How to choose polyimide PCB material? This blog mainly covers properties and datasheet, selection guide, types, material supplier for polyimide PCB material.

Are you troubled these issues with polyimide PCB material?

- Do your flexible circuit boards frequently delaminate or warp in high-temperature and high-humidity environments, leading to shortened equipment lifespan?

- In complex bending applications, do your PCBs frequently break due to material fatigue, affecting product reliability?

- When pursuing thinner and lighter designs, is your supply chain hampered by high material costs and long lead times, hindering innovation?

As a polyimide PCB manufacturer, EBest Circuit (Best Technology) can provide you service and solutions:

- High-Temperature and High-Humidity Stability Service: We provide customized polyimide material formulations, enhancing substrate adhesion and environmental resistance to ensure dimensional stability under extreme conditions ranging from -40°C to 200°C, extending equipment lifespan.

- Dynamic Bending Reinforcement Solution: Utilizing proprietary modified polyimide lamination technology, the material’s bending life is increased to over 1 million cycles. Combined with simulation design support, it precisely matches your structural needs, eliminating the risk of breakage.

- Cost Optimization and Rapid Response: Leveraging large-scale production and a flexible supply chain, we provide cost-effective standard products and rapid prototyping services, shortening lead times to within 7 days, helping you accelerate product launch.

Welcome to contact us if you have any request for polyimide PCB material: sales@bestpcbs.com.

What Is Polyimide PCB Material?

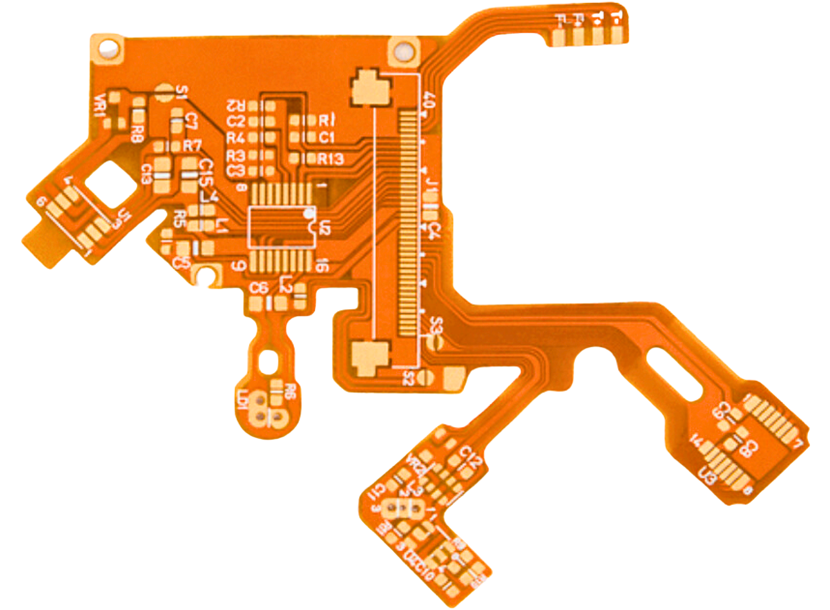

Polyimide (PI) PCB material is a special substrate material designed specifically for high-performance, high-reliability printed circuit boards (PCBs). Made of polyimide resin, its core characteristics lie in its excellent resistance to extreme high temperatures (typically operating stably above 260°C for extended periods) and outstanding thermal stability. It maintains excellent electrical insulation, high mechanical strength, and good chemical stability even under drastic temperature changes. This material is particularly suitable for manufacturing flexible printed circuit boards (FPCs) and rigid-flex boards, and is widely used in fields with extremely stringent requirements for heat resistance, dimensional stability, and reliability, such as aerospace, military electronics, automotive engine control units, and core components of high-end mobile devices.

What Is Key Property of Polyimide PCB Material?

Key Properties of Polyimide PCB Material:

- High Temperature Resistance: Glass transition temperature (Tg) ranges from 250°C to 350°C, with some high-performance variants exceeding 400°C. It maintains stable operation in extreme environments from -269°C to 400°C and withstands short-term exposure above 500°C, making it ideal for aerospace engines and automotive engine peripherals.

