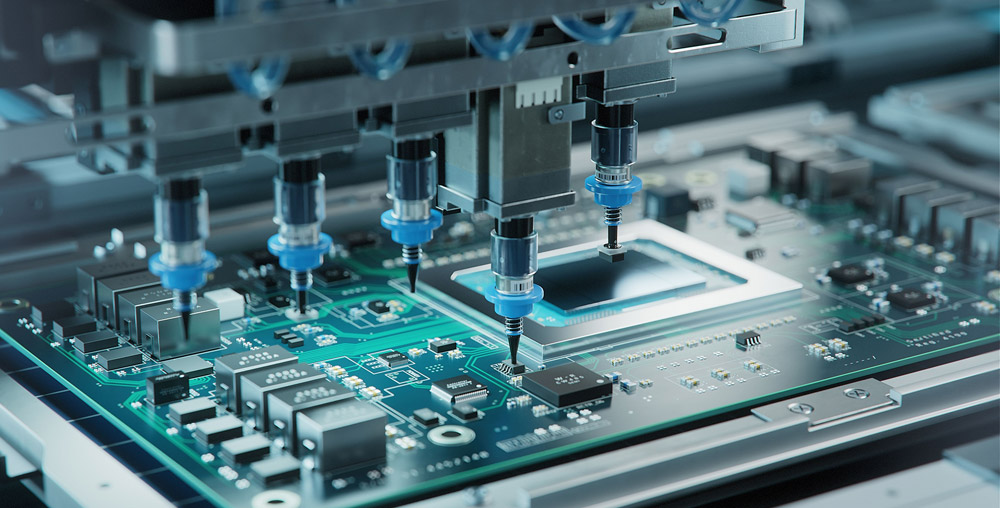

Latvia’s PCB manufacturing sector boasts reliable production capabilities and strict quality control, making PCB Latvia manufacturer a trusted choice for regional electronic projects. With a manufacturing capacity utilization rate of 75.1% in late 2025, the industry balances precision and efficiency to meet diverse project needs. Whether for prototyping or mass production, PCB Latvia manufacturer integrates advanced technologies and European standards, solidifying its position in the Baltic electronic supply chain. This guide covers top suppliers, quality benchmarks, pain points, and selection strategies to support informed decisions for Latvia PCB projects.

Top 10 PCB Manufacturer in Latvia

| Company Name | Main Business | Core Advantages | Process Capability | Lead Time |

| EBest Circuit Co., Limited | Metal core PCB design/fabrication | 18-year experience, ISO certified, 30,000„é° factory | Single/multi-layer MCPCB, 0.4-1.6mm thickness | Prototype 4-7d; Mass 10-12d |

| ELT EHS SIA | GNSS module PCB fabrication | Riga-based hub, geopositioning expertise, CE/RoHS | Rigid PCB, SMT assembly, 0.8-2.0mm thickness | Prototype 7-10d; Mass 14-21d |

| Rotolab SIA | PCB prototyping & laser marking | Rapid turnarounds, JTAG testing, local sourcing | Custom prototype, YAG laser marking, 2-4 layer PCB | 24-72h prototype; 5-7d small batch |

| VEF Radiotehnika RRR SIA | SMT PCB manufacturing | Latvian heritage, mature SMT, EU compliant | Through-hole assembly, 2-6 layer RoHS PCB | Mass 10-15d; Custom 15-20d |

| Elko Group SIA | Industrial PCB integration | One-stop service, ISO 9001, Riga campus | Rigid/flexible PCB, cable harness, small batch | Assembly 7-12d; Turnkey 12-18d |

| Elektronikas Serviss SIA | Automotive rigid PCB | Aluminum/copper substrate, RoHS/REACH | Precision drilling, 2-8 layer industrial PCB | Prototype 6-8d; Mass 12-16d |

| PCB Baltic SIA | Custom PCB assembly | Flexible volume, global supply chain | Hybrid PCB, 2-6 layer custom material | Custom 8-14d; Bulk 14-22d |

| Tech Print SIA | LED PCB fabrication | Thermal optimization, CE marked | MCPCB for LED, 2-4 layer thermal enhancement | LED PCB 5-10d; Assembly 7-12d |

| Nordic Electronics SIA | High-frequency PCB | Networking expertise, ISO 13485 certified | Wireless module integration, 4-8 layer PCB | Prototype 8-10d; Mass 15-20d |

| Fopi Electronics SIA | Industrial PCB testing | Non-destructive testing, local after-sales | Environmental resistance, 2-6 layer rigid PCB | Industrial 10-16d; Test-included 16-20d |

Quality Certifications for PCB Latvia Manufacturer

- ISO 9001:2015: A baseline mandatory certification for Latvia PCB company operations. It establishes a standardized quality management system, covering production processes, raw material inspection, and after-sales service to ensure consistent product quality.‚Äč

