LGA vs BGAβ represents a critical junction in electronics design, defining how a semiconductor die connects to its printed circuit board (PCB). This choice directly impacts electrical performance, thermal management, manufacturability, reliability, and ultimately, the scalability of your entire assembly process. This article provides a comprehensive LGA vs BGAβ comparison, analyzing their pros and cons to guide you toward the optimal selection for scalable production.

When planning for high-volume or evolving product lines, the wrong package choice can become a bottleneck. Are you struggling to balance signal integrity with space constraints, or worried about field failures and costly rework? The decision between a Land Grid Array (LGA)β and a Ball Grid Array (BGA)β is more than technicalβit’s strategic for long-term success.

When selecting LGA vs BGA for scalable assembly needs, engineers and designers often face several intertwined challenges:

- Balancing performance and density: High-speed signal integrity often competes with compact package size.

- Maintaining long-term reliability: Heat cycles and vibration can strain solder joints and reduce durability.

- Managing assembly difficulty: Complex BGA soldering can reduce initial yield and requires advanced equipment.

- Controlling cost with future needs: LGA sockets add upfront cost, while BGA offers density but no upgrade path.

- Supporting testing and rework: Accessing and repairing hidden BGA joints can be difficult and costly.

Navigating the LGA vs BGA decision requires professional expertise that spans design, materials, and manufacturing. A proficient PCB and assembly partner can directly address these pain points:

- Electrical and DFM support: Simulations and manufacturability checks refine LGA and BGA layouts.

- Advanced materials and processes: Reliable substrates and tuned solder profiles improve joint performance.

- Turnkey precision assembly: AOI and X-ray strengthen quality in the LGA vs BGA soldering flow.

- Cost-optimized, scalable planning: Guidance helps balance LGA socket cost with BGA density and volume needs.

- Accurate diagnostics and rework: X-ray and micro-rework tools streamline fault detection and repair.

At BEST Technology, we specialize in high-precision PCB fabrication and assembly, including complex packages like BGA and LGA. Our special expertise ensures that your choice between LGA package vs BGAβ is not a compromise but a strategic advantage. We provide the engineering support and manufacturing excellence to scale your production reliably. A warm welcome to Contact us at sales@bestpcbs.comβ to discuss your project.

What Is LGA vs BGA?

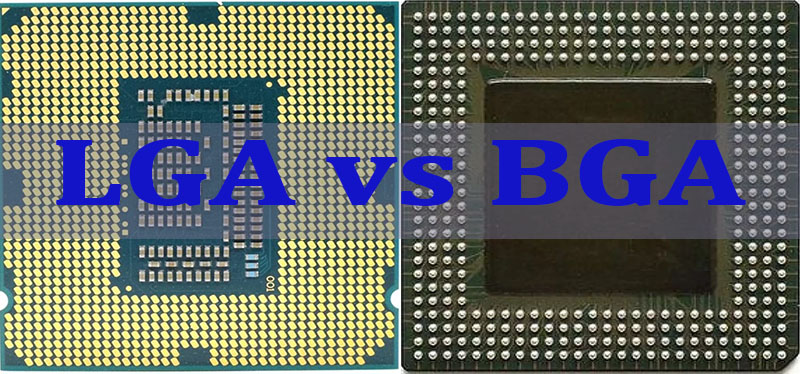

To understand the LGA vs BGβA debate, we must first define them. Both are surface-mount technologies for integrated circuits, but their connection methods differ fundamentally.

- What Is the Full Form of LGA BGA?

- LGAβ stands for Land Grid Array. The package has flat, bare copper pads (lands) on its bottom side.

- BGAβ stands for Ball Grid Array. The package has an array of small solder balls pre-attached to its underside.

The core distinction lies in the final connection method. An LGA packageβ is typically placed into a corresponding socket, which contains spring-loaded pins that make contact with the LGA lands. In contrast, a BGA packageβ is soldered directly onto the PCB by reflowing its solder balls. This leads to the primary bga and lga difference: LGA offers separability (like a CPU socket), while BGA provides a permanent, high-density connection.

Key Characteristics at a Glance:

| Feature | LGA (Land Grid Array) | BGA (Ball Grid Array) |

|---|---|---|

| Connection Methodβ | Socket with spring pins | Solder balls, direct attach |

| Permanenceβ | Removable / Socketable | Permanent / Soldered |

| Primary Advantageβ | Upgradability, easier CPU replacement | Higher I/O density, better electrical performance |

| Typical Use Caseβ | Desktop CPUs, upgradable modules | Smartphones, GPUs, high-performance ASICs |

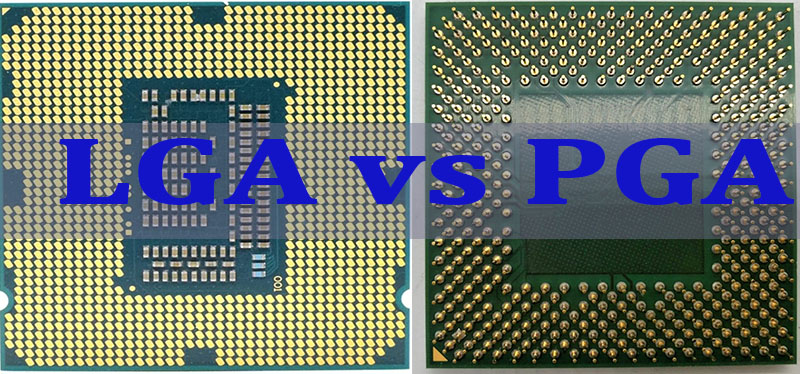

Why Is LGA Better Than PGA?

