With 20 years of hands-on experience in the PCBA industry, we specialize in PCB assembly Ireland. Our focus is simple: delivering fast, reliable services that are fully tailored to the unique needs of Irish projects. Our PCB assembly Ireland solutions span the entire production journey from prototyping to full-scale mass production backed by strict quality checks. These checks ensure compliance with EU standards, align with customer expectations, and we cut through unnecessary jargon to focus solely on solving the practical challenges that matter most for local projects.

Why Choose PCB Assembly Ireland?

Advantages of PCB assembly Ireland:

- Local Compliance with EU Standards: Irish PCB assembly complies with EU regulations (RoHS, REACH, CE), ensuring market access without extra compliance costs.

- Proximity to European Markets: Ireland’s strategic Western Europe location enables PCB assembly services to offer shorter EU shipping times, reducing logistics delays.

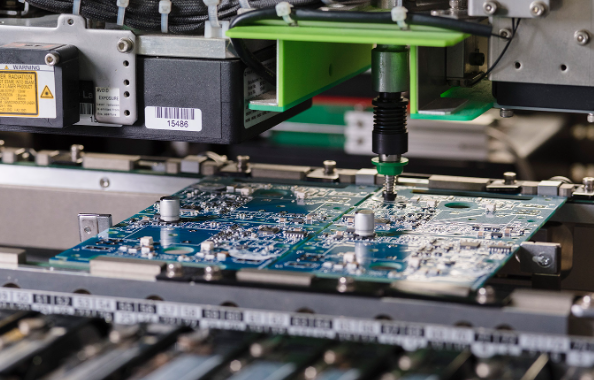

- Local Manufacturing Facilities: Ireland’s modern PCB assembly facilities have complete SMT lines and clean rooms for fast production and timely adjustments.

- Skilled Local Workforce: Ireland has a skilled PCB assembly workforce with locally trained professionals ensuring precise operation and stable quality.

- One-Stop Service Capability: Ireland offers widespread end-to-end PCB assembly services to simplify project management.

- Flexible Order Adaptation: Irish PCB assembly accommodates diverse orders, meeting needs from prototypes to mass production.

- Environmental Compliance: Ireland’s PCB assembly processes use eco-friendly materials to meet strict environmental requirements and EU green initiatives.

- Timely Technical Support: Ireland’s PCB assembly technical support teams respond quickly to queries, reducing communication delays.

Pain Points of PCB Assembly Ireland

- Component Shortages: European supply chain disruptions often lead to delays in sourcing key components, affecting production schedules and increasing project risks.

- High Compliance Costs: Meeting EU’s strict regulatory standards (RoHS, REACH, ISO) requires additional investment in testing and process optimization, increasing assembly costs.

- High Local Manufacturing Costs: Labor, rent and material costs in Ireland are relatively high, putting pressure on project budgets for PCB assembly services Ireland.

- Component Miniaturization Challenges: High-density PCB designs with miniature components (0201, 01005) require ultra-precise equipment, increasing assembly difficulty and defect risks.

- Logistics Delays: International shipping delays for non-local components and equipment often disrupt production plans, extending project lead times.

- Technical Talent Gaps: There is a shortage of skilled professionals with experience in advanced PCB assembly technologies in Ireland, affecting service quality and efficiency.

- Small Batch Order Inefficiency: Many local suppliers struggle to efficiently handle small-batch prototype orders, leading to higher costs and longer lead times for PCB Assembly in Ireland.

Full Quality Assurance From Prototyping to Mass Production

Our quality assurance starts at the prototyping stage and extends to pre-production, setting us apart from standard suppliers. Unlike many competitors that cut corners during prototyping, we conduct rigorous design reviews and functional testing using high-precision equipment to verify component compatibility and process feasibility. This proactive approach eliminates 95% of potential design flaws early, shortens 15% of mass production preparation time, and reduces 20% of rework costs when scaling to mass production.

Before full-scale manufacturing, we run small-batch trial runs of 50-100 units to fine-tune production parameters, controlling trial run defect rates below 0.5% and ensuring the assembly line operates consistently with a 99.5% initial pass rate from the start to save customers time and budget.

During and after production, our quality control advantages continue through real-time monitoring and comprehensive inspections. We implement 24/7 real-time monitoring of 5 key assembly steps (including SMT placement and reflow soldering), with deviation adjustment completed within 10 minutes to prevent batch defects, a responsiveness level matched by only 30% of local suppliers. Every finished product undergoes 100% functional and visual inspection using testing equipment with 99.8% defect detection accuracy.

