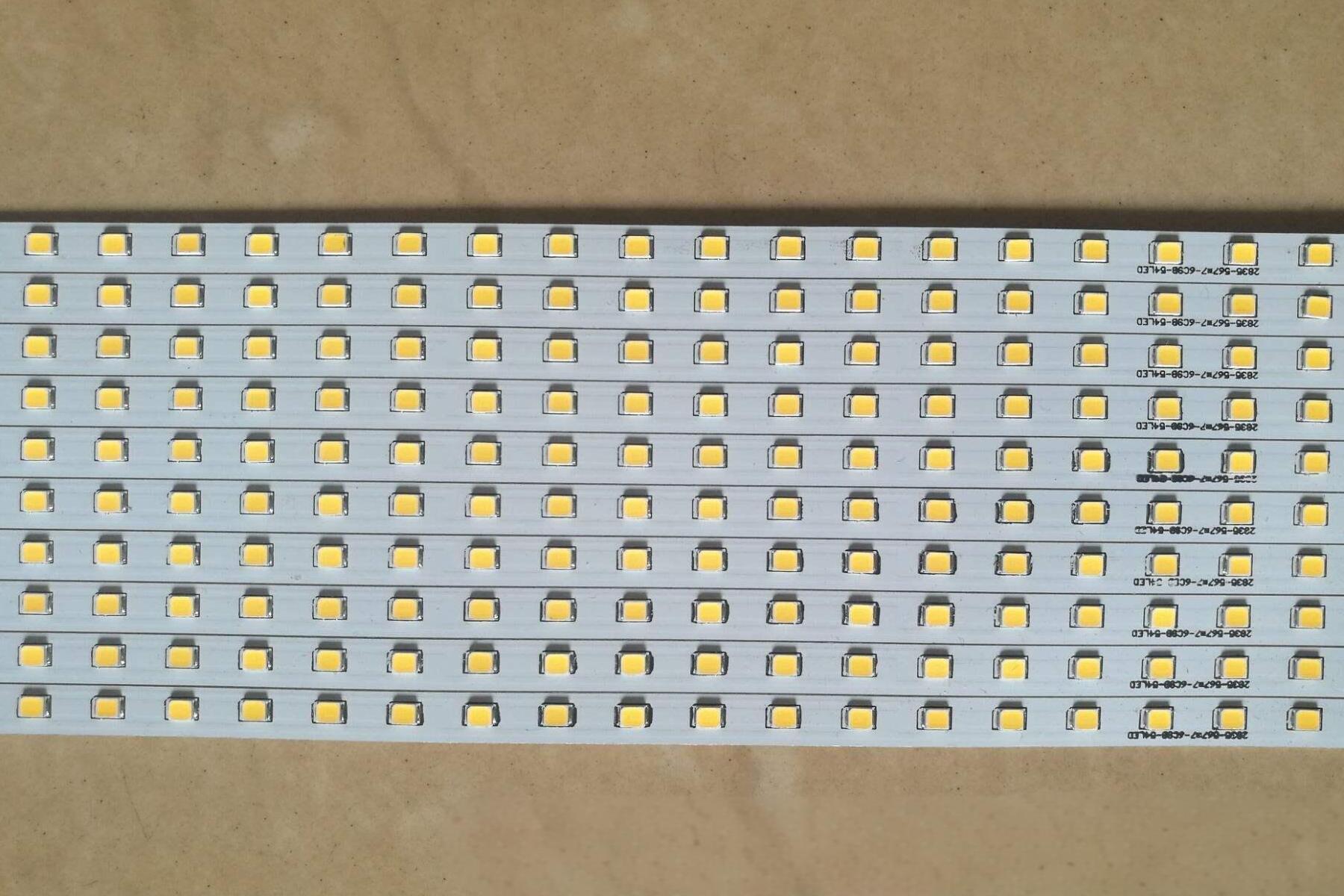

LED bulb MCPCB is a metal-based circuit board designed to support and cool LED chips. It replaces standard PCBs in LED bulbs to handle high heat. Aluminum MCPCB is the most common type used in LED bulbs. It offers excellent heat transfer, improves bulb lifespan, and ensures stable lighting in compact spaces.

