What is high frequency inverter board? This guide covers its basics, how it works, function and application and differences from low-frequency ones through this blog.

Are you troubled with these questions?

- Is EMC interference crashing your inverter system?

- Does poor heat dissipation jack up costs and lower yields?

- Is supply chain chaos delaying deliveries?

As a professional PCBA service supplier, EBest Circuit (Best Technology) can provide you service and solution:

- DFM DesignâCut costs and boost yields upfront.

- Copper Block CoolingâKeep high-frequency operations stable.

- 1K+ Capacity & Agile SupplyâOn-time delivery, guaranteed.

Welcome to contact us if you have any inquiry for inverter board PCBA service: sales@bestpcbs.com.

What Is High Frequency Inverter Board?

A high-frequency inverter board is a power electronic device that converts direct current (DC) into alternating current (AC). Its core feature is the use of high-frequency switching technology (typically above 20kHz), which rapidly switches power devices (such as MOSFETs and IGBTs) on and off to achieve power conversion. Compared to traditional low-frequency inverters (50/60Hz), high-frequency inverter boards significantly reduce device size and improve efficiency by utilizing high-frequency transformers and pulse-width modulation (PWM) technology.

How Does a High Frequency Inverter PCB Board Work?

- DC input: DC power from batteries or solar panels enters the inverter board.

- High-frequency inversion: Power devices (such as IGBTs) switch rapidly under the control of high-frequency PWM signals, converting DC power into high-frequency AC pulses (typically 20kHz-1MHz).

- High-frequency transformation: High-frequency AC power is converted (stepped up or down) by a small high-frequency transformer.

- Rectification and filtering: The high-frequency AC power output from the transformer is converted to DC power by a rectifier bridge, and then smoothed to a stable DC voltage by a filter circuit.

- Power frequency inversion: The filtered DC power is converted to 50/60Hz AC power by an inverter circuit (such as a full-bridge or half-bridge configuration) and output to the load.

- Feedback control: A sampling circuit monitors the output voltage and current in real time and adjusts the PWM duty cycle to maintain a stable output.

What Does a High Frequency Inverter Board Do?

Functions of high frequency inverter PCB board:

- DC-AC Conversion: Converts DC power from batteries, solar panels, or other sources into 220V/50Hz or 110V/60Hz AC power for use in industrial equipment.

- Voltage/Frequency Regulation: Utilizing PWM control technology, the output voltage and frequency are adjustable to meet varying load requirements.

- Waveform Optimization: Utilizes sinusoidal or modified sine wave output to reduce harmonic interference and improve power quality.

- Protection Function: Integrated overvoltage, overcurrent, short-circuit, and overheating protection mechanisms ensure safe operation.

- Lightweight Design: The high-frequency transformer’s compact size reduces overall weight, making it easier to integrate and move.

What Is a High Frequency Inverter Circuit Board Used for?

Application of high frequency inverter circuit board:

- New Energy – Photovoltaic micro-inverters, energy storage converters.

- Industrial Automation – Servo drives, UPS (uninterruptible power supplies).

- Consumer Electronics – Automotive inverters, LED driver power supplies.

- Medical Equipment – Portable X-ray machines, laser therapy device power supplies.

Difference between Low Frequency and High Frequency Inverter Board

| Comparison Dimension | High-Frequency Inverter Board | Low-Frequency Inverter Board |

| Operating Frequency | >20kHz | 50/60Hz |

| Transformer Size | Small | Large |

| Efficiency | 90%-95% | 80%-90% |

| Size/Weight | Lightweight, 1/3-1/2 the volume of low-frequency models | Bulky, requires large installation space |

| Load Capacity | Light loads | Heavy loads |

| Impact Resistance | Weak | Strong |

| Noise Level | <30dB (quiet) | 40-50dB (noisy) |

| Cost | High initial cost, long-term energy savings | Low initial cost, high energy consumption |

| Lifespan | 5-8 years | 10-15 years |

| Application Scenarios | solar energy storage | industrial heavy-duty use |

Why Choose EBest Circuit (Best Technology) as Invert Board Assembly Manufacturer?

