PCB assembly in Mexico has become a preferred choice for North American electronics projects, leveraging nearshore advantages to reduce logistics costs and shorten lead times. Rooted in the region’s booming nearshore outsourcing trend, local operations uphold RoHS/ISO certifications and align closely with North American market requirements to maximize these perks. For labor-intensive projects with over 20% manual assembly, PCB assembly in Mexico optimizes cost structures by minimizing cross-border risks and strengthening supply chain resilience, balancing precision craftsmanship with rapid response to meet the agile demands of industrial and consumer electronics sectors.

Top 10 PCB Assembly Manufacturer in Mexico

| Company Name | Main Business | Core Advantages | PCBA Capabilities | Lead Time |

| EBest Circuit Co., Limited (Best Technology Circuit Co., Limited) | PCB assembly, EMS services, component procurement | Nearshore location, RoHS/ISO certified, North American market focus | SMT/THT assembly, X-ray inspection, high-density board assembly | 24-48 hours for prototypes, 5-7 days for mass production |

| Jabil Mexico S.A. de C.V. | Automotive/medical PCBA, full-service EMS | IATF 16949/ISO 13485 certified, border facility layout | High-volume SMT/THT, rigid-flex assembly, functional testing | 48 hours for prototypes, 3-7 days for mass production |

| Flex Mexico (Flextronics) | Aerospace/industrial PCBA, turnkey EMS solutions | AS9100 certified, rapid prototyping, supply chain integration | HDI PCB assembly, X-ray inspection, thermal cycle testing | 24-72 hours for prototypes, 5-10 days for mass production |

| Sanmina Mexico S.A. de C.V. | Medical/aerospace PCBA, custom EMS services | ISO 13485/AS9100D certified, ITAR compliant | Complex PCBA, wire bonding, cleanroom assembly | 72 hours for prototypes, 7-12 days for mass production |

| Benchmark Electronics Mexico | Industrial/automotive PCBA, engineering services | ISO 9001/IATF 16949 certified, DFM support | Medium-to-high volume assembly, ESD protection, in-circuit testing | 48-72 hours for prototypes, 6-9 days for mass production |

| Plexus Corp. Mexico | Medical/industrial PCBA, product realization services | ISO 13485 certified, regulatory compliance expertise | High-reliability PCBA, environmental stress testing, traceability systems | 3 days for prototypes, 8-14 days for mass production |

| Celestica Mexico S.A. de C.V. | Automotive/telecom PCBA, end-to-end EMS | IATF 16949 certified, nearshore logistics optimization | SMT/THT assembly, BGA rework, functional validation | 48 hours for prototypes, 4-8 days for mass production |

| Elcoteq Mexico (now part of DB Schenker Electronics) | Consumer/industrial PCBA, low-to-medium volume production | RoHS/ISO 9001 certified, cost-effective solutions | Standard SMT assembly, visual inspection, electrical testing | 72 hours for prototypes, 5-10 days for mass production |

| Kimball Electronics Mexico | Medical/automotive PCBA, contract manufacturing | ISO 13485/IATF 16949 certified, continuous improvement systems | Precision PCBA, conformal coating, reliability testing | 3 days for prototypes, 7-11 days for mass production |

| TTM Technologies Mexico | Aerospace/defense PCBA, high-density interconnect boards | AS9100/ITAR certified, advanced testing capabilities | HDI PCBA assembly, X-ray inspection, BGA/CSP handling | 5 days for prototypes, 10-15 days for mass production |

Quality Standards for PCB Assembly in Mexico

- IPC-A-610 (PCBA Acceptability Standard): Serves as the core standard, defining three acceptance levels based on application scenarios. Level 1 applies to consumer electronics, Level 2 to commercial/industrial products, and Level 3 to high-performance devices like medical and aerospace equipment.

- IPC-A-620 (Wire Harness Assembly Standard): Governs wire harness and cable assembly processes, ensuring consistency in connection reliability, insulation protection and mechanical durability for Mexico PCBA projects.

- IPC-A-600 (PCB Board Quality Standard): Specifies requirements for bare PCB board quality, covering material integrity, pad condition, trace accuracy and surface finish to lay a solid foundation for assembly.

- RoHS Compliance: Mandatory for all PCB assembly service in Mexico, restricting the use of hazardous substances (e.g., lead, mercury) to meet global environmental and market access requirements.

- ISO 9001 Certification: Supports continuous quality improvement by establishing systematic processes for production control, inspection and corrective actions, ensuring consistent performance across batches.

