PCB prototype in Egypt has become a reliable option for fast, cost-effective small-batch circuit board sampling, with local manufacturers offering diverse capabilities to meet global standards. Most Egyptian facilities focus on precision and efficiency, making PCB prototype in Egypt suitable for various electronic projects that require quick design verification and reliable performance without excessive lead times or costs.

Top 10 Egypt PCB Factories for Prototyping

| Company Name | Main Business | Core Advantage | PCB Process | Prototyping Lead Time |

| EBest Circuit Co., Limited | PCB prototype, PCB assembly, FR4 PCB manufacturing | IPC Class III compliance, 1-32 layer capability, competitive pricing | SMT, THT, HDI, impedance control, various surface treatments | 1-layer: 3-4 days; 2-layer: 4-6 days; 4-layer: 8-10 days |

| PEModule | PCB assembly, electronics manufacturing, PCB prototype | Localization service, high-end German/Japanese equipment, RoHS compliance | SMT, THT, hybrid assembly, laser cut stencils | Standard: 2-5 days; Expedited: 24-72 hours |

| Ultima True Engineering Industries | Electronic control products, PCB prototype and manufacturing | Serves MENA and Africa, world-class quality control | Single/double-layer PCB, SMT assembly, basic soldering | Standard: 4-7 days |

| Ronex Misr | SMT production, PCB prototype, electronic assembly | Dual Fuji and Siemens SMT lines | SMT assembly, single/double-layer PCB prototyping | Standard: 3-6 days |

| Egypt Italy for Modern Industry Co., Ltd | PCB manufacturing, prototype service, electronic component supply | Experienced management, reliable quality and service | Single/double-layer PCB, basic surface treatment (HASL, OSP) | Standard: 5-8 days |

| Pyramid Electronics | PCB design, prototype, assembly, 3D printing for enclosures | One-stop service, reverse engineering capability | Single/double-layer PCB, SMT/THT assembly | Standard: 4-7 days |

| Tec | SMT solutions, PCB prototype, electronic manufacturing | Pioneer in Egypt’s SMT industry, advanced equipment | SMT assembly, single/double-layer PCB prototyping | Standard: 3-6 days |

| Micro Ohm Electronics | PCB board manufacturing, prototype service, electronic tools | Competitive pricing, small-size PCB expertise | Single/double-layer FR2 PCB, basic prototyping | Small-size: 2-5 days |

| Cairo Electronics Manufacturing Co. | PCB prototype, low-volume production, electronic assembly | Fast response, flexible order handling | Single/double-layer PCB, SMT assembly | Standard: 3-7 days |

| Alexandria PCB Solutions | PCB prototype, assembly, quality testing | Strategic location in Alexandria, export-ready service | Single/double-layer PCB, impedance control (optional) | Standard: 4-8 days |

Where Can I Find Reliable PCB Prototype Services in Egypt?

To efficiently find reliable PCB prototype services in Egypt, combine targeted channel selection and preliminary verification based on your project’s scale, budget, and quality needs. Practical approaches include leveraging both offline/online channels and applying professional verification methods to identify trustworthy local providers.

- Local Industrial Clusters: Focus on industrial zones in Cairo and Alexandria, where most reliable PCB prototype manufacturers (such as Pyramid Electronics, Ronex Misr) are concentrated. You can visit factories on-site for consultations, check production equipment, and verify sample quality in person.

- International B2B Platforms: Use well-known platforms like Alibaba and MFG.com to find verified Egyptian PCB prototype suppliers. These platforms provide detailed factory profiles, process capabilities, customer reviews, and transaction guarantees for easy comparison and screening.

- Egyptian Industry Associations: Contact the Egyptian Electronic Manufacturers Association (EEMA) to obtain a directory of certified PCB prototype facilities. Members of the association usually comply with international quality standards and have standardized production processes.

- Direct Factory Contact: Reach out to leading manufacturers directly via their official websites, such as PEModule (a cost-effective option supporting startup projects) and SMT Egypt. You can get customized quotes, technical support, and real-time updates on prototype progress.

- Local Electronic Exhibitions: Attend electronic industry exhibitions held in Cairo regularly, where Egyptian PCB manufacturers (including UETPCB Egypt and Hitec Pioneers) showcase their prototype capabilities. It’s a good opportunity to communicate face-to-face and establish cooperative relationships.

- Customer Referrals: Consult peers or partners who have previously cooperated with Egyptian PCB manufacturers. Their real cooperation experiences can help you screen reliable suppliers and avoid potential risks, especially for small-batch prototype orders.

