Are you looking for PCB manufacturing Pretoria? This guide covers fast prototyping, cost-effective solutions, and quality assurance for engineers and designers.

PCB manufacturing Pretoria supports fast builds for brands that need stable quality and short delivery cycles. The demand for PCB manufacturing Pretoria keeps growing as more local firms move into electronics, automation, telecom, mining technology, and consumer hardware. Pretoria businesses prefer short communication loops, transparent pricing, and predictable production. This guide breaks down Pretoria PCB services, production strengths, pricing logic, and the signs of a trustworthy supplier.

Why Choose PCB Manufacturing Pretoria?

Advantages of PCB Manufacturing Pretoria:

- Accelerated Time-to-Market: Benefit from significantly shorter lead times. With local logistics and dedicated prototype lines, you can iterate designs and receive functional boards days sooner than with overseas suppliers.

- Enhanced Design for Manufacturability (DFM) Feedback: Collaborate directly with experienced engineers. Receive real-time, specific DFM feedback that aligns your design with local process capabilities, preventing costly revisions and ensuring first-pass success.

- Stringent Quality Assurance & Control: Trust in robust, multi-stage inspection protocols. Local facilities employ Automated Optical Inspection (AOI), flying probe testing, and impedance control checks to guarantee the reliability and performance of every board.

- Cost-Effectiveness for Prototyping & Mid-Volumes: Achieve greater budget efficiency. Eliminate unexpected import duties, reduce shipping costs, and minimize the financial impact of design changes thanks to proximity and clear communication.

- Superior Supply Chain Resilience & Communication: Mitigate risks with a simplified and transparent supply chain. Enjoy direct contact with your manufacturing team for instant updates, swift issue resolution, and greater control over your project timeline.

Types of PCB Manufacturing Pretoria

- Single-Layer FR4 PCB Manufacturing

- Double-Layer FR4 PCB Manufacturing

- Multilayer FR4 PCB Manufacturing (4‚Äď12 Layers)

- Metal Core PCB (MCPCB) Production

- High-Frequency and RF PCB Manufacturing

- Flexible PCB Manufacturing (Flex PCB)

- Rigid-Flex PCB Manufacturing

- Prototype PCB Fabrication

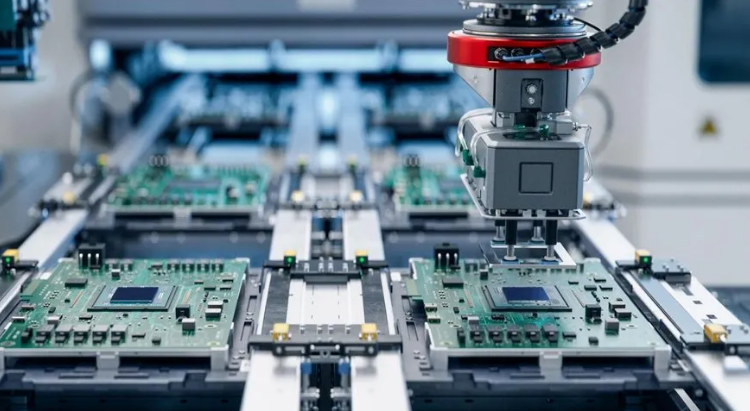

- PCB Assembly (SMT + Through-Hole)

Cost-Effective PCB Solutions in PCB Manufacturing Pretoria

Cost efficiency is a defining advantage of Pretoria’s PCB manufacturing factory, local providers cut unnecessary expenses while maintaining quality, directly saving your project budget.

- Design Optimization (DFM for Cost): Engineers don‚Äôt just fix manufacturability issues‚ÄĒthey refine designs to reduce waste, e.g., adjusting board size to fit more units per production panel (saving 10%-30% on material costs) or replacing complex layers with efficient routing where possible.‚Äč

- Volume-Tiered Pricing: Transparent bulk discounts kick in at 500+ units for standard PCBs, with 1000+ unit orders typically unlocking 15%-25% savings. For long-term projects, fixed-price contracts shield you from raw material price fluctuations.‚Äč

- Tooling & Setup Efficiencies: Repeat orders reuse existing tooling (no $200-$500 retooling fees per run) and leverage pre-approved design files to cut setup time by 40%, lowering labor costs.‚Äč

- Local Supply Chain Savings: Partnering with nearby material suppliers (e.g., Gauteng-based copper laminate distributors) slashes inbound shipping costs by 60%-70% compared to importing from Asia or Europe, with no customs delays or duties (which can add 10%-15% to offshore orders).‚Äč

- Waste Reduction Programs: Leading factories use automated cutting and material nesting software, reducing scrap rates to under 2% (vs. 5%-8% for less efficient facilities), passing material savings directly to clients.‚Äč

Quick-Turn PCB Prototyping Services for PCB Factory in Pretoria

In product development, speed to prototype directly impacts time-to-market and Pretoria’s PCB factories excel at delivering high-quality quick-turn prototypes without cutting corners. These services are tailored for engineers, startups, and R&D teams who need to validate design concepts, test functionality, and make iterative changes fast.

