PCB Prototyping USA delivers precise, rapid-turnaround solutions for diverse electronic projects, catering to small-batch trials and custom specifications. Our PCB Prototyping USA service integrates advanced processes and strict quality control to meet the region’s rigorous industry standards, supporting seamless transition from design to mass production.

Are You Facing these Problems of PCB Prototyping USA?

- Long lead times for urgent projects, delaying product launch timelines even for small-batch prototype PCB USA.

- Hidden costs from design mismatches and rework due to lack of pre-production analysis for PCB prototyping USA.

- Inconsistent quality across samples, failing to meet industry standards for high-precision applications.

- Limited capability for specialized boards like HDI or RF prototypes, restricting project innovation.

- Poor technical support response, leaving project bottlenecks unresolved for days.

One-Stop Service From Requirements to Delivery

We deliver a one stop PCB prototype service USA, covering demand confirmation to final delivery with a 98%+ end-to-end risk interception rate. Backed by 20 years in PCB prototyping USA, we‚Äôve handled 100,000+ custom projects, enabling us to pre-empt 95% of potential process issues upfront. Our production line integrates MES intelligent management systems and 3D AOI detectors (with 99.9% defect coverage) , aligning production with your timeline and achieving a 98.5% on-time delivery rate . We guarantee your USA PCB prototype meets specifications with ¬Ī0.003mm/m dimensional precision , stays within a ¬Ī3% budget deviation, and arrives as scheduled. Choose us for a partnership that turns design concepts into tangible products efficiently, with proven cost and time savings.

Why Choose EBest Technology(Best Technology) for PCB Prototyping?

- 1-piece minimum order with 24-hour rapid prototyping and shipping for urgent projects, helping you seize market opportunities faster than competitors in PCB prototyping USA.

- Strict quality assurance backed by ISO9001:2015, ISO13485:2016, REACH, RoHS, and IATF16949 certifications. Every prototype PCB USA undergoes 12+ quality inspections, achieving a 99.8% pass rate.

- Free DFM analysis that reduces rework costs by up to 40%, identifying design flaws before PCB prototyping USA production starts.

- Cost-sensitive design solutions, optimizing material selection and processes to cut production costs by 15-25% without compromising quality.

- One-stop service covering design optimization, prototyping, assembly, and testing, streamlining your PCB prototype service USA workflow.

- 20 years of production experience, enabling flexible handling of custom orders and adapting quickly to design adjustments for PCB prototyping USA.

- Diverse prototyping options including rigid boards, flexible boards, rigid-flex boards, metal core boards, and ceramic boards, meeting multi-scenario needs.

- Strong process capability, specializing in best manufacturers high-density PCB prototypes USA and RF boards with precision line width/space as low as 3/3mil.

- Free technical support with 2-hour online response and one-on-one service, resolving project issues promptly during PCB prototyping USA.

Top 10 PCB Prototype Manufacturer USA

| Company Name | Prototyping Service | Core Advantages | Process Capability | Prototyping Lead Time |

| EBest Circuit Co., Limited (Best Technology Circuit Co., Limited) | 1-piece custom prototyping, free DFM analysis, 24-hour urgent service, one-stop assembly & testing, technical consulting | 20-year experience, multi-certification (ISO9001/IATF16949), 98.5% on-time delivery rate | HDI/RF boards, rigid-flex, ceramic boards, 3/3mil line width/space, ¬Ī0.003mm/m dimensional precision | 24hrs (urgent), 3-5 days (regular) |

| Advanced Circuits | Free DFM audit, high-layer prototyping, RF/microwave board sampling, rework support, online progress tracking | USA‚Äôs 3rd largest PCB manufacturer, aerospace-grade quality, laser drilling technology | 1-40 layer boards, 20oz heavy copper, impedance control ¬Ī5%, laser-drilled microvias | 48hrs (urgent), 4-6 days (regular) |

| Murrietta Circuits | Military/aerospace-grade prototyping, design optimization, full-process testing, small-batch sampling | 40+ years of experience, one-stop design-manufacturing-testing, military certification | Rigid-flex boards, high-reliability military boards, environmental testing compliance | 72hrs (urgent), 5-7 days (regular) |

| AP Circuits | Quick-turn prototyping, standard & custom material sampling, basic assembly matching, electrical testing | Cost-effective, 40+ years of local service, stable supply chain for common materials | 1-16 layer rigid boards, 4/4mil line width/space, standard surface finishes (HASL/ENIG) | 24hrs (simple boards), 3-4 days (complex boards) |

| IEC Electronics | Medical/aerospace prototyping, counterfeit part detection, failure analysis, small-batch validation | ISO13485 certified, medical/aerospace expertise, strict quality traceability | High-reliability boards, precision assembly, advanced fault analysis capability | 5-8 days (regular), 72hrs (medical urgent orders) |

