Why choose Colorado polyimide flex PCB manufacturer? This blog is mainly about selection guide and required quality certifications for Colorado flex manufacturers.

Are you troubled with these questions?

- What to do when flexible PCB cracks easily after repeated bending?

- How to ensure stable soft board performance in high-temperature environments?

- How to control costs when design and production cycles are too long?

As a professional Polyimide flex PCB manufacturer, EBest Circuit (Best Technology) can provide you serv ice and solution:

- Customized Flexibility Design: Leverage 19 years of experience for simulation-optimized bending structures, ensuring integrity through million-cycle bending tests and extending product life by 30%.

- High-Temperature Adaptability Solution: Select polyimide materials with -40°C to 200°C resistance, combined with precision lamination to disperse thermal stress, ensuring stable operation in harsh environmentsâproven in consumer electronics and medical devices.

- Rapid Response Manufacturing System: Intelligent production lines + end-to-end service reduce sample delivery to 7 days, compress mass production cycles by 20%, cutting costs while accelerating time-to-market.

Welcome to contact us if you have any inquiry for flexible polyimide PCB: sales@bestpcb.com.

Why Choose Colorado Polyimide Flex PCB Manufacturer?

Reasons Why Choose Colorado Polyimide Flex PCB Manufacturer:

- Localized rapid delivery: Colorado hosts multiple local PCB manufacturers, such as Advanced Circuits and PCB Prime, capable of completing the entire process from production to delivery within 1 day to 4 weeks, significantly shortening project cycles.

- Professional processing capabilities for polyimide materials: Local manufacturers have mature experience in polyimide flexible board production, providing circuit boards with high heat resistance (long-term operating temperature over 200°C), excellent chemical stability, and mechanical flexibility, suitable for harsh environments in aerospace, medical, and automotive electronics.

- Comprehensive service coverage: From design review, prototype production, multi-layer boards (up to 40 layers) to assembly (SMT/THT), Colorado manufacturers offer one-stop solutions, avoiding communication and quality risks associated with cross-regional collaboration.

- Strict quality and compliance standards: Most manufacturers hold certifications such as ISO 9001, ITAR, and UL, and implement processes like impedance control, microvia laser drilling, and dynamic bending tests during production to ensure performance in high-frequency, high-reliability scenarios.

- Technical support and customization: Engineering teams in Colorado are familiar with complex designs such as rigid-flex boards, HDI, and high-frequency materials (e.g., Rogers), providing customized solutions for signal integrity, thermal management, and space constraints.

- Supply chain resilience: Local production reduces delivery delays caused by international logistics, tariffs, or geopolitical factors, while facilitating on-site audits and sample verification to lower project risks.

Top Polyimide Flex PCB Manufacturers in Colorado

Advanced Circuits (AdvancedPCB)

- Business: Offers manufacturing of rigid, flexible, and rigid-flex circuit boards from prototyping to mass production, covering high-speed, RF, and microwave applications.

- Strengths: Boasts U.S.-based production facilities, provides free design verification software, no minimum order quantity, rapid delivery (same-day shipping available), and adheres to international standards such as IPC and RoHS for quality systems.

AlteraFlex Circuits

- Business: Specializes in rapid prototyping and mid-to-large volume production of flexible and rigid-flex circuit boards with assembly, serving regions like Denver and Aurora in Colorado.

- Strengths: Features an engineering team with over 30 years of experience, offers 24/7 project management and local technical support, and supports end-to-end processes from design to mass production.

PCB Unlimited

- Business: Manufactures flexible and rigid-flex circuit boards, primarily using polyimide as the substrate material for its flexible boards.

- Strengths: Exhibits flexible order handling capabilities, supports small-to-medium batch production with competitive pricing, and provides a comprehensive range of material options and surface treatment processes.

Nexus PCB

- Business: A Denver-based PCB design and manufacturing expert, offering over 30-layer rigid, flexible, and rigid-flex boards with advanced processes such as blind/buried vias and non-conductive via filling.

- Strengths: Provides rapid lead times ranging from 24 hours to 10 days, suitable for commercial and military-grade applications, and possesses high-density interconnect (HDI) technology capabilities.

Required Quality Certifications for Colorado Polyimide PCB Project

ISO 9001: Global Quality Management System Standard

- Widely recognized by US customers, this certification demonstrates the ability to consistently deliver products meeting international standards, applicable to high-reliability fields such as medical and industrial control.