Before the dominance of LGA vs BGA, Pin Grid Array (PGA)β was common, especially for CPUs. In the PGA vs LGAβ comparison, LGA offers decisive advantages that made it the successor for modern desktop processors:

- Reduced Risk of Pin Damage:β PGA packages have fragile pins on the chip that can easily bend during handling or installation. LGA moves these pins to the socket, which is cheaper to replace if damaged.

- Higher Pin Density:β Flat pads (lands) on an LGA package can be placed closer together than round pins, allowing for more connections in the same area.

- Better Electrical Performance:β Shorter electrical paths and lower inductance in the socket design can support higher-frequency signals.

- Improved Thermal Interface:β The flat surface of an LGA package allows for more uniform and efficient contact with a heatsink or cold plate.

- Simplified Socket Design:β Modern LGA socketsβ (like LGA 1700β or LGA 1851) provide a secure, zero-insertion-force (ZIF) mechanism that is reliable for end-users.

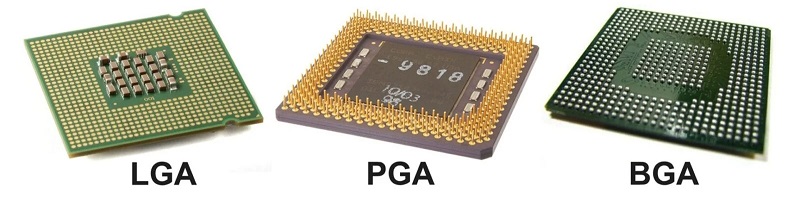

What Distinguishes BGA vs LGA vs PGA From a Structural and Electrical Standpoint?

The bga vs lga vs pgaβ comparison hinges on their structural approach to connecting the die to the world. Hereβs a breakdown from both perspectives:

Structural & Mechanical Standpoint:

- PGA:β Pins on package, holes in PCB. Prone to pin bending. Good mechanical retention before soldering.

- LGA:β Flat pads on package, spring pins in socket. Robust package, delicate socket pins. Allows for separable connections.

- BGA:β Solder balls on package, pads on PCB. Excellent mechanical coupling aftersoldering. Permanent connection.

Electrical & Performance Standpoint:

- PGA:β Longer pin lengths can increase inductance, potentially limiting very high-speed performance.

- LGA:β Shorter connection path in the socket than PGA, enabling better high-frequency response (e.g., for CPUβ power delivery).

- BGA:β Shortest possible electrical path from die to PCB, minimizing inductance and resistance. This is superior for high-speed signals like DDR memory or SerDes interfaces, making it the choice for most advanced BGA vs LGA CPUβ designs in mobile and high-performance computing.

How Do Engineers Evaluate a Full LGA vs BGA Comparison for Long-Term Device Performance?

A thorough LGA vs BGA comparisonβ for long-term performance extends beyond initial assembly. Key evaluation criteria include:

- Thermal Cycling Reliability:β BGA solder joints are susceptible to fatigue from CTE (Coefficient of Thermal Expansion) mismatch. LGA socketβ connections avoid this but introduce another interface. Evaluation involves accelerated life testing.

- Mechanical Shock & Vibration:β BGA packages, once soldered, generally form a very robust mechanical bond. LGAβ connections rely on the socket’s retention mechanism, which must be designed to withstand shock.

- Electrical Contact Degradation:β Over time and repeated cycles, the contact points in an LGA socketβ can oxidize or wear, potentially increasing contact resistance. BGA connections, being soldered, do not have this issue.

- Thermal Management:β Both allow for effective heat sinking, but the interface material differs (thermal paste/grease for LGA vs. often thermal interface material or solder for BGA).

- Upgradability & Field Service:β This is the most significant differentiator. LGAβ facilitates repair and upgrade; BGAβ typically requires complete board rework, impacting total cost of ownership over the product’s life.

How Do As-Shipped Height vs Mounted Height Vary for LGA and BGA Packages?

Understanding as-shipped height vs mounted height for lga and bga packagesβ is crucial for mechanical design and clearance planning.

- As-Shipped Height:β This is the package’s physical height as received from the supplier.

- BGA:β Height includes the die, substrate, and the solder balls’β standoff.

Formula:BGA_AsShipped = Substrate Thickness + Mold Cap Height + Ball Height. - LGA:β Height is simpler, typically just the substrate and mold cap.

LGA_AsShipped = Substrate Thickness + Mold Cap Height.

It does not include the socket.

- BGA:β Height includes the die, substrate, and the solder balls’β standoff.

- Mounted Height:β This is the total height from the PCB surface to the top of the package after assembly.