- Ultra-Fast Lead Times: 1-2 layer prototype boards are available for same-day pickup or next-day delivery within Pretoria and Gauteng; 3-4 layer prototypes typically ship in 2-3 business days, and complex 6-8 layer prototypes in 4-5 days.‚Äč

- Comprehensive File Compatibility: Full support for industry-standard formats including Gerber (RS-274X), ODB++, IPC-2581, and CAD files from popular software like Altium Designer, KiCad, and Eagle‚ÄĒwith free file validation to catch errors before production.‚Äč

- Flexible Order Sizes: MOQs start at 1 board, allowing teams to test designs without overinvesting; volume discounts apply for prototype runs of 10-50 units, ideal for small-scale usability testing.‚Äč

- Free Design Support: Complimentary DFM (Design for Manufacturability) reviews within 2 hours of file submission, identifying issues like insufficient trace width (minimum 0.1mm supported), tight via spacing, or incompatible surface finishes to reduce rework.‚Äč

- Material & Finish Options: Prototypes can be produced on FR-4 (standard), FR-4 High-Tg (for high-temperature applications), or Rogers materials (for RF/microwave designs), with surface finishes including ENIG (most popular for prototypes), HASL, and OSP to match final production specs.‚Äč

- On-Demand Testing Add-Ons: Optional flying probe testing (adds 12-24 hours) to verify electrical connectivity, and visual inspection reports with high-resolution images to document prototype quality.

Production Capabilities of PCB Factory in Pretoria

| Capability Category | Typical Values in Pretoria Factories |

| Minimum Trace/Space | 4/4 mil (0.10/0.10 mm) |

| Minimum Drill Size | 0.20 mm |

| Layer Count | 1‚Äď12 layers |

| Surface Finishes | HASL, ENIG, OSP, Silver, ENEPIG |

| Materials | FR4, High-Tg FR4, Aluminum, Rogers, PTFE |

| Via Types | Through, Blind, Buried, Micro |

| Solder Mask Colors | Green, Black, White, Red, Blue |

From Design to Delivery: PCB Production Process in Pretoria Factory

Pretoria’s PCB factories follow a streamlined, transparent workflow to transform designs into deliverable prototypes:

1. Design Review & DFM Checks: Engineers validate designs for manufacturability (DFM), identifying risks like insufficient trace widths (minimum 0.1mm), tight via spacing, or incompatible finishes to prevent production delays.

2. Material Sourcing: Certified suppliers provide high-grade laminates (FR-4, FR-4 High-Tg, Rogers for RF), copper, and solder mask, ensuring materials match final production specs.

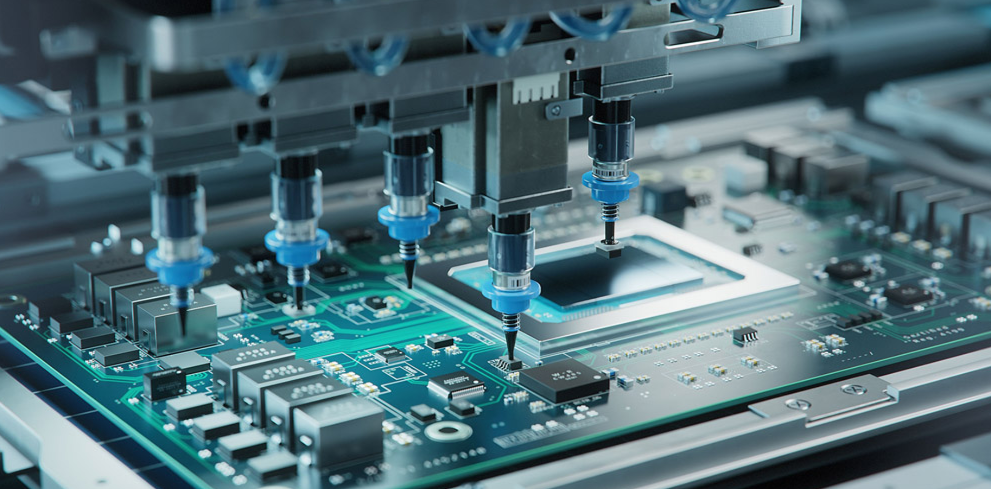

3. Pattern Printing & Etching: Circuit designs are transferred to substrates via precision printing/laser imaging, then excess copper is etched away to form conductive pathways.

4. Drilling & Plating: Microvias/blind vias are drilled and plated with copper to enable interlayer connections, with ¬Ī0.05mm accuracy for high-density layouts.

5. Solder Mask & Silkscreen: A protective solder mask layer is applied and cured; silkscreen adds component labels for assembly clarity.

6. Surface Finishing: Options include ENIG (superior solderability), HASL (cost-effective), or OSP (eco-friendly) to enhance conductivity and corrosion resistance.