- Third-Party Quality Certification Platforms: Search for Egyptian PCB prototype manufacturers certified by UL, TUV, or other international organizations. These certifications ensure that manufacturers have strict quality control systems and can produce prototypes meeting global standards.

- Electronic Component Suppliers: Cooperate with local electronic component suppliers in Egypt. They often have long-term cooperative relationships with PCB prototype factories and can recommend reliable manufacturers that match your project requirements, such as Sama Marketing which provides component supply and PCB prototyping.

Which Quality Standards do PCB Prototype in Egypt Meet?

Quality Standards for PCB Prototype in Egypt:

- IPC Core Standards: Most Egyptian PCB prototype factories strictly follow IPC-A-600 (PCB Appearance Standard) and IPC-6012 (Rigid PCB Performance Standard). These standards define acceptable appearance defects, dimensional tolerances, and electrical performance requirements, ensuring PCB prototype in Egypt meets basic to high-grade quality for reliable project design verification.

- IPC Soldering Standards: In addition to core standards, leading manufacturers comply with IPC-J-STD-001 (Requirements for Soldered Electrical and Electronic Assemblies), ensuring consistent solder joint quality, which is critical for the reliability of PCB prototypes during assembly and use.

- ISO Certifications: Key Egyptian PCB prototyping facilities hold ISO 9001 (Quality Management System) and ISO 14001 (Environmental Management System) certifications. These certifications standardize production workflows, quality control processes, and environmental practices, guaranteeing consistent prototype quality across batches.

- RoHS 2.0 Compliance: Lead-free manufacturing processes are universally adopted by Egyptian PCB factories, fully meeting EU RoHS 2.0 requirements. This restricts hazardous substances (lead, cadmium, mercury, etc.) in prototypes, making PCB prototype in Egypt suitable for global markets, including the EU and North America.

- UL Flame Retardant Standards: Reputable manufacturers (such as UETPCB Egypt and Egyptian Electronic Technology) comply with UL 94 flame retardant standards, using FR-4 substrates with V-0 flame retardant grade to enhance the safety and durability of PCB prototypes.

- Egyptian Local Compliance: All PCB prototypes produced in Egypt meet local regulations, including ESMA (Egyptian Telecommunication Regulatory Authority) certification and EOS 3000 industrial safety standards, ensuring seamless market access in Egypt and the MENA region.

How to Ensure the Quality of PCB Prototype in Egypt?

Methods to ensure the quality of PCB prototype in Egypt:

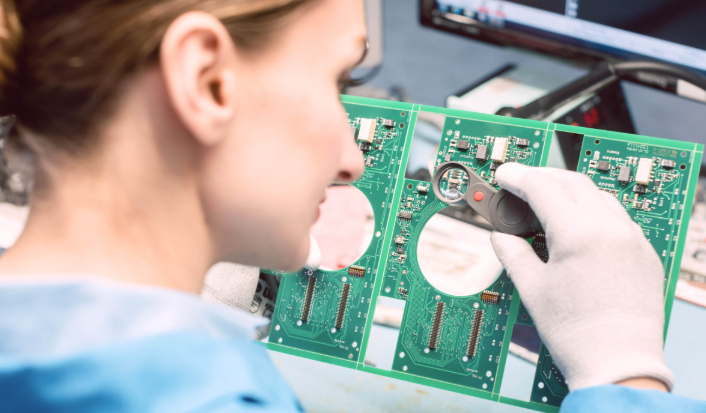

- Verify Factory Certifications: Confirm Egyptian PCB prototype factories hold ISO 9001 (quality management) certification covering ≥95% of production processes, IPC certifications (IPC-A-600 Class 2 or Class 3, IPC-6012 for rigid PCBs), plus local ESMA 2020/12 compliance. Ask for quality control documents (production flowcharts, inspection checklists) that specify a first-article inspection pass rate of ≥99.5% to ensure standardized workflows.

- Request Pre-Production Samples: For critical projects, request 1-2 pre-production samples to check key parameters: PCB thickness (tolerance ±0.1mm, high-precision models ±0.05mm), copper foil thickness (1oz=35μm±10%, 2oz=70μm±10%), surface finish (ENIG: Au≥0.05μm, Ni≥3μm; HASL: tin layer 20-50μm), and dimensional tolerances (board edge ±0.1mm, line width ±0.02mm), ensuring alignment with your design requirements.