Pain Points of PCB Assembly in Mexico

- Cost & Efficiency Imbalance: Labor-intensive projects (over 20% manual assembly) face labor cost-productivity conflicts. Tariff fluctuations and logistics issues erode the cost advantage of PCB assembly in Mexico.‚Äč

- Quality Compliance Pressure: Meeting IPC-A-610/620 standards, BGA X-ray inspection and RoHS/ISO 9001 compliance adds high costs to Mexico PCBA operations.‚Äč

- Supply Chain & Response Gaps: Inadequate local components rely on imports, risking Asian disruptions. 24-48-hour prototype targets are hard to meet for North American agility.‚Äč

- Precision & Environmental Risks: Strict SMT/THT parameters (¬Ī0.1mm alignment, ‚ȧ3¬įC/sec reflow) and unstable humidity/ESD protection cause process failures.‚Äč

- High Testing Costs: IPC-A-610 tests and -40¬įC~85¬įC thermal cycling demand heavy equipment/time, conflicting with production timelines.‚Äč

- Policy & Localization Barriers: Complex USMCA clauses and poor non-border infrastructure hinder scaled PCB assembly service in Mexico expansion.

Why Choose EBest( Best Technology) for Mexico PCB Assembly?

Reasons why choose EBest(Best Technology) for Mexico PCB assembly:

- 19 Years of Localized Expertise: With a track record of successful Mexico PCB assembly projects, we deeply understand local market demands, regulatory nuances and supply chain dynamics, ensuring seamless alignment with regional operations.‚Äč

- Comprehensive Compliance Certifications: Hold authoritative certifications including IATF 16949 (automotive), ISO 9001:2015, ISO 13485:2016 (medical), AS9100D (aerospace), REACH, RoHS and UL. This portfolio guarantees full compliance for cross-industry Mexico PCBA projects.‚Äč

- Rapid Turnaround Capabilities: Deliver prototypes in 24 hours and accelerate mass production lead times, directly addressing the response speed gaps of local manufacturers and aligning with North American agile production needs.‚Äč

- Free DFM Analysis Service: Leverage design-for-manufacturability expertise to optimize layouts, pre-empt rework risks at the design stage and control costs for labor-intensive projects.

- Full-Process Traceability via MES System: Implement MES-driven traceability to record component batches, production details and test results, resolving quality consistency concerns and enabling rapid issue localization.‚Äč

- Stable Environmental & ESD Control: Maintain a 40%-60% RH controlled environment and professional ESD protection measures, eliminating component damage risks from static or humidity fluctuations during precision assembly.‚Äč

- One-Stop Mexico PCB Assembly Service: Integrate component sourcing, precision assembly, comprehensive testing and on-time delivery into a streamlined workflow, reducing coordination costs and supply chain friction.‚Äč

- Advanced Reliability Testing Capabilities: Equipped with X-ray inspection and -40¬įC~85¬įC thermal cycle testing, meeting the high-reliability standards required for medical, automotive and aerospace PCB assembly service in Mexico.

Our Mexico PCB Assembly Service With Turnkey Solution

- Component procurement: Reliable supply chain with alternative component solutions to avoid shortages.

- Design optimization: Free DFM analysis to improve assembly feasibility and reduce production costs.

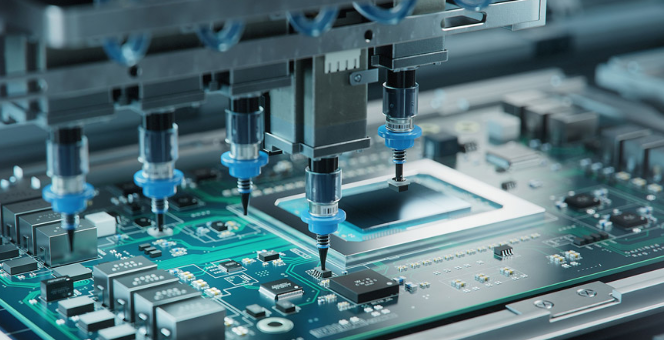

- SMT/THT assembly: Precision processes with ¬Ī0.1mm stencil alignment and ‚ȧ3¬įC/sec reflow slope control.

- Comprehensive testing: Including electrical testing, X-ray inspection and environmental stress testing.

- Packaging & delivery: Customized packaging for safe transportation, with nearshore delivery advantages.

- After-sales support: Technical consultation and problem-solving throughout the product lifecycle.

