As global electronics manufacturing moves away from hazardous substances, lead free solder material has become the industry standard for PCB assembly. Driven by regulations such as RoHS and REACH, lead-free solder is now used in consumer electronics, automotive PCBs, industrial control boards, and medical devices.

However, not all lead-free solder materials are the same. Their composition, melting temperature, mechanical strength, and reliability vary significantlyâmaking material selection critical for high-quality PCB assembly.

This guide explains what lead-free solder is, its composition, properties, types, melting temperatures, common soldering issues, and finally answers the key question: âWhich lead free solder material is best for PCB assembly?â

What Is Lead Free Solder Material?

Lead free solder material is a metallic alloy used to join components to a PCB without the use of lead. Traditional solder contained 40% lead (Sn60/Pb40) or 37% lead (Sn63/Pb37). These alloys were easy to use but posed environmental and health concerns. Today, electronics manufacturers worldwide use lead-free formulations based on tin, silver, copper, bismuth, nickel, or small alloying elements.

From a customerâs perspective, lead free solder material is important because it directly affects:

- Solder joint strength

- Heat tolerance

- Long-term reliability

- Appearance of solder joints

- Compatibility with high-density SMT packages

- Product compliance with RoHS, REACH, and WEEE regulations

Lead-free solder also withstands higher temperatures, which is critical for modern high-density PCBs.

Is Lead-Free Solder Still Toxic?

Lead-free solder eliminates leadâa major toxic substanceâbut that does not mean every alloy is completely risk-free. For normal PCB manufacturing environments, lead-free solder is considered safe and non-toxic when handled properly.

From a customer standpoint:

- Lead-free solder is significantly safer than leaded solder

- It does not release toxic lead fumes during reflow

- Flux fumesânot the solderâare usually the irritation source

- Lead-free waste requires less strict disposal procedures

Most concerns come from misunderstanding. Lead-free alloys like SAC305 (Sn96.5 Ag3.0 Cu0.5) are not harmful under standard handling and reflow conditions. With adequate ventilation and proper gloves, operators face minimal exposure risks.

Lead Free Solder Material Composition

Lead-free solder material compositions vary depending on cost targets, performance needs, and thermal sensitivity of the PCB. Below is a customer-friendly comparison of common alloys:

Common lead-free soldering compositions

| Alloy Type | Composition | Characteristics | Best Use |

| SAC305 | Sn96.5 / Ag3.0 / Cu0.5 | Most popular global alloy; balanced cost and performance | SMT reflow, general assembly |

| SAC405 | Sn95.5 / Ag4.0 / Cu0.5 | Higher silver for stronger joints and better wetting | Automotive, medical, mission-critical devices |

| SAC0307 | Sn99 / Ag0.3 / Cu0.7 | Cost-effective low-silver alternative | Consumer electronics, cost-controlled projects |

| Sn99.3Cu0.7 | Tin/copper mix | Slightly higher melting point; durable in wave soldering | Wave solder baths |

| Sn-Bi alloys | Tin + Bismuth blends | Low melting point; ideal for heat-sensitive substrates | LED boards, flex circuits, thin PCBs |

| Sn-Ag alloys | Tin + Silver | Good wetting and moderate melting range | Fine-pitch soldering |

| Ni-doped SAC | SAC + Ni | Improved grain refinement | Automotive, aerospace |

For most consumer and industrial applications, SAC305 is the ideal balance of performance and cost. Customers requiring high-temperature reliability (automotive, aerospace, telecom) may consider doped SAC alloys.

Lead Free Solder Material Properties

Lead-free solder is a low-lead soldering material based mainly on tin-based alloys such as Sn-Ag-Cu, Sn-Cu, and Sn-Bi. It is designed to replace traditional Sn-Pb solder and meet environmental regulations such as RoHS while reducing heavy-metal pollution. Itâs properties can be explained from different aspects:

1. Physical & Process Characteristics

- Melting Range: Wide, typically 138°Câ250°C depending on alloy. SAC305 melts around 217°C. Most alloys have a narrow solidâliquid range for stable soldering.

- Wetting: Good wetting behavior during reflow (30â90 seconds above liquidus) and wave soldering (â4 seconds contact), forming reliable joints.

- Conductivity: Electrical conductivity around â¥9.5Ã10ⶠS/m and thermal conductivity near 66 W/m·K, similar to Sn-Pb alloys.

- Oxidation & Flow: Strong anti-oxidation and smooth flow with low dross generation, reducing defects such as bridging and solder spikes.

2. Mechanical Performance

- Strength & Fatigue: Mechanical strength and fatigue life can be optimized through alloy design. Sn-Ag-Cu systems (e.g., 95.4Sn/3.1Ag/1.5Cu) offer strength comparable to or better than Sn-Pb.

- Brittleness: Higher Ag or Cu content may reduce ductility, so alloy balance is important.

- Reliability: Lead-free joints maintain stability under vibration and thermal cycling, suitable for harsh applications like automotive electronics.