UL Certification: Mandatory Safety Certification for North American Market

- Underwriters Laboratories’ authoritative certification verifies the electrical safety performance of PCBs (e.g., fire resistance, voltage resistance, compliance of flame-retardant materials). It is a mandatory requirement for entering the US market, particularly suitable for high-temperature applications of polyimide materials.

AS9100: Specialized Certification for Aerospace Industry

- Based on ISO 9001 expansion, applicable to the US aerospace supply chain (e.g., Boeing, NASA suppliers). It requires critical characteristic identification, production environment control, and full traceability to ensure reliability under extreme conditions.

IATF 16949: Automotive Industry Quality Benchmark

- Standard of the International Automotive Task Force, mandatory for US automakers such as Ford and General Motors. It focuses on defect prevention and supply chain consistency, suitable for high-reliability automotive electronics PCBs

ISO 13485: Medical Device Quality Management Standard

- Specialized quality management system for the US medical device industry, integrating FDA regulatory requirements. It emphasizes risk management and full lifecycle traceability, applicable to medical equipment PCBs.

FCC Certification: US Electromagnetic Compatibility Mandatory Standard

- Federal Communications Commission certification verifies the electromagnetic radiation and interference immunity of PCBs. Essential for PCBs with wireless modules (e.g., Bluetooth, Wi-Fi) to comply with US electromagnetic compatibility regulations.

CB Certification: International Mutual Recognition Accelerates US Market Access

- Through IECEE standard test reports, it can quickly convert to US certifications such as UL, reducing redundant testing costs and accelerating US customer recognition of product compliance.

How to Choose Colorado Polyimide Flex PCB Manufacturers?

A Detailed Guide to Colorado Polyimide Flex PCB Manufacturer:

1. Technical Capability Verification

- Require provision of patent documents for double-sided/multi-layer flexible PCB design and polyimide material special treatment process parameters (e.g., temperature resistance range -200°C to +300°C, bending life â¥1 million cycles).

- Verify minimum line width/spacing precision (e.g., â¤50μm), HDI design capability, and successful case data in medical/aerospace fields (e.g., pacemaker circuit boards, satellite antenna flexible components).

2. Quality Certification Verification

- Mandatory requirements include ISO 9001, ISO 13485 (medical), UL 94 V-0 certifications, and request for polyimide material high-temperature/chemical corrosion resistance special test reports (e.g., ASTM D522 vertical combustion test).

- Confirm compliance with EU RoHS, REACH environmental directives, and US FDA medical device registration requirements, with third-party certification documents provided.

3. Supply Chain Transparency Management

- Require demonstration of raw material procurement (polyimide film suppliers must be Tier 1 manufacturers such as DuPont/Kaneka), conductive paste batch traceability system, and real-time monitoring of key node data (e.g., lamination temperature curves, etching uniformity).

- Reject intermediary-type suppliers relying on external subcontracting and ensure the manufacturer has a complete in-house production line (including laser cutting, chemical nickel/gold plating equipment).

4. Customized Service Responsiveness

- Evaluate 24-hour rapid prototyping capability (e.g., sample delivery within 48 hours) and small-batch production feasibility (e.g., MOQ â¤100 pieces), and verify experience in handling special requirements (e.g., non-rectangular irregular boards, embedded components like resistors/capacitors between layers).

- Confirm provision of free DFM analysis services, including manufacturability assessment reports (e.g., pad design optimization suggestions) and electrical performance simulation data.

5. Cross-Timezone Communication Support

- Select manufacturers with multilingual technical teams (English + German/Japanese/etc.) providing 7Ã24 online support, specifying communication channels (e.g., dedicated customer portal, video conferencing systems) and response timelines (e.g., urgent issues replied within 2 hours).

- Verify presence of local warehouses or partner service providers in target markets (e.g., Munich, Germany; Tokyo, Japan) to shorten logistics cycles to 3-5 working days.

6. Cost Transparency Guarantee

- Require itemized quotation sheets (material costs â¤40%, processing costs â¤30%, testing costs â¤15%, logistics costs â¤15%), with clear price fluctuation mechanisms for mass production (e.g., annual decrease of 3%-5%) and volume discount policies (e.g., â¥1000 pieces enjoy 10% discount).

- Verify availability of extended warranty periods (e.g., extended to 2 years), spare parts inventory sharing (e.g., 500 spare pieces in stock), and other long-term cooperation terms to reduce maintenance costs.

7. Environmental Sustainability Commitment

- Prioritize manufacturers certified with ISO 14001, requesting specific environmental indicators (e.g., waste recycling rate â¥95%, unit energy consumption â¤5kWh/m², carbon footprint â¤2kg COâe/m²).