- RoHS Certification: An EU mandatory environmental certification for electronic products. It restricts the use of 10 hazardous substances (e.g., lead, mercury) in Latvia PCB manufacturing, with lead content limited to ‚ȧ0.1% to comply with EU environmental directives.‚Äč

- REACH Certification: Another EU mandatory environmental certification. It regulates the registration, evaluation, authorization, and restriction of chemicals used in Latvia PCB plant production, ensuring no harmful substances pose risks to human health and the environment.‚Äč

- CE Certification: A mandatory safety certification for products entering the EU market. All PCB Latvia products must obtain CE marking, proving compliance with EU technical directives including EMC and safety requirements.‚Äč

- ISO 13485: Mandatory for Latvia PCB manufacturer serving the medical industry. It specifies quality management system requirements for medical device-related PCBs, ensuring compliance with medical industry safety and effectiveness standards.‚Äč

- IATF 16949: Essential for Latvia PCB factory supplying the automotive sector. This certification aligns with global automotive industry quality standards, covering production control, traceability, and defect prevention for automotive-grade PCBs.‚Äč

- IPC-A-610: A mandatory assembly quality standard. It defines acceptability criteria for Latvia PCB assembly processes, ensuring soldering, component mounting, and wiring meet industry-wide quality benchmarks.

Pain Points of PCB Latvia Manufacturer

- ‚ÄčHigh material costs due to reliance on imported high-grade substrates, increasing per-unit production expenses for small-batch orders.‚Äč

- Limited local supply chain for specialty components, leading to delays when sourcing custom materials or obsolete parts.‚Äč

- Capacity constraints with average utilization at 75.1%, making it challenging to handle sudden surge in large-volume orders.‚Äč

- Strict EU environmental regulations raising production costs for waste treatment and sustainable material adoption.‚Äč

- Technical gaps in high-layer HDI PCB fabrication, limiting ability to cater to advanced electronic project requirements.‚Äč

- Inconsistent lead times caused by cross-border logistics delays for raw materials and component shipments.

How to Choose a Reliable PCB Latvia Manufacturer?

Selection Guide to PCB Latvia Manufacturer:

1. Certification & Compliance Standards: Prioritize ISO 9001, UL, or IEC 61190-certified suppliers (e.g., ALMIKO Ltd, VOLBURG Ltd) to ensure quality control and regulatory adherence. Verify certifications via official directories.

2. Technical Capabilities & Specialization: Assess capabilities for multi-layer PCBs (up to 24+ layers), HDI (High Density Interconnect), impedance control, and materials (e.g., FR4, Rogers). ALMIKO Ltd, for example, supports Gerber/Excellon file formats and offers stencil production. Avoid suppliers lacking advanced tech documentation (e.g., layer stack-up details).

3. Turnaround Time & Logistics: Evaluate lead times, ALMIKO provides 3‚Äď15 working days (negotiable), with logistics via DHL/FedEx. European-based suppliers (e.g., Riga-based) reduce dependency on cross-border delays. Confirm DDP/DDU terms for cost transparency.

4. Cost Structure & Transparency: Analyze pricing models, setup fees, per-unit costs, and hidden charges (e.g., tooling, testing). IBISWorld reports the 2026 Latvian PCB market size at ‚ā¨78.6M, with 30 companies, compare quotes across 3+ suppliers to identify competitive rates.

5. Customer Support & Communication: Prioritize suppliers with 24/7 technical support (e.g., ALMIKO’s 25-year experience) and multiple communication channels (email/phone). Verify responsiveness through client reviews or direct inquiries. Avoid firms with opaque communication.

6. Supply Chain Resilience: Check component sourcing capabilities (e.g., ALFA RPAR AS’s local component supply network) to mitigate raw material shortages. European suppliers often align with REACH/RoHS standards, ensuring compliance.

7. Case Studies & References: Request case studies for similar projects (e.g., aerospace/industrial PCBs) to gauge reliability. ALMIKO’s portfolio includes prototypes and volume production, validate claims via client testimonials.

8. Scalability & Flexibility

Confirm ability to scale from prototypes to mass production. Suppliers like VOLBURG Ltd offer box-build services, accommodating growing project needs. Avoid fixed-capacity manufacturers for dynamic projects.

How to Inspect the Quality Management System of PCB Latvia Manufacturer?

