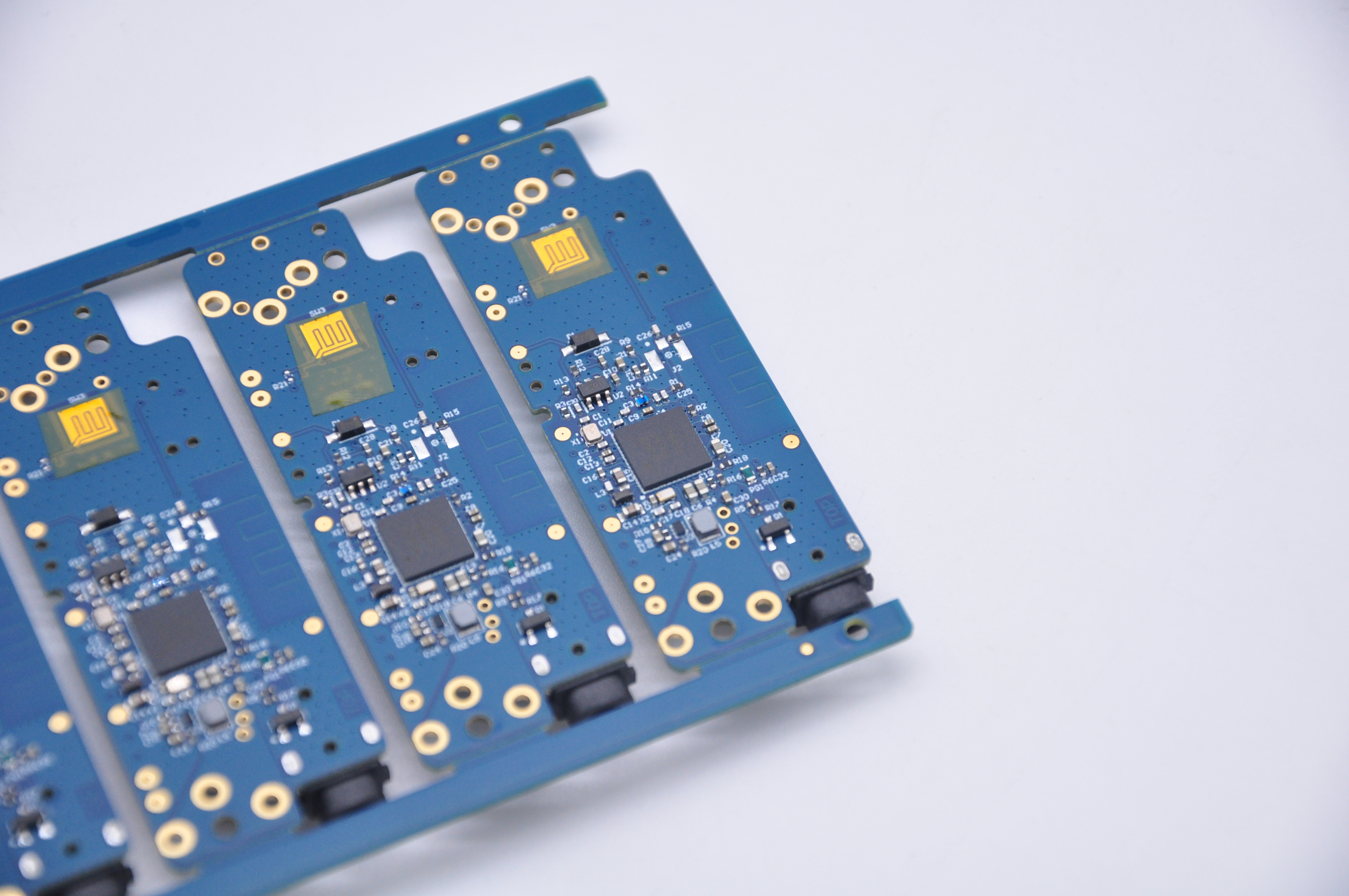

IPC-A-610 is the leading standard for judging the quality of finished PCB assemblies. It defines how solder joints should look, how components should sit, and what qualifies as an acceptable electronic assembly. For any company focused on dependable PCB assembly, IPC-A-610 remains a powerful foundation for quality and trust.