3. Environmental & Cost Characteristics

- Compliance: Lead content is typically below 1000 ppm, fully RoHS-compliant and safer for workers and the environment.

- Cost: Generally 2â3Ã higher than traditional solder due to tin and silver pricing, but the impact on total product cost is usually limited.

4. Application & Compatibility

Lead-free solder is widely used in consumer electronics, automotive systems, medical devices, and new-energy applications. It works with standard fluxes and existing equipment such as 8-zone reflow ovens, though reflow profiles and process parameters may require adjustment to accommodate higher melting temperatures.

Types of Lead Free Soldering Method

Lead-free soldering involves several manufacturing methods designed around different processes, temperature profiles, and assembly requirements. When customers review PCB assembly quotes, the type of soldering used has a major impact on product durability, electrical integrity, and cost. Below are the core types of lead free soldering used in modern electronics production.

1. Lead-Free Reflow Soldering (SMT Reflow)

This is the most common method for mounting surface-mount components (SMDs). Manufacturers print lead-free solder paste onto pads, place components via pick-and-place machines, and heat the PCB in a controlled reflow oven. Reflow soldering has many advantages:

- Suitable for nearly all SMT components

- Works with SAC305, SAC405, SAC0307, and Sn-Bi pastes

- Ensures consistent joint quality in mass production

- Supports fine-pitch ICs, BGA, QFN, 0201/01005 components

Typical reflow peak temperature

- 235â250°C, depending on the alloy and PCB materials

Reflow soldering is the backbone of every modern SMT line and the main reason SAC305 is widely used.

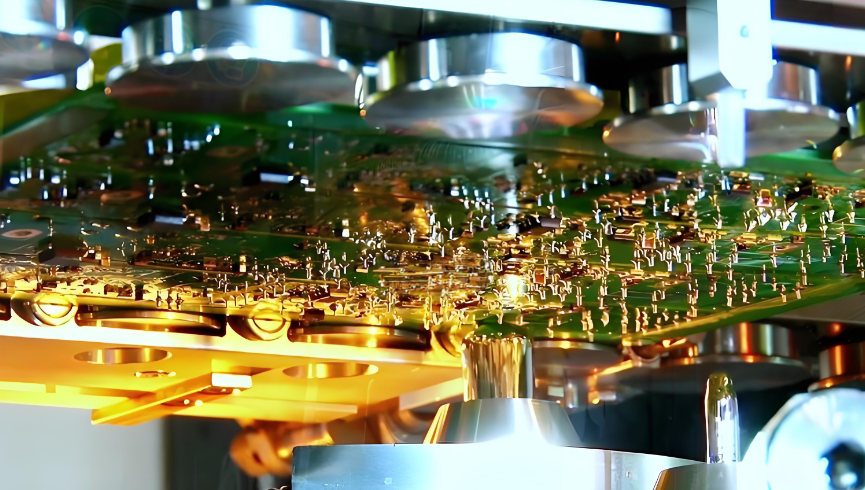

2. Lead-Free Wave Soldering

Wave soldering is used primarily for through-hole components and mixed-technology assemblies.

During lead-free wave soldering, the PCB passes over a molten solder âwaveâ typically made of Sn99.3Cu0.7 or other tin-rich alloys.

Why customers care:

- Ideal for high-volume assemblies with many through-hole connectors

- Faster than hand soldering

- Strong, uniform joints across large PCBs

- But requires strict temperature control due to higher melting points

Common lead-free wave solder alloy

- Sn99.3/Cu0.7, with optional micro-alloying (Ni, Ge) to reduce copper dissolution

Typical pot temperature

- 255â265°C, depending on alloy

3. Lead-Free Selective Soldering

Selective soldering is used when only certain through-hole components must be soldered without exposing the entire PCB to a wave. A programmable nozzle creates localized molten solder âmini waves.â

Why customers care:

- Protects heat-sensitive components

- Reduces overall thermal stress

- Useful for complex PCBs with dense SMT areas

- Generates precise and stable joints

Common alloys

- Sn99.3Cu0.7

- SAC variants for specialized cases

Selective soldering is popular in industrial controllers, automotive electronics, and telecom boards.