What is LED bulb MCPCB?

LED Bulb MCPCB is a specialized type of circuit board designed to handle the unique demands of LED lighting. Unlike regular PCBs, it features a metal baseâusually aluminiumâthat helps manage the intense heat LEDs generate.

In a compact bulb where space is limited, heat can build up quickly. The MCPCB works as a silent protector. It absorbs and transfers heat away from the LEDs, keeping the bulb cool, safe, and long-lasting.

The LED bulb MCPCB doesnât just manage heatâit stabilizes performance. Without it, your bulb might flicker, burn out fast, or even overheat.

Why choose Aluminium MCPCB board for LED bulb?

Aluminium MCPCB boards are the go-to choice for LED bulbs. Why? Because aluminium delivers superior thermal conductivity, low cost, and lightweight properties. It keeps the LED components safe, efficient, and cool under pressure.

When you use an aluminium MCPCB board for LED bulb, youâre choosing durability without sacrificing design. Aluminium is also recyclable, which makes it a greener option for sustainable lighting. Plus, it resists wear and corrosion, helping your bulb last longer, even in tough environments like factories or outdoors.

This material is also easier to shape and fit into bulb housings. That makes the manufacturing process smoother and faster, which leads to better quality and more affordable LED lighting for everyone.

How is LED bulb MCPCB different from regular PCBs?

Most traditional PCBs use FR4, a fiberglass-based material that canât handle high heat well. Regular PCBs might work in low-temperature electronics, but LED bulbs are a different story.

LEDs emit heat as they shine. If you use a regular PCB, the heat stays trapped, slowly damaging the LEDs. Over time, this leads to reduced brightness, shorter lifespan, and possible safety issues.

On the other hand, LED bulb MCPCBs, especially those made with aluminium, are heat masters. They move the heat away from sensitive components, improving efficiency and making your bulb last longer.

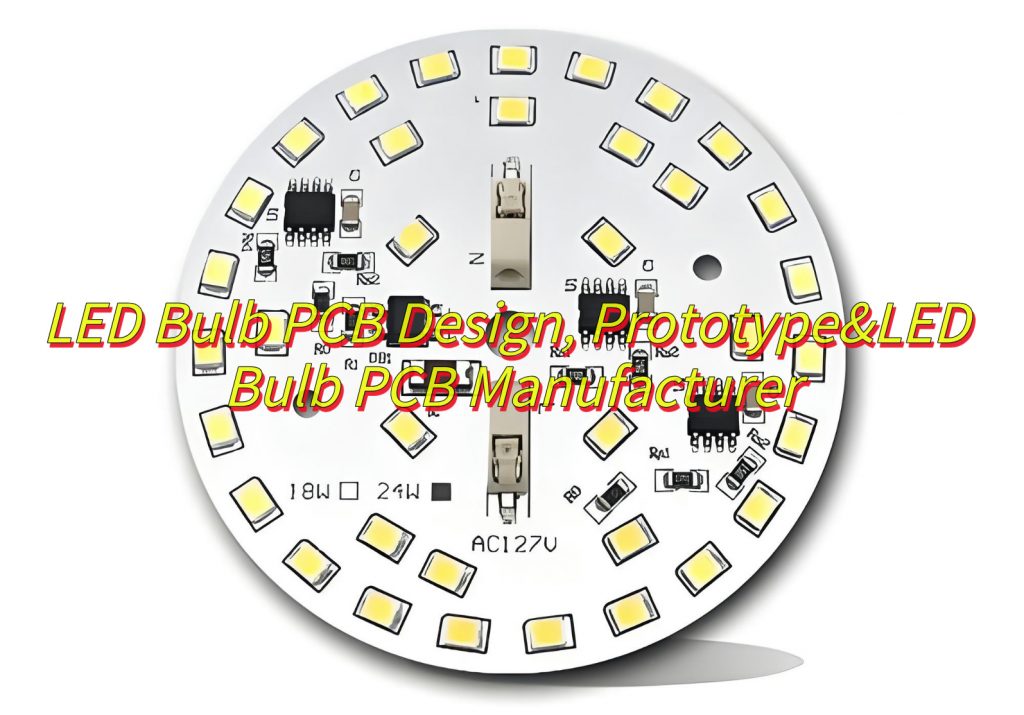

What is AC DC LED bulb MCPCB?