What Is IPC-A-610 Standard?

The IPC-A-610 standard is the worldâs most accepted guide for the acceptability of electronic assemblies. It sets the rules for what is âgood,â what is âacceptable,â and what must be rejected in a finished PCB assembly. It also provides visual examples, measurement details, and inspection criteria.

This standard covers many parts of assembly work. Solder joints. Through-holes. SMT components. Wire dressing. Coatings. Terminations. Hardware. Cleaning. And more.

When teams follow IPC-A-610, they share a common language for quality. That is why this standard remains powerful across the global electronics industry.

Manufacturers like EBest Circuit (Best Technology), who focus on PCB assembly and quality-driven processes, use IPC-A-610 as a foundation for day-to-day inspection and internal training. It guides the quality gates that protect customer products.

Although the document looks technical, its purpose is simple: Deliver consistent, reliable, safe, and high-performance PCB assemblies.

What Does IPC A 610 Certification Include?

The IPC-A-610 certification proves that someone understands the acceptability criteria described in the standard. There are two main certification levels:

1. CIS â Certified IPC Specialist

This level suits operators, inspectors, assemblers, QC technicians, and engineers who work hands-on with PCBs. CIS training includes:

- Solder joint evaluation

- SMT and through-hole inspection

- Terminal connection standards

- Cleaning requirements

- Material handling rules

- Visual defect recognition

- Acceptability criteria for different classes

The goal is simple. A CIS holder must be able to inspect assemblies using the standard as a guide.

2. CIT â Certified IPC Trainer

This level suits people who want to train others. CIT certification is more advanced. It includes:

- In-depth review of the entire standard

- Training methodology

- Verification of technical skills

- Higher-level inspection judgment

- Instructor skills evaluation

Companies across the world require IPC-A-610 certification for assembly technicians. This builds trust and reduces risk.

This is why many PCB assembly providers, including EBest Circuit (Best Technology), encourage IPC-A-610 training for their teams.

How to Get IPC A 610 Certification?

Getting certified is not complicated. But it must be done through approved training centers. Here is the process:

- Step 1: Choose an IPC-authorized training center

IPC partners with certified instructors worldwide. Many offer remote options.

- Step 2: Join the training program

Training usually lasts 3â4 days for CIS. CIT training may take longer. You will learn with:

- Printed manuals

- Visual examples

- Hands-on inspections

- Real defect samples

- Group sessions

- Instructor lectures

- Step 3: Take the exam

At the end of the course, you will take written and visual tests. These confirm your understanding of the standard.

- Step 4: Receive your certificate

If you pass, you receive an official IPC certificate. It stays valid for two years. After that, you must renew it.

PCB manufacturers often prefer hiring certified specialists. It also improves customer confidence in every assembly batch. Many customers request certified inspectors for handling high-value or high-reliability products.

How Thick Is IPC A 610 Coating?

Actual thickness comes from other standards, such as IPC-CC-830, material datasheets, or customer specifications.

However, IPC-A-610 does describe what acceptable coating must look like:

- Smooth

- Even

- No bubbles

- No bare spots

- No bridging in sensitive areas

- No cracks

- No peeling

- No foreign particles

Most coatings fall between 25â75 microns depending on the material. Acrylic, silicone, and polyurethane coatings each have their typical ranges.

IPC A 610 Acceptability of Electronic Assemblies â What Are the Basics?

IPC-A-610 focuses on acceptability, not assembly methods. It teaches inspectors how to check finished assemblies. The core areas include:

- 1. Soldering Quality. The standard covers:

- Wetting

- Fillet sizes

- Lead coverage

- Void limits

- Component alignment

- Solder volume

- Solder bridges

It also includes clear pictures for each class, which helps inspectors make consistent decisions.

- 2. Component Placement. It sets rules for:

- Centering

- Orientation

- Lead protrusion

- Lead bending

- Damage limits

- Tilt and skew tolerance

This avoids misalignments that can cause field failures.

- 3. Through-Hole Connections. Inspection includes:

- Barrel fill percentage

- Lead extension

- Internal wetting

- Topside coverage

- Land wetting

Good through-hole soldering gives long-term strength, especially for connectors and power components.