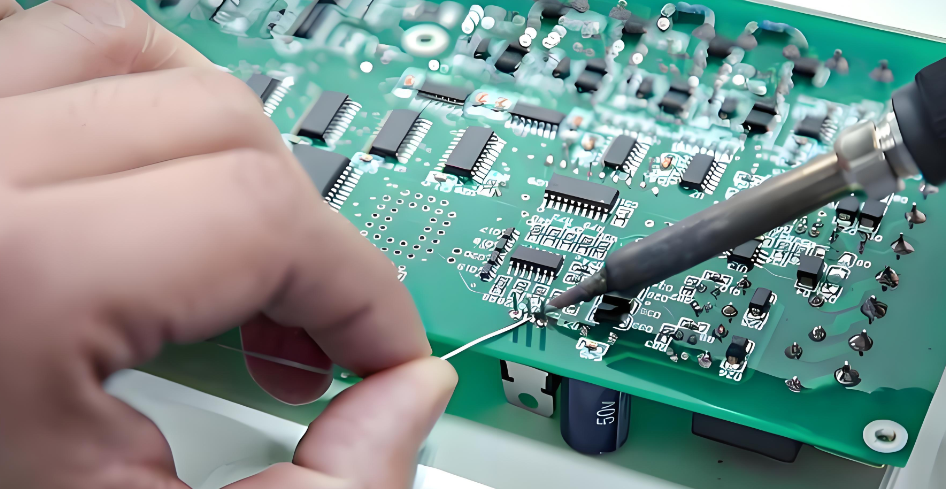

4. Lead-Free Hand Soldering

Used for repair, prototyping, or small-batch assembly. Technicians use solder wire (typically SAC305 or SAC0307) and temperature-controlled irons.

Why customers care:

- Required for last-minute rework

- Used in prototype and engineering samples

- Easy way to repair or modify boards

- Quality depends heavily on operator skill and iron temperature

Hand soldering temperature

- 350â380°C for SAC alloys

- 280â310°C for Sn-Bi low-temp solder

Here is a quick comparison between these lead-free solder material methods:

| Soldering Type | Main Features | Typical Alloys | Customer Use Case |

| Reflow Soldering | Standard SMT process | SAC305, SAC0307 | Consumer & industrial electronics |

| Wave Soldering | High-volume through-hole | Sn99.3Cu0.7 | Power boards, large PCBs |

| Selective Soldering | Localized soldering | Sn-Cu, SAC | Mixed-technology PCBs |

| Hand Soldering | Rework / prototyping | SAC305 wire | Engineering builds, repairs |

Does 60/40 Solder Contain Lead?

Yes, 60/40 solder (Sn60/Pb40) contains 40% lead, so it is not RoHS compliant and must not be used in modern commercial electronics.

Lead-free solder materials replace this alloy entirely in global manufacturing unless exemptions apply (e.g., military or aerospace exceptions).

Lead-Free Solder Melting Temperature Chart

Below is a melting temperature chart customers can use as a reference during material selection or reflow profile planning:

| Lead-Free Alloy | Melting Temperature (°C) | Notes |

| SAC305 | 217â220°C | Most common for SMT |

| SAC405 | 217â225°C | Higher Ag content improves strength |

| SAC0307 | ~227°C | Budget option; slightly higher melting point |

| Sn99.3Cu0.7 | 227°C | Ideal for wave soldering |

| Sn-Bi | 138â170°C | Best for low-temp applications |

| Sn63/Pb37 (leaded) | 183°C | For comparison only |

Customers should always verify that their components can tolerate the peak reflow temperature required by the alloy.

What Are the Main Issues With Lead-Free Soldering?

Lead-free soldering is reliable, but it requires proper process control. Common challenges include:

- Higher melting point that stresses components

- Slower wetting that demands optimized flux

- Sometimes duller appearance of joints

- Increased copper dissolution in wave soldering

- Sensitivity to reflow temperature deviations

Why Is My Lead-Free Solder Not Melting?

Typical causes include:

- Iron or reflow temperature not high enough.

- Insufficient heat transfer due to oxidation or contamination.

- Using a low-power soldering iron unable to maintain temperature.

- Weak flux activity preventing proper heat flow.

- Applying the solder to a large thermal pad without preheating.

Lead-free solder requires around 30â40°C higher heat than leaded solder.

Which Lead Free Solder Material Is Best for PCB Assembly?

For most customers, SAC305 (Sn96.5/Ag3.0/Cu0.5) is the best lead-free solder material for PCB assembly.

Why SAC305 Is Ideal for Most Applications?

- Widely used across global SMT factories

- Excellent wetting on FR4, HDI, flexible, and ceramic substrates

- Strong mechanical performance

- Good thermal cycling reliability

- Low voiding rate with proper reflow control

- Compatible with nearly all flux chemistries

- Proven in millions of consumer and industrial electronics

When Other Alloys Might Be Better?

- SAC0307 â When cost is the priority

- Sn-Bi â For low-temperature PCBs and LED products

- SAC405 â For high-reliability automotive or medical electronics

- Sn99.3Cu0.7 â For wave soldering to reduce cost

Customer Recommendation

If you are unsure which alloy to choose, start with SAC305 for standard SMT reflow because it aligns with:

- Reliability expectations

- Cost targets

- Compatibility with modern assembly lines

- Strong field performance

FAQs

1. What is the most common lead-free solder in SMT assembly?

SAC305 is the industry standard for most SMT production lines.

2. Is lead-free solder as strong as leaded solder?

Yes. Lead-free joints are typically stronger in mechanical strength and thermal fatigue resistance.

3. Why is lead-free solder harder to work with manually?

It melts at a higher temperature and wets more slowly, requiring better temperature control.

4. What flux should be used with lead-free solder?

Most solder pastes use no-clean or water-soluble fluxes optimized for SAC alloys.

5. Can lead-free solder be used with ENIG finish?

Yes, ENIG is one of the best surface finishes for consistent wetting.