It refers to a special MCPCB used in bulbs that can operate with both alternating current (AC) and direct current (DC). These boards are equipped with additional circuitry to manage voltage conversion and stabilize current flow.

It can be used in various settingsâhomes, offices, emergency lighting, solar lighting.

An AC DC LED bulb MCPCB is ideal for markets where power sources vary. It keeps performance consistent, reduces the chance of failure, and expands the bulbâs usability.

How does LED bulb driver circuit work?

The LED bulb driver circuit is usually integrated into the MCPCB itself or connected to it. It converts high-voltage AC power into a lower-voltage DC current that LEDs need. It also stabilizes voltage fluctuations, protecting sensitive components.

Driver circuit controls the electrical input to the LEDs. It ensures the current stays steady and within safe limits. These circuits help cut down on energy waste, reduce heat, and extend the life of your bulb.

What is LED bulb MCPCB used for?

LED bulb MCPCBs are used in light bulbs. But thereâs more to it.

Theyâre essential in any LED lighting that demands compact size, heat management, and long-term reliability. This includes:

- Residential LED bulbs

- Commercial ceiling lights

- Emergency lighting

- Solar-powered lamps

- Automotive LED lights

- Industrial high-bay lights

These boards can be customized in shape, layer count, and thickness to match specific lighting needs. From a tiny reading lamp to a streetlight, MCPCBs play a central role.

Can 15 watt LED bulb MCPCB handle heat well?

15 watt LED bulb MCPCB is typically made with thicker aluminium and better thermal vias. These help spread heat across a larger surface and transfer it efficiently to the bulbâs housing.

With smart layout and quality soldering, it can easily handle the thermal load. The key lies in choosing the right materials and thickness. At EBest Circuit (Best Technology), for example, we design each LED bulb MCPCB to match the wattageâs thermal needs, so it performs without breaking a sweat.

Is 50 watt LED bulb MCPCB durable enough?

50 watt LED bulb MCPCB usually include larger heat sinks and thicker copper layers to carry higher currents. It powers high-brightness lighting and must handle serious heat. They also feature stronger insulation layers to prevent breakdown over time.

Used in high-power LED floodlights, industrial lamps, or streetlights, 50 watt LED bulb MCPCBs are built for endurance. Their design ensures thermal resistance, electrical stability, and rugged durability.

What is the difference between MCPCBs for LED bulbs of different watt?

As the wattage goes up, the complexity and strength of the board must increase. Hereâs how they differ:

- 9W LED bulb MCPCB: Thin, compact, ideal for home lighting.

- 12W LED bulb MCPCB: Slightly thicker, handles more heat, often used in ceiling lights.

- 15W LED bulb MCPCB: Needs improved heat sinking, used in brighter spaces.

- 18W LED bulb MCPCB: Stronger thermal design, may require larger base.

- 50W LED bulb MCPCB: Built like a tank. Thicker copper, extra thermal vias, more robust structure.

Also, pricing varies. A 9W LED bulb MCPCB price is lower. A 50 watt LED bulb MCPCB will cost more due to the materials and design complexity.

Conclusion:

LED bulb MCPCB combines heat dissipation, power and performance in one compact circuit board. Choosing an aluminum MCPCB board for LED bulb gives you better thermal control, longer life, and safer operation.

Want custom or bulk LED bulb MCPCBs tailored to your project? Reach out to sales@bestpcbs.com