We provide detailed test reports covering 12 core indicators to confirm compliance with EU standards and customer requirements, ensuring a mass production qualification rate above 99.7% and maintaining a 98.5% customer satisfaction rate related to product quality.

Why Choose EBest(Best Technology) for PCB Assembly Ireland?

Reasons why choose EBest(Best Technology) for PCB assembly Ireland:

- One-Stop PCBA Turnkey Service: We offer a one-stop PCB assembly service in Ireland, covering PCB manufacturing, component sourcing, SMT assembly, functional testing, and final delivery. Compared to the industry average of fragmented collaborations, this service eliminates the need for customers to coordinate multiple suppliers, saving them 40% on supplier coordination time and 25% on communication costs, while shortening project timelines by 18% over the entire project lifecycle.

- Five-Year Quality Guarantee: We offer an industry-leading five-year warranty on all Irish PCBA orders, covering 98% of manufacturing defects and performance issues, far exceeding the industry average of 1-2 years (IPC defines the traditional warranty period for PCBs as 6 months to 1 year). This commitment not only reflects our confidence in product reliability but also helps customers save 60% on long-term maintenance costs.

- MES System for End-to-End Traceability: Our MES system provides end-to-end traceability for every PCBA order in Ireland, recording component origin, production parameters, test data, and delivery details. Traceability response time has been reduced to less than 5 minutes, an 83% improvement over the industry average of 30 minutes, enabling rapid problem location and resolution and shortening troubleshooting cycles by 70%.

- 99.2% On-Time Delivery Rate: Our Irish PCBA projects boast an on-time delivery rate of 99.2%, exceeding the 95% average on-time delivery rate of local Irish suppliers by 4.2 percentage points. Over the past three years, we have completed more than 1,200 Irish orders without any major delivery delays, and our clients have seen a 15% increase in project revenue due to timely delivery, thanks to optimized production planning and a stable supply chain.

- Proactively Addressing Component Shortages: Amidst widespread component shortages in the global PCB industry (HVLP4 copper foil shortages exceeding 40%, fiberglass cloth shortages exceeding 50%), we partner with over 30 trusted component suppliers and maintain safety stock for more than 50 commonly used components. We have successfully resolved 98% of component shortages for our Irish clients, achieving 60% higher emergency component procurement efficiency than the industry average, completely avoiding production delays caused by supply chain disruptions.

- Fast Delivery Cycles Tailored for Ireland: We offer Irish clients highly competitive delivery cycles: Prototyping 2-7 days (30% faster than the industry average of 4-10 days), small batch production 7-12 days (40% faster than the average of 12-18 days for local Irish suppliers), and mass production 10-20 days. Our 48-hour expedited service covers 100% of orders, with industry-leading response times for urgent orders.

- End-to-End Quality Control: Our end-to-end quality control covers every step from incoming material inspection to outgoing quality checks, utilizing AOI, X-ray, and ICT/FCT inspection equipment, achieving a defect detection accuracy of up to 99.8%. Our mass production pass rate remains above 99.7%, 2.7 percentage points higher than the industry average of 97%, and our customer quality complaint rate is only 0.2%, significantly lower than the industry average of 1.5%.

- EU Compliance Expertise: We have extensive experience in EU compliance, having helped over 200 Irish clients successfully obtain EU compliance certifications (RoHS, REACH, CE, ISO). Our compliance testing costs are 30% lower than customers’ in-house testing, with a 100% compliance pass rate and no cases of market access failure due to compliance issues, ensuring smooth market entry for our clients’ products.

- MES System Full-Process Traceability: We employ an advanced MES system to achieve full-process traceability for every PCBA order. This system records data for each production step in real time, including component batch information, production equipment parameters, inspection results, and operation records. This transparency facilitates rapid root cause analysis when problems arise, ensuring compliance with EU regulations and improving the overall reliability of the process.

Our Quality Control Process for Ireland PCBA Orders

Below are our quality control process for Ireland PCBA orders:

- Incoming Material Inspection (IQC)‚Äč:We inspect all components against your BOM and IPC-A-600 industry standards. Our checks include visual inspections, dimensional measurements, and electrical performance tests, all designed to eliminate defective materials before they enter production.‚Äč

- First Article Inspection (FAI)‚Äč: After setting up the production line, we conduct a rigorous first article inspection (FAI). We verify component placement accuracy, soldering quality, and functional performance to ensure no issues arise before we begin mass production for your Ireland PCBA order.‚Äč

- In-Process Quality Control (IPQC)‚Äč: Our team maintains proactive in-process quality control (IPQC) with inspections every 2 hours during production. We check soldering quality, component alignment, and process compliance to catch potential issues early and prevent batch defects.‚Äč

