Looking for PCBA contract manufacturing service? This guide explains China PCBA contract manufacturing, its process, benefits, and how EBest Circuit (Best Technology) supports your projects from idea to shipment.

PCBA contract manufacturing provides a practical solution for companies seeking fast, stable, and cost-effective electronic production, enabling teams to focus on design while experienced partners manage fabrication and assembly. In todayÔÇÖs global market, this PCBA contract manufacturing approach reduces risk, shortens timelines, and leverages ChinaÔÇÖs mature supply chain and broad process capability as a top choice. As demand grows for smaller, smarter, and more advanced products, trusted partners like EBest Circuit (Best Technology) become essential, supporting brands, startups, and OEMs with consistent results, clear communication, and dependable engineering guidance across PCB fabrication, component sourcing, and surface-mount assembly to turn concepts into predictable-quality products step by step.

What Is PCBA Contract Manufacturing Service?

PCBA contract manufacturing is a production model where a company outsources the fabrication and assembly of printed circuit board assemblies to a specialized factory. Instead of managing several vendors, buyers rely on one partner that handles everything. This approach removes unnecessary steps and keeps the project workflow smooth.

In simple terms, you provide your design files. Then the manufacturer handles PCB fabrication, materials sourcing, assembly, soldering, testing, and packaging. Some customers also request firmware loading and functional checks to create a complete unit. Because of this integrated approach, PCBA contract manufacturing helps reduce cost, lower engineering mistakes, and avoid production delays. As a result, companies can stay focused on product improvement and market growth.

Why Choose China PCBA Contract Manufacturing Service?

Benefits of China PCBA Contract Manufacturing Service:

- Full Industrial Chain Ecosystem Synergy: Covers the entire chain from laminate materials, components, solder paste suppliers, testing labs to logistics hubs. This integrated ecosystem shortens lead times and reduces operational costs while providing “one-stop” supply chain services.

- Full Production Scale Coverage: Supports all stages from small-batch prototyping to million-unit mass production, meeting needs for rapid iteration during development and stable supply during mass production phases.

- International Certification Quality Assurance: Certifications including ISO9001, ISO13485 (medical), AS9100D (aerospace), and IATF16949 (automotive) ensure product quality stability, meeting stringent requirements for automotive, medical, and other high-reliability applications.

- Advanced Process Technology Capability: Rich experience in HDI boards, high-frequency laminates, fine-pitch devices (01005/008004), and complex multi-stage assemblies enables high-performance product realization in communications, IoT, medical devices, automotive control systems, and industrial monitoring equipment.

- Cost-Performance Advantage: Competitive pricing for high-quality products combined with advanced equipment and professional engineering support achieves optimal balance of cost, quality, and responsiveness.

What Does China PCBA Contract Manufacturing Service Include?

China PCBA Contract Manufacturing Service Include:

Component Sourcing & Supply Chain Management:

- Procures components based on BOM (Bill of Materials).

- Manages supplier networks and mitigates material shortage risks.

PCB Bare Board Production Oversight (Optional)

- May handle in-house PCB fabrication or outsource manufacturing.