- Confirm adoption of lead-free processes, water-based cleaning, and other green production technologies, supporting customer participation in carbon footprint accounting (e.g., providing production process emission data) and emission reduction target setting (e.g., commitment to carbon neutrality by 2025).

Why Colorado Clients Choose EBest Circuit (Best Technology) for Polyimide PCB?

Reasons Why Colorado Clients Choose EBest Circuit (Best Technology) for Polyimide PCB:

- Free DFM Analysis: Provide free Design for Manufacturing (DFM) analysis to identify production risks in advance, reduce rework costs for international clients, and ensure first-pass design success.

- 19 Years of Flexible PCB Expertise: Deep specialization in polyimide flexible PCB for 19 years, with extensive process databases to precisely match complex technical requirements of international clients and shorten development cycles.

- Senior Engineer Team: Average 10+ years of industry experience per engineer, familiar with European and American technical standards, offering full-process technical support from design to mass production to resolve international clients’ technical challenges.

- Rapid Prototyping Service: 48-hour quick prototyping to support international clients in rapid design verification and market opportunity capture, ideal for small-batch, multi-variety international orders.

- Low MOQ Flexible Production: MOQ as low as 1 piece, no minimum order quantity restrictions, significantly reducing inventory pressure and capital occupation for international clients, adapting to customized small-batch needs.

- Cost Competitiveness Guarantee: Through scaled production and supply chain optimization, offer price advantages comparable to international peers while ensuring profit margins, assisting international clients in cost control.

- Dual Quality Certification System: Certified by ISO 9001 Quality Management System and ISO 13485 Medical Device Quality Certification, meeting stringent European and American standards to provide traceable quality assurance for international clients.

- Strict Quality Control Process: Adopt AQL sampling standards and full-process quality monitoring, with 12 inspection procedures from raw materials to finished products, ensuring zero-defect delivery for international clients.

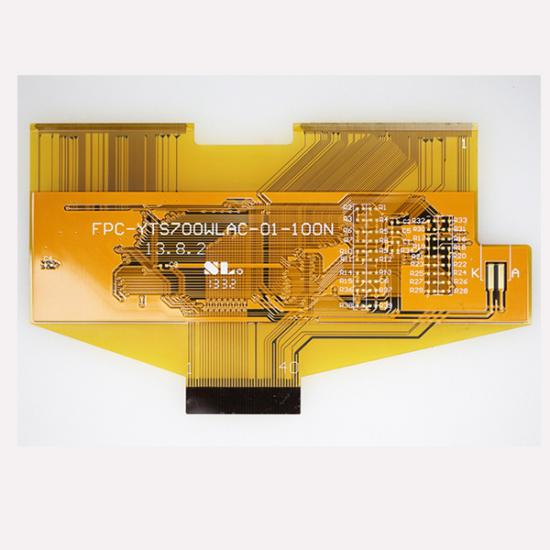

Our Polyimide Flex PCB Fabrication Capabilities

| Item | Capabilities |

| Layers Count | 1-10L |

| Max Board Dimension: | 1L:500*2000mm; 2L:250*1380mm |

| Conductor Thickness: | 1/3 OZ (12 um) – 4OZ (140um) |

| Min Line Width/Line Space: | 2/2mil |

| Min Hole Spacing: | NPTH:16mil; PTH:20mil |

| Hole Position Deviation: | ±4mil (0.10mm) |

| Outline Tolerance: | Laser: +0.15mm/-0.05mm; |

| Die Punch: +0.10/-0.20 mm | |

| Surface Treatment: | ENIG(Au 4u”), Hard Gold Plating (Au 50u”), Immersion Silver, Immersion Tin, OSP, ENEPIG |

