The LED automotive lighting aluminum base PCB stands at the forefront of modern vehicle lighting technology. This specialized printed circuit board offers superior performance, durability, and heat managementâmajor factors that automotive manufacturers demand today. In this article, weâll break down its working principle, explore its design benefits, and reveal how EBest Circuit (Best Technology) addresses industry challenges with precision-engineered solutions.

EBest Circuit (Best Technology) is a dependable automotive LED PCB factory in a truly competitive market, providing better precision LED automotive lighting aluminum base PCB solutions for over 19 years. With the practical experience gained, we gain the competitive edge of providing DFM analysis, material procurement, MCPCB prototype, fabrication, and SMT LED PCB assembly solutions. Our sales engineers and technical engineers always stay open to collaborating closely with clients and delivering customized, high-performance lighting aluminum base PCB solutions tailored to automotive challenges. Any questions or need to visit our LED PCB production and assembly factory, pls let us know at sales@bestpcbs.com.

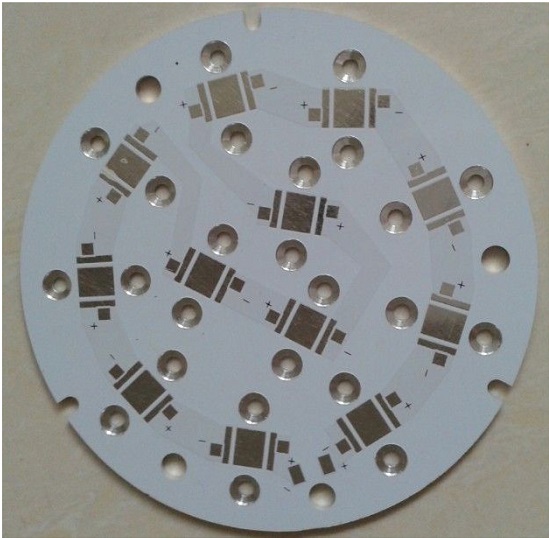

What is an LED Automotive Lighting Aluminum Base PCB?

An LED Automotive Lighting Aluminum Base PCB is a specialized high-performance circuit board tailored for vehicle LED lighting and automotive electronics. Key details include:

- Three-layer structure:

- Circuit layer (where the electrical paths reside)

- Insulation layer (provides electrical isolation while allowing heat transfer)

- Metal base layer (typically aluminum, acting as a heat spreader)

This differs from traditional double-sided PCBs and enhances durability and heat dissipation.

- Thermal management performance:

- Aluminum base boasts a thermal conductivity between 180 to 200 W/(m·K), which is roughly 900 times higher than that of standard FR-4 boards.

- This enables rapid heat dispersion, protecting LED chips from overheating and extending service life.

- Broad application scope:

- Beyond LED automotive lighting (headlights, brake lights, turn signals, interior lights), it is widely used in other automotive electronic systems such as regulators, ignition modules, and control units.

- Robust mechanical performance:

- The aluminum core provides excellent vibration resistance and structural stability, crucial for the harsh automotive environment.

What is the Working Principle of LED Automotive Lighting Aluminum Base PCB?

The working principle centers on two main functions: electrical conduction and thermal management. Key points include:

- Efficient electrical path:

The PCBâs circuit traces deliver stable and precise power to LED chips, ensuring consistent light output and optimal energy use. - Heat generation:

LEDs produce heat as a byproduct when emitting light. Excess heat can reduce LED efficiency and shorten lifespan if not properly controlled. - Aluminum base as a heat sink:

The aluminum layer absorbs heat from the LEDs quickly and spreads it across a larger surface area. - Thermal resistance reduction:

This rapid heat dispersion lowers thermal resistance, preventing hotspots that can cause component failure. - Improved LED durability:

By managing heat effectively, the PCB helps extend the operating life of LEDs, maintaining brightness and reliability over time.

What are the Functions of the Automotive LED PCB?

The automotive LED PCB performs several essential functions that go beyond basic electrical connectivity:

- Physical and electrical support:

Provides a stable platform for LED components, ensuring reliable operation despite harsh vibrations and road conditions. - Thermal management:

Effectively dissipates heat to prevent premature LED failure caused by overheating. - Enhances vehicle safety:

Guarantees consistent lighting performance, delivering clear illumination and signaling for safer driving. - Supports LED automation:

Integrates with vehicle control systems to enable adaptive lighting features, such as adjusting brightness and beam direction based on driving scenarios.

Key Design Tips for Reliable LED Automation in Automotive Lighting PCB

Designing a reliable LED Automotive Lighting Aluminum Base PCB requires careful attention to several factors.

- First, the choice of aluminum thickness affects heat dissipation capacity; thicker cores usually perform better but add weight.

- Next, optimizing the circuit layout minimizes resistance and enhances power delivery. It’s essential to select high-quality dielectric layers to maintain insulation between metal and circuitry without compromising thermal transfer. Designers must also consider vibration resistance and moisture protection, as automotive environments are demanding.

- Lastly, planning for LED automation means integrating control circuits that manage light intensity, color temperature, and response time.

How Aluminum LED Base Plates Improve Heat Dissipation in Vehicles?

Aluminum LED base plates stand out in automotive lighting because of their exceptional ability to manage heat. The metal base acts as a thermal highway, moving heat away from the LED chips quickly and evenly. This thermal conduction reduces hotspots, which are common failure points in LED arrays. Additionally, the aluminum base improves mechanical strength, helping the PCB endure thermal cycling without cracking. For vehicles, where components face constant temperature fluctuations and vibration, this feature extends product lifespan and reliability, ensuring safety and consistent performance.

How to Choose an Aluminum PCB LED for a Car?

Selecting the right aluminum PCB LED involves balancing performance, cost, and durability.

- First, verify the thermal conductivity rating of the aluminum core; higher conductivity means better heat management.

- Next, check the dielectric material’s thermal resistance to confirm efficient heat transfer between circuitry and the base. Itâs crucial to assess the PCBâs thickness and layer count based on the lighting systemâs power requirements. Also, consider certifications and compliance with automotive standards to guarantee safety and longevity.

- Finally, review the manufacturerâs quality control process and after-sales support, as these greatly impact the final product reliability.

What are the Pros of the EBest Circuit (Best Technology) in Automotive LED PCB Manufacturing?

EBest Circuit (Best Technology) sets itself apart by effectively solving key customer challenges. Its advantages include:

- Delivers robust, high-precision PCBs that withstand harsh automotive conditions while maintaining vehicle safety and lighting efficiency.

- Strict quality control aligned with ISO9001 and IATF16949 certifications ensures every aluminum LED base plate meets top automotive standards.

- Close collaboration with clients to optimize designs for superior heat dissipation and seamless integration with LED automation systems.

- Offering shorter lead times, helping manufacturers avoid production delays without compromising product performance.

- Presenting EMS LED PCB manufacturing since 2006, including prototype, fabrication, MCPCB assembly, and box build services.

In summary, the LED Automotive Lighting Aluminum Base PCB is more than just a circuit boardâitâs a vital element ensuring sustained superior performance and safety in modern vehicle lighting. Its unique aluminum core design tackles heat dissipation challenges head-on, supporting powerful LED systems in harsh environments. From its working principle to design strategies and material selection, this PCB type meets the exacting demands of automotive applications. Partnering with a trusted manufacturer like EBest Circuit (Best Technology), who understands these demands and addresses customer challenges early with proven solutions, can make all the difference. For any automotive LED PCB project quote requests, pls send us an email at sales@bestpcbs.com to get our direct support.