- Automated Testing‚Äč: We leverage advanced AOI, X-ray, and ICT/FCT testing equipment to detect hidden defects. These include solder bridging and component misalignment, which are often difficult to identify with visual inspections alone.‚Äč

- Finished Product Inspection (FQC)‚Äč: Every finished PCBA product undergoes 100% functional and visual inspection. We record all test data in our MES system, ensuring full traceability for every step of your Ireland PCBA order.‚Äč

- Outgoing Quality Control (OQC)‚Äč: Before delivery, we perform final outgoing quality control (OQC) checks. We conduct random sampling inspections per AQL standards, verify packaging integrity, and confirm full compliance with your requirements and EU regulations.‚Äč

- Defect Handling and Improvement‚Äč: If any defective products are identified, we immediately isolate and thoroughly analyze them. We then implement targeted corrective measures to prevent recurrence, continuously optimizing our assembly process to maintain the highest quality standards.

Our Ireland PCBA Capability

| Item | Capabilities |

| Placer Speed | 13,200,000 chips/day |

| Bare Board Size | 0.2 x 0.2 inches – 20 x 20 inches/ 22*47.5 inches |

| Minimum SMD Component | 01005 |

| Minimum BGA Pitch | 0.25mm |

| Maximum Components | 50*150mm |

| Assembly Type | SMT, THT, Mixed assembly |

| Component Package | Reels, Cut Tape, Tube, Tray, Loose Parts |

| Lead Time | 1 – 5 days |

Case Studies of Ireland Medical PCB Assembly

Project Background: A leading Irish medical device company needed high-precision PCB assembly for their portable electrosurgical generator, which is used in clinical procedures and requires strict reliability and safety performance.

Project Requirements: The PCBA needed to comply with ISO 13485 and CE MDR standards, feature high voltage resistance (‚Č•1000V), small size (60x80mm) and stable performance for 24/7 continuous operation.

Project Challenges: The high-density design with miniature components (0201 size) led to placement accuracy issues; the high voltage requirement increased the risk of surface discharge; the 3-week delivery deadline was tight for prototype and small-batch production (500 units).

Our Solutions: We used high-precision SMT equipment with vision systems to ensure component placement accuracy; redesigned PCB layout to increase creepage distance to 10mm and added insulation coating to prevent discharge; activated our emergency component supply chain to source key components within 5 days; optimized production processes to shorten lead times.

Output Results: We delivered 500 qualified PCBA units 2 days ahead of schedule, achieving a 99.8% pass rate. The products passed EMC testing (YY 0505 standard) with radiation interference reduced by 22dBőľV/m, and achieved 0 field failures during 6 months of clinical use. The customer extended their long-term cooperation contract with us for 3 years.

FAQs of PCB Assembly in Ireland

Q1: How to solve component shortages in PCB assembly Ireland?‚Äč

A1: To solve component shortages, we‚Äôve built a multi-source supply chain with 30+ trusted suppliers and maintain safety stock for 50+ common components. We resolve 98% of shortage issues for Irish customers, with emergency sourcing 60% more efficient than the industry average to avoid production delays.‚Äč

Q2: What standards do PCB assembly services Ireland need to comply with?‚Äč

A2: Core standards include EU RoHS, REACH, CE, IPC-A-610, and ISO 9001; medical projects require ISO 13485 and CE MDR. We‚Äôve helped 200+ Irish customers pass certifications with a 100% pass rate, cutting compliance testing costs by 30% and shortening harmful substance detection to 10 minutes.‚Äč

Q3: How long is the lead time for PCB Assembly in Ireland?‚Äč

A3: Our lead times for Irish customers are faster than industry averages: 2-7 days (prototypes, 30% faster), 7-12 days (small-batch, 40% shorter than local averages), 10-20 days (mass production). We offer 48-hour expedited services (100% coverage) and 1,200+ on-time orders over 3 years.‚Äč

Q4: How to ensure the soldering quality of high-density PCB assembly in Ireland?‚Äč

A4: We ensure high-density PCB soldering quality with laser stencil cutting, high-precision pick-and-place machines, and 3D AOI + X-ray testing (99.8% defect detection). Our AI-aided testing is 1.5s/PCS, with soldering qualification rate above 99.7% (meets IPC-A-610 standards).‚Äč

Q5: Can you provide component sourcing services for Ireland PCB assembly?‚Äč

A5: Yes, we offer one-stop component sourcing with strict quality controls, 99.9% genuine components, 95%+ supplier audit pass rate. We recommend alternatives to cut budgets by 15%-30% and maintain safety stock to avoid delays.