Case Studies of Our Polyimide Flex PCB Project

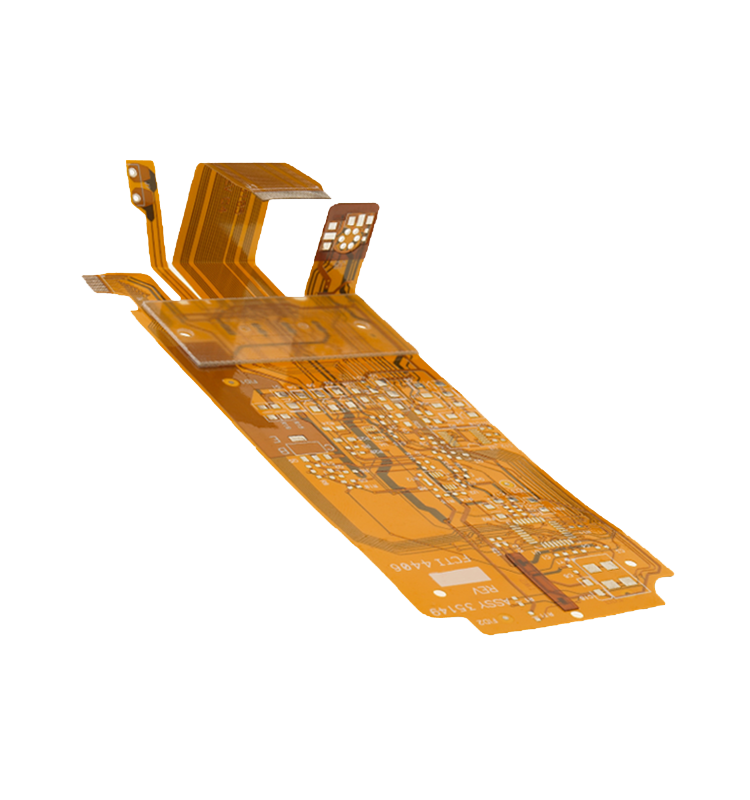

Project Background

A deep space exploration device requires long-term operation under conditions of intense vibration, wide temperature range (-55°C to 125°C), and strong radiation. The original solution used traditional rigid wiring harnesses, weighing 1.5 pounds (approximately 680 g), with complex wiring and error-prone assembly, failing to meet the device’s dual requirements for lightweight design and reliability.

Solution

1. Material Selection

- The substrate employs glass fiber reinforced polyimide (copper-clad glass-supported polyimide) and pure polyimide film (flexible polyimide film), combined with polyimide prepreg and acrylic adhesive, ensuring dimensional stability and chemical resistance at high temperatures.

- The cover layer is entirely polyimide, covering copper foil and the pad-trace transition area, significantly enhancing bending resistance.

2. Structural Design

- Designed as a 30-layer rigid-flex combination board with 7 press cycles, achieving high-density interconnection and isolating signal, power, and ground layers within limited space.

- Teardrop-shaped pad-trace transition structures reduce stress concentration, preventing copper foil fracture caused by dynamic bending.

3. Process Innovation

- Concurrent engineering was adopted, and the entire manufacturing process was completed in-house, shortening the development cycle and reducing outsourcing risks.

- The polyimide cover thickness in critical areas was increased to 25 μm, further improving mechanical durability.

Solution Results

- Significant Weight Reduction: The final circuit board weighs only 87 g, approximately 87% lighter than the original wiring harness, greatly reducing system load.

- Enhanced Reliability: Operated continuously for 90 days in extreme Martian surface environments, far exceeding the original 30-day mission target, with no electrical or mechanical failures.

- Technology Inheritance: This solution became the baseline design for subsequent deep space missions, validating the maturity and reliability of polyimide flexible circuits in aerospace-grade applications.

How to Get A Quote for Polyimide Flex PCB Project?

All Materials Required for Polyimide Flex PCB Project:

- Technical Specification Sheet: English version, including number of layers, dimensions, thickness (e.g., 25μm polyimide), temperature resistance range (-200â to 300â), impedance control value, flexibility grade (bending radius â¥1mm), material certification standards (e.g., UL EI4401, IPC-4204).

- Design File Package: Gerber files (including impedance layer and drilling files), BOM list (accurate to component models/packages), CAD design drawings (3D models or STEP files).

- Testing and Certification Documents: Sample thermal shock test report, bending life test report (â¥1 million cycles), UL/SGS certification originals, RoHS/REACH compliance declaration, IPC-6013D Class 2/3 standard compliance certificate.

- Production Capacity and Quality Certification: Production capacity certificate for monthly output â¥5000ã¡, AQL sampling standard process, quality management system documents (e.g., ISO 9001/TS 16949).

- Business and Logistics Documents: English version inspection report, certificate of origin, packaging specifications (anti-static/moisture-proof), DHL/FedEx international logistics agreement, payment method confirmation letter (e.g., T/T 30% advance payment).

- Intellectual Property and Legal Documents: NDA non-disclosure agreement, intellectual property ownership statement, draft contract (including technical parameters, acceptance criteria, liability for breach of contract).

Welcome to contact us if you have any request for polyimide flex PCB: sales@bestpcbs.com.