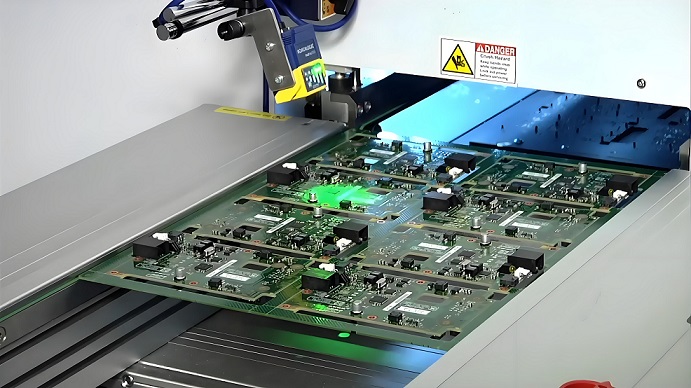

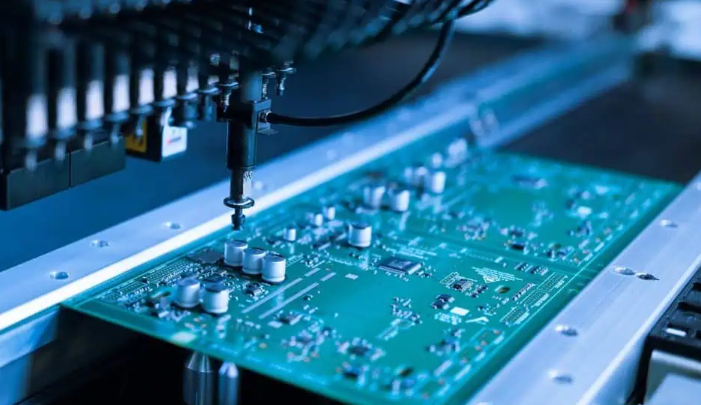

SMT Assembly

- Utilizes high-speed pick-and-place machines to mount micro-components onto PCBs.

Through-Hole Component Insertion

- Implements manual/automated DIP (Dual In-line Package) insertion followed by wave/selective soldering.

Soldering Processes

- Reflow soldering (for SMT) and wave/selective soldering (for DIP).

Post-Soldering Cleaning (Optional)

- Removes solder residues, critical for high-reliability applications.

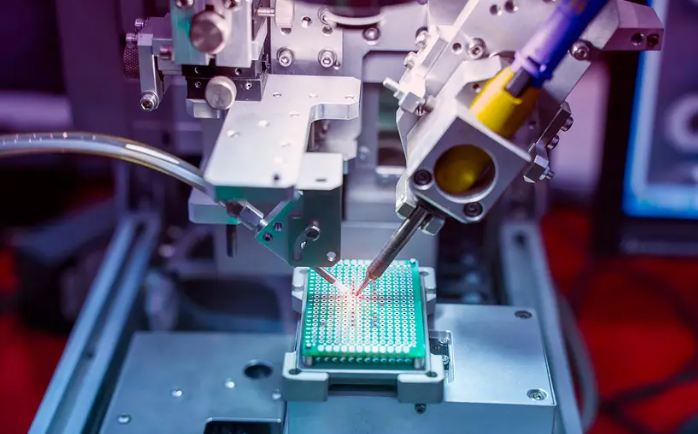

Testing & Inspection

- AOI (Automated Optical Inspection), X-Ray inspection, ICT (In-Circuit Test), FCT (Functional Circuit Test), burn-in testing, etc.

Assembly & System Integration

- Performs box-build assembly (housing PCBA, connecting cables, etc.)

Packaging & Logistics

- Packages finished products per customer specifications and coordinates global shipment.

Delivery Output

- Provides fully functional, quality-assured PCBA modules or complete turnkey products.

PCBA Contract Manufacturing Process

PCBA Contract Manufacturing Full Process:

1. Engineering Review: Design for Manufacturability Verification

- Technical team cross-checks Gerber files, BOM, pick-and-place data, and assembly drawings

- Validates line width/spacing against HDI process capabilities, BOM material availability, and pad design compatibility with automated equipment.

- Prevents design-related mass production issues through proactive risk mitigation.

2. PCB Fabrication: Precision & Material Control

- Customizes PCB substrates (FR4, Rogers high-frequency materials), copper thickness, solder mask accuracy, and impedance control as required.

- Key processes include inner layer etching, laminate alignment (┬▒0.05mm drilling tolerance), surface finishing (ENIG/OSP), and AOI defect detection.

3. Component Sourcing & Logistics: Full Chain Traceability

- Procures active (ICs, MCUs), passive (resistors/capacitors), connectors, power modules, sensors, and wireless chips from certified suppliers.

- ERP system tracks real-time inventory, delivery risks, and batch quality; VMI (Vendor Managed Inventory) implemented for critical components.

4. Stencil Preparation: Solder Paste Application Accuracy

- Laser-cuts stainless steel stencils with ┬▒5╬╝m aperture precision.

- Uses stepped stencils for ultra-fine components (01005/008004) to ensure uniform solder paste volume and prevent bridging/defective soldering.