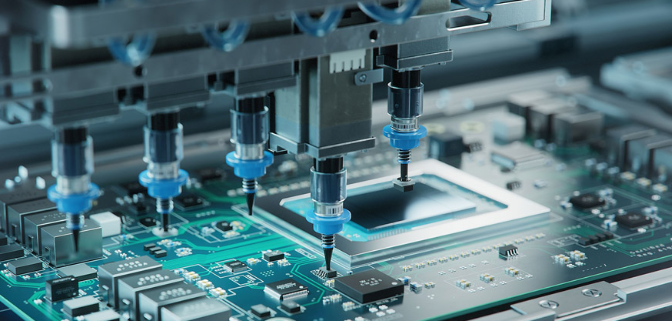

- Specify Quality Inspection Requirements: Require AOI (automated optical inspection) with ≥99.8% coverage for appearance defects (detecting minimum line width/spacing 0.05mm, false positive rate ≤0.3%) and flying probe testing with ≥99.5% test point coverage for electrical performance. This ensures detection of short circuits, open circuits, and poor via connectivity (≤1Ω conductivity abnormality) in PCB prototype in Egypt.

- Clarify Material Specifications: Confirm high-quality substrates (e.g., FR-4 high-TG ≥170℃, Td≥300℃, dielectric constant εr=4.2±0.2 at 1GHz), specify copper thickness (1oz=35μm, 2oz=70μm, max 4oz=140μm) with ±10% tolerance, surface finish type, and line width/line spacing (minimum 0.1mm, tolerance ±0.02mm) in the order.

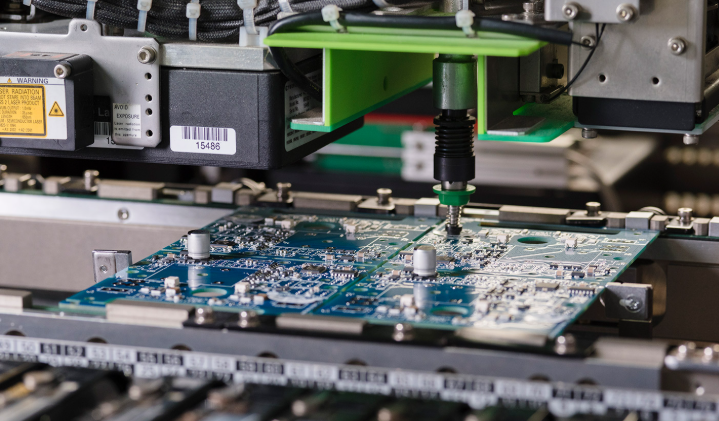

- Confirm Production Process Control: Ask manufacturers to provide key process parameters: lamination (175±5℃, 350±50psi, 75±10 minutes), drilling precision (laser drilling ±0.02mm, mechanical drilling ±0.05mm), soldering temperature (reflow peak 245±5℃, 30-60 seconds holding time), and solder paste thickness (0.12-0.15mm, ±0.02mm tolerance) to ensure consistent prototype quality.

- Establish Real-Time Communication: Maintain daily progress updates (before 10:00 AM local time) and require instant feedback (≤1 hour) for key production nodes (material preparation, drilling, testing). Set a ≤2-hour response time for design/process issues and ≤4-hour solution proposal to avoid quality deviations.

- Clarify After-Sales Quality Guarantee: Confirm terms for rework/remanufacturing (completed within 3 business days for factory-caused defects) and a prototype pass rate guarantee of ≥99.8%. Specify that factory-caused defects (e.g., mismatched design, poor soldering) incur 0 additional costs, with delayed rework compensated at 0.5% of the order value per day, plus a 30-day quality warranty.

What is the Typical Lead Time for PCB Prototype in Egypt?

| PCB Type | Layer Count | Typical Lead Time (Business Days) |

| Rigid PCB | 1-2 layers | 2-4 |

| Rigid PCB | 4-6 layers | 5-7 |

| Rigid PCB | 8-10 layers | 7-10 |

| Rigid-Flex PCB | 2-6 layers | 8-12 |

| High-Frequency PCB | 2-6 layers | 6-9 |

What Are the Typical Costs for PCB Prototyping Services in Egypt?

Costs for PCB prototype in Egypt vary by layer count, size, quantity and process, with transparent pricing for small batches. Single-sided prototypes (10 pieces, 100x100mm) start at $30-$50. Double-sided prototypes (10 pieces, 100x100mm) range from $45-$70. 4-layer prototypes (10 pieces, 100x100mm) cost $80-$120, while 6-layer prototypes (10 pieces, 100x100mm) are $130-$180. Special processes (ENIG surface finish, blind/buried vias, impedance control) add 20%-50% to the base cost. Smaller quantities (1-5 pieces) may have a 10%-15% premium, while quantities over 50 pieces often qualify for volume discounts.