| Benchmark Electronics | High-precision prototyping, cleanroom assembly, system integration testing, custom material matching | Global certification system, high-reliability electronics focus, large-scale production transition support | HDI boards, 1-24 layer boards, microwave/RF boards, impedance control ¬Ī3% | 4-6 days (regular), 96hrs (urgent) |

| SigmaTron International | Automotive/consumer electronics prototyping, cost-optimized sampling, SMT assembly matching | IATF16949 certified, cross-border supply chain, prototype-to-mass production seamless transition | Rigid boards, flexible boards, 1-12 layer boards, automotive-grade environmental resistance | 3-5 days (regular), 48hrs (automotive urgent orders) |

| Eltek Ltd. | Advanced PCB prototyping, high-frequency material sampling, defense-grade testing, design consultation | US State Department licensed, defense/aerospace focus, advanced high-frequency technology | PTFE/LCP high-frequency boards, HDI, 1-32 layer boards, strict signal integrity control | 6-9 days (regular), 5 days (defense urgent orders) |

| Sunstone Circuits | Online instant quoting, 1-piece prototyping, free DFM analysis, fast turnaround sampling | Digitalized operation, 24/7 customer service, high efficiency for R&D projects | 1-20 layer boards, rigid-flex, 3/3mil line width/space, standard & lead-free finishes | 24hrs (express), 2-3 days (standard) |

| Bay Area Circuits | Custom prototyping, high-density sampling, RF/microwave board testing, material customization | Silicon Valley-based, high-tech industry expertise, fast technical response | HDI boards, RF/microwave boards, 1-24 layer boards, 2/2mil line width/space | 72hrs (urgent), 4-5 days (regular) |

How to Choose the Right PCB Prototype Manufacturer USA?

Selection Guide to PCB Prototype Manufacturer USA:

- Verify certification completeness, ensuring compliance with ISO9001:2015 (general quality management), IATF16949 (automotive-grade requirements), and industry-specific standards like ISO13485 for medical applications. Certifications should cover the entire PCB prototyping USA process, not just mass production, to guarantee batch consistency.?

- Check urgent service capability, confirming 24-hour delivery for single-piece USA PCB prototype with a 95%+ success rate. Focus on whether the service includes essential testing (e.g., open/short circuit detection) and dedicated production lines to avoid quality compromises for speed.?

- Evaluate DFM service quality, prioritizing manufacturers that cut rework rates to below 5% via pre-analysis. The service should cover line width/space verification, aperture matching, and impedance pre-calculation, with 30-minute rapid feedback that marks optimization points clearly for PCB prototyping USA.?

- Assess process range and precision, ensuring support for required board types (HDI, RF, rigid-flex) and core parameters like 3/3mil line width/space. For high-density or high-frequency projects, confirm laser drilling capability and layer alignment accuracy (‚ȧ5őľm deviation) for PCB prototyping USA.?

- Review technical support efficiency, requiring 2-hour online response and 7√ó24-hour availability. The one-on-one service should address not only operational issues but also provide guidance on material selection and process optimization for USA PCB prototype projects.?

- Confirm material quality & supply stability, ensuring core materials (e.g., HVLP copper foil, PTFE for high-frequency boards) meet RoHS/REACH standards. Verify 30% safety stock for key materials and the ability to provide alternative equivalents to mitigate shortages in PCB prototyping USA.?

- Check quality control system, prioritizing manufacturers with IQC/IPQC/OQC full-process inspection and 99%+ prototype yield rate. IQC should test material dielectric properties; IPQC monitor lamination temperature curves; OQC conduct 100% AOI and X-Ray testing for PCB prototyping USA.

How to Evaluate the Technical Capability of USA PCB Factory?

Evaluation Guide to the Technical Capability for PCB Factory in USA:

- Check minimum line width/space capability: Aim for 2/2mil precision (verified by laser interferometer) for high-end high-density projects, with 3/3mil as the baseline for regular high-density boards. This parameter directly impacts signal transmission efficiency, particularly for 12+ layer boards.‚Äč

- Verify impedance control accuracy: General high-frequency PCB prototyping USA requires ¬Ī5% tolerance, while automotive radar and satellite communication (‚Č•10GHz) scenarios need ¬Ī3% precision. Calibrate via TDR testing equipment to keep signal delay at microsecond level.‚Äč

- Assess material compatibility: Confirm support for PTFE (dielectric constant 2.1-2.3, for ‚Č•50GHz projects) and LCP (heat resistance ‚Č•280‚ĄÉ, for high-temperature environments). All materials must pass UL certification and meet 94V0 flame-retardant standard, with verifiable material test reports.‚Äč