- BGA:β Very close to the as-shipped height, with only a slight reduction as solder balls collapse during reflow.

BGA_Mounted β AsShipped Height. - LGA:β Significantly greater. It is the sum of the LGA packageβ height plusβ the socket height.

LGA_Mounted = Package Height + Socket Height.

This is a critical consideration in space-constrained designs.

- BGA:β Very close to the as-shipped height, with only a slight reduction as solder balls collapse during reflow.

How Does Soldering Technique Differ When Choosing LGA vs BGA Soldering for Production?

The lga vs bga solderingβ process is fundamentally different and dictates assembly workflow.

LGA “Soldering” (Actually Socketing):

- The solder process is for the socket itself, which is typically a through-hole or surface-mount component soldered to the PCB.

- The LGA packageβ is then mechanically placed into the socket and secured with a lever or latch.

- No direct solderingβ occurs between the package and the PCB. This allows for non-destructive removal.

BGA Soldering (Reflow Process):

- Solder Paste Printing:β Paste is applied to PCB pads.

- Component Placement:β The BGA packageβ is accurately placed onto the paste.

- Reflow Soldering:β The entire board passes through a reflow oven. The heat melts the solder paste and the package’s solder balls, forming the permanent joints.

- Inspection:β Requires X-ray inspection to verify solder joint integrity beneath the chip.

How Should Designers Select Between LGA Package vs BGA When Balancing Cost, Density, and Assembly?

Choosing lga package vs bgaβ requires a multi-faceted decision framework focused on scalability:

| Decision Factor | Favors LGA Package | Favors BGA Package |

|---|---|---|

| Upgradability / Serviceabilityβ | High (e.g., desktop CPUs) | Low (e.g., consumer electronics) |

| I/O Density & Electrical Performanceβ | Lower | Higherβ (shorter paths, less inductance) |

| Unit Assembly Cost (Low Volume)β | Lower (simpler board assembly) | Higher (requires precise reflow & X-ray) |

| Unit Assembly Cost (High Volume)β | Higher (cost of socket added) | Lowerβ (direct attachment, no socket cost) |

| Board Real Estateβ | Larger (footprint includes socket) | Smallerβ (package footprint only) |

| Thermal & Mechanical Designβ | Interface with socket | Direct attachment to PCB for heat spreading |

| Risk Managementβ | Easier field replacement | Higher risk of non-repairable board failure |

For scalable assembly needs, if your product requires future upgrades (like a server CPU) or field repair, LGAβ is strategic. If the priority is maximum miniaturization, best electrical performance for high-speed signals, and lowest per-unit cost at high volumes, BGAβ is the clear choice.

Why Choose EBest Circuit (Best Technology) for Dealing With LGA vs BGA Assembly Challenges?

The lga vs bgaβ decision carries implications through the entire product lifecycle. At BEST Technology, we understand that this choice is central to your product’s performance, reliability, and manufacturability. Our expertise is not just in assembling boards but in providing consultative guidance during the design phase to optimize for your specific scalable assembly needs.

We offer:

- Design for Excellence (DFX) Reviews:β We analyze your schematics and layouts to recommend the optimal package type based on electrical, thermal, and mechanical goals.

- High-Precision Assembly Lines:β Equipped for both complex BGA reflow solderingβ with X-ray inspection and precise LGA socketβ population.

- Advanced Testing & Rework:β Overcoming the disadvantages of BGAβ with state-of-the-art diagnostics and rework stations.

- Supply Chain & Scalability Support:β We help you plan for volume production, ensuring component availability and process stability whether you choose LGA or BGA.

Pls feel free to contact our team at sales@bestpcbs.com to start a conversation about your next LGA or BGA assembly project.

FAQs

Is LGA 1851 dead?

- No, LGA 1851 is Intel’s latest desktop CPU socket for its next-generation processors (like the Arrow Lake series). It is a current and active platform, not dead.

Is 7800X3D PGA or LGA?

- The AMD Ryzen 7 7800X3D uses an LGAβ socket. Specifically, it uses the AM5 socket, which is AMD’s shift from PGA (used in AM4) to LGA.

What are the disadvantages of BGA?

The main disadvantages of BGA packagesβ are:

- Permanent soldering prevents upgrades or easy replacement,

- Requires X-ray inspection to verify solder joints,

- Complex and expensive rework process,

- Susceptibility to solder joint fatigue from thermal cycling.

What are the advantages of BGA package?

Key advantages of BGA packageβ include:

- 1) Very high I/O density in a small area,

- 2) Excellent electrical performance for high-speed signals due to short connections,

- 3) Low inductance and good thermal path to the PCB,

- 4) Robust mechanical bond to the board after soldering.

What is the difference between LGA and QFN?

- LGA (Land Grid Array)β and QFN (Quad Flat No-leads)β are both leadless packages, but they differ. An LGA has an array of flat pads across its entire bottom side and is often used for high-pin-count devices like CPUs, frequently with a socket. A QFN has pads only around its perimeter (and sometimes a thermal pad in the center), is typically smaller, and is always soldered directly to the PCB, making it more comparable to a small BGAβ than an LGA socket-based part.