Looking for PCB manufacturer in Armenia? This blog is mainly about the challenges of Armenia PCB manufacturing and our solutions and recommend PCB manufacturer.

When seeking a reliable PCB manufacturer in Armenia, businesses often face challenges in balancing quality, cost, and delivery time. Our company, as a professional global PCB service provider, offers comprehensive one-stop solutions tailored to the unique needs of the Armenia market, making us a trusted partner for PCB manufacturer in Armenia seekers. We understand the local industry characteristics and technical requirements, providing customized Armenia PCB design, prototyping, manufacturing, and assembly services to support the smooth operation of local electronic projects.

Are You Facing These Challenges of Armenia PCB Manufacturing?

- Do you often encounter repeated prototyping failures due to design not considering production compatibility, such as unreasonable pad layout or insufficient line spacing?

- Is it difficult to find a partner that accepts small-batch orders, forcing you to bear high costs for mass production even in the R&D stage?

- Does the long lead time of local PCB manufacturing seriously delay your project launch schedule?

- Are you troubled by unstable product quality, such as board warping, poor soldering, or signal interference after PCB assembly?

- Do you struggle to balance cost control and product performance when selecting PCB materials and processes?

- Is it challenging to meet international compliance standards for PCB products, affecting your market expansion?

One-Stop Solution from Requirement to Delivery

- Professional Design Support: Provide free DFM analysis to check and optimize design schemes in advance, avoiding prototyping failures caused by design defects, ensuring smooth transition from design to production.‚Äč

- Flexible Order Acceptance: We welcome both small-batch prototyping and mass production orders, with no minimum order quantity restrictions, fully meeting your R&D and production needs at different stages.‚Äč

- Efficient Delivery System: Implement 24-hour rapid prototyping for emergency orders and ensure a 99.2% on-time delivery rate for mass production, effectively shortening your project cycle.‚Äč

- Strict Quality Control: Adopt full inspection for mass production, equipped with advanced AOI and X-ray testing equipment, and implement strict quality control processes to ensure stable and reliable product quality.‚Äč

- Cost Optimization Scheme: Combine 19 years of production experience to provide cost-sensitive solutions, select appropriate materials and processes, and help you reduce production costs without compromising performance.‚Äč

- Comprehensive Compliance Guarantee: Our products fully meet ISO9001:2015, ISO13485:2016, REACH, RoHS, IATF16949 and other international standards, providing complete compliance documents to support your market expansion.

Why Armenia Customers Choose Us as Their PCB Manufacturer?

- 19 Years of Production Experience: With nearly two decades of experience in the PCB industry, we have rich technical accumulation and project experience, which can help you avoid potential risks and reduce costs.

- Free DFM Analysis: Provide free design for manufacturability analysis before production, pointing out potential problems in the design and giving optimization suggestions to improve the pass rate of prototyping and production.

- Complete Certification System: We have obtained ISO9001:2015, ISO13485:2016, REACH, RoHS, IATF16949 and other authoritative certifications, ensuring that our products comply with international market regulations and facilitating your product export.

- Competitive Pricing: We have established a mature global supply chain, which enables us to provide competitive prices while ensuring product quality, helping you gain advantages in market competition.

- Cost-Sensitive Design Solutions: Our professional team analyzes your design schemes in depth, optimizes material selection and process design, and reduces unnecessary costs for you.

- 24-Hour Rapid Prototyping: For emergency orders, we can complete prototyping within 24 hours, quickly responding to your urgent project needs and accelerating your product launch process.

- Fast and On-Time Delivery: With a scientific production scheduling system and efficient logistics partners, we achieve a 99.2% on-time delivery rate, ensuring that your production plan is not affected by delivery delays.

- Superior Quality Assurance: Mass production realizes 100% full inspection, and strict quality control processes are implemented from raw material incoming inspection to finished product delivery, ensuring that each batch of products meets the required standards.