- Mechanical Strength: Tensile strength reaches 100-300MPa, bending modulus 2-5GPa, combining high strength with flexibility. This supports foldable/curved designs for flexible electronics like foldable smartphones and wearable devices.

- Electrical Insulation: Volume resistivity is 10^16-10^18 Ω·cm, dielectric constant 3-4 (reduced to below 2.5 with fluorine or nano-air incorporation), and low dielectric loss (about 1×10^-3). These reduce signal interference and transmission loss, ensuring stability in high-frequency and high-speed circuits.

- Chemical Resistance: Resistant to acids, alkalis, and organic solvents, though not concentrated sulfuric/nitric acid or halogens. Suitable for corrosive environments like chemical monitoring and marine electronics.

- Radiation and Thermal Stability: Retains 90% strength after 5×10^9 rad fast electron irradiation and exhibits low outgassing in high vacuum. This meets radiation protection and thermal control needs for satellites and medical implants.

- Dimensional Stability: Low coefficient of thermal expansion (CTE) of 2×10^-5/°C to 3×10^-5/°C, with biphenyl-based variants as low as 1×10^-6/°C, close to metal CTE. This minimizes warpage under temperature fluctuations, ensuring precision in high-density interconnect (HDI) designs.

- Flame Retardancy: Self-extinguishing with low smoke emission and over 50% char yield, complying with UL-V0/V1 standards for enhanced electronic device safety.

- Biocompatibility: Non-toxic and certified for biocompatibility in certain models, suitable for medical implants and reusable surgical instruments requiring repeated sterilization.

Polyimide PCB Material Datasheet

| Parameter Item | Typical Value & Unit |

| Density | 1.39 – 1.45 g/cm³ |

| Water Absorption (24h immersion) | 0.2% – 0.3% |

| Color | Amber/Dark Brown |

| Glass Transition Temperature (Tg) | >250°C (some models >400°C) |

| Thermal Decomposition Temperature (Td) | 550 – 600°C |

| Coefficient of Thermal Expansion (CTE) < Tg | 12 – 20 ppm/°C (X/Y axis) |

| Coefficient of Thermal Expansion (CTE) > Tg | 30 – 60 ppm/°C (Z axis) |

| Thermal Conductivity | 0.1 – 0.35 W/(m·K) |

| Dielectric Constant (Dk) @10GHz | 3.2 – 3.6 |

| Dissipation Factor (Df) @10GHz | 0.001 – 0.005 |

| Volume Resistivity | 10¹⁵ – 10¹⁷ Ω·cm |

| Surface Resistivity | 10¹³ – 10¹⁵ Ω/sq |

| Electrical Strength | 120 – 200 kV/mm |

| Tensile Strength | 230 – 350 MPa |

| Tensile Modulus | 2.5 – 3.5 GPa |

| Flexural Strength | 300 – 450 MPa |

| Peel Strength (1oz copper foil) | 0.7 – 1.2 N/mm |

| Maximum Continuous Operating Temperature | 240 – 260°C |

| Short-term Solderability (Sn/Ag/Cu) | 30s @ 400°C |

| Laser Processability | Excellent (UV/CO₂ laser) |

Common Polyimide PCB Material Types

Kapton Series Polyimide Film (DuPont)

- Core Parameters: Tg > 250°C, Td > 360°C, thickness range 7.5–125μm, width 1500mm.

- Application Scenarios: Aerospace (e.g., NASA Mars rover), flexible printed circuits (FPC), high-frequency antennas.

- Certification Standards: Complies with UL-94 V0 flammability rating, passes ASTM D5204 space radiation resistance tests.

- Advantages: Long-term operating temperature ≥ 250°C, chemical corrosion resistance, high mechanical strength (tensile strength > 200MPa), suitable for extreme environments.

Upilex Series Polyimide Film (UBE Industries)

- Core Parameters: Upilex S type Tg > 280°C, dimensional stability < 50ppm/°C, moisture absorption < 0.5%.

- Application Scenarios: 5G base station high-frequency circuits, precision medical devices, satellite communication modules.

- Technical Features: Linear polyimide molecular structure, stable dielectric constant (3.4–3.6 at 1GHz), dielectric loss < 0.003.

- Certification Status: ISO 9001 quality management system certified, JIS C 6481 standard compliant.