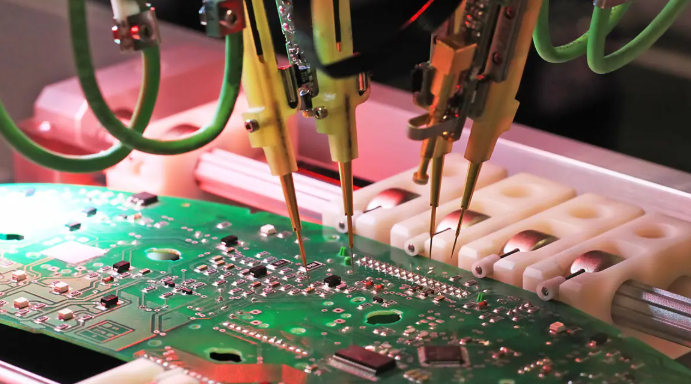

- Review quality inspection processes: Ensure 100% AOI testing (detection precision ‚ȧ0.02mm, defect recognition rate ‚Č•99.5%) and X-Ray inspection. X-Ray must fully penetrate blind/buried vias to cover 100% of internal layer connections, avoiding hidden soldering defects.‚Äč

- Evaluate HDI/RF board experience: Prioritize manufacturers with 5000+ HDI/RF project cases, where 12+ layer HDI boards account for over 40%. RF board capabilities should support up to 60GHz frequency for satellite communication and radar applications.‚Äč

- Check certification coverage: Confirm certifications match industry needs. IATF16949 applies to automotive (compliant with PPAP process), ISO13485 for medical (full traceability), and aerospace-grade quality authentication. Certifications must cover all prototyping production lines.‚Äč

- Assess design optimization capabilities: DFM analysis should cut rework rates by 30%-40%, covering pad matching, impedance pre-calculation and layer stackup optimization. Cost-saving schemes need to reduce material costs by 15%-25% without sacrificing performance.

How to Evaluate the Delivery Time for PCB Factory in USA?

Evaluation Guide to the Delivery Time for PCB Factory in USA:

- Confirm urgent order lead time: Ensure 24-hour delivery for single-piece simple prototype PCB USA; for complex boards (HDI/RF, 8+ layers), verify 48-72 hour expedited capability, with an urgent order success rate ‚Č•95%.‚Äč

- Review regular order cycle stability: Require a 98%+ on-time delivery rate over the past 12 months, and confirm clear compensation plans (e.g., freight waiver, priority rework) for delays caused by the manufacturer.‚Äč

- Assess material inventory capacity: Focus on core materials (HVLp copper foil, PTFE for high-frequency boards) with a safety stock ‚Č•30%, and confirm the ability to provide equivalent alternatives within 24 hours when shortages occur.‚Äč

- Check production line automation level: Ensure automated equipment accounts for over 70%, covering core processes like cutting, drilling, and AOI testing, which can improve PCB prototyping USA efficiency by 20%+.‚Äč

- Evaluate order scheduling flexibility: Confirm 24-hour response to design adjustments; minor tweaks (line width/space fine-tuning) should not extend lead time, while major changes have clear timeline extension standards.‚Äč

- Review logistics cooperation: Verify partnerships with reliable local logistics providers for next-day/2-day delivery, offer real-time logistics tracking, and control PCB prototyping USA transportation damage rate ‚ȧ0.1% with replacement guarantees.

FAQs of PCB Prototyping USA

Q1: How to avoid signal integrity issues in high-frequency PCB prototyping in the US?

A1: We use an impedance matching optimization scheme with a tolerance of ¬Ī5% and utilize high-frequency materials such as PTFE. Our pre-production simulation and DFM analysis can identify potential signal integrity issues, ensuring stable signal transmission.

Q2: Why do rework issues frequently occur during PCB prototyping in the US? How to avoid them?

A2: Rework mainly stems from mismatches between design and manufacturing processes. We provide free DFM analysis to check pad dimensions, component layout, and process compatibility, reducing the rework rate to below 5%.

Q3: How to address material shortages in custom PCB prototyping projects in the US?

A3: We have global supply chain resources and maintain a 30% safety stock of core materials. For scarce materials, we provide equivalent alternative solutions to ensure production continuity.

Q4: How to ensure quality consistency between PCB prototyping and mass production in the US?

A4: We apply the same quality standards and processes to both prototypes and mass production, conducting full-process traceability and over 12 inspection steps to achieve 99.8% quality consistency.

Q5: Can urgent PCB prototype orders in the US meet quality standards?

A5: Yes, our 24-hour emergency service strictly adheres to quality checks, including AOI, X-ray, and electrical testing, ensuring that accuracy and reliability are not compromised.