One Stop PCB Solution Service We Can Provide

As a professional Armenia PCB company partner, we integrate multiple services to provide convenient and efficient support for your projects:‚Äč

- PCB Design Optimization: Our professional team conducts in-depth analysis of your design schemes, combining manufacturability and cost factors to provide targeted optimization suggestions, reducing production risks and costs.‚Äč

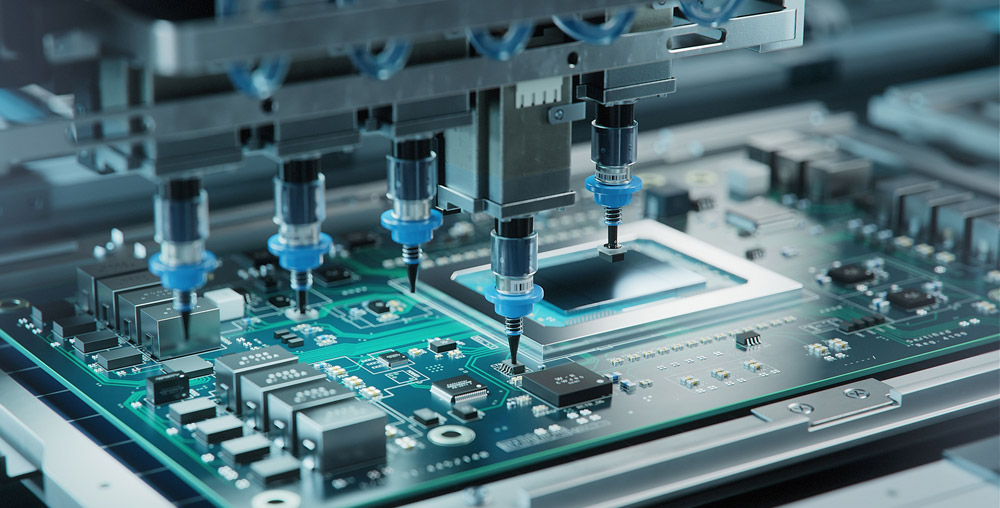

- PCB Prototyping: Equipped with advanced production equipment, we provide 24-hour rapid prototyping services for various types of PCBs, ensuring fast delivery while guaranteeing prototype accuracy and performance.‚Äč

- Mass Production: With large-scale production capacity and mature processes, our Armenia PCB Plant can meet mass production needs of different scales, ensuring consistent product quality and stable delivery.‚Äč

- PCB Assembly: Provide integrated assembly services, including component purchasing, soldering, testing and other links, realizing seamless connection from PCB manufacturing to finished product assembly.‚Äč

- Quality Testing and After-Sales: Conduct comprehensive testing for finished products, covering electrical performance, reliability and other aspects; provide timely after-sales support to solve problems encountered in the use process.

Our PCB Manufacturing Capabilities

| Item | Capabilities |

| Layer Count | 1 – 32 Layers |

| Max Board Dimension | 2424″ (610610mm) |

| Min Board Thickness | 0.15mm |

| Max Board Thickness | 6.0mm – 8.0mm |

| Copper Thickness | Outer Layer: 1oz~30oz, Inner Layer: 0.5oz~30oz |

| Min Line Width/Line Space | Normal: 4/4mil (0.10mm); HDI: 3/3mil (0.076mm) |

| Min Hole Diameter | Normal: 8mil (0.20mm); HDI: 4mil (0.10mm) |

| Min Punch Hole Dia | 0.1″ (2.5mm) |

| Min Hole Spacing | 12mil (0.3mm) |

| Min PAD Ring(Single) | 3mil (0.075mm) |

| PTH Wall Thickness | Normal: 0.59mil (15um); HDI: 0.48mil (12um) |

| Min Solder PAD Dia | Normal: 14mil (0.35mm); HDI: 10mil (0.25mm) |

| Min Soldermask Bridge | Normal: 8mil (0.2mm); HDI: 6mil (0.15mm) |

| Min BAG PAD Margin | 5mil (0.125mm) |

| PTH/NPTH Dia Tolerance | PTH: ¬Ī3mil (0.075mm); NPTH: ¬Ī2mil (0.05mm) |

| Hole Position Deviation | ¬Ī2mil (0.05mm) |

| Outline Tolerance | CNC: ¬Ī6mil (0.15mm); Die Punch: ¬Ī4mil (0.1mm); Precision Die: ¬Ī2mil (0.05mm) |

| Impedance Controlled | Value>50ohm: ¬Ī10%; Value‚ȧ50ohm: ¬Ī5ohm |

| Max Aspect Ratio | 0.334027778 |

| Surface Treatment | ENIG, Flash Gold, Hard Gold Finger, Gold Plating(50mil), Gold finger, Selected Gold plating, ENEPIG, ENIPIG; HAL, HASL(LF), OSP, Silver Immersion, Tin Immersion |

| Soldermask Color | Green/White/Black/Yellow/Blue/Red |

Our Quality Control Processes

- Incoming Material Inspection: Conduct strict quality testing on all raw materials such as copper clad laminates, solder paste and components to ensure that they meet the required standards and certification requirements.‚Äč

