules, and material requirements, engineers can enhance system performance and durability. EBest Circuit (Best Technology) supports these goals with high-precision PCB manufacturing, rigorous quality assurance, and extensive industry expertise. For reliable ‚ÄčPCB edge connector‚Äč solutions, pls feel free to contact us at sales@bestpcbs.com.