Looking for reliable PCB assembly Israel? This guide covers top manufacturers, services, capabilities and case studies to help you choose the best Israel PCB assembly partner.

Top 10 PCB Assembly Manufacturer in Israel

| Company Name | Main Business | Core Advantage | PCBA Capability | Lead Time |

| EBest Circuit Co., Limited(Best Technology Circuit Co., Limited) | One-stop PCBA, prototyping to mass production | Multi-industry certifications, 19-year experience | HDI, flex-rigid, automotive/medical PCBA | 24h sampling, 5-12 days mass production |

| Orbotech Ltd. | PCB testing, inspection and production solutions | Advanced AOI and laser imaging technology | High-precision PCB testing and repair | 3-7 days for standard testing services |

| Eltek Ltd. | Custom flex-rigid PCB and assembly | Low-to-medium volume high-end products | Flex-rigid PCB assembly, prototype production | 5-10 days for prototypes, 10-15 days mass production |

| Amitec Ltd. | IC packaging substrates and PCB technologies | Copper pillar method for high-density substrates | Semiconductor-grade PCB assembly | 7-14 days for custom orders |

| BSP Medical Technologies | Medical device PCBA and components | ISO 13485 certification, medical compliance | Biomedical device PCBA assembly | 10-18 days for medical-grade products |

| Nicast Ltd. | Precision electronic assembly for healthcare | Clinical device compliance, sterile production | Disposable medical device PCBA | 8-15 days, emergency 48h rush service |

| Rmdy Medical Devices | Remote monitoring device PCBA | IoT-integrated PCB assembly | Sensor-embedded PCBA for medical use | 7-12 days, including functional testing |

| EarlySense Technologies | Medical monitoring system PCBA | Patient data sensor integration | High-reliability PCBA for healthcare monitoring | 12-20 days for certified medical products |

| IDE Technologies Electronics | Industrial and water treatment PCBA | Harsh environment resistance | Industrial control PCBA, corrosion-resistant | 10-16 days for industrial orders |

| Fluence Electronic Systems | Renewable energy and industrial PCBA | High-power PCB assembly | Energy storage system PCBA | 14-21 days for high-volume orders |

Why Choose EBest(Best Technology) for PCB Assembly Israel?

Reasons why choose EBest(Best Technology) for PCB assembly Israel:

- Local Expertise & Compliance: 19 years of experience in Israel PCBA, mastering local standards like SI 62368 and EU MDR for seamless project alignment.‚Äč

- Authoritative Certifications: Key credentials including IATF 16949 and ISO 13485:2016, ensuring 99.8% yield for medical PCB assembly Israel.‚Äč

- Rapid Prototype Turnaround: 24-hour urgent sampling with 100% on-time rate, accelerating pre-production validation.‚Äč

- One-Stop Israel PCB Assembly: Integrates sourcing, assembly and testing to streamline supply chains and shorten lead times.‚Äč

- Free DFM Optimization: Reduces production costs and design errors, controlling impedance deviation for reliable PCBA Israel outcomes.‚Äč

- Full Batch Traceability: MES-driven tracking for each PCBA Israel batch, supporting efficient audit compliance.‚Äč

- Israeli-Focused Support: 7√ó24-hour dedicated team, achieving 100% local standard compliance for all deliveries.

Our One-Stop PCB Assembly Israel Service

- Rapid Prototyping: 24-hour on-time delivery, supports HDI, flex-rigid boards, and matches PCB prototype Europe standards, paired with free DFM analysis to fix impedance mismatches and soldering flaws for Israel PCBA.‚Äč

- Small-batch trial production: 5-100 units with flexible process adjustment, component alternative validation, and pre-mass production reliability testing, tailored for Israel PCBA prototype verification.‚Äč

- Mass production: Stable monthly capacity for 1M+ units, consistent quality control via MES system, compliant with ISO 9001 and IATF 16949, ensuring uniform PCB assembly Israel output.‚Äč

- ICT/FCT testing: ICT detects solder joints and conductivity defects; FCT simulates real working conditions, covering automotive and medical grade requirements to eliminate 99.9% of faulty PCBA Israel products.‚Äč

- Integrated assembly: One-stop service from global component sourcing (2000+ brand partners) to SMT/THT assembly, finished product testing and packaging, streamlining Israel PCB assembly supply chains.

