Metal Core Printed Circuit Boards (MCPCBs) are widely used in high-power applications like LED lighting, automotive systems, and power electronics. They offer superior thermal management compared to standard FR4 PCBs, but several variables impact their final pricing. Whether youâre prototyping or placing a volume order, understanding these factors helps you make informed decisions and avoid unexpected costs.

At EBest Circuit (Best Technology), we manufacture a wide range of MCPCBs tailored to customer requirements. Below, weâve broken down the main elements that influence pricing so you can better evaluate your design options.

Key Technical Factors That Affect MCPCB Pricing

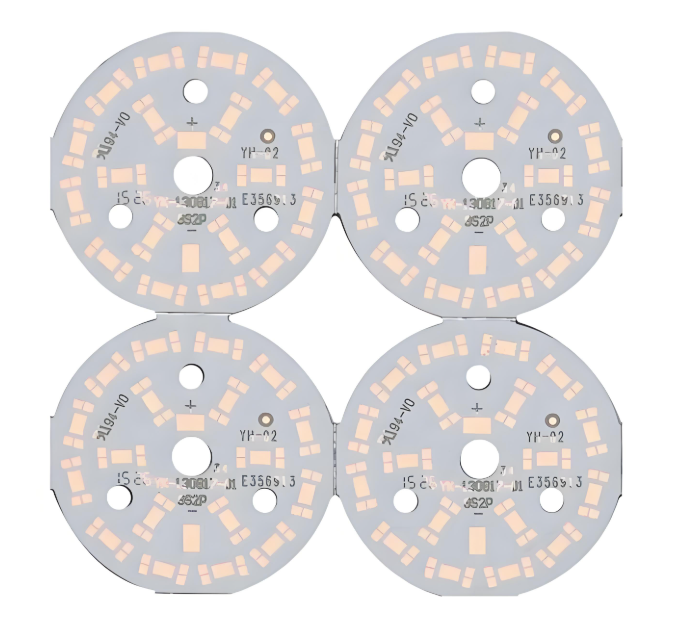

1. Board Dimensions

Size is the starting point for cost evaluation. For non-rectangular shapes like circles, pricing is based on the longest two sidesâtypically the diameter for round boards. Larger boards require more base material and longer processing time, which increases the unit price.

2. Copper Thickness

Copper thickness directly affects both thermal performance and cost. We offer standard and high-current options, including 0.5 OZ, 1 OZ, 2 OZ, 3 OZ, up to 8 OZ. Thicker copper enhances current-carrying capacity but also raises the complexity and expense of manufacturing.

3. Thermal Conductivity

A higher thermal conductivity helps to dissipate heat more efficiently. For example, 3W/m·K materials offer better heat transfer but are more expensive than standard options. The choice often depends on the power density of your application.

4. Surface Finishing

We support finishes such as HASL_LF (lead-free hot air leveling), OSP (Organic Solderability Preservative), and ENIG (Electroless Nickel Immersion Gold). ENIG is the premium choice due to its excellent solderability and oxidation resistance, though it comes at a higher cost.

5. Board Thickness

The most common MCPCB thickness is 1.6mm ±10%, which meets most design standards. Boards thinner than 1mm or thicker than 2mm will cost more due to non-standard processing. Our maximum capacity reaches 4.0mm ±10% for specific projects.

6. Solder mask Type and Color

Solder mask adds not only a protective layer but also an aesthetic touch. We offer white, black, blue, green, and red options. For high-end applications like LED boards, Taiyo solder mask is preferred for its excellent reflectivity, though it is priced higher than regular options.

7. Stack-Up and Construction

The complexity of the PCB stack-up has a big impact on both cost and manufacturing time. Single-layer boards are simpler and cheaper, while multi-layer, double-sided, or heat sink-integrated boards increase the number of processes, materials, and quality inspections required.

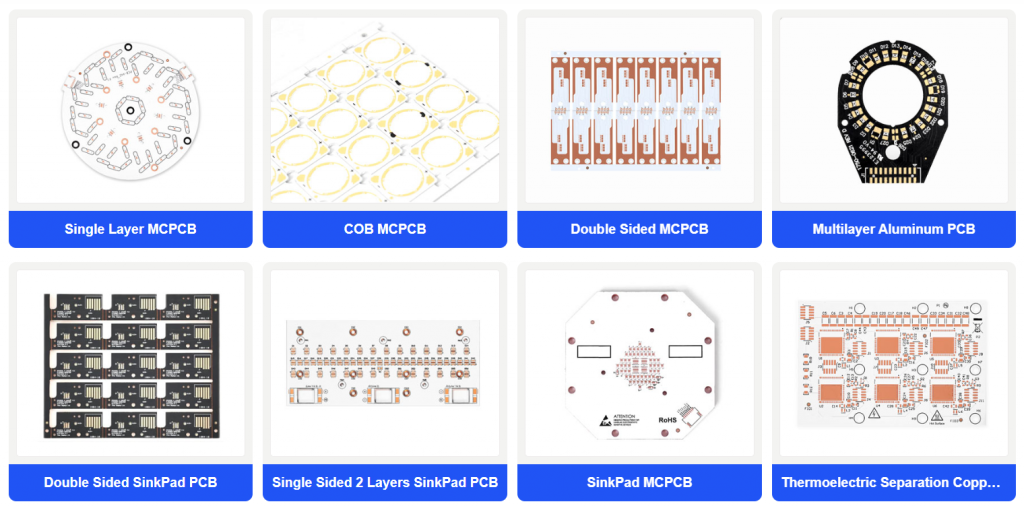

MCPCB Types We Offer

Our company specializes in producing a wide range of MCPCB types to suit various thermal and mechanical requirements:

- Single Layer MCPCB

- Two Layers MCPCB

- Double-Sided MCPCB

- Multi-Layer MCPCB

- Chip-on-Board (COB) MCPCB

- Heat Sink Integrated MCPCB

Each type is customizable to your exact application needsâwhether you’re building high-power LED lighting, automotive electronics, or power conversion devices.

How to Choose the Right Parameters Without Overspending?

When planning your MCPCB project, it’s essential to balance performance requirements with budget constraints. Here are a few suggestions:

- Match copper thickness to your current needs â don’t over-specify if lower OZ will suffice.

- Select surface finishing based on reliability needs â use ENIG for sensitive components, OSP for more budget-friendly builds.

- Ask about solder mask options early â especially for LED projects requiring high reflectivity.

- Consider standard thicknesses â unless your application has unique structural or thermal demands.

- Let us help with stack-up decisions â especially for complex or multi-functional boards.

At EBest Circuit (Best Technology), we guide you through each stage of development, offering design support, material recommendations, and volume-based quotations that match your project goals.

Need help optimizing your MCPCB design for performance and cost?

Contact our team today for a fast, professional quote and expert guidance tailored to your application.