Reasons why choose us as high frequency invert board assembly manufacturer:

- High-Precision Automated Assembly – We use SMT for ±0.02mm placement accuracy, reducing manual errors by 90% and boosting first-pass yield to 99.8% to lower your repair costs.

- Flexible Modular Production – Switch from small batches (MOQ 50pcs) to mass production, converting prototypes to volume in 24-72 hours to speed up your product launch.

- Eco- friendly & Lead-Free Compliance – Fully RoHS/REACH-compliant with halogen-free solder and nitrogen reflow ovens, ensuring faster time to market.

- Dual X-Ray + AOI Inspection: Real-time checks on solder voids (<5%) and component polarity, covering 100% of hidden joints (BGA/QFN) to catch 95% of defects early.

- IP67 Protective Coating: Optional silicone/acrylic/polyurethane layers withstand -40°C~150°C, cutting salt/moisture/dust failures by 70% to extend outdoor product life.

- Extreme Stress Testing: 72-hour full-load testing under -20°C~85°C cycles ensures <0.1% field failure rates for rock-solid reliability.

- Component Traceability: QR codes track every supplier, date, and test result from wafer batch to assembly for instant failure analysis and quality control.

- Free DFM Optimization: Our free report suggests 20+ cost-saving design tweaks (e.g., pad spacing, layout) to cut your assembly expenses by an average of 15%.

