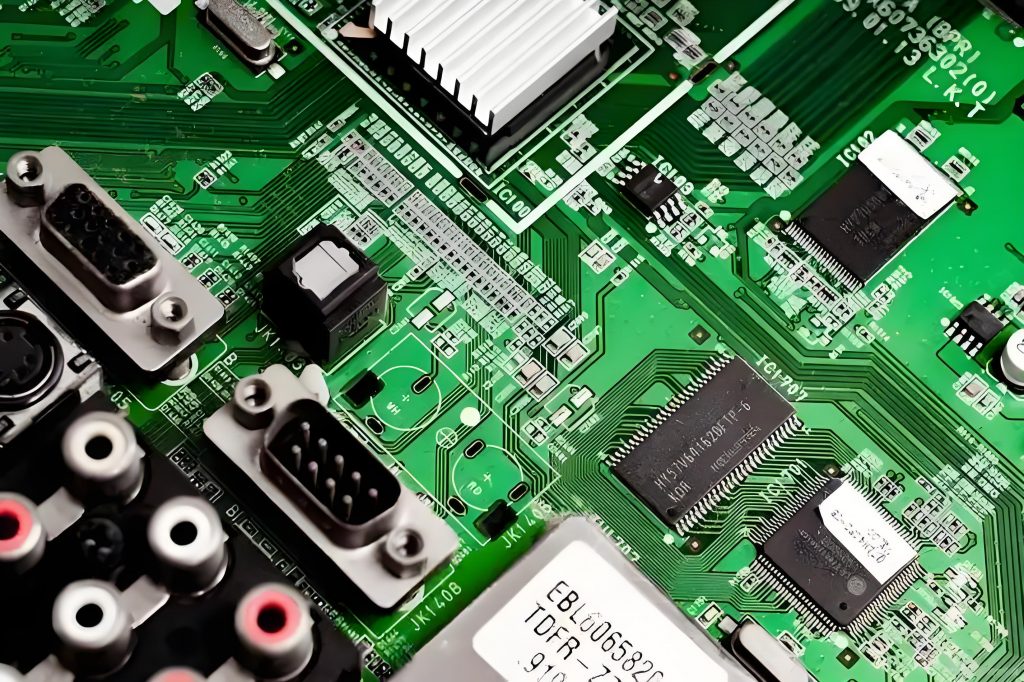

Circuit board damage happens for many reasonsâheat, moisture, aging parts, or physical stress. But with the right knowledge and tools, pcb repair is absolutely possible. Whether itâs a simple home device or an AC control board, identifying the issue early helps cut costs and prevent deeper damage.

If youâre dealing with an HVAC unit, industrial equipment, or a sensitive medical device, working with professionals makes sense. EBest Circuit (Best Technology) supports customers around the world with reliable PCB production and testing. From standard single-layer boards to complex multilayer and ceramic solutions, weâre committed to high performance and long-lasting quality.

What Are Most Circuit Problems Due To?

Most circuit board problems are caused by heat, moisture, power surges, dust, and aging. These issues affect the board either slowly over time or all at once. Heat, in particular, is a silent killer. When components get too hot, they wear out faster. Solder joints also become weak. Over time, the board may stop working even if thereâs no visible damage.

Moisture is another hidden threat. If water or humidity gets inside the board, it can cause corrosion. Corrosion eats away at the copper traces and makes connections weak. If youâre in a humid climate or near the ocean, your electronics may wear out faster unless sealed properly.

Another problem is physical stress. If the board is bent or shaken a lot, microcracks can appear. These cracks are hard to see but can break connections inside the board. Eventually, signals canât travel properly, and the board may fail.

What Usually Goes Bad on a Circuit Board?

Some parts of a circuit board are more likely to fail than others. Capacitors are one of the most common troublemakers. They are often found in power supplies, and over time they dry out or leak. When that happens, your device might stop turning on, or it might behave oddly.

Resistors can also burn out, especially if thereâs a short circuit. When a resistor fails, it often turns black or breaks apart.

Integrated circuits (ICs) are another weak point. These chips control important functions. They are small and sensitive. A small voltage spike can damage them instantly.

Solder joints are also a common problem. Over time, these joints can crack. This causes the component to lose contact with the board. Re-soldering usually solves the issue, but only if the board isnât too damaged.