- 4. Cleanliness. The standard ensures:

- No flux residues

- No contamination

- No fingerprints

- No moisture traps

Clean assemblies perform better and have fewer failures.

- 5. Hardware and Mechanical Support. IPC-A-610 covers:

- Screw torque

- Washer placement

- Adhesive use

- Structural support

- Connector fixation

Strong mechanical support improves durability.

- 6. Coating and Potting. The rules focus on:

- Even coverage

- No cracks

- No bubbles

- No exposed conductors

- No bridging unwanted areas

Coating protects electronics from moisture, corrosion, vibration, and pollution.

- 7. Wire Dressing. This section includes:

- Proper routing

- Strain relief

- Tie-down methods

- Avoiding sharp bends

Good wire dressing increases reliability in high-stress environments.

What Are the Classes of IPC-A-610?

The standard divides products into three classes. Each class has a different reliability goal.

Class 1 â General Electronics. For simple devices. Examples:

- Toys

- Low-cost consumer gadgets

- Basic electronics

Performance is required, but cosmetic standards are relaxed.

Class 2 â Dedicated Service Electronics. This is the most common class. Examples:

- Home appliances

- Industrial controllers

- Communication devices

- Automotive infotainment

- Consumer electronics with higher durability needs

Devices must work reliably. Failures should be rare. Cosmetic quality matters more. Most PCB assembly companies, including EBest Circuit (Best Technology), follow Class 2 for mainstream production.

Class 3 â High-Reliability Electronics. This class has the strictest criteria. Examples:

- Medical equipment

- Aerospace systems

- Automotive safety systems

EBest Circuit (Best Technology) holds AS9100D aerospace certification. It can be manufactured in mainstream environments according to Category 3 standards.

Which IPC-A-610 Class Is Best for Your PCB Assembly?

Choosing the correct class depends on your final application. Here is a simple guide:

- Choose Class 1 when cost matters more than cosmetic quality.

- Choose Class 2 for most commercial and industrial products.

- Choose Class 3 for mission-critical devices where safety and reliability matter.

You must match your productâs purpose with the required class. Over-specifying increases cost. Under-specifying increases risk.

For example:

- A home thermostat typically uses Class 2

- A heart monitor requires Class 3

- A toy car might use Class 1

EBest Circuit (Best Technology)âs assembly lines commonly build Class 2 and Class 3 products. These two classes represent the largest share of today’s electronics manufacturing demand.

Why Is IPC A 610 Class 3 Stricter Than Class 2?

The reason is simple: risk.

Class 3 products must work with no excuses. They must perform in harsh environments. They must resist vibration. They must survive temperature changes. They must avoid failure even after long operation cycles.

Because of that, Class 3 rules include:

- Tighter solder fillet requirements

- Higher barrel fill percentages

- Fewer acceptable cosmetic variations

- More strict alignment rules

- No allowance for minor surface flaws

- Stronger requirements for bonding and support

- More strict criteria for lead trimming

- Higher internal wetting standards

That is why Class 3 exists. Even small defects can cause catastrophic results in life-critical applications.