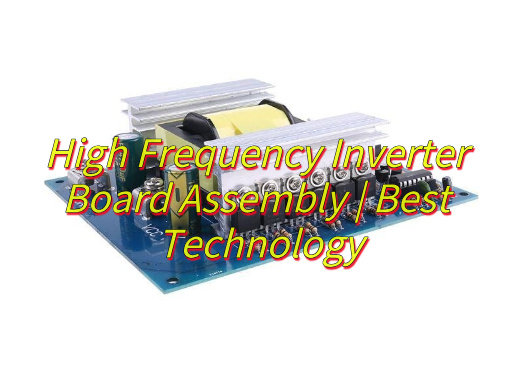

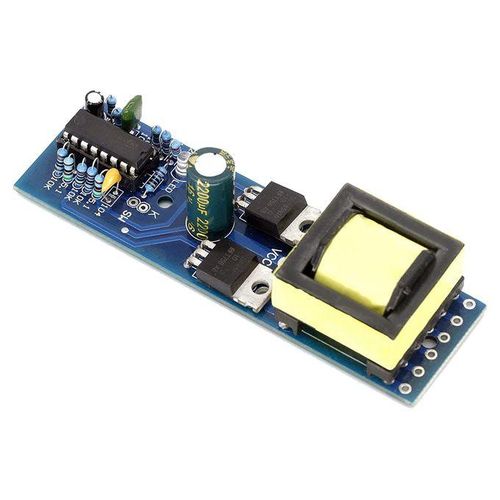

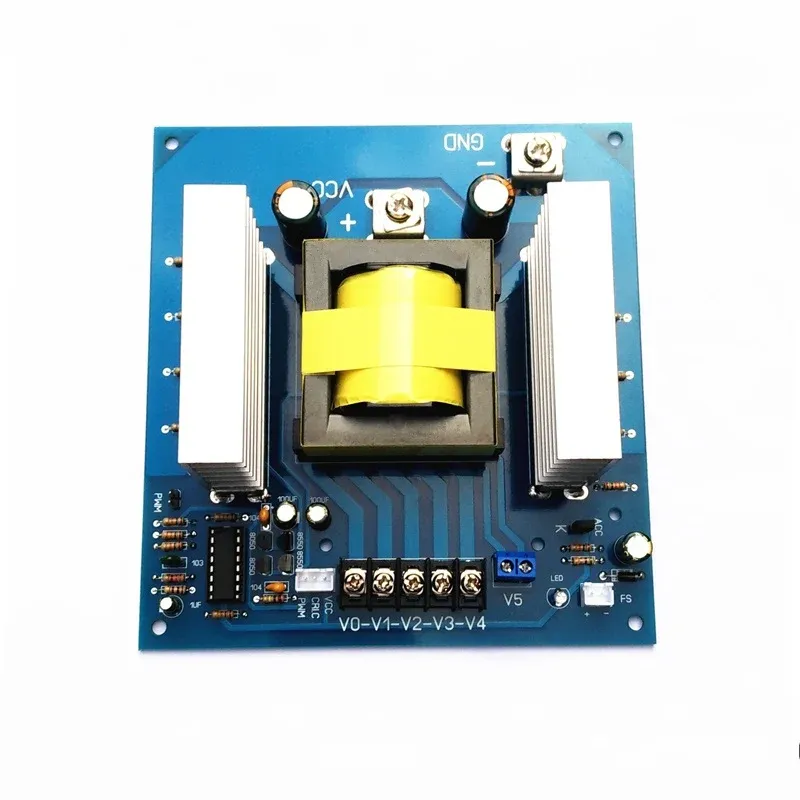

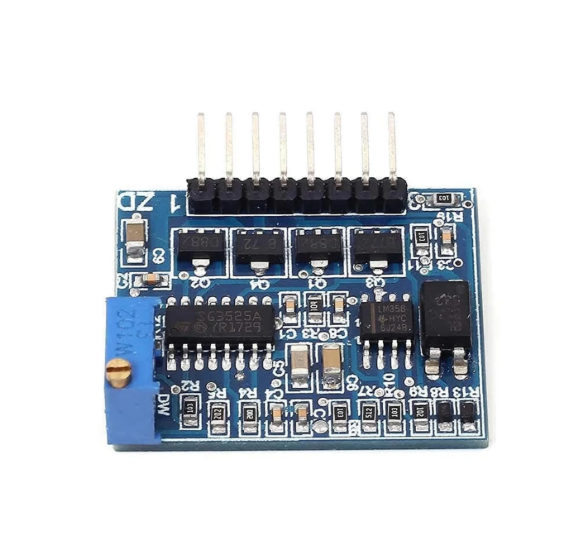

Below is a photo of inverter board we assembled:

Our PCB Assembly Capabilities

| Item | Capabilities |

| Placer Speed | 13,200,000 chips/day |

| Bare Board Size | 0.2 Ã 0.2 inches â 20 Ã 20 inches / 22 Ã 47.5 inches |

| Minimum SMD Component | 01005 |

| Minimum BGA Pitch | 0.25mm |

| Maximum Components | 50 Ã 150mm |

| Assembly Type | SMT, THT, Mixed assembly |

| Component Package | Reels, Cut Tape, Tube, Tray, Loose Parts |

| Lead Time | 1 â 5 days |

How to Get a Quote for Invert Board Assembly Service?

1. Core Design Documents

- PCB Production Files: Gerber files (including drill drawings); Impedance control requirements.

- BOM List: Full component list (model, package, manufacturer PN); Alternative part options clearly marked.

- Assembly Drawing: Component polarity markings; Heat sink mounting positions; Glue/potting points.

2. Process Specifications

- Soldering Method: Reflow / Wave / Selective soldering.

- Special Processes: Conformal coating areas; Potting thickness requirements; X-ray inspection points.

- ESD Protection: Compliance standard (e.g., ANSI/ESD S20.20).

3. Material Supply Options

- Customer-provided all materials.

- Assembler provides common parts (resistors/caps, etc.).

- Key component sourcing requirements (e.g., TI-authorized distributors).

4. Testing & Acceptance Criteria

- ICT/FCT Testing: Test program files (.pcf format)

- Burn-In Testing: Temperature cycle parameters (e.g., 85â full load, 4 hours)

- Visual Inspection: IPC-A-610 Class 2/3 standard

5. Order Basics

- Batch Quantity: Initial order + estimated monthly demand.

- Delivery Address (for logistics cost calculation).

- Packaging: ESD bags / Blister trays / Vacuum sealing.

Welcome to contact us if you have any request for high frequency inverter board assembly service: sales@bestpcbs.com.