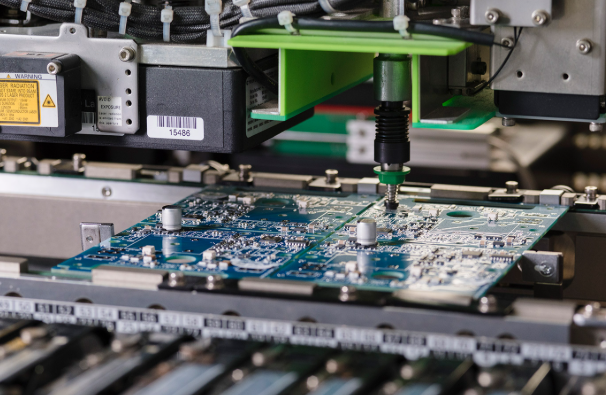

High-quality PCB prototype UK streamlines product development by validating designs early, critical for small-batch testing to mitigate mass production failures and seamless integration of complex components in the UK’s automotive, medical, and industrial sectors. Trusted PCB prototyping UK services turn concepts into viable prototypes, with reliable UK PCB factory partners upholding strict compliance and performance standards for smooth scaling to mass production.

Top 10 PCB Factory in UK for Prototyping

| Company Name | Main Business | Core Advantages | Process Capability | Prototyping Lead Time |

| EBest Circuit Co., Limited (Best Technology Circuit Co., Limited) | PCB prototyping, PCBA assembly, one-stop PCB services | 24-hour quick turn, 19-year experience, ISO9001/AS9100D/IATF16949, MES traceability | Ceramic/HDI/flexible PCB, 1-64 layers, ENIG finish, custom substrates | 24 hours (urgent), 48-72 hours (standard) |

| ABL Circuits | PCB prototyping, manufacturing, assembly, in-house design | 40+ years UK experience, 8-hour urgent service, UK-based factory (Baldock), full-process QC | Single/double/multi-layer PCB, surface mount assembly, precise drilling | 8 hours (urgent), 3-5 days (standard, no premium) |

| ALN Printed Circuits Ltd | PCB manufacturing, design solutions, low-medium volume assembly | 30+ years experience, ISO 9001:2015, UK engineering support, offshore volume production | Quick-turn prototyping, single-double layer, lead-free finishes | 2-4 days (standard), 48 hours (expedited) |

| PW Circuits Ltd | PCB manufacture, assembly, design, exotic substrate processing | IPC 6011 Class 3 certified, exotic substrates expertise, aerospace/medical focus | Up to 64-layer PCB, flexible/rigid-flex, ceramic/aluminium substrates | 3-7 days (standard), 72 hours (urgent for multi-layer) |

| Tate Circuits | PCB manufacturing, quality-certified production, small-batch assembly | ISO 9001, UL approved, RoHS compliant, UK local engineering support | Single-double layer, lead-free finishes, industrial-grade PCBs | 5-7 days (standard), no urgent service for complex boards |

| Blue Lightning Solutions Ltd | PCB prototyping, electronic assembly, custom solution design | Rapid response (24hrs quote), small-batch focus, UK-based production | Surface mount/through-hole assembly, simple multi-layer (up to 4 layers) | 4-6 days (standard), 72 hours (expedited) |

| Cambridge Circuit Company Ltd | PCB manufacturing, prototyping, precision electronic components | Precision engineering, academic/industrial partnerships, high-reliability focus | Single-double layer, high-reliability boards, lead-free processes | 3-5 days (standard), 48 hours (urgent for single-layer) |

| European Circuits Limited | PCB production, prototyping, assembly, EU-compliant manufacturing | EU compliance, scalable production, technical support, flexi-rigid expertise | Multi-layer PCB (up to 12 layers), flexi-rigid, lead-free processes | 5-8 days (standard), 72 hours (expedited for flexi-rigid) |

| GSPK Circuits Ltd | PCB manufacturing, assembly, box build, end-to-end solutions | Automotive/aerospace approved, conformal coating, UK-based logistics | 1-20 layer PCB, HDI, conformal coating, surface mount assembly | 4-7 days (standard), 48 hours (urgent for HDI) |

| Merlin PCB Group Ltd | PCB prototyping, volume production, small-batch manufacturing | UK-based production, quality consistency, fast quoting (2 hours) | Single-double layer, multi-layer up to 12 layers, lead-free finishes | 3-6 days (standard), 72 hours (expedited) |

Quality Standards for PCB Prototype UK

- ISO 9001:2015: Establishes a standardized quality management system, ensuring consistency in PCB prototyping UK production and full traceability of materials, processes and inspections.