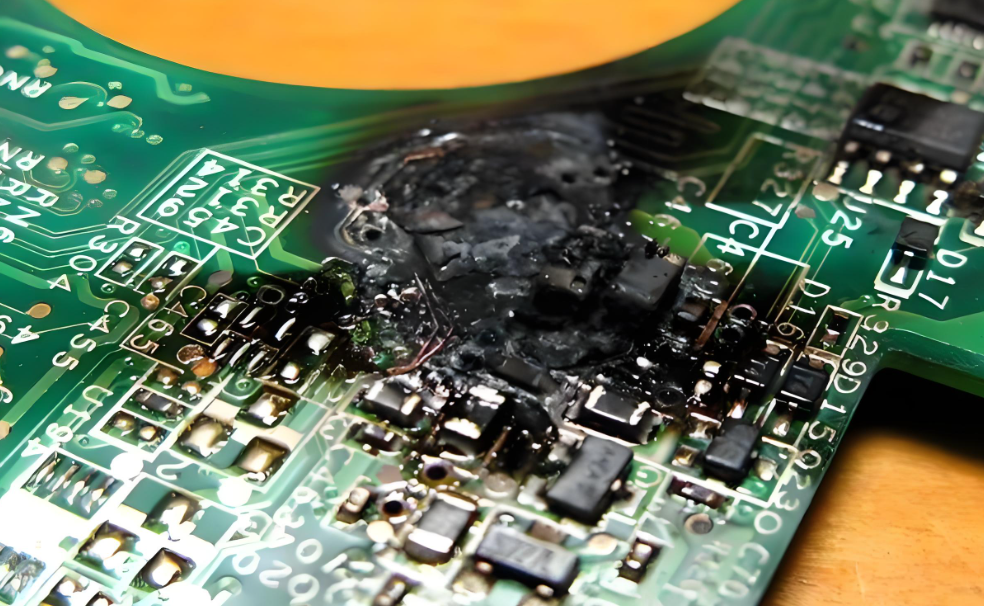

What Would Cause a Circuit Board to Burn?

A burned circuit board is a serious problem. It usually happens due to:

- Short circuits

- Power supply issues

- Component failure (like a failed transistor or voltage regulator)

- Poor PCB design or low-quality manufacturing

- Dust buildup causing arcing or hot spots

Burn marks, melting, or a burnt smell are signs of severe board damage. In some cases, PCB repair is still possible. But if the internal layers are affected, replacement may be the only option.

How to Tell If a Circuit Board Is Blown?

Itâs not always easy to tell if a board is blown just by looking. But there are a few signs to check:

1. Physical Clues

- Burn marks or dark spots

- Swollen or leaking capacitors

- Cracked chips

- Melted areas or broken traces

2. Electrical Behavior

- The device wonât turn on

- It powers on but acts erratically

- Parts of the device stop working

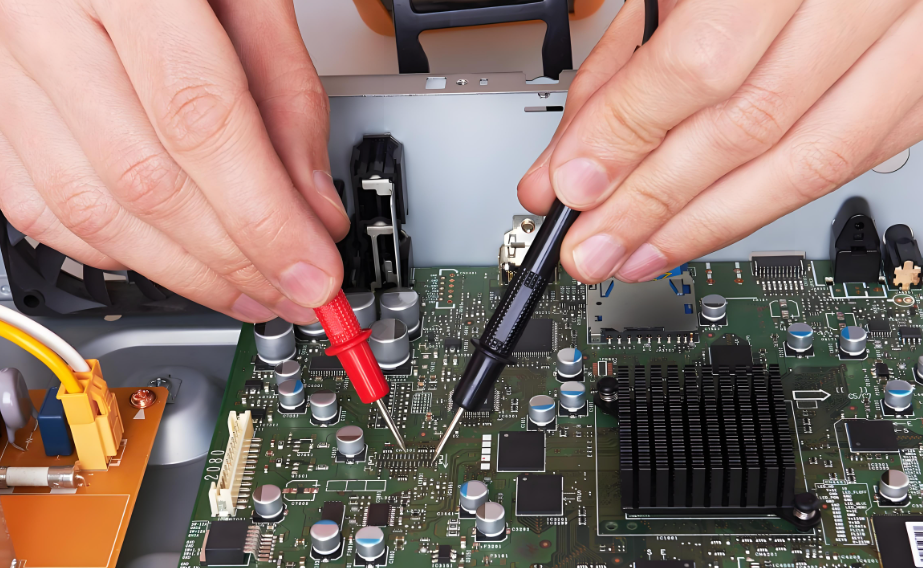

3. Testing with Tools

- Use a multimeter to check voltage and resistance

- Check continuity to find broken paths

- A lack of signal or power at test points means something’s wrong

If any of these signs appear, the board might be blown. Depending on the damage, PCB board repair cost may vary from low to high.

How Long Should a Circuit Board Last?

A well-made PCB can last 10 to 20 years. Some last even longer if kept in a clean, cool, dry place. But others fail within just a few years. It depends on:

- Quality of components

- How hot the board gets

- How clean the environment is

- How often the device is used

For example, a control board in an AC unit might last 10â15 years. But if itâs exposed to heat and dust, failure can happen sooner. Keeping regular cleaning and maintenance help extend life. And replace worn-out capacitors and clean off dust yearly to prevent common failures.

What Does PCB Repair Actually Mean?

The term PCB repair means fixing any part of a circuit board thatâs no longer working. That might include:

- Replacing broken components

- Repairing damaged traces or pads

- Fixing bad solder joints

- Cleaning dirty or corroded parts

PCB repair doesnât always need advanced skills. If you understand the circuit and can use a multimeter and soldering iron, small repairs are possible. For more complex repairs, itâs better to visit a service center.