7. Quality Testing: Automated Optical Inspection (AOI), X-ray alignment checks, and flying probe/electrical tests verify functionality. Medical/automotive sectors can request detailed visual inspection reports.

8. Packing & Logistics: ESD-safe packaging with cushioning ensures damage-free transit. Local same-day or next-day delivery, or national shipping, meets rapid prototyping timelines.

Top PCB Factory in Pretoria List

| Factory | Main Business | Advantages | Production Capability | Typical Lead Time |

| Deman Manufacturing | PCB assembly, rapid prototyping, contract manufacturing | ISO9001 certified; strong for industrial and automotive builds; fast response; one-stop service | SMT & THT assembly; quick-turn PCBA; coating; in-circuit and functional testing | 24‚Äď72 hours for prototypes; production based on project |

| Omnigo | High-reliability PCBA, turnkey electronic manufacturing | Large 4,500 m² facility; trusted in telecom, military, and industrial markets; strong engineering support | Full SMT/THT; conformal coating; functional test; turnkey project execution | Project-based lead times; optimized RFQ for faster onboarding |

| Solve Direct Electronics | PCB manufacturing, Class 3 PCBA, IPC training | IPC Class 3 capability; strict ESD control; suitable for high-reliability builds | PCB fabrication; advanced soldering; inspection; Class 3 assembly | Quality-driven timelines; defined per application |

| Circuitboard Manufacturing | Bare PCB fabrication (rigid, flex, alu-rigid) | 25+ years in PCB fabrication; fast-turn prototype support; strong local reputation | Single-sided to multilayer PCBs; flex & alu-rigid; prototype to volume | Fast prototypes; varies by complexity |

| EAS Electronics | PCB design, repairs, low-volume assembly | Supports redesign and industrial maintenance; ideal for engineering updates and small runs | PCB design + assembly; testing and diagnostics | Service-dependent |

| EBest Circuit (Best Technology) (Global PCB Factory) | Advanced global PCB fabrication + PCBA | ISO9001, ISO13485, IATF16949, AS9100D; MES traceability; competitive global pricing | 2‚Äď30 layer PCBs; HDI (2+N+2 / 3-step); Rogers/PTFE/ceramic; heavy copper; rigid-flex; MCPCB; one-stop PCB + PCBA | Fast DFM in 24h; prototypes in 3‚Äď7 days; stable mass production |

How to Select A Reliable PCB Factory in Pretoria?

A Detailed Selection Guide to PCB Factory in Pretoria:

1. Production Capability & Technology Alignment

- Prioritize factories with proven expertise in HDI, multi-layer boards, and specialty substrates like aluminum/FPC. EBest Circuit (Best Technology) offers advanced MSAP/mSAP processes for line widths ‚ȧ40őľm, ideal for 5G/IoT devices.

- Evaluate lead times: Rapid prototyping (3-5 days) for validation, volume production (7-14 days) for standard cycles. EBest Circuit (Best Technology)’s flexible scaling handles urgent needs without compromising quality.

2. Quality Assurance & Process Control

- Look for factories with IPC-compliant inspection systems: AOI, X-ray testing, and flying probe checks. EBest Circuit (Best Technology) implements batch traceability with CoC and IPC-A-600 reports, ensuring defect-free outputs.

- Reliability testing (temperature cycling, humidity resistance) aligned with IPC-TM-650 standards. EBest Circuit (Best Technology)’s closed-loop feedback system optimizes processes via real-time data analysis.

3. Customer-Centric Support & Transparency

- Seek 24/7 technical advisory for DFM optimization (e.g., layout simplification, material selection). EBest Circuit (Best Technology) provides tailored solutions, from specialty high-Tg FR-4 to small-batch trials (10+ units).

- Real-time tracking from file confirmation to delivery. EBest Circuit (Best Technology)’s transparent logistics updates via trusted carriers ensure on-time performance.

4. Industry Experience & Trust Signals

- Choose factories with sector-specific expertise: Medical/automotive certifications (ISO 13485, IATF 16949) for high-reliability needs. EBest Circuit (Best Technology)’s case studies highlight successful deployments in safety-critical applications.

- Client testimonials emphasize reliability: EBest Circuit (Best Technology)‚Äôs ‚Äú98%+ yield in industrial control boards‚ÄĚ and ‚Äúconsistent delivery within agreed timelines‚ÄĚ build trust among South African engineers.

5. Strategic Partnership & Value Alignment

- Verify long-term collaboration potential through site visits and contract clarity. EBest Circuit (Best Technology)’s scalable production and post-sales support (test reports, failure analysis) reduce lifecycle risks.

- Align with suppliers who prioritize local market needs: EBest Circuit (Best Technology)’s South African-focused services include quick-turn prototyping and cost-effective volume solutions tailored to regional demand.

Welcome to contact us now if you have any request for PCB design, prototyping, mass production and PCBA service: sales@bestpcbs.com.