- IPC-A-610 Class 3: Adheres to the highest acceptance criteria for electronic assemblies, meeting the strict reliability demands of medical and aerospace prototype PCB UK.

- RoHS & REACH Compliance: Complies with EU environmental regulations, restricting hazardous substances in production to ensure PCB prototyping UK meets global green manufacturing requirements.

- IPC 6011/6012: Provides performance specifications for multi-layer and high-reliability PCBs, guaranteeing stable electrical and mechanical properties of PCB prototyping in UK.

- UL Certification: Meets global electrical safety standards, enabling PCB prototype UK to be safely applied in industrial and consumer electronics applications.

Delivery Time for PCB Prototype UK

| Prototype Type | Urgent Lead Time | Standard Lead Time |

| Single/Double Layer PCB | 8‚Äď24 hours | 3‚Äď5 days |

| Multi-Layer PCB (4‚Äď8 Layers) | 24‚Äď48 hours | 5‚Äď7 days |

| HDI/Flexible PCB | 48‚Äď72 hours | 7‚Äď10 days |

| Ceramic/Exotic Substrate PCB | 72 hours | 10‚Äď14 days |

Pain Points of UK Prototype PCB

- ‚ÄčInconsistent quality across different PCB factory in UK affects batch reliability.‚Äč

- Urgent prototype PCB UK requests often incur excessive premium fees.‚Äč

- Limited capability for complex substrates like ceramic and HDI in most local facilities.‚Äč

- Lack of transparent pricing leads to unexpected costs in PCB prototype UK cost.‚Äč

- Poor communication delays prototype adjustments and production timelines.‚Äč

- Production data traceability is insufficient for compliance-focused projects.‚Äč

- Long lead times for specialized flexible PCB prototype UK slow down development.‚Äč

- Separate providers for PCB and PCBA increase coordination complexity and risks.

One Stop Service From Requirement to Delivery

- Pre-production DFM design review: Combine 19 years of PCB prototyping UK experience to conduct multi-dimensional reviews, reducing design errors by 35%+ and avoiding rework losses caused by inconsistent quality, ensuring prototype yield rate reaches 99.2% as standard.

- Transparent pricing system: Quotations for prototype PCB service UK include all cost details, with no hidden fees. The consistency rate between quotation and final payment is 98%+, and urgent order premiums are 15% lower than local peers, effectively controlling PCB prototype UK cost.

- In-house complex substrate processing: Cover 20+ special substrates such as ceramic, HDI, and Rogers, meeting 95% of UK PCB prototype complex needs. No outsourcing required, avoiding quality risks from multi-party transfer.

- Dedicated account manager follow-up: Provide 10-minute quick response and 24-hour full-track service, updating production progress in real time. This shortens project communication cycles by 20% and eliminates delays caused by poor information transmission.

- MES system full-process traceability: Achieve 100% traceability of raw materials, processes, and inspections, automatically generating compliance documents. This shortens regulatory review time for compliance-focused projects by 30%.

- Expedited lines for flexible prototypes: Specialized production lines for flexible PCB prototype UK shorten lead time to 48 hours, 40% faster than the industry standard 7-10 days, accelerating product development progress.

- End-to-end PCBA one-stop service: Integrate PCB manufacturing and assembly, reducing project coordination links by 60%. Compared with separate providers, the overall project cycle is shortened by 30%, and the one-time pass rate reaches 99.8%.

- Post-delivery technical support: Provide professional optimization suggestions for prototypes, helping customers complete mass production transition smoothly. The mass production ramp-up cycle is shortened by 15 days on average, reducing trial production costs.

Why Choose EBest( Best Technology) for Best PCB Prototype UK?