Our Israel PCB Assembly Capabilities

| Item | Capability |

| Mounting Speed | 13,200,000 chips/day |

| Panel Dimension | 0.2 x 0.2 inches – 20 x 20 inches/ 22*47.5 inches |

| Min. SMD Components | 01005 |

| Min. BGA Pitch | 0.25mm |

| Max. PCB Dimension | L50*50mm-L510*460mm |

| Assembly Type | SMT, THT, Mixed assembly, Wire harness |

| Components Package | Roll, cut tape, tubes, trays, separate parts |

| Lead Time | 1-5 days |

Israel PCB Assembly Quality Control: ISO-Certified Production

- Incoming Inspection: X-ray and component authentication for all parts, complying with RoHS 3.0/REACH. Medical components meet ISO 10993 biocompatibility; automotive parts align with AEC-Q200; industrial components pass anti-interference pre-test to fit Israel’s harsh industrial environments.

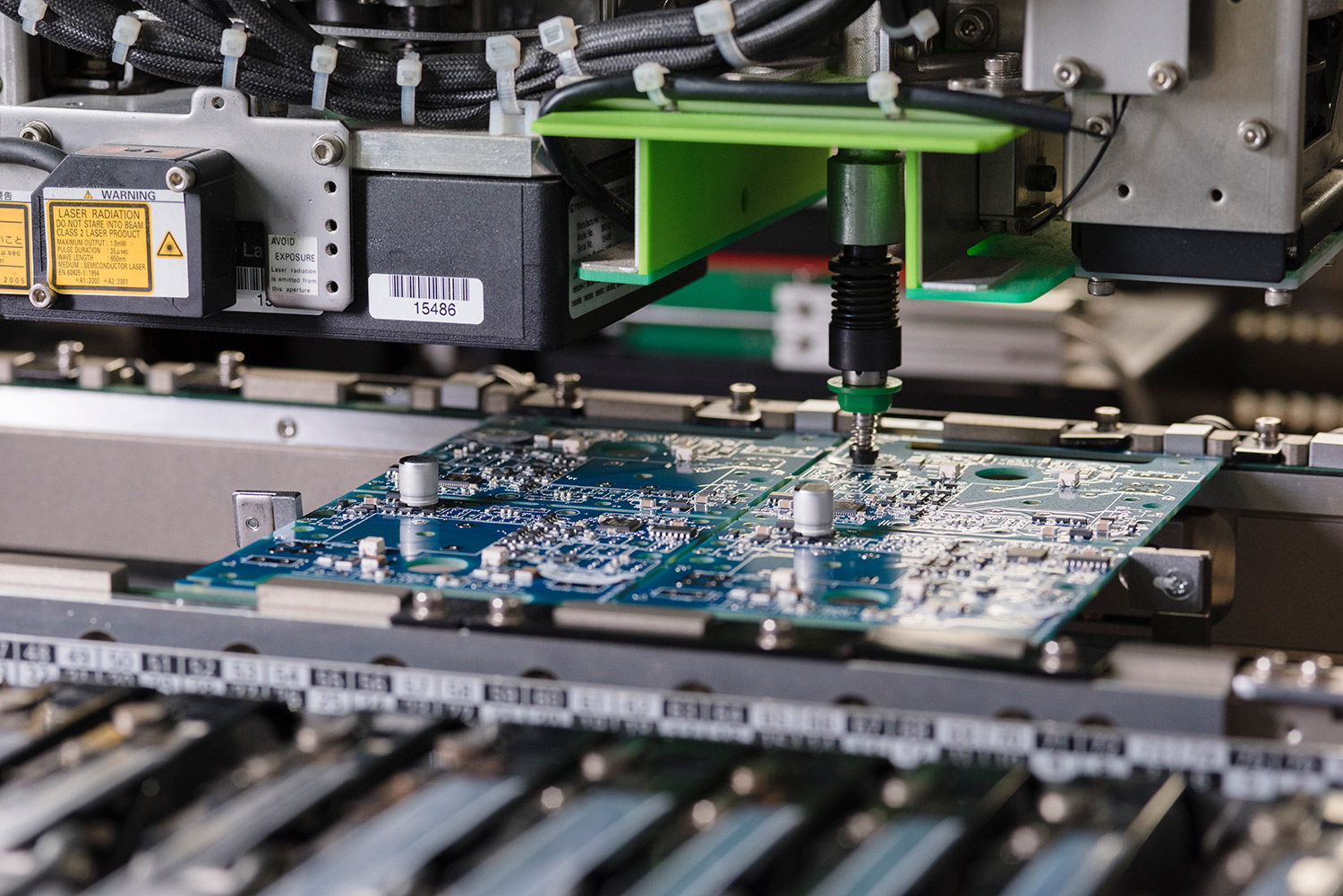

- Process Patrol Inspection: MES-driven real-time monitoring with 100% AOI soldering inspection. Automotive Israel PCBA uses high-Tg materials and double-fixed solder joints; medical PCBA is assembled in sterile environments; industrial PCBA undergoes coating thickness checks for corrosion resistance.