5. SMT Assembly: High-Speed Precision Operations

- Employs advanced pick-and-place machines (e.g., Siemens SIPLACE series) achieving Ôëą36,000cph placement speed for 0201 components.

- N2-reflow oven maintains six-zone temperature profile control (┬▒2Ôäâ error) for reliable solder joints.

6. Through-Hole Assembly & Soldering: Automated & Manual Integration

- Selective wave soldering with customized fixtures minimizes tin slag contamination.

- Manual soldering + X-ray inspection for high-reliability products ensures mechanical strength and electrical performance compliance.

7. Testing & Inspection: Multi-Dimensional Quality Assurance

- AOI detects solder joint defects, X-ray inspects BGA internal connections, ICT verifies circuit continuity, FCT simulates real-world functionality.

- Burn-in testing screens for early-life failures to achieve <0.1% defect rate in delivered products.

8. Cleaning, Packaging & Global Logistics: Secure Delivery

- Ultrasonic cleaning removes post-solder flux residues; vacuum packaging prevents moisture/dust damage

- Custom packaging with protective materials and real-time ERP logistics tracking supports DHL/FedEx/air/sea shipment to global destinations

Types of Our PCBA Contract Manufacturing Service

- Prototype PCBA service: Used for early evaluation, concept verification, and quick engineering builds. Short lead times and high flexibility are typical at this stage.

- Small-batch production: Ideal for pilot runs and small orders. This service helps customers validate performance before mass production.

- Mass production: When demand increases, factories scale up to support stable production with consistent quality. Automated lines maintain uniformity.

- Turnkey service: This includes PCB fabrication, components sourcing, assembly, testing, and shipping. Buyers only provide design documents.

- Partial turnkey or kitted service: Some customers supply certain components. The factory handles the rest.

- Specialized PCBA builds: This includes RF boards, high-density interconnect boards, high-frequency modules, ceramic assemblies, aluminum base assemblies, and automotive PCBs.

Why Choose EBest Circuit (Best Technology) for PCBA Contract Manufacturer?

Reasons Why Choose EBest Circuit (Best Technology) for PCBA Contract Manufacturer:

- Advanced technology enhances product performance: High-speed placement machines and precision inspection systems enable 01005 ultra-small component assembly, ensuring electrical performance 20%-40% better than industry benchmarks.

- Full-chain quality control system: Dual ISO 9001 and IATF 16949 certifications with SPC statistical process control and AOI/X-ray smart inspection achieve repair rates below 0.02%.

- Rapid response and global delivery network: 48-hour rapid prototyping with DHL/UPS air freight to Europe and North America meets urgent delivery needs.

- Structural cost optimization: DFM design optimization reduces material waste by 30% while automated storage systems lower overall costs by 15%.

- Green manufacturing compliance: RoHS/REACH-compliant lead-free processes and eco-friendly materials meet EU environmental regulations.

- Supply chain resilience: Strategic inventory agreements with global top-tier component suppliers compress critical material lead times to under 24 hours.

- One Stop Solution: NPI full-process support from DFM analysis to mass production testing shortens time-to-market by 40%.

- Digital transparency platform: Real-time tracking via ERP and MES systems with customer-exclusive portals for full-process visibility.

- Authoritative certifications and patents: UL safety certifications, IPC-A-610 standards, and proprietary patents pass rigorous factory audits by leading enterprises.

- Cross-industry success stories: Proven expertise in automotive electronics, industrial control, and consumer electronics with over 80% customer retention rates.

Case Studies of Our PCBA Contract Manufacturing

Case Study: Medical-Grade Cardiac Monitor PCBA Contract Manufacturing

Project Background:

An international medical device company launched a new generation of portable cardiac monitors, requiring PCBA modules to operate stably in a wide temperature range of -40┬░C to 85┬░C, meet IEC 60601-1-2 medical-grade EMI/EMC standards, and compress batch production cycles to 28 days. As the PCBA contract manufacturer, we achieved project goals through full-process collaborative innovation.