Our PCB Assembly Capabilities

| Item | Capabilities |

| Placer Speed | 13,200,000 chips/day |

| Bare Board Size | 0.2 x 0.2 inches – 20 x 20 inches/ 22*47.5 inches |

| Minimum SMD Component | 01005 |

| Minimum BGA Pitch | 0.25mm |

| Maximum Components | 50*150mm |

| Assembly Type | SMT, THT, Mixed assembly |

| Component Package | Reels, Cut Tape, Tube, Tray, Loose Parts |

| Lead Time | 1 – 5 days |

Our Quality Control Process for Mexico PCB Assembly

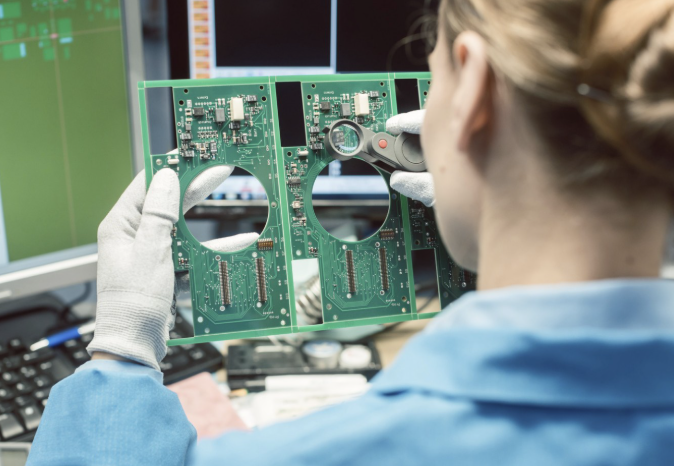

- Incoming Material Inspection (IMI): We inspect all incoming materials for source defects. Components are verified for authenticity, solderability and specification compliance. PCB boards undergo pad integrity, oxidation and impedance checks, with all materials cross-checked against BOM lists to ensure no defective parts enter production and support stable Mexico PCBA processes.‚Äč

- First Article Inspection (FAI): We inspect the first unit of each batch before mass production. Aligned with IPC-A-610 standards, we verify solder quality, component placement and process parameters. All data is documented to confirm design consistency and avoid batch errors for efficient PCB assembly in Mexico.‚Äč

- In-Process Inspection (IPQC): We implement real-time monitoring and random sampling during production. For SMT, we control stencil alignment (¬Ī0.1mm) and reflow slope (‚ȧ3¬įC/sec); for THT, we check soldering time (‚ȧ3s) and fill rate (‚Č•95%). Humidity (40%-60% RH) and ESD protection (‚ȧ100V) are checked regularly to detect deviations early.‚Äč

- Finished Product Testing (FQT): We perform visual, electrical and reliability tests to qualify products. IPC-A-610 Level 2/3 visual inspection, ICT and FCT are conducted. Medical and automotive products get additional -40¬įC~85¬įC thermal cycle and vibration tests to meet high-reliability demands of PCB assembly service in Mexico.‚Äč

- Rework & Re-inspection: Unqualified products are marked and isolated immediately. Our certified technicians analyze causes and execute targeted rework. Post-rework products undergo FQT again, with data recorded to ensure only qualified products move forward and complete the quality loop.‚Äč

- Full-Lifecycle Traceability: We use MES systems to record component batches, production details and test results. Each Mexico PCBA product gets a unique code for rapid issue localization, full tracking and continuous improvement support, aligning with ISO 9001 and industry compliance.

Case Studies of Our Mexico Medical PCB Assembly

Project Background‚Äč: We partnered with a Mexico-based medical device maker focused on portable diagnostic equipment. The client aimed to launch a new product for the North American market, relying on PCB assembly in Mexico to leverage nearshore advantages, shorten supply chain cycles, and meet regional regulatory access requirements.

Project Requirements‚Äč:

- Compliance: Strict adherence to ISO 13485 medical standards and IPC-A-610 Level 3 (medical-aerospace grade) requirements, with full compliance to RoHS and REACH.‚Äč

- Precision: Assemble 12-layer HDI PCBs with 01005 micro-components and BGA devices, controlling BGA void rate ‚ȧ3%.‚Äč

- Delivery: 500 prototypes delivered within 24 hours for clinical validation, and 10,000-unit mass production completed in 7 days.‚Äč

- Traceability: Full-process data tracking for each unit, supporting end-to-end lifecycle traceability required for medical devices.‚Äč

Project Challenges‚Äč:

- Micro-assembly Difficulty: 01005 components require solder paste volume control at 0.002mg/point, posing high demands on printing precision.‚Äč

- Thermal Stress Risk: 12-layer HDI PCBs are prone to warpage during reflow soldering, with warpage tolerance limited to ‚ȧ0.3mm.‚Äč

- Component Shortage: A key medical-grade BGA component was out of stock globally, requiring urgent alternative sourcing with technical verification.‚Äč

Our Solutions‚Äč

- Precision Process Optimization: Adopted laser-aligned stencil printing (precision ¬Ī0.02mm) and optimized reflow curve (120‚ĄÉ‚Üí150‚ĄÉ‚Üí180‚ĄÉ gradient heating) to control PCB warpage and micro-component soldering quality.‚Äč

- Component Sourcing Support: Leveraged localized supply chain resources for Mexico PCBA, identified a RoHS-certified alternative BGA component, and completed thermal compatibility and reliability tests within 8 hours.‚Äč