Inspection Guide to Quality Management System of PCB Latvia Manufacturer:

- Verify the validity and pertinence of certifications: Confirm ISO 9001:2015 certification is issued by EU-recognized bodies (e.g., T√úV, SGS). For medical orders, ensure ISO 13485 covers cleanroom control; for automotive, IATF 16949 must include PPAP documentation support, which is a core requirement for Latvia PCB manufacturer serving high-end industries.‚Äč

- Review process-specific quality control plans: For drilling, plating and solder mask application, check if plans include parameter tolerances (e.g., drilling hole diameter ¬Ī0.02mm), inspection frequency (once per 50pcs) and SOP (Standard Operating Procedure) alignment with IPC standards, ensuring each key process has measurable control points.‚Äč

- Validate full-chain traceability systems: Ensure each batch is trackable via digital codes (Ecode or commodity barcode) from raw material batch numbers, production equipment IDs to finished product testing data. The system should enable locating problematic batches within 2 hours to minimize losses.‚Äč

- Assess in-house testing coverage and precision: Confirm X-ray inspection achieves ‚Č•99.2% defect detection rate, solderability tests comply with IPC-J-STD-002, and impedance measurement maintains ¬Ī5% tolerance for high-frequency Latvia PCB. Prioritize factories with SPC (Statistical Process Control) data for test results.‚Äč

- Request customer complaint and correction records: Focus on 12-month data: top PCB manufacturer in Latvia maintains a complaint rate ‚ȧ0.3%. Check if each complaint has root-cause analysis, rectification measures (completed within 72 hours) and follow-up verification to prevent recurrence.‚Äč

- Confirm LVS and CE compliance: LVS must cover electrical safety, EMC (Electromagnetic Compatibility) and environmental indicators; CE marking should be supported by full test reports. Verify quarterly audit records from Latvia‚Äôs Consumer Rights Protection Center to ensure ongoing compliance.‚Äč

- Evaluate employee training and qualification: Check if new staff receive 100-hour pre-job training on IPC-A-600/IPC-610, and in-service staff have semi-annual refresher courses. Require qualification certificates for key positions (e.g., plating, testing) with a passing rate ‚Č•95%.

How to Evaluate the Production Capacity of Latvia PCB Manufacturer?

Evaluation Guide to Quality Management System of PCB Latvia Manufacturer:

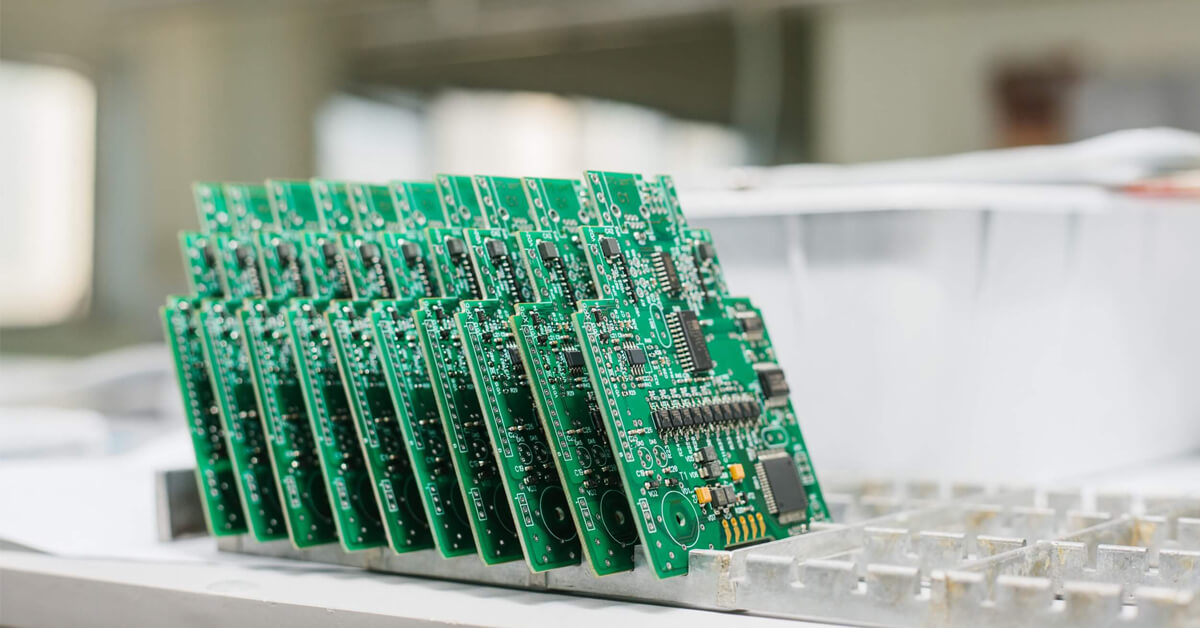

- Confirm monthly production capacity to match your order scale: Use ICAPE-MMAB‚Äôs 550 sqm/month as a reference and verify alignment with your batch size. Ensure it stably handles small batches (‚ȧ500pcs) or large-volume orders (‚Č•1000pcs) without efficiency loss.