Project Requirements Breakdown

- Reliability Verification: Must pass 1,000-hour accelerated life testing (THB 85┬░C/85% RH) and 500 thermal shock cycles (-55┬░C to 125┬░C);

- Signal Integrity: ECG signal acquisition module noise must be below 2╬╝Vrms, with common-mode rejection ratio (CMRR) Ôëą110dB;

- Manufacturability: Support flexible small-batch production (500 pieces/batch) while reserving capacity for future annual production of 500,000 pieces;

- Cost Control: Target BOM cost reduction of 15%, with process defect rate controlled within 0.3%.

Solution Implementation

1. Design Collaboration Optimization

- Utilized Ansys HFSS for PCB layout simulation, optimized critical signal paths (e.g., ECG acquisition differential pairs), and reduced crosstalk by 40% through layer stack adjustment;

- Introduced 3D-MID (molded interconnect device) technology to deposit metal circuits directly on plastic substrates, reducing traditional connector usage and saving 20% space;

- Conducted DFM (design for manufacturability) review, optimizing minimum trace width/spacing from 6mil to 5mil, increasing routing density by 15%.

2. Material and Process Innovation

- Selected high-Tg (180┬░C) halogen-free FR-4 substrate with ENIG (electroless nickel immersion gold) surface treatment for solder pad oxidation resistance;

- Adopted AEC-Q200-certified automotive-grade MLCC capacitors and 0201 package resistors to enhance component temperature resistance;

- Implemented “double-sided reflow + selective wave soldering” processes, with X-ray + AOI dual inspection for critical BGA devices to ensure solder joint defect rate <50ppm.

3. Testing and Quality Control

- Developed dedicated test fixtures for 100% ICT (in-circuit testing) + FCT (functional testing), integrating ECG signal simulators to verify acquisition accuracy;

- Implemented “first article inspection + process sampling + final inspection” three-tier quality control, with destructive physical analysis (cross-sectioning) performed on 5 pieces per batch;

- Established traceability system, binding production data (temperature profiles, test records) to each PCBA to meet medical device UDI (unique device identification) requirements.

Output Results and Value Delivery

- Delivery Cycle: Completed design verification to mass production in 25 days, 3 days ahead of schedule;

- Quality Performance: First batch of 500 pieces passed ISO 13485 quality system certification, achieved zero failures in accelerated life testing, and CMRR measured at 115dB;

- Cost Efficiency: BOM cost reduced by 18% (3% above target), process defect rate at 0.25%, with annual capacity planning supporting 500,000-piece expansion needs;

- Client Feedback: Product received FDA 510(k) certification after market launch, market share increased by 20%, and client repurchase rate reached 98%.

How to Get A Quote for PCBA Contract Manufacturing Service?

Steps to Get A Quote for PCBA Contract Manufacturing Service:

1. Submit Complete Documentation: Provide BOM (Bill of Materials) in Excel format with component specifications, Gerber files, PCB layout, and assembly drawings. Include test requirements (ICT/FCT), conformal coating needs, and compliance standards (RoHS, ITAR, etc.).

2. Specify Quantity & Timeline: Clarify order volume, annual forecast, and required delivery dates. For prototypes, indicate urgency; for mass production, detail production cycles and batch sizes.

3. Outline Technical Specifications: Define PCB dimensions, layer count, thickness, material, and special processes (e.g., gold plating, blind vias). Include packaging preferences (ESD-safe, serialized labeling) and logistics requirements.

4. Engage in Pre-Quote Communication: Discuss DFM (Design for Manufacturability) feedback, component sourcing strategies, and quality certifications. Address potential risks (e.g., component shortages) and mitigation plans.

5. Request Formal RFQ Submission: Formalize the quote request with all above details. Manufacturers will assess costs (material, labor, testing) and provide a breakdown with lead times, payment terms, and value-added services.

6. Review & Compare Proposals: Evaluate quotes based on cost, technical capability, certifications, and past performance. Prioritize transparency in pricing and responsiveness to technical inquiries.

7. Finalize Contract Terms: Sign a contract detailing deliverables, quality standards, IP protection (NDA), and dispute resolution. Ensure alignment on change management processes for design updates.

Welcome to contact us if you have any request for PCBA contract manufacturing service: sales@bestpcbs.com.