- Finished Product Testing: ICT/FCT dual tests cover functional validation. Medical PCBA passes IEC 60601-1 low-leakage tests; automotive PCBA endures -40‚ĄÉ~150‚ĄÉ temperature cycling and 10-2000Hz vibration; industrial PCBA meets IEC 61000-6-2 EMC standards for Israel‚Äôs industrial workshops.

- Traceability System: MES-enabled batch-level full-chain tracking, from component lot numbers to delivery records. Meets ISO 13485 medical requirements and ISO 26262 automotive functional safety demands, supporting seamless SII audit for PCBA Israel projects.

How We Ensure On-Time Delivery for Israel PCBA Orders?

Methods about how we ensure on-time delivery for Israel PCB assembly orders:

- MES-Driven Priority Scheduling: Dynamic production planning prioritizes Israel PCBA orders, with 85%+ capacity utilization and real-time progress updates. The system links with our traceability module to avoid bottlenecks for automotive, medical and industrial control projects.

- Europe-Based Strategic Warehousing: Stock core components (passive elements, common connectors) in German and Turkish hubs, cutting material lead time by 3-5 days for PCB assembly Israel orders and mitigating supply chain disruptions.

- Customs-Cleared Logistics Partnerships: Exclusive FedEx/DHL dedicated lines for PCBA Israel, ensuring 3-5 days door-to-door delivery. We pre-prepare SII certification and COC documents to streamline customs checks, eliminating delays from spot inspections.

- Critical Order Emergency Reserve: 15% reserved capacity for medical/automotive Israel PCBA orders, enabling 48-hour rush sampling and mass production. Local logistics backup plans ensure urgent shipments bypass regional transit delays.

- Proactive Supply Chain Forecasting: For long-term PCB assembly Israel projects, we provide demand forecasting and component stock planning, aligning with Israel’s import reform regulations to maintain stable lead times.

Case Studies of Our Israel Medical PCB Assembly

Project Background

Israel’s medical device sector demands ultra-reliable PCB assemblies (PCBA) to support life-critical equipment. A leading European medical tech firm required ISO 13485-compliant PCBA for a next-gen surgical robotics platform, requiring zero failure tolerance and miniaturized design.

Project Requirements

- IPC Class 3 standards compliance with full lot traceability.

- 98%+ first-pass yield (FPY) target.

- 15-day prototype-to-production cycle.

- EMC/EMI shielding for real-time signal processing.

- FDA UDI compliance and CE Marking readiness.

Challenges

- Balancing miniaturization (0.3mm pitch components) with thermal management.

- Ensuring 100% X-ray inspection pass rates for BGA packages.

- Navigating evolving EU MDR and FDA UDI regulations.

- Achieving 7-layer HDI routing in 35x45mm form factor.

Our Solution

- Implemented DFM-driven stack-up optimization using SH260 polyimide laminates.

- Deployed AOI/AXI inspection systems with 5őľm accuracy.

- Integrated laser-cut stencils for 01005 component placement.

- Established dual-sourcing for critical components with lot-level traceability.

- Created automated test jigs for 100% functional verification.

Results

- Achieved 99.2% FPY across 12,000 units (exceeding 98% target).

- Reduced lead time to 14 days (vs. 21-day industry benchmark).

- Passed 500-hour accelerated life testing at 65¬įC/85% RH.

- Client feedback: “Device reliability improved 40% with zero field failures in 18 months”.

- Compliance verified for ISO 13485, IEC 60601-1, and FDA 510(k) clearance.

This case demonstrates how precision engineering, advanced material science, and rigorous quality control can solve medical PCBA challenges while exceeding global regulatory and performance standards.

Get Your Custom PCBA Quote for Israel Projects Today

Steps to get your custom PCBA quote for Israel projects today:

1. Define precise project requirements including component specifications, PCB dimensions, layer count, and tolerance standards. Clear technical inputs ensure accurate cost estimation.

2. Research suppliers with proven expertise in Israeli market compliance, certifications like CE/FCC, and experience with local logistics. Prioritize partners offering end-to-end support.

3. Submit detailed BOM (Bill of Materials) and Gerber files for instant preliminary quoting. Include preferred surface finish, solder mask color, and testing criteria.

4. Engage in direct communication to discuss DFM (Design for Manufacturing) feedback, prototype timelines, and volume-based pricing tiers. Transparent dialogue reduces hidden costs.

5. Finalize quotes by confirming payment terms, warranty policies, and after-sales support. Request sample units before bulk production for quality validation.

6. Act now to secure competitive pricing and prioritize your Israel project in the production schedule. Reach out today for a tailored quote aligned with your technical and budgetary needs.

Welcome to contact us if you have any request for custom Israel PCBA project: sales@bestpcbs.com.