- Strict Quality Control: Used 3D X-ray inspection for BGA void detection, matched with cleanroom assembly (Class 1000) to meet cleanliness standards, and implemented MES system for full-process data recording.‚Äč

Project Results:

- Yield & Quality: Prototype and mass production yield reached 99.85%, BGA void rate stabilized at 1.8%-2.5%, and all units passed -40‚ĄÉ~85‚ĄÉ thermal cycle testing (500 cycles) with no functional failures.‚Äč

- Delivery Performance: 500 prototypes were delivered in 22 hours, 10,000 units completed mass production in 6.5 days, supporting the client‚Äôs clinical validation schedule.‚Äč

- Compliance & Traceability: All products passed ISO 13485 audit, with each unit‚Äôs traceability code covering component batches, production parameters, and test results.‚Äč

Customer Feedback‚Äč: ‚ÄúThe team‚Äôs professional PCB assembly service in Mexico solved our core pain points of compliance, precision and delivery. The stable yield and strict traceability system helped us pass FDA pre-market inspection smoothly, reducing product launch cycle by 30%. The alternative component solution also avoided supply chain disruptions, and we have expanded cooperation to 8 product lines, relying on their localized expertise for long-term medical device production.‚ÄĚ

FAQs of PCB Assembly in Mexico

Q1: Do your Mexico PCB assembly services meet industry-specific compliance and certification requirements?‚Äč

A1: Yes. We hold a full suite of authoritative certifications to support cross-industry projects, including IATF 16949 (automotive), ISO 13485:2016 (medical), AS9100D (aerospace), ISO 9001:2015, REACH, RoHS and UL. All PCB assembly in Mexico processes align with IPC-A-610/620 standards, ensuring compliance with North American and global market access requirements, especially for high-reliability sectors.‚Äč

Q2: How do you protect customer intellectual property (IP) for Mexico PCBA projects?‚Äč

A2: IP protection is a top priority. We sign a customized Non-Disclosure Agreement (NDA) with every customer before project initiation. Internally, we implement strict data access controls, only authorized personnel can access design files, BOM lists and project details. All electronic data is encrypted, and physical documents are securely stored. We never share or reuse customer intellectual property for any purpose beyond the contracted project.‚Äč

Q3: What after-sales support do you provide for Mexico PCB assembly services?‚Äč

A3: We offer a 12-month warranty for all PCBA products. For quality issues, our technical team provides 24-hour response support. Localized service teams in Mexico are available for on-site troubleshooting and guidance if needed. We also maintain full-process traceability via MES systems, enabling rapid localization of any issues and efficient resolution to minimize project disruptions.‚Äč

Q4: Is there a minimum order quantity (MOQ) for your Mexico PCBA services?‚Äč

A4: No mandatory MOQ. We support flexible order volumes to meet diverse needs, from prototype orders (1-10 pieces) for new product development to small-batch (100-500 pieces) and large-scale mass production. This flexibility helps reduce upfront costs for R&D projects while ensuring stable supply for mass production, perfectly matching North American agile production demands.‚Äč

Q5: How do you handle component shortages for Mexico PCB assembly projects?‚Äč

A5: Our professional sourcing team leverages localized supply chain resources for PCB assembly service in Mexico to identify certified, compatible alternative components quickly. We conduct strict technical verification (including thermal compatibility, reliability testing) and provide detailed cost comparison reports for customer approval. This process typically takes 8-24 hours, avoiding supply chain disruptions and keeping projects on schedule.

How to Get A Quote for Your PCBA Project?

Steps to get a quote for your PCBA project:

- Prepare Your Project Details: Outline your PCBA requirements: layer count, material preferences (e.g., FR-4, polyimide), component specs, and any special features like high-frequency substrates or thermal management needs. Include volume expectations and timeline goals for clarity.

- Identify Specialized Assembly Partners: Research PCBA providers with expertise in your industry‚ÄĒwhether aerospace, automotive, medical, or IoT. Prioritize those offering North American-based support, quick-turn prototypes, and certifications like ISO 9001 or AS9100 for reliability.

- Submit a Non-Binding Inquiry: Reach out via email or online form with your project outline. Include key details but avoid overcomplicating‚ÄĒmost suppliers can refine estimates with brief initial specs. Mention any urgency (e.g., 24-hour prototype needs) to gauge feasibility.

- Expect Transparent Communication: Reputable partners will ask clarifying questions to refine your quote. Be prepared to discuss DFM (Design for Manufacturing) feedback, material alternatives, or process adjustments to optimize cost and performance.

- bEvaluate quotes based on total value: lead times, quality guarantees, and technical support. Look for partners who balance speed, precision, and cost without hidden fees or compromises on certifications.

Ready to Start? Submit your PCBA specs today to get a free quote and DFM analysis: sales@bestpcbs.com.