- Verify process coverage: Check maximum layer count (local factories mostly cover 1-14 layers; ultra-high layers over 16 require external cooperation), substrate range (FR-4, aluminum, high-frequency materials) and special processes (heavy copper up to 10oz, V-groove, HDI microvias).

- Evaluate core equipment performance: Focus on CNC drilling machines (¬Ī0.02mm accuracy), AOI systems (‚Č•99% defect detection rate) and supporting equipment such as electroplating lines and exposure machines to ensure process stability.

- Assess small-batch and prototype flexibility: Most Latvia PCB plants excel in quick-turn prototypes. Confirm prototype turnaround (3-5 days for ‚ȧ10pcs) and changeover efficiency (‚ȧ2 hours between different designs) to fit agile production needs.

- Audit raw material supply reliability: Secure stable access to FR-4, high-frequency (Rogers/PTFE) and metal substrates. Confirm backup suppliers to avoid 2-3 week delays for imported materials common in the region.

- Check peak demand response capacity: Confirm shift arrangements (2-3 shifts daily) and overtime capability. Top PCB manufacturer in Latvia can boost production capacity by 30% through overtime to meet tight deadlines.

How to Evaluate the Delivery Time of PCB Manufacturing Company Latvia?

Evaluation Guide to Delivery Time of PCB Latvia Manufacturer:

- Clarify standard/expedited lead times by order volume: Prototypes (‚ȧ10pcs): 3-5 days standard, 24-48 hours expedited. Small-batch (100-500pcs): 7-10 days; mass production (‚Č•1000pcs): 10-15 days. Confirm upfront expedited costs (5%-15% of order value) with a PCB Latvia manufacturer.‚Äč

- Confirm local delivery zones and logistics: Riga/Zone I: 1-day DPD delivery (2% failure rate). Zone III remote areas: 2-3 days via TNT. Check if the Latvia PCB factory covers secondary delivery costs for damaged goods.‚Äč

- Check delayed delivery penalties and compensation: Reliable partners include 0.5% daily order value deduction (capped at 10%) for delays in contracts. Confirm compensation for critical orders (free expedited rework, priority fulfillment).‚Äč

- Evaluate standard material inventory: Prioritize factories with ‚Č•90% common substrate (FR-4, aluminum) coverage in local warehouses. Check inventory turnover (7-14 days ideal) and safety stock (supports 30% monthly volume) for faster Latvia PCB fulfillment.‚Äč

- Assess supply chain contingency plans: Confirm alternative material suppliers (48-hour response) to mitigate 2-3 week delays of imported high-frequency materials. Verify backup production capacity for downtime.‚Äč

- Request 6-month OTIF data: Target 95%+ OTIF (exceeds 82% regional average). Ask for order-type breakdown and third-party verification from the PCB manufacturer in Latvia.‚Äč

- Clarify custom process impact on lead times: HDI microvias (+2 days), rigid-flex (+3-4 days), heavy copper (‚Č•6oz, +1-2 days). Discuss optimization to reduce extensions for Latvia PCB manufacturing.

FAQ of Latvia PCB Manufacturing

Q1: How to resolve PCB panel warping during production?‚Äč

A1: We use balanced copper layer design and controlled thermal processes to minimize warping. Our pre-preg material selection (matched to substrate Tg) reduces warpage rate to below 0.5%. Contact us for a custom DFM review to optimize panel design.‚Äč

Q2: Why do prototypes have longer lead times in Latvia, and how to speed this up?‚Äč

A2: We maintain stock of standard FR-4 and aluminum substrates, enabling 3-day prototype turnaround. Our digital order system streamlines design approval, cutting 1-2 days from lead time. Inquire for our expedited prototype service.‚Äč

‚Äč

Q3: How to ensure impedance control for high-frequency Latvia PCB?‚Äč

A3: We use TDR impedance measurement equipment and tight process control (¬Ī5% tolerance). Our partnership with local material suppliers ensures consistent dielectric constant. Let us quote your high-frequency PCB project for tailored solutions.‚Äč

‚Äč

Q4: What causes solder mask adhesion issues, and how to prevent them?‚Äč

A4: Adhesion issues stem from inadequate surface cleaning. We implement plasma cleaning before solder mask application, achieving 99% adhesion rate. Our in-process testing catches issues early. Request a sample to verify quality.‚Äč

‚Äč

Q5: How to handle custom material requirements for Latvia PCB manufacturing?‚Äč

A5: We have a global supply chain for specialty materials (such as PTFE) with 7-day lead times, faster than local averages. Our material engineers help select alternatives if needed. Contact us to discuss your custom material specifications.