Apical Polyimide Substrate (Kaneka Corporation)

- Core Parameters: Tg > 260°C, thermal decomposition temperature > 400°C, thickness range 25–225μm.

- Application Scenarios: Flexible display devices, automotive electronics (e.g., engine control units), superconducting facility insulation layers.

- Special Performance: Low-temperature resistance to -269°C (liquid helium environment), radiation resistance > 100kGy, suitable for nuclear industry equipment.

- Production Scale: Annual global capacity exceeds 5 million square meters, primarily exported to high-end manufacturing in Europe and America.

High Tg Polyimide Copper Clad Laminate (e.g., Tenghui VT-901)

- Core Parameters: Tg = 250°C, Td = 395°C, CTE < 50ppm/°C (Z-axis direction).

- Application Scenarios: Aerospace HDI boards, military radar systems, high-power power modules.

- Certification Cases: European Space Agency (ESA) certified, meets IPC-4101E standards, suitable for ACB Group HDI manufacturing.

- Performance Advantages: Lead-free soldering resistance (peak temperature 260°C), via reliability improved by 5 times compared to FR-4 materials.

Adhesiveless Polyimide Flexible Copper Clad Laminate (DuPont Pyralux Series)

- Core Parameters: Vacuum sputtering/electroplating copper technology, no adhesive layer, thickness 18–35μm.

- Application Scenarios: 5G smartphone FPC antennas, wearable devices (e.g., smartwatches), high-frequency RF modules.

- Technical Advantages: 30% reduction in high-frequency signal loss, enhanced flexibility (bending radius < 1mm), fatigue resistance > 100,000 cycles.

- Manufacturers: DuPont, Toray-DuPont joint venture, global market share exceeds 60%.

Metal-Based Polyimide Composite Materials

- Core Parameters: Aluminum base thermal conductivity > 2W/mK, copper base thermal conductivity > 5W/mK, PI layer thickness 25–100μm.

- Application Scenarios: LED lighting heat dissipation modules, IGBT driver boards, new energy vehicle battery management systems.

- Performance Comparison: 3–5 times higher heat dissipation efficiency than traditional FR-4, thermal cycling life doubled.

- Typical Case: Tesla Model 3 battery pack uses aluminum-based PI composite boards for efficient heat dissipation and lightweight design.

Transparent Polyimide Film (Mitsubishi Gas Chemical AURUM)

- Core Parameters: Light transmittance > 88%, Tg > 260°C, thickness 12.5–50μm.

- Application Scenarios: Flexible OLED displays, optical lens protective films, transparent conductive films.

- Technical Breakthrough: World’s only industrially produced transparent PI material, meets flexible electronic display requirements.

- Market Application: Core material for Samsung Galaxy Z Fold series foldable smartphones.

How to Choose Polyimide PCB Material?

Below is a detailed selection guide for polyimide PCB material:

1. Core Performance Parameter Matching

- Heat Resistance: Prioritize materials with glass transition temperature (Tg) ≥250°C and thermal decomposition temperature (Td) ≥360°C, such as DuPont Kapton series (Tg>250°C) or Ube Upilex S type (Tg>280°C), to ensure stability during high-temperature soldering (peak 260°C) and long-term operation (200-300°C).

- Electrical Performance: For high-frequency scenarios (e.g., 5G antennas), focus on dielectric constant (3.4-3.6@1GHz) and dissipation factor (<0.003). Adhesive-free Pyralux series is recommended (30% signal loss reduction). For high-voltage applications, ensure insulation resistance ≥10³MΩ.

- Mechanical Strength: Tensile strength >200MPa, bending radius <1mm, fatigue life >100,000 cycles, suitable for dynamic applications like flexible screens and wearables.

2. Core Performance Parameter Matching

- Aerospace: Select materials with radiation resistance >100kGy and dimensional stability <50ppm/℃, such as Tenghui VT-901 (ESA certified) or Kaneka Apical (resistant to liquid helium low temperatures), meeting extreme environment requirements for satellites and Mars rovers.

- Automotive Electronics: Prioritize metal-based PI composite boards (aluminum-based thermal conductivity >2W/mK, copper-based >5W/mK) or high-Tg polyimides, suitable for IGBT driver boards and battery management systems with thermal and vibration requirements.