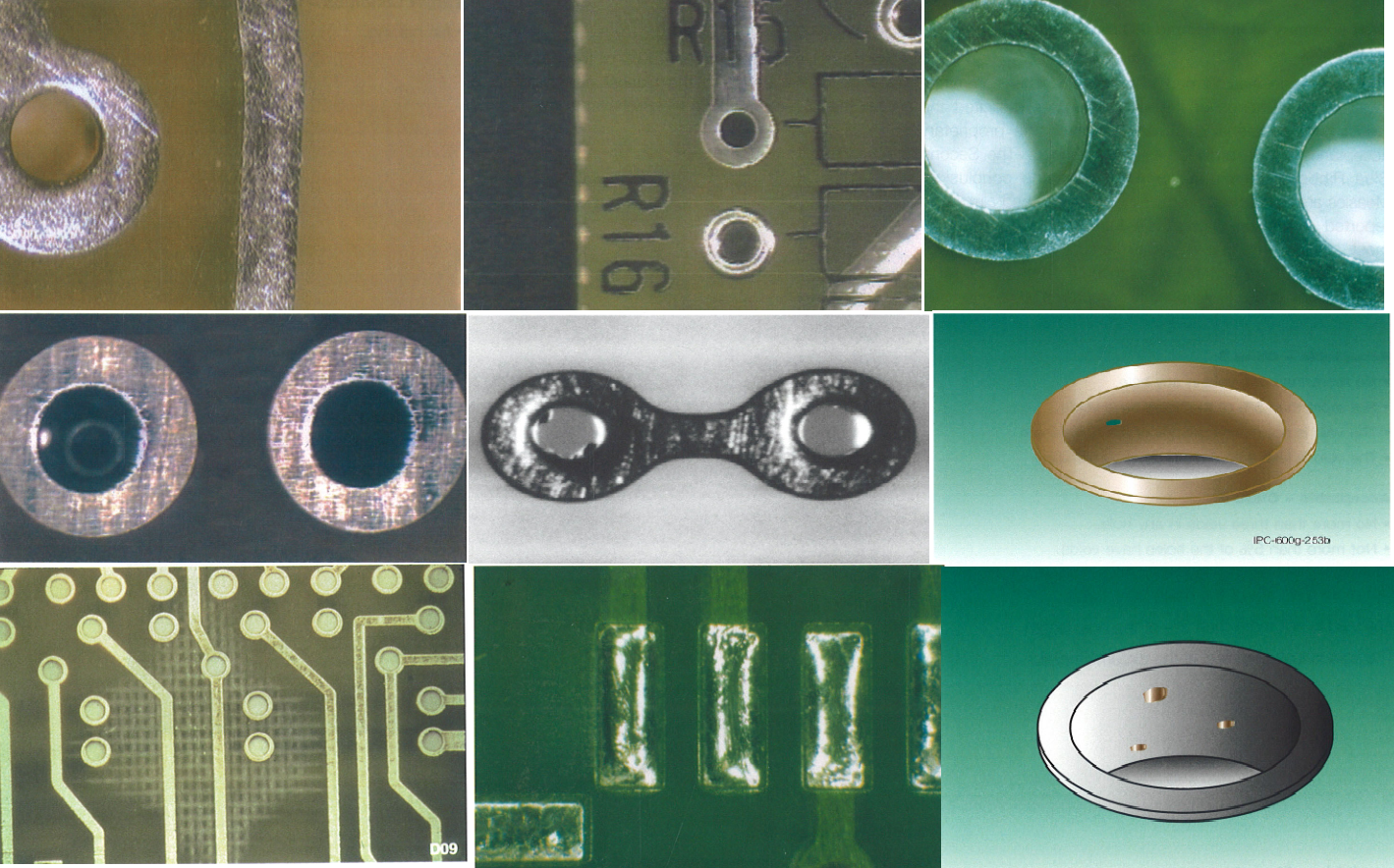

IPC A 610 vs IPC A 600 â Whatâs the Key Difference?

These two standards often confuse people. But their roles are very different.

IPC-A-600, Focuses on bare PCB quality. It covers:

- Copper features

- Plating thickness

- Hole quality

- Laminate defects

- Internal voids

- Delamination

- Solder mask criteria

This standard checks the board before assembly.

IPC-A-610, Focuses on acceptability of the finished assembly. It covers:

- Solder joints

- Component placement

- Conformal coating

- Wire connections

- Mechanical support

- Cleanliness

- Terminal features

This standard checks the board after assembly.

Simple explanation:

- IPC-A-600 = Is the PCB built correctly?

- IPC-A-610 = Is the assembly built correctly?

Most OEMs use both. This gives full quality control from board fabrication to final assembly.

PCB assembly companies like EBest Circuit (Best Technology) work directly with IPC-A-610. PCB factories use IPC-A-600. Together, they build complete quality assurance.

Conclusion:

IPC-A-610 is the most trusted global standard for evaluating PCB assembly quality. This standard includes three classes, each matched to different product needs. Class 2 suits most applications. Class 3 suits high-reliability environments.

EBest Circuit (Best Technology) applies IPC-A-610 principles in PCB assembly to ensure stable quality and trusted results for each project.

For project inquiries, support, or PCB assembly needs, contact: sales@bestpcbs.com