Do Egyptian PCB Manufacturers Take Small-Batch PCB Prototype Orders?

Yes, most Egyptian PCB manufacturers accept small-batch PCB prototype orders. The majority of local facilities specialize in small to medium batches, with minimum order quantities (MOQ) as low as 1 piece for prototypes. This flexibility caters to projects that require design verification or small-scale testing without large production commitments. Tailored pricing options are often available for small batches to ensure cost-effectiveness while maintaining quality standards. Small-batch orders also benefit from the same lead time and quality checks as larger orders, making them a practical choice for quick project iterations.

Is Expedited Delivery Available for Egyptian PCB Prototypes?

Yes, expedited delivery is available for PCB prototype in Egypt, with most manufacturers offering accelerated turnaround options for urgent projects. Standard expedited lead time for single/double-sided prototypes is 24-48 hours, while 4-6 layer prototypes can be delivered in 3-4 business days. Expedited services typically add 30%-60% to the base cost, depending on the prototype complexity and urgency. Manufacturers prioritize expedited orders by allocating dedicated production resources and streamlining quality checks, ensuring speed without compromising performance. It is recommended to confirm expedited availability and pricing when placing the order, especially for prototypes with special process requirements.

FAQs of PCB Prototyping in Egypt

Q1: Why do PCB prototypes from Egypt sometimes have uneven circuit traces or inconsistent etching?

A1: Uneven circuit traces and inconsistent etching in PCB prototypes often result from improper etching solution concentration, unstable temperature control, or uneven exposure during the photolithography process. Choose Egyptian manufacturers that control etching parameters strictly: etching solution concentration (FeCl3: 38-42 Baume), temperature (45±3℃), and etching time (60-90 seconds). Most local facilities use automated spray etching equipment with ±1℃ temperature precision and post-etching AOI inspection (≥99.8% coverage) to eliminate such issues.

Q2: Can Egyptian PCB manufacturers handle prototypes with fine lines and small vias?

A2: Yes, most reliable Egyptian PCB prototyping facilities can produce prototypes with fine lines and small vias, a key capability of professional PCB sampling. Leading factories use high-precision laser drilling machines (drilling precision ±0.02mm) and advanced photolithography equipment, supporting minimum line width/line spacing of 0.08mm-0.1mm and minimum via diameter of 0.2mm. Post-production AOI and flying probe testing ensure fine line integrity and via connectivity, meeting IPC-A-600 Class 2 or Class 3 standards.

Q3: How to resolve PCB prototype warpage issues from Egyptian manufacturers?

A3: Warpage is a common issue in PCB prototyping, usually caused by improper substrate selection, uneven lamination pressure, or inconsistent cooling. To resolve it, specify high-TG FR-4 substrates (TG≥170℃, Td≥300℃) and request manufacturers to use programmed lamination curves (175±5℃, 350±50psi, 75±10 minutes). Post-production annealing (120℃ for 2 hours) can correct minor warpage, ensuring prototypes meet IPC-A-600 Class 2 warpage requirements (≤0.75% of board length).

Q4: Do Egyptian PCB prototypes meet international PCB sampling quality standards?

A4: Yes, all reliable Egyptian PCB prototyping manufacturers produce samples that comply with international PCB sampling standards, primarily IPC-A-600 (PCB Appearance Standard) and IPC-6012 (Rigid PCB Performance Standard). Prototypes meet strict specifications for dimensional tolerance (board edge ±0.1mm), copper thickness tolerance (±10%), surface finish uniformity (ENIG: Au≥0.05μm, Ni≥3μm), and via connectivity (≤1Ω). Manufacturers also provide AOI and flying probe test reports to verify compliance with global sampling standards.

Q5: What should I do if the delivered PCB prototype does not match my Gerber design specifications?

A5: First, provide the manufacturer with your original Gerber files and design specifications (line width, aperture, layer stack-up, copper thickness) for detailed comparison. Reputable Egyptian facilities offer free DFM (Design for Manufacturability) checks before PCB prototyping to identify and resolve design conflicts in advance. If a mismatch occurs due to factory error (e.g., incorrect line width, wrong aperture size, layer misalignment), they will remanufacture the prototype within 3 business days at no additional cost. To avoid this, confirm the DFM review report and pre-production sample (if requested) before full prototype production.