- In-Process Quality Control: Set multiple quality inspection points in the production process, monitor key parameters of each process in real time, and timely correct deviations to avoid defective products flowing into the next process.‚Äč

- Finished Product Full Inspection: Adopt advanced testing equipment such as AOI automatic optical inspection and X-ray inspection to conduct comprehensive testing on finished PCBs, covering electrical performance, solder joints, circuit connectivity and other aspects.‚Äč

- Quality Traceability Management: Establish a complete quality traceability system, record the production information, inspection results and other data of each batch of products, which is convenient for tracking and handling in case of quality problems.‚Äč

- Regular Quality Review: Conduct regular reviews of production quality data, summarize problems and optimize processes continuously to improve overall product quality.

Case Studies of Our Armenia PCB Manufacturing

Project Background

‚ÄčAn Armenian electronic device company focused on developing intelligent security equipment needed customized high-precision PCB boards for their new product line. Their previous supplier failed to meet technical requirements, leading to a supply gap that required urgent resolution by a reliable PCB manufacturer in Armenia.‚Äč

Project Requirements‚Äč

The project required 8-layer high-density PCB boards with strict requirements on signal integrity and dimensional accuracy. Prototyping needed to be completed within 4 days, and mass production delivery within 12 days. Cost control within the customer’s budget was also a core requirement.‚Äč

Project Difficulties‚Äč

First, the high-density routing of the 8-layer board led to potential signal crosstalk issues. Second, the PCB needed to withstand high-temperature operating environments, requiring special material selection. Third, the tight delivery schedule posed great challenges to production scheduling and logistics.‚Äč

Our Solutions‚Äč

- Conducted free DFM analysis: Focus on extracting key parameters (layer count, board thickness, material) from design files, optimizing layout rationality and hole position precision, reducing design defects by 40% and improving manufacturability by 35%‚Äč.

- Selected high-performance materials: Adopted low-loss materials with dielectric loss (Df) ‚ȧ 0.002 and high-temperature resistant (‚Č• 150‚ĄÉ) copper clad laminates, reducing signal transmission loss by 40% to ensure stable anti-interference performance in industrial environments‚Äč.

- Applied advanced manufacturing technology: Used laser drilling with minimum aperture 0.1mm and position tolerance ¬Ī0.01mm, matched with automatic lamination technology to control interlayer alignment deviation within 0.02mm, ensuring drilling accuracy and layer alignment quality of 12-layer high-density boards‚Äč.

- Opened urgent order green channel: Allocated exclusive production processes and full-time follow-up personnel, realized 2-day prototype delivery (industry average urgent delivery is 3-5 days), and provided real-time production progress synchronization‚Äč.

- Optimized mass production process: Adopted parallel operation of etching & plating, solder mask printing & silkscreen processes, shortened the overall production cycle by 20%, ensuring 5,000-piece mass production delivery 2 days in advance.

Output Results‚Äč

We successfully delivered all PCB products on time, and the product pass rate reached 100% after testing. The emergency power supply equipment equipped with our PCB boards operated stably in the harsh environment of Syria. The customer was highly satisfied with our efficient service and reliable product quality, and signed a long-term cooperation agreement with us, becoming our long-term partner of PCB Manufacturer in Syria.

How to Get a Quote for Armenia PCB ProjectsÔľü

Steps to Get A Quote for Armenia PCB Project:

- Provide project details: Send your PCB design files (Gerber files are preferred), specifications (such as layer number, line width/line spacing, size), quantity, surface treatment requirements and delivery time requirements to our email.‚Äč

- Contact our professional team: You can call our service hotline or consult online through our official website, and our professional consultants will reply to you within 1 hour.‚Äč

- Receive preliminary quote: Our team will calculate the cost according to your project details and provide a preliminary quote within 4 hours, including product price, production cycle and other information.‚Äč

- Confirm details and finalize quote: Communicate with you to confirm the details of the project, adjust the quote according to special requirements, and issue a formal quote document after confirmation.‚Äč

- Start cooperation: After you confirm the quote and sign the contract, our team will immediately arrange the production plan to ensure that the project progresses smoothly according to the requirements.

Welcome to contact us if you have any request for Armenia PCB project: sales@bestpcbs.com.