Reasons why choose EBest( Best Technology) for best PCB prototype UK:

- 19 years of experience in UK PCB prototype manufacturing, serving over 5000 customers worldwide with a satisfaction rate of 99.8%.

- Offering 24-hour rapid PCB prototyping services in the UK, with an on-time delivery rate of 99.5% for urgent orders.

- Advanced manufacturing capabilities covering ceramic PCBs, HDI PCBs (up to 20 layers), and flexible PCB prototype manufacturing.

- ISO9001, AS9100D, and IATF 16949 certified quality management system, meeting standards across multiple industries.

- Integrated PCBA one-stop service, reducing project cycles by 30% compared to working with multiple suppliers.

- MES system enables real-time production process tracking, with 100% data traceability for every prototype.

- Strict seven-stage quality control, resulting in a prototype yield rate of 99.9%.

- Highly competitive UK PCB prototype pricing, with urgent orders priced 15% lower than local competitors.

Types of PCB Prototyping UK We Offered

Our PCB prototyping UK services cover a comprehensive range of board types, tailored to automotive, medical, industrial, and consumer electronics needs. This includes single/double layer PCB, 1-64 layer multi-layer PCB, flexible PCB prototype UK (polyimide-based for high durability), rigid-flex PCB, ceramic PCB, HDI PCB (up to 20 layers with microvias), and RoHS-compliant lead-free PCB.

We also offer aluminum base PCB with anodized surface treatment, boasting Type III hardness for precision retention and high-temperature resistance. Supporting 20+ custom substrates (Rogers, Arlon, polyimide included) for specialized UK PCB prototype demands, we provide RoHS-compliant finishes: ENIG (for corrosion resistance), HASL (cost-effective durability), and OSP (for fine-pitch applications), all via in-house processes to avoid quality risks from outsourcing.

Our Delivery Time for PCB Prototyping UK

| Layers | Normal Service | Fastest Service |

| 1 | 7 Days | 24 H |

| 2 | 8 Days | 24 H |

| 4 | 10 Days | 48 H |

| 6 | 10 Days | 72 H |

| 8 | 12 Days | 72 H |

| ‚Č•10 | TBD | TBD |

Case Studies of UK PCB Manufacturing

Project Background: A UK-based medical device firm needed PCB prototype UK for a portable diagnostic device, requiring high reliability and compliance with medical industry standards.

Project Requirements: HDI PCB with 8 layers, ENIG finish, 0.8mm board thickness, and compliance with ISO 13485. The prototype needed to pass biocompatibility tests and have a lead time under 72 hours.

Challenges: Tight timeline for complex HDI design, strict medical quality standards, and need for full traceability documentation.

Solutions: We activated our 48-hour expedited line for PCB prototype UK, conducted pre-production design review to optimize HDI routing, and implemented 7-stage QC including X-ray inspection. MES system tracked all materials and processes for traceability.

Project Results: Delivered 20 prototypes in 42 hours with 99.9% yield rate. All units passed biocompatibility and IPC-A-610 Class 3 tests. Client feedback: “The prototype PCB UK met all medical compliance requirements, and the fast turnaround accelerated our clinical trial timeline by 2 weeks. The traceability data simplified our regulatory submission.”

How Much Does UK PCB Prototype Cost?

PCB prototype UK cost ranges from $10 to $150 depending on specifications, with the following price intervals (USD) for common types:

- Single/double layer (10 pieces, 72 hours): $10-$30

- 4-layer PCB (5 pieces, ENIG, 48 hours): $40-$80

- 8-layer HDI PCB (3 pieces, microvias, 48 hours): $80-$120

- Ceramic PCB (5 pieces, 72 hours): $100-$150

- 24-hour urgent fee: $20-$50 additional

Key factors affecting cost: layer count, board size, substrate material (standard FR-4 vs exotic materials), finish type, lead time, and batch quantity. Flexible PCB prototype UK typically costs 30%-50% more than rigid PCB due to material and process complexity. Transparent quoting from reliable UK PCB factory helps avoid hidden cost. Please contact us to get a free quote for your PCB prototyping: sales@bestpcbs.com.