- Medical Devices: Choose biocompatible transparent PI (e.g., Mitsubishi AURUM, light transmittance >88%) or Apical series, ensuring non-toxicity, corrosion resistance, and compliance with FDA/ISO 10993 standards.

3. International Certification and Standard Compliance

- Core Certifications: UL-94 V0 (flame retardant), ASTM D5204 (space radiation), ISO 9001 (quality system). European customers should focus on ESA, MIL-STD-810G aerospace standards; Japanese market requires JIS C 6481 compliance.

- Industry Standards: IPC-4101E (substrate specifications), IPC-6011 (performance requirements), RoHS/REACH (environmental restrictions), ensuring material traceability and compliance.

4. Cost and Supply Chain Optimization

- Cost Control: Balance performance and cost by application. Adhesive-free Pyralux series, though higher in unit price, reduces signal loss and long-term costs. Metal-based composite boards lower system costs in thermal management scenarios.

- Supply Chain Reliability: Prioritize suppliers with overseas factories or long-term partnerships, such as DuPont and Toray-DuPont joint ventures (market share >60%), ensuring delivery cycles and after-sales support.

5. Environmental and Sustainability Considerations

- Environmental Compliance: Materials must pass RoHS 2.0, REACH SVHC list, avoiding hazardous substances like lead and mercury. Recyclable designs (e.g., 80-90% Kapton recovery rate) align with circular economy trends.

- Low-Carbon Production: Select suppliers using green processes (e.g., catalytic enhanced imidization, ultrasonic-assisted solvent removal) to reduce energy consumption and carbon emissions, meeting EU Carbon Border Adjustment Mechanism (CBAM) requirements.

Common Polyimide PCB Material Suppliers

DuPont (USA)

- Products: Kapton® series polyimide films (H/F/V, HN/FN/VN variants), Pyralux® flexible circuit materials.

- Technical Advantages: Pioneer in industrial polyimide production. Kapton films offer thermal stability from -269°C to 400°C, excellent electrical insulation, dimensional stability, and chemical resistance. Pyralux AP series supports high-frequency signal transmission for 5G, AI servers, and aerospace.

- Applications: Flexible printed circuit boards (FPC), aerospace, semiconductor packaging, automotive motor insulation, consumer electronics (e.g., Apple, Huawei supply chains).

UBE Industries (Japan)

- Products: Upilex® polyimide films (R/S/C types), Iupicel®N copper-clad laminates.

- Technical Advantages: Biphenyl-based polyimide structure. Upilex S films withstand over 300°C, feature low moisture absorption and superior dimensional stability. Iupicel N non-adhesive FPC laminates reduce performance degradation.

- Applications: FPC substrates, flexible displays, high-frequency circuits, automotive electronics, semiconductor packaging.

Kaneka Corporation (Japan)

- Products: Apical polyimide films, Pixeo® high-heat-resistant PI films.

- Technical Advantages: Pyromellitic PI technology. Apical films provide dimensional stability and corona resistance. Pixeo films exceed 260°C glass transition temperature with >88% transparency for flexible displays and optical components.

- Applications: FPCs, satellite communications, superconducting insulation, EV battery insulation, 5G base station antennas.

SKC Kolon PI (South Korea)

- Products: High-performance PI films (IN/IF/IS series), flexible composites.

- Technical Advantages: Thickness control (12.5–25μm), high tensile strength, low dielectric constant for ultra-thin designs in FPC and OLED applications.

- Applications: Smartphone flexible screens, wearables, automotive electronics, high-frequency modules.

Mitsui Chemicals (Japan)

- Products: AURUM™ thermoplastic polyimide, transparent PI films.

- Technical Advantages: AURUM™ withstands over 260°C, balancing heat resistance and processability. Transparent PI films meet display industry light transmission requirements.

- Applications: Precision components, automotive seals, aerospace engine parts, flexible display substrates.

- Global Presence: Japanese facilities, North American/European sales networks, collaborations with global automotive/electronics firms.

DuPont-Toray (Joint Venture)

- Products: Kapton® PI films and composites.

- Technical Advantages: Combines DuPont technology with Toray’s production scale, supporting 1500mm film widths for mass FPC production.