Is It Possible to Repair a Circuit Board?

Yes, circuit boards can be repaired. But it depends on the type of damage. If a part is broken, it can usually be replaced. If a trace is cut, it can often be patched with a jumper wire. Here are some common PCB repair methods:

- Component Replacement: If a resistor, capacitor, or chip fails, desolder it and install a new one.

- Trace Repair: Use a jumper wire or conductive ink to reconnect broken traces.

- Solder Joint Fixes: Reflow old solder or add fresh solder to cracked joints.

- Cleaning Corrosion: Use alcohol and a brush to remove oxidation or rust.

Some repairs are easy. Others, like fixing broken inner layers, may not be possible without factory tools. For home users, many fixes are possible with basic PCB repair tools. At EBest Circuit (Best Technology), we offer free pcb board repair service if your board be bad during the operation or assembly, we can repair it for you and for free.

How Much Does It Cost to Replace the AC Control Board?

The AC PCB repair cost or replacement cost depends on the board model and brand.

1. Simple AC PCB Repair

If only one or two components are bad, a technician may charge $50â$100. If the board is easily accessible and parts are common, the cost stays low.

2. AC PCB Replacement

If the board is totally fried or has a rare fault, full replacement might be needed. That can cost:

- $150â$250 for residential units

- $300â$400 for high-end or commercial ACs

Labor may be extra if the unit is hard to open. In some cases, it’s cheaper to fix the board using local services with AC PCB repair experience.

PCB Repair Tools You Might Need

To repair a circuit board, you donât need a full lab. A small kit with the right tools is enough for most jobs. Here are essential PCB repair tools:

1. Soldering Iron: A must-have for replacing components

2. Desoldering Pump or Braid: To remove old solder cleanly

3. Multimeter: To test voltages and check for open circuits

4. Tweezers and Magnifying Glass: Helpful for handling small parts

5. Hot Air Rework Station: Needed for surface-mount parts (SMD)

6. PCB Holder or Clamp: Keeps your board stable while working

7. Isopropyl Alcohol and Brush: For cleaning dust or corrosion

With practice, many home users can fix basic issues. Just make sure to work slowly and carefully.

Can You Do AC PCB Repair Yourself?

If you have some knowledge of electronics and the right tools, you might fix an AC control board yourself. You can:

- Replace burnt capacitors

- Re-solder loose joints

- Clean the board to remove dirt or corrosion

But there are risks. AC boards often control high-voltage parts. A mistake could damage the systemâor cause injury. You should not attempt AC PCB repair if:

- Youâre not familiar with electronics

- The damage looks severe

- You donât have the proper tools

In those cases, itâs better to call your PCB manufacturer or seeking for a qualified repair shop at your local.

How to Prevent Circuit Board Damage?

Repairing is great, but prevention is better. You can reduce the chance of needing pcb repair by:

- Keeping electronics clean and dry

- Avoiding power surges with surge protectors

- Ensuring proper ventilation to reduce overheating

- Mounting boards securely to avoid mechanical stress

Scheduling regular inspection and cleaning, especially for industrial and HVAC systems

Preventive steps are usually cheaper than dealing with a blown board.

When to Replace Instead of Repair?

In some cases, fixing the board doesnât make sense. You should replace it if:

- Damage covers a large area

- The board has many burned or broken parts

- Itâs cheaper to replace than repair

- Itâs hard to find parts for the repair

If your AC is old and parts are rare, itâs often smarter to upgrade both the board and the unit. Youâll avoid repeated repair costs.

About EBest Circuit (Best Technology)

EBest Circuit (Best Technology) is a reliable PCB manufacturer in China. We specialize in small to medium-volume PCB Manufacture, PCB Assembly, and Electronic Manufacturing Services. As one of the highly experienced circuit board suppliers, our products and services include a wide range of printed circuit boards such as rigid PCBs, flex PCBs, rigid-flex PCBs, aluminum PCBs, RF Microwave PCBs, high-speed PCBs, high-frequency PCBs, and HDI PCBs.

Apart from being an experienced printed circuit board manufacturer, EBest Circuit (Best Technology) also provides turnkey assembly, component sourcing, box build assembly, PCBA testing, and complete electronics test and assembly. We are a one-stop PCB manufacturer dedicated to meeting all your PCB board manufacture demand.

FAQs

1. What does PCB repair mean in electronics?

It refers to fixing damaged components, traces, or solder joints on a circuit board to restore functionality.

2. Can a burnt PCB be fixed?

Yes, if the damage is limited to outer layers and doesnât affect inner traces, itâs often repairable.

3. How much does PCB board repair cost?

It ranges from $50 to $150 depending on the extent of damage and labor involved.

4. What tools are used for PCB repair?

Common tools include soldering irons, multimeters, hot air guns, tweezers, and desoldering tools.

5. Is AC PCB repair worth it?

If the board is rare or expensive, yes. But sometimes, full replacement is more cost-effective.