- Applications: Flexible circuits, high-frequency modules, EV battery insulation, aerospace lightweight parts.

Evonik (Germany)

- Products: P84® polyimide fibers, high-performance PI powders.

- Technical Advantages: P84 fibers resist 300°C, chemical corrosion for industrial filtration, protective gear, and aerospace seals. PI powders enable customized engineering plastics.

- Applications: High-temperature filtration, aerospace, semiconductor manufacturing, advanced equipment protection.

SABIC (Saudi Arabia)

- Products: EXTEM™ thermoplastic polyimide resins.

- Technical Advantages: 311°C glass transition temperature, flame-retardant, halogen-free, customizable transparency/opacity.

- Applications: Aerospace, automotive lightweighting, high-frequency modules, medical devices.

How to Select A Reliable Polyimide PCB Material Supplier?

1. Rigorous Review of Quality Certifications and Industry Qualifications

- Prioritize suppliers with ISO 9001/14001, UL, and RoHS/REACH compliance to ensure materials meet international safety and environmental standards. For example, DuPont Kapton films are NASA-certified for aerospace applications; Ube’s Upilex series is IATF 16949 certified for the automotive industry, meeting the demands of high-precision electronics.

- Verify that suppliers possess third-party testing reports for material performance (e.g., thermal stability, dielectric constant, chemical resistance) to ensure data traceability.

2. Rigorous Review of Quality Certifications and Industry Qualifications

- Clearly define application scenario requirements, High-frequency, high-speed communication requires low dielectric constants (e.g., DuPont Pyralux AP series Dk≈3.5); high-temperature applications require glass transition temperatures (Tg≥260℃) (e.g., Mitsui Chemicals AURUM™); flexible displays require high light transmittance (e.g., Kanekachi Pixeo® transparent PI film with >88% light transmittance).

- Compare supplier product specifications to ensure that parameters such as film thickness tolerance (e.g., ±1μm), tensile strength, and coefficient of thermal expansion match design requirements, avoiding selection errors.

3. Assess supply chain stability and global footprint

- Select suppliers with global production bases and localized technical support. For example, DuPont has factories in the US, Taiwan, and Europe, ensuring rapid delivery and after-sales response; SKC Kolon has factories in South Korea, Shenzhen, and Southeast Asia, catering to the needs of Asian and emerging markets.

- Confirm whether the supplier provides JIT (Just-in-Time) or VMI (Vendor Managed Inventory) services to reduce inventory costs and delivery cycle risks.

4. Verify R&D capabilities and customization services

- Prioritize suppliers with independent laboratories and patented technologies. For example, the Toray-DuPont joint venture can provide 1500mm wide films suitable for large-scale FPC production; Evonik P84® fiber supports customized modification for high-temperature filtration.

- Confirm whether the supplier provides material selection consultation, process optimization support (such as lamination parameters, etching processes), and certification assistance (such as UL certification, automotive industry PPAP documents) to ensure full-process support from design to mass production.

5. Analyze customer cases and industry reputation

- Refer to the supplier’s historical customer list, such as DuPont supplying Apple and Huawei; Ube Industries’ deep cooperation with global PCB manufacturers; and SABIC serving the aerospace and medical device fields.

- Verify supplier reliability through industry forums and third-party evaluations (such as Gartner supply chain reports) to avoid choosing suppliers with quality disputes or delivery issues.

6. Assess cost-effectiveness and long-term cooperation potential

- Compare the pricing structures of different suppliers, considering bulk purchase discounts and annual framework agreement benefits, but be wary of low-price traps (such as sacrificing material purity or process control).

- Prioritize suppliers that offer long-term technical cooperation, joint R&D (such as jointly developing high-frequency PI materials), and supply chain transparency to build strategic partnerships to meet future technological iteration needs.

7. Test Samples and Validation Compatibility

- The supplier is required to provide free samples or small-batch trial production of materials to verify their performance in specific applications (e.g., bending resistance, signal loss, thermal stability) through actual testing.

- Accelerated aging tests (e.g., high temperature and humidity, thermal shock) and reliability verification should be conducted to ensure the material’s stability under extreme environments and avoid quality defects after mass production.

Welcome to contact us if you have any inquiry for polyimide